Technical Contents

Engineering Guide: Plastic Injection Moulding Companies Uk

Engineering Insight: The Critical Role of Precision in Plastic Injection Moulding

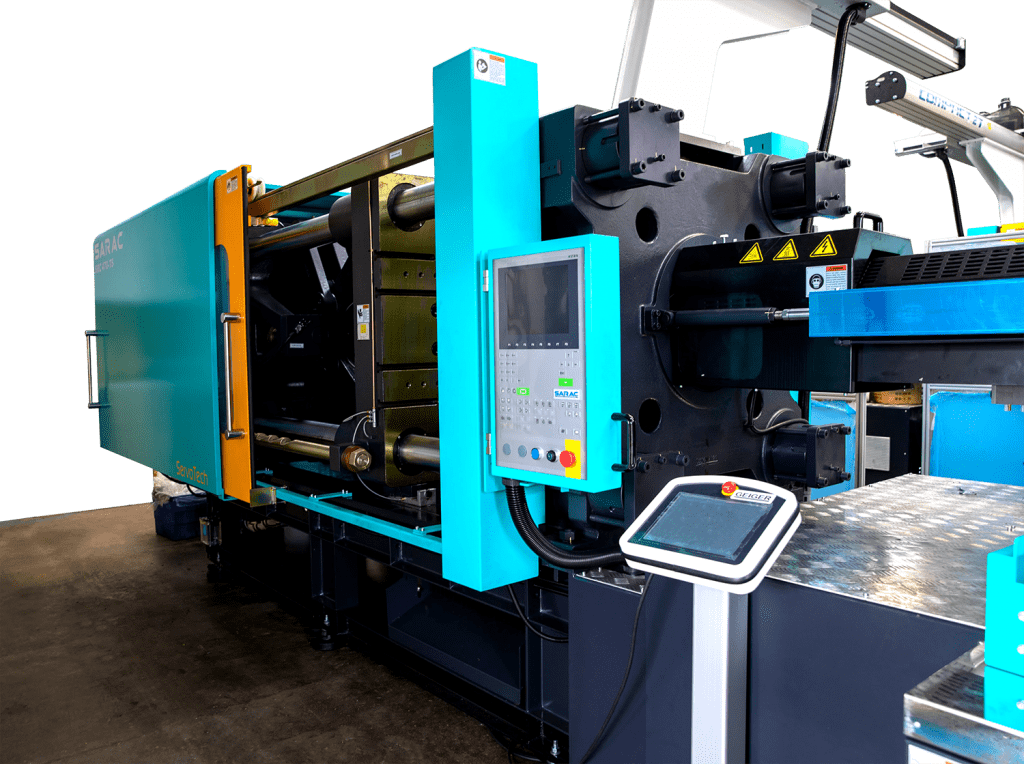

In the competitive landscape of plastic injection moulding, particularly among companies operating in the UK, precision engineering is not merely a quality benchmark—it is a foundational requirement. As industries such as medical devices, automotive, and aerospace demand increasingly complex components with tighter tolerances, the performance of the moulding equipment and the accuracy of the tooling directly influence product reliability, production efficiency, and overall cost-effectiveness. For plastic injection moulding companies in the UK, partnering with a precision metal manufacturing specialist like Wuxi Lead Precision Machinery ensures that every component meets the highest standards of dimensional accuracy and durability.

At Wuxi Lead, we understand that precision begins at the micro level. Our custom metal manufacturing processes are engineered to deliver tolerances as tight as ±0.002 mm, a capability forged through years of experience serving high-stakes sectors including Olympic-grade sports equipment and military defence systems. These applications demand zero margin for error—whether it’s a load-bearing component in a combat vehicle or a high-performance part used in Olympic track systems. This same level of exactness is applied to the tooling, fixtures, and custom machinery we supply to injection moulding operations across Europe.

Precision in mould manufacturing translates directly into consistency during production. Micro-variations in cavity dimensions, cooling channel alignment, or ejection mechanisms can lead to flashing, warping, or part rejection. By leveraging advanced CNC machining, wire EDM, and coordinate measuring machine (CMM) inspection protocols, Wuxi Lead ensures that each mould performs reliably over millions of cycles. Our UK clients benefit from reduced downtime, lower scrap rates, and faster time-to-market—critical advantages in a sector where efficiency defines profitability.

Our collaboration with plastic injection moulding companies in the UK goes beyond supply. We engage in engineering consultations to optimize mould design for manufacturability, material flow, and thermal management. This proactive approach minimizes trial-and-error during commissioning and enhances long-term performance.

Below are key specifications that define our precision manufacturing capabilities:

| Specification | Detail |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished to mirror finish if required) |

| Materials Handled | P20, H13, S136, 718H, Stainless Steel, Aluminium, Titanium |

| Maximum Machining Size | 2000 x 1200 x 1000 mm |

| Machining Processes | 5-axis CNC milling, Wire EDM, Grinding, Drilling |

| Quality Assurance | Full CMM inspection, GD&T reporting, First Article Inspection (FAI) |

| Industries Served | Automotive, Medical, Aerospace, Defence, Consumer Electronics |

Wuxi Lead Precision Machinery brings a proven legacy of excellence to every project. Our work with Olympic and military-grade applications has instilled a culture of uncompromising quality—one that directly benefits plastic injection moulding companies in the UK seeking reliable, high-performance tooling solutions. In an industry where precision defines performance, partnering with a leader in custom metal manufacturing is not just strategic—it is essential.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

Wuxi Lead Precision Machinery delivers the exacting standards demanded by UK plastic injection moulding companies for critical mold components. Our specialization in custom metal manufacturing for molds—cavities, cores, inserts, and structural plates—is built upon advanced equipment and rigorous quality control, ensuring components perform reliably in high-volume production environments. We understand that dimensional accuracy directly impacts part consistency, cycle times, and ultimately, your profitability. Our integrated processes eliminate the guesswork and rework common with less capable suppliers, providing UK mold makers with components that fit and function perfectly on the first try.

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers, primarily DMG MORI and Makino platforms. This technology is non-negotiable for complex mold geometry. Simultaneous 5-axis movement allows us to machine intricate undercuts, deep ribs, and organic contours inherent in modern mold designs within a single setup. This eliminates cumulative errors from multiple fixtures, significantly improving positional accuracy and geometric integrity. The result is superior surface finish directly off the machine, reducing hand polishing time and preserving critical cooling channel geometry. We routinely machine hardened tool steels like H13, S136, and P20 to tight tolerances, maintaining thermal stability essential for long mold life under production heat and pressure cycles.

Quality assurance is not a final checkpoint but an embedded process. Every critical dimension and geometric feature undergoes verification using calibrated Coordinate Measuring Machines (CMM), specifically Zeiss CONTURA systems operating within a climate-controlled metrology lab. Our CMM inspection protocols follow ISO 10360 standards, providing full traceability and comprehensive GD&T analysis. Inspection reports detail actual measurements against your CAD model or drawing, including form, position, and profile deviations. This data-driven validation ensures components meet the stringent requirements necessary for zero-defect molding, preventing costly press downtime and scrap associated with out-of-tolerance tooling. Our ISO 9001 certified quality management system governs all processes, from material certification to final packaging.

The following table details our standard achievable tolerance capabilities for critical mold features, validated through our CMM inspection process. These represent typical production capabilities for hardened tool steels; specific project requirements may allow for tighter control.

| Feature Type | Dimensional Tolerance | Geometric Tolerance (GD&T) | Measurement Method |

|---|---|---|---|

| Core/Cavity Details | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | Zeiss CMM |

| Insert Bore/Shaft Fit | ±0.003 mm (±0.0001″) | ±0.002 mm (±0.0001″) | CMM + Air Gaging |

| Pocket Depths | ±0.010 mm (±0.0004″) | Flatness ≤ 0.010 mm | CMM |

| Critical Angles | ±0.05° | Profile ≤ 0.010 mm | CMM |

| Standard Features | ±0.020 mm (±0.0008″) | Position ≤ 0.020 mm | CMM / Manual |

This combination of advanced 5-axis CNC machining and uncompromising CMM-based quality control delivers the precision foundation UK plastic injection moulding companies require. We translate your complex designs into flawless metal components, minimizing your assembly time and maximizing mold performance and longevity from day one of production.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of custom metal components used in plastic injection moulding applications. For UK-based plastic injection moulding companies sourcing high-precision parts from global suppliers like Wuxi Lead Precision Machinery, understanding the properties and applications of aluminum, steel, and titanium is essential to optimize tooling life, cycle times, and part quality. Each material offers distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum alloys, particularly 6061 and 7075, are widely used for prototype moulds and low- to medium-volume production runs. Their high thermal conductivity allows for faster cooling cycles, improving throughput during trial runs or short production batches. Aluminum is also easier to machine, reducing lead times and manufacturing costs. However, its lower hardness and wear resistance make it less suitable for long-term, high-volume applications. It is best deployed in situations where rapid iteration and cost control are priorities.

Steel, especially tool steels like P20, H13, and S136, remains the standard for high-volume injection moulding. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. P20 is commonly used for mould bases and cores due to its good machinability and moderate toughness. H13 excels in applications involving high thermal stress, such as hot runner systems, thanks to its excellent heat resistance. For corrosive environments or medical-grade plastic production, stainless variants like S136 provide enhanced resistance to rust and chemical degradation, ensuring longer service life and reduced maintenance.

Titanium alloys, while less common in standard mould construction, offer exceptional strength-to-density ratios and corrosion resistance. Their use is typically reserved for specialized components such as inserts, ejector pins, or wear-prone areas where weight reduction and longevity are critical. Though more expensive and challenging to machine, titanium’s performance in aggressive environments justifies its use in niche, high-performance tooling applications.

Surface finishing further enhances material performance. Anodizing, particularly for aluminum components, increases surface hardness, improves wear resistance, and provides electrical insulation. Type II (sulfuric acid) anodizing is commonly used for general protection and aesthetic finish, while Type III (hardcoat anodizing) delivers thicker, more durable layers suitable for functional surfaces subject to friction or abrasion. Anodized layers are integral to the base metal, ensuring they do not flake or peel under thermal cycling.

The following table summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 6061 | 30–35 | 167 | Moderate | Prototyping, low-volume tooling |

| P20 Steel | 28–32 | 36 | Low | Mould bases, core inserts |

| H13 Steel | 48–52 | 30 | Moderate | High-heat cavities, hot runners |

| S136 Steel | 50–54 | 28 | High | Corrosion-resistant moulds |

| Titanium Gr5 | 36–40 | 7.2 | Very High | Wear components, specialized inserts |

Selecting the right material and finish ensures optimal performance, longevity, and return on investment for injection moulding tooling systems. Wuxi Lead Precision Machinery supports UK manufacturers with expert consultation to match material properties with production requirements.

Manufacturing Process & QC

Precision-Driven Production Process for Injection Moulding Excellence

Achieving zero-defect performance in plastic injection moulding demands an integrated, rigorously controlled production process. At Wuxi Lead Precision Machinery, we engineer this reliability from initial concept through to high-volume output, specifically addressing the stringent quality expectations of UK manufacturers. Our methodology eliminates costly iterations and production delays by embedding precision at every phase, ensuring your moulds deliver consistent part quality from the first shot.

The process begins with collaborative Design for Manufacturability (DFM). Our engineering team works directly with your UK-based design inputs, utilizing advanced CAD/CAM software and mould flow analysis. This phase critically evaluates gate placement, cooling channel geometry, material selection, and structural integrity before metal is cut. We identify potential sink marks, warpage, or ejection issues early, translating your functional requirements into a manufacturable, robust tool design. This proactive validation prevents 90% of common production defects at the source, significantly reducing time-to-market.

Prototyping transitions the validated design into physical reality under controlled conditions. Using our high-precision CNC machining centres and EDM equipment, we produce a single-cavity prototype mould. This stage is not merely a proof-of-concept; it is empirical validation under near-production parameters. We conduct rigorous material trials, pressure tests, and dimensional inspections on the prototype parts. Any micro-adjustments to venting, tolerances, or surface finish are implemented immediately based on real data, not assumptions. This rapid, data-driven iteration ensures the final production tool is perfected before full-scale manufacturing commences.

Mass production leverages our zero-defect framework through closed-loop process control. Every production mould undergoes 100% metrology verification against the original CAD model using CMM and optical scanners prior to shipment. During your operation, the mould’s performance is sustained by our engineered tolerances and hardened components. Continuous monitoring via integrated sensors tracks critical parameters like cavity pressure, temperature stability, and cycle time deviations in real-time. Any variance outside the pre-defined SPC limits triggers automatic process correction, preventing non-conforming parts from progressing. This systematic approach guarantees sustained repeatability and eliminates scrap rates that erode UK production margins.

Our core manufacturing capabilities enable this uncompromising quality standard. The table below details the precision infrastructure supporting your zero-defect outcomes:

| Parameter | Specification Range | Process Control Integration |

|---|---|---|

| Machine Tonnage | 50T – 2000T | Real-time clamp force monitoring |

| Positioning Accuracy | ±0.005 mm | Laser calibration verification |

| Surface Finish | Ra 0.025 µm – Ra 0.8 µm | In-process profilometry checks |

| Cooling Efficiency | Optimized thermal simulation | Flow rate & temp sensors |

| Material Handling | ISO 9001:2015 Certified | Full material traceability logs |

This end-to-end process, grounded in empirical validation and closed-loop correction, transforms design intent into flawless production reality. Wuxi Lead Precision Machinery delivers not just moulds, but a guaranteed pathway to zero-defect manufacturing for the demanding UK market. Partner with us to convert precision engineering into your competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored to the exacting demands of plastic injection moulding companies across the UK. With over 15 years of experience in CNC machining, EDM, and complex fabrication, we have built a reputation for reliability, accuracy, and seamless international collaboration. Our advanced manufacturing capabilities and strict quality control protocols ensure that every component we produce meets the highest standards of performance and durability—critical for maintaining efficiency and consistency in high-volume injection moulding operations.

We understand that UK-based moulding companies require partners who can deliver on tight tolerances, rapid turnaround, and consistent repeatability. That’s why we invest in cutting-edge 5-axis CNC systems, automated inspection technologies, and a fully integrated quality management system compliant with ISO 9001:2015. From prototype development to full-scale production, our team works closely with your engineering staff to translate designs into high-performance metal parts—on time and within specification.

Our core strengths lie in producing mould bases, cavity and core inserts, ejector systems, slides, lifters, and other precision tooling components used in the construction and maintenance of injection moulds. By combining domestic-grade materials such as H13, P20, 718, and S136 with our advanced heat treatment and surface finishing techniques, we deliver components that resist wear, corrosion, and thermal fatigue—extending tool life and reducing downtime.

We serve clients across the UK automotive, medical, consumer electronics, and industrial equipment sectors, providing a cost-effective alternative to domestic manufacturing without compromising on quality. Our streamlined logistics network ensures fast, reliable delivery via DHL, FedEx, or sea freight, with full shipment tracking and documentation support.

Below are key technical specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling; turning up to Ø300 mm |

| Tolerance | ±0.005 mm typical, down to ±0.002 mm for critical features |

| Surface Finish | Ra 0.2–1.6 μm, polished or textured as required |

| Materials | Tool steels (H13, P20, 718, S136), stainless steels, aluminium, brass, copper alloys |

| Max Workpiece Size | 1200 x 800 x 600 mm |

| EDM | Wire EDM and sinker EDM available for complex geometries |

| Quality Control | CMM, optical comparators, roughness testers, hardness testing |

| Lead Time | 10–25 days depending on complexity and volume |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to your success. We bridge the gap between Chinese efficiency and European precision, offering scalable solutions that support your growth and innovation.

Contact us today at [email protected] to discuss your next project. Let Lead Precision become your trusted partner in high-accuracy metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.