Technical Contents

Engineering Guide: Plastic Injection Moulding Services

Engineering Insight Precision in Plastic Injection Moulding Services

While Wuxi Lead Precision Machinery specializes in custom metal manufacturing, our engineering expertise extends critically to supporting high-integrity plastic injection moulding services. This intersection is vital: precision metal components form the core of moulds and tooling that directly determine the quality, consistency, and functionality of plastic parts. In sectors where failure is not an option—such as medical devices, aerospace, or automotive systems—the tolerances achieved during mould fabrication and the stability of the injection process are non-negotiable. Sub-micron deviations in mould steel translate directly to part warpage, flash, or dimensional drift in the final plastic component, compromising assembly integrity and product lifespan. True precision engineering begins long before polymer injection; it is embedded in the CNC-machined accuracy of the mould cavity, core, and cooling channels, ensuring thermal homogeneity and repeatable part geometry across millions of cycles.

The cost of imprecision manifests acutely in high-volume production. A tolerance deviation of ±0.05mm may seem negligible on paper but can trigger catastrophic assembly failures in micro-electromechanical systems or fluidic medical devices. At Lead Precision, we mitigate this risk through integrated metrology. Our moulds undergo rigorous CMM validation against 3D CAD models, with surface finishes held to Ra 0.025µm for optical-grade applications. This discipline stems from our foundational work in mission-critical sectors. We engineered mould tooling for precision components used in Olympic timing systems—where 0.001-second accuracy is mandatory—and supplied certified parts for defense sector applications demanding zero-defect reliability under extreme environmental stress. These projects ingrained a culture where tolerances are not targets but absolute boundaries.

Our approach merges advanced simulation with empirical validation. Moldflow analysis predicts polymer flow, cooling rates, and potential sink marks, but we validate these models using in-mould pressure sensors and real-time thermal imaging during initial trials. This eliminates guesswork, reducing scrap rates by up to 35% compared to conventional setups. The result is plastic parts that meet stringent ISO 2768-mK or ASTM D945 standards consistently, even with engineering resins like PEEK or liquid crystal polymers that magnify processing sensitivities.

Below are critical precision parameters we control for demanding plastic injection moulding projects:

| Parameter | Lead Precision Capability | Industry Standard Baseline |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Finish (Cavity) | Ra 0.025 µm | Ra 0.1 µm |

| Melt Temperature Control | ±1.0°C | ±3.0°C |

| Clamp Force Repeatability | ±0.5% | ±2.0% |

| Part Weight Variation | < 0.15% | < 0.5% |

Precision in plastic injection moulding is not merely about tighter numbers—it is a systemic commitment to material science, thermal dynamics, and metrological rigor. For Wuxi Lead Precision Machinery, this commitment is proven through decades of delivering zero-failure components for applications where human performance and safety hinge on microscopic accuracy. Partner with us to transform your plastic part specifications from aspirations into engineered reality.

Precision Specs & Tolerances

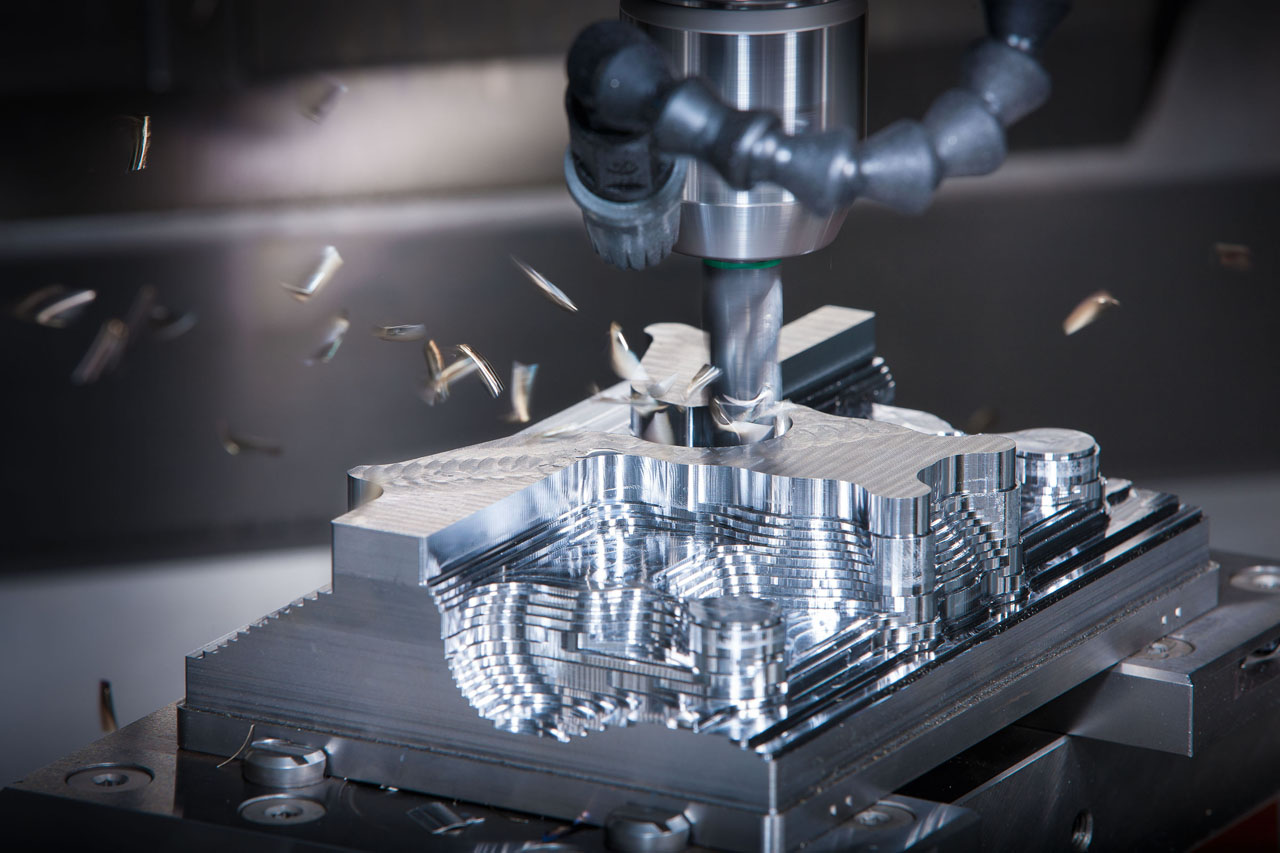

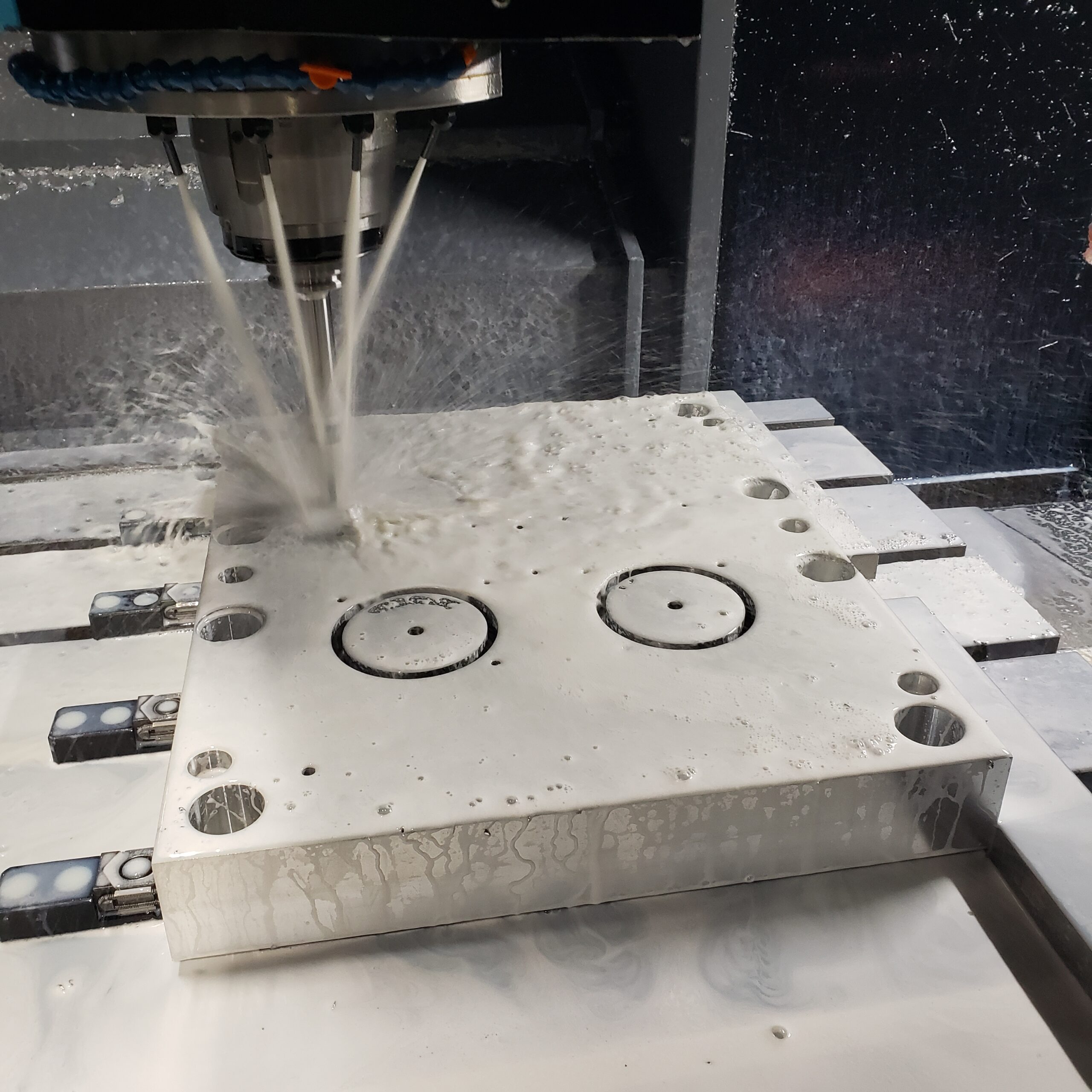

Wuxi Lead Precision Machinery delivers advanced plastic injection moulding services integrated with high-precision custom metal manufacturing capabilities, enabling the production of complex, mission-critical components for aerospace, medical, automotive, and industrial applications. Our technical expertise is anchored in state-of-the-art 5-axis CNC machining centers, which provide unmatched flexibility and accuracy in fabricating moulds, inserts, and precision metal tooling. These multi-axis systems allow simultaneous machining from five different angles, minimizing setup changes and ensuring superior geometric consistency across intricate part geometries. This capability is essential for producing high-performance injection moulds with complex cooling channels, fine surface finishes, and tight dimensional tolerances.

All manufacturing operations are supported by a rigorous quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Our Zeiss and Hexagon CMM systems perform full-spectrum dimensional verification, including first-article inspection reports (FAIR), production part approval (PPAP), and statistical process control (SPC) data. Every component undergoes comprehensive metrology analysis to validate conformity to engineering specifications, ensuring repeatability and compliance with ISO 9001 and IATF 16949 standards. This closed-loop quality process enables real-time correction and continuous improvement throughout production.

Our plastic injection moulding services leverage these precision metal manufacturing foundations to produce durable, high-cycle moulds capable of maintaining tight tolerances over extended production runs. Tooling is fabricated from premium-grade steels such as P20, 718H, H13, and stainless steel, with optional surface treatments including nitriding, chrome plating, and PVD coating to enhance wear resistance and part release performance. Mould bases are designed and machined in-house, allowing full control over lead time, fit, and functionality.

The following table outlines the standard and precision tolerance capabilities achievable through our integrated manufacturing and inspection processes:

| Feature | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | CMM, Micrometer |

| Flatness | 0.05 mm | 0.01 mm | CMM, Surface Plate |

| Parallelism | 0.05 mm | 0.01 mm | CMM, Dial Indicator |

| Perpendicularity | 0.05 mm | 0.015 mm | CMM, Square & Indicator |

| Circular Runout | 0.03 mm | 0.005 mm | CMM, V-Block & Indicator |

| Surface Finish (Ra) | 3.2 µm | 0.4 µm | Profilometer |

| Hole Position (Ø) | ±0.05 mm | ±0.01 mm | CMM, Pin Gauge |

These specifications reflect our commitment to delivering injection moulding solutions where precision, reliability, and repeatability are non-negotiable. By combining 5-axis CNC machining with comprehensive CMM-based quality assurance, Wuxi Lead Precision Machinery ensures that every metal component and mould meets the most demanding technical requirements.

Material & Finish Options

Material Selection for Precision Injection Molds: Aluminum, Steel, and Titanium

Selecting the optimal mold material is a critical engineering decision impacting part quality, production volume, lead time, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your specific application requirements for plastic injection molding. Aluminum alloys offer significant advantages for prototyping and low-to-medium volume production due to their superior thermal conductivity, enabling faster cycle times and reduced energy consumption. They are also significantly easier and faster to machine, accelerating time-to-market. However, aluminum’s lower hardness limits its use for abrasive resins or extremely high-volume runs where wear resistance is paramount. Steel, particularly pre-hardened or hardened tool steels like P20, H13, or 420 stainless, provides exceptional hardness, wear resistance, and longevity. This makes steel the definitive choice for high-volume production, molds requiring fine surface finishes, or applications involving glass-filled or other abrasive engineering plastics. Steel molds maintain dimensional stability over millions of cycles but require longer machining and heat treatment times. Titanium alloys, while possessing excellent strength-to-weight ratio and corrosion resistance, are rarely the primary choice for standard injection molds due to high cost, challenging machinability, and lower thermal conductivity compared to aluminum. Their niche application is typically restricted to highly specialized, corrosive environments where other materials fail, often as inserts rather than full mold bases.

The following table provides key comparative specifications for common mold base materials:

| Property | Aluminum 7075-T6 | P20 Pre-Hard Steel | H13 Tool Steel |

|---|---|---|---|

| Typical Hardness (HRC) | 15-20 | 28-32 | 48-52 |

| Thermal Conductivity (W/m·K) | 130 | 30 | 25 |

| Machinability Rating | Excellent | Good | Fair |

| Typical Mold Life (Cycles) | 10,000 – 100,000 | 100,000 – 500,000+ | 500,000 – 1M+ |

| Primary Use Case | Prototypes, Low/Med Volume | Medium/High Volume | High Volume, Abrasive Resins |

Surface finish selection is equally vital for part aesthetics, release properties, and longevity. Anodizing is the predominant and highly effective finish for aluminum molds. Hard anodizing (Type III) significantly increases surface hardness (up to 60-70 HRC), enhances wear and corrosion resistance, and provides excellent release characteristics for many plastics. It creates a durable, non-conductive oxide layer integral to the aluminum substrate. While standard anodizing (Type II) offers good corrosion protection, hard anodizing is generally recommended for production molds. Steel molds utilize different finishing processes; common options include chrome plating for corrosion resistance and ease of release, or specialized texturing like EDM or chemical etching for cosmetic surfaces. Nitriding is sometimes employed to increase surface hardness on steel. The optimal finish depends on the resin type, part geometry, required surface texture, and production volume.

Wuxi Lead Precision Machinery leverages deep materials science expertise to guide clients through this complex selection process. We analyze your resin, part complexity, volume targets, and surface requirements to recommend the precise material and finish combination maximizing performance and cost-efficiency. Consult our engineering team early in your design phase to ensure your mold foundation delivers exceptional results.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the plastic injection moulding process begins with meticulous design engineering, where functionality, material behavior, and manufacturability converge. Our engineering team collaborates closely with clients to analyze part geometry, tolerances, surface finish requirements, and end-use conditions. Utilizing advanced 3D CAD software and mold flow simulation tools, we optimize gate locations, cooling channels, and ejection systems to prevent warpage, sink marks, and other defects. This stage ensures that every design is not only aesthetically and functionally sound but also inherently manufacturable with minimal risk. Design for manufacturability (DFM) reviews are conducted rigorously to identify potential issues early, reducing costly revisions and delays downstream.

Prototyping: Validating Performance Before Scale

Once the mold design is finalized, we proceed to prototype development using high-precision CNC machining or EDM to fabricate prototype molds from tool steel or aluminum, depending on required durability and production volume. These molds are used to produce initial sample parts under actual injection molding conditions. Prototyping allows for comprehensive validation of fit, form, function, and material performance. We conduct dimensional inspections using CMM (Coordinate Measuring Machines), visual surface analysis, and functional testing to ensure compliance with specifications. Client feedback is integrated at this stage, enabling iterative refinements until the part meets all performance and quality benchmarks. This phase is critical in achieving zero defects in mass production, as it confirms process stability and identifies any hidden risks.

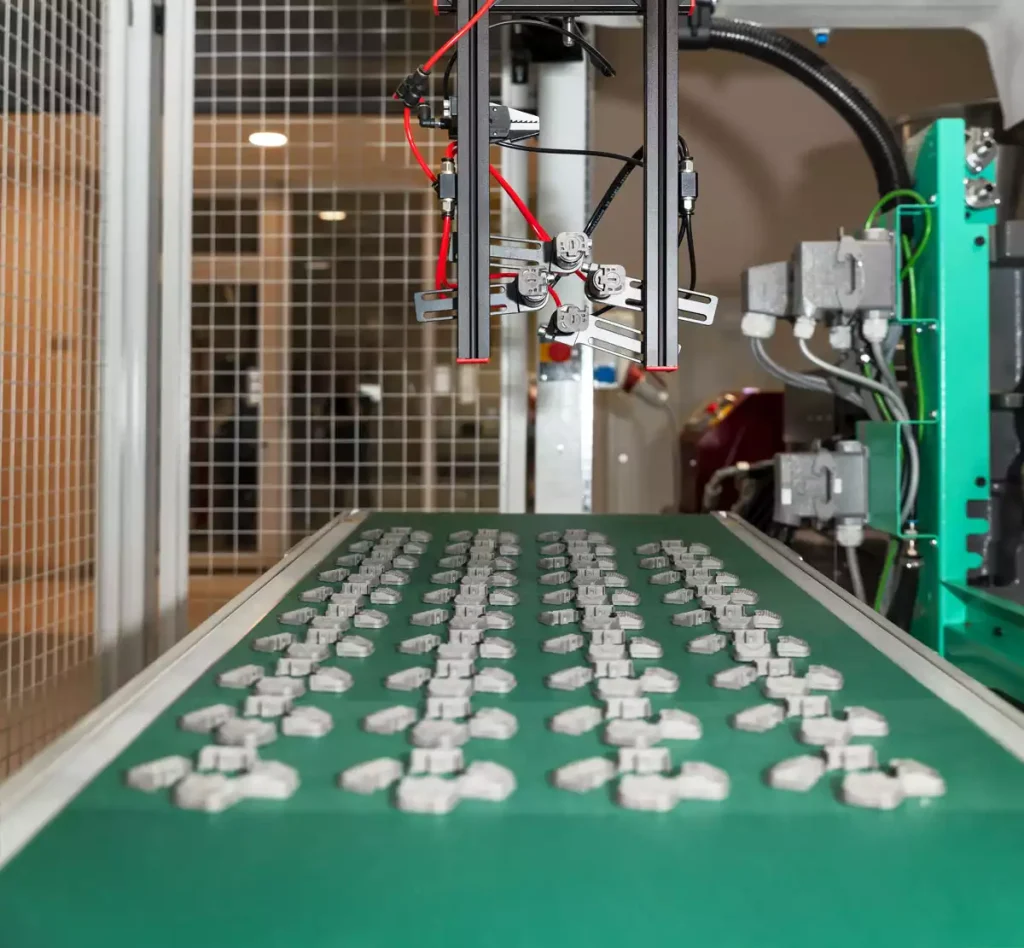

Mass Production: Consistency Through Control

With design and prototyping validated, we transition to full-scale production using hardened steel molds built for longevity and repeatability. Our state-of-the-art injection molding machines, ranging from 50 to 2000 tons of clamping force, are integrated with real-time monitoring systems that track pressure, temperature, cycle time, and shot consistency. Automated quality control systems, including in-line vision inspection and statistical process control (SPC), ensure every part conforms to exacting standards. Each production run is supported by documented process validation and first-article inspection reports. Preventive maintenance schedules and operator training programs further reinforce process reliability.

To support diverse client needs, we offer a range of material options and production capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50 – 2000 Tons |

| Shot Weight Capacity | 1 – 3000 g |

| Tolerance Capability | ±0.02 mm |

| Materials Supported | ABS, PC, PP, PA (Nylon), POM, PBT, PEEK, LCP, TPE |

| Mold Steel Types | P20, 718, H13, S136, 2738 |

| Production Capacity | Up to 5 million parts/year per mold |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers plastic injection moulding services with a zero-defect objective, ensuring reliability, repeatability, and excellence for every client.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Injection Moulding Excellence

Wuxi Lead Precision Machinery delivers more than plastic injection moulding services; we provide engineered manufacturing solutions for demanding industrial applications. As your strategic partner, we integrate precision metal fabrication expertise with advanced polymer processing to solve complex production challenges. Our facility in Wuxi operates under ISO 9001:2015 standards, utilizing German-engineered machinery and stringent process controls to ensure repeatability for aerospace, medical, and automotive components. We eliminate the guesswork in high-tolerance plastic part production through data-driven mould flow analysis, scientific moulding protocols, and real-time SPC monitoring.

Our technical capabilities are engineered for mission-critical applications where dimensional stability and material integrity are non-negotiable. Below are core specifications defining our production envelope:

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Clamping Force | 50 – 2000 Tons | Hydraulic & Hybrid |

| Shot Weight (PS) | 1g – 3000g | ±0.05% repeatability |

| Tolerance Control | Up to ±0.005mm | Cpk ≥ 1.67 guaranteed |

| Material Expertise | Engineering resins, LSR, PEEK | USP Class VI certified |

| Mould Construction | H13, S136, 420SS | Mirror polish to SPI A1 |

This infrastructure supports your most rigorous requirements—from micro-moulded medical connectors under 0.5g to structural automotive housings exceeding 500g. Our engineering team collaborates during DFM to optimize gate placement, cooling channels, and ejection systems, reducing cycle times by 18-22% while maintaining part integrity. Unlike commodity moulders, we treat every project as a co-engineering initiative, with dedicated process validation dossiers including cavity pressure curves, material lot traceability, and first-article inspection reports compliant with AS9102 or PPAP Level 3.

Quality is embedded at every phase through our dual-stage verification system. All critical dimensions undergo in-process CMM checks using Zeiss METROTOM 800 CT scanners, while material batches are validated via FTIR spectroscopy against OEM specifications. This prevents costly downstream failures in assemblies where plastic-metal interfaces require micron-level alignment—a capability honed through our parent company’s 15-year heritage in precision CNC machining for Tier 1 suppliers.

Initiate your next high-complexity programme with confidence. Contact our engineering team at [email protected] with your CAD files and production targets. We will provide a comprehensive capability assessment within 48 hours, including mould flow simulation data, feasibility study, and a transparent cost breakdown aligned with your quality gates. Partner with Wuxi Lead Precision Machinery where plastic injection moulding converges with metal-grade precision engineering. Your specifications define our commitment—not the reverse.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.