Technical Contents

Engineering Guide: Plastic Injection Moulders

Engineering Insight: The Critical Role of Precision in Plastic Injection Moulding

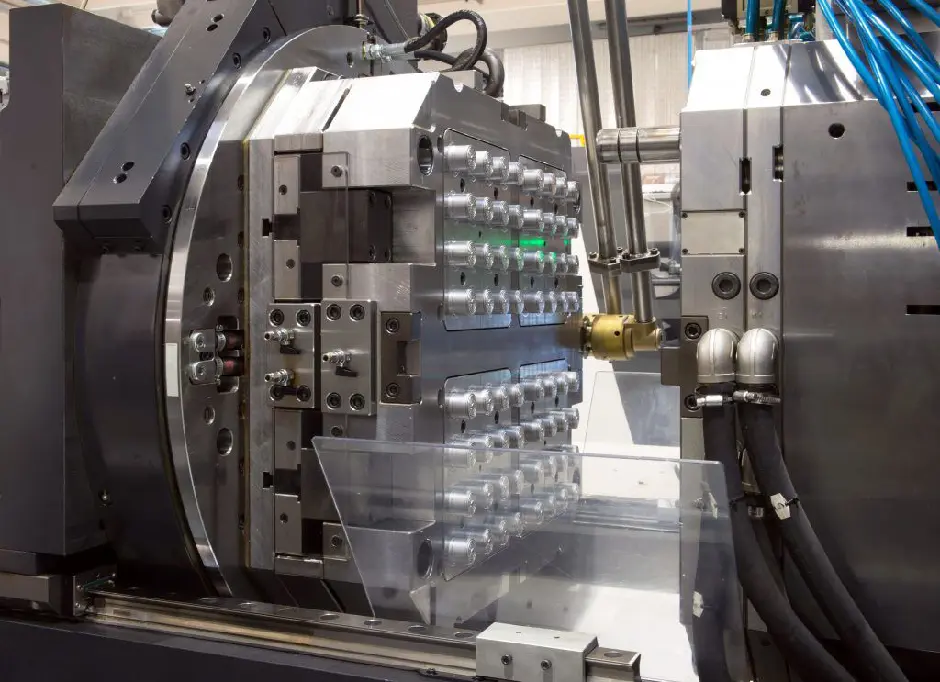

In the realm of high-performance manufacturing, plastic injection moulding stands as a cornerstone process, enabling the mass production of complex, high-integrity components across industries such as automotive, medical, aerospace, and consumer electronics. However, the success of this process hinges not merely on the injection technology itself, but on the precision engineering of the metal tooling—moulds—that define the final product. At Wuxi Lead Precision Machinery, we understand that the foundation of any reliable injection moulding operation lies in the accuracy, durability, and repeatability of the custom metal components that form the mould.

Precision in mould manufacturing directly impacts part consistency, surface finish, dimensional stability, and overall production efficiency. Even micron-level deviations in cavity or core alignment can lead to flash, warpage, or incomplete filling—defects that compromise functionality and increase scrap rates. Furthermore, high-cycle production demands moulds that maintain integrity over tens or hundreds of thousands of cycles. This requires not only exacting CNC machining but also advanced material selection, thermal treatment, and surface engineering.

Our experience at Wuxi Lead Precision Machinery spans over a decade of delivering mission-critical metal components to sectors where failure is not an option. We have engineered and manufactured precision tooling systems used in applications tied to Olympic-grade equipment and military-grade hardware—environments that demand zero tolerance for error. These projects have reinforced our commitment to tight tolerances, rigorous quality control, and full traceability in every phase of production.

Our custom mould bases, cavity inserts, ejector systems, and cooling channel components are machined to tolerances as tight as ±0.002 mm, ensuring perfect alignment and minimal wear over extended use. Utilizing advanced 5-axis CNC machining, wire EDM, and surface grinding technologies, we produce mould components that meet ISO 9001 and IATF 16949 standards, with full inspection reports available upon request.

The integration of precision metal components into plastic injection moulds is not a detail—it is the determinant of success. As manufacturing evolves toward smarter, faster, and more sustainable processes, the demand for higher precision in mould tooling will only intensify. At Lead Precision, we stand at the forefront of this evolution, combining technical mastery with proven performance in the most demanding applications.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Materials | P20, 718H, S136, H13, 420 Stainless Steel, Aluminum 7075 |

| Machining Capabilities | 5-Axis CNC, Wire EDM, Surface & Cylindrical Grinding |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished to mirror finish if required) |

| Heat Treatment | Vacuum Hardened, Nitrided, or Through-Hardened (50–58 HRC) |

| Quality Standards | ISO 9001, IATF 16949, Full CMM Inspection Reporting |

| Applications | Automotive, Medical, Aerospace, Defense, Consumer Electronics |

Precision Specs & Tolerances

Technical Capabilities for Precision Injection Mould Manufacturing

Wuxi Lead Precision Machinery delivers engineered metal solutions specifically for the demanding requirements of high-performance plastic injection moulds. Our core strength lies in integrating advanced multi-axis machining with rigorous metrology, ensuring mould components meet the exacting dimensional and surface finish standards critical for part consistency, reduced cycle times, and extended mould life. We understand that precision in the mould directly translates to profitability and quality in your production, making our technical capabilities a strategic asset for mould makers facing complex geometries and tight tolerances.

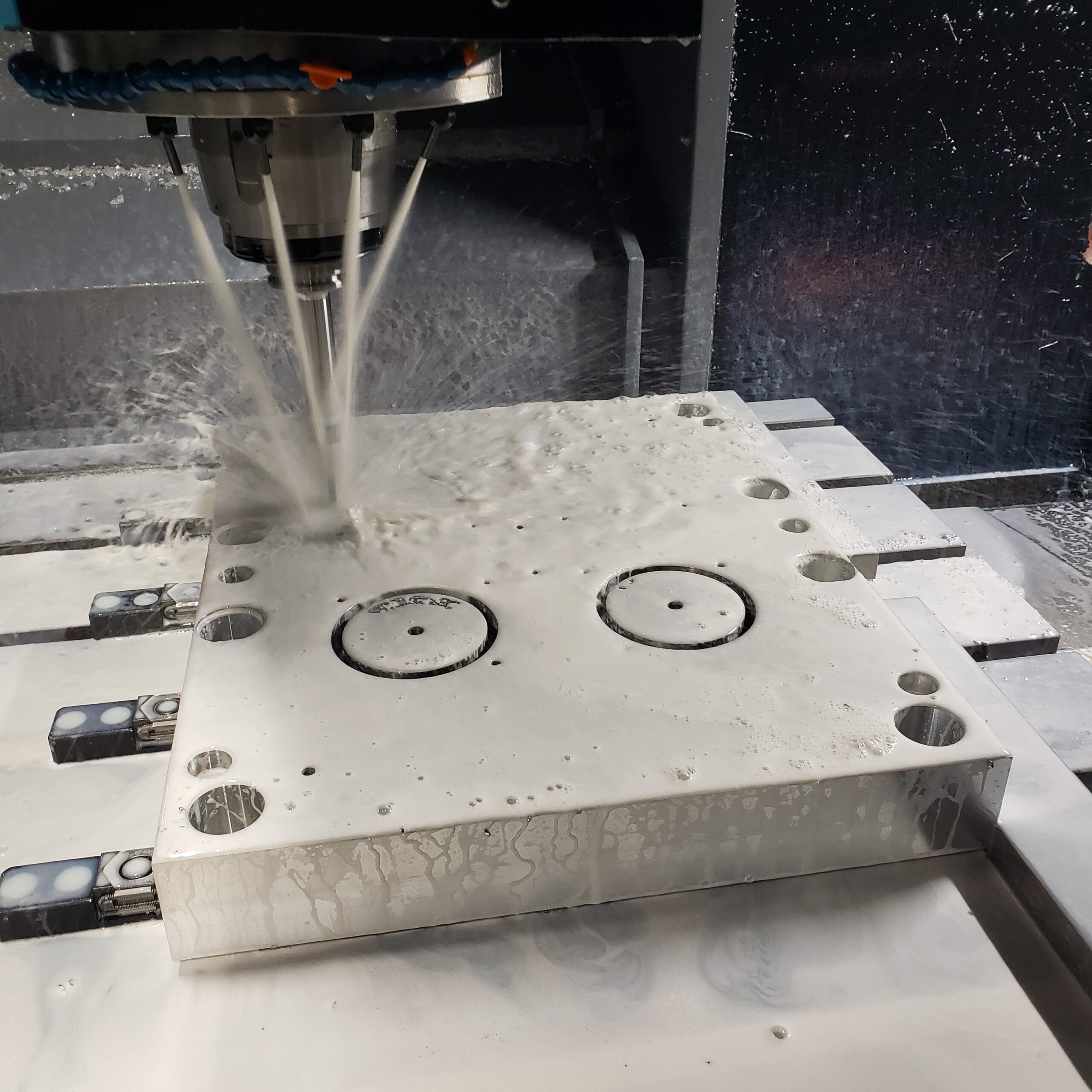

Our primary manufacturing platform centers on state-of-the-art 5-axis CNC machining centers. This technology is fundamental for efficiently producing intricate mould cores, cavities, slides, and lifters with complex undercuts and organic shapes that are increasingly common in modern consumer, medical, and automotive applications. The simultaneous 5-axis movement allows for single-setup machining of highly complex features, significantly reducing cumulative error from multiple fixtures, minimizing handling-induced inaccuracies, and improving overall geometric accuracy. This capability is essential for achieving the precise wall thicknesses, consistent parting lines, and critical shut-off surfaces demanded by high-cavity or family moulds. Furthermore, our 5-axis platforms enable optimal toolpath strategies for superior surface finishes directly off the machine, reducing or eliminating the need for extensive hand polishing on critical cosmetic surfaces, thereby accelerating time-to-market.

Quality assurance is not a final step but an integrated process throughout production. Every critical component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols are specifically tailored for injection mould validation, focusing on critical dimensions, geometric tolerances (GD&T), cavity/core matching, cooling channel positioning, and ejector pin alignment. Full inspection reports, including detailed deviation maps against the CAD model, are provided, offering complete traceability and verification that the manufactured component meets the stringent specifications required for successful mould trials and production. This data-driven QC process minimizes costly trial-and-error during mould commissioning and ensures predictable, high-yield production from day one.

The following table details our standard achievable tolerance ranges for critical mould features, reflecting our commitment to precision manufacturing under controlled environmental conditions:

| Feature Type | Standard Production Tolerance | Precision Mould Tolerance | Ultra-Precision Mould Tolerance |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.015 mm | ±0.005 mm | ±0.002 mm |

| Linear Dimensions (in) | ±0.0006 in | ±0.0002 in | ±0.00008 in |

| Geometric Tolerances (GD&T) | ±0.020 mm | ±0.008 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | 0.2 µm |

| Cavity/Core Matching | ±0.025 mm | ±0.010 mm | ±0.005 mm |

Partnering with Wuxi Lead means access to manufacturing precision engineered for the realities of injection moulding. Our 5-axis CNC expertise combined with CMM-validated quality control provides the dimensional integrity necessary to minimize trial runs, maximize part quality, and ensure your moulds deliver consistent performance throughout their operational lifespan. We translate complex design intent into reliable, high-precision metal components, directly supporting your success in competitive markets.

Material & Finish Options

Material selection is a critical decision in the design and manufacturing of precision tooling for plastic injection moulders. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to meet the rigorous demands of high-volume and high-precision injection molding applications. The choice between aluminum, steel, and titanium directly impacts mold longevity, cycle time, surface finish quality, and overall production cost-efficiency.

Aluminum is widely used for prototype molds and low-to-medium volume production due to its excellent machinability and superior thermal conductivity. This allows for faster cooling cycles, improving throughput during trial runs and short production batches. While not as hard as steel or titanium, modern high-strength aluminum alloys such as 7075 and 6061 offer sufficient durability for thousands of cycles when properly treated. Aluminum is also significantly lighter, reducing handling complexity and enabling quicker mold changes.

Steel remains the standard for high-volume production molds due to its exceptional hardness, wear resistance, and dimensional stability. Tool steels such as P20, H13, and S136 are commonly selected based on required polishability, corrosion resistance, and operating temperature. These steels can endure millions of cycles with minimal degradation, making them ideal for long production runs. However, steel molds require more time and cost to machine and often need heat treatment to achieve optimal performance.

Titanium, while less common, offers a unique combination of high strength-to-density ratio, excellent corrosion resistance, and thermal stability. It is typically reserved for specialized applications where extreme durability and resistance to aggressive environments are required. Due to its high cost and challenging machinability, titanium is used selectively, often in aerospace or medical-grade molding systems where material integrity is non-negotiable.

Surface finishing, particularly anodizing, plays a vital role in enhancing the performance of aluminum molds. Anodizing creates a durable, corrosion-resistant oxide layer that improves surface hardness and wear resistance. It also allows for color coding and aesthetic customization without compromising dimensional accuracy. For steel molds, alternatives such as chrome plating, nitriding, or polishing to optical-grade finishes are more common, depending on the application.

Below is a comparative overview of key material properties relevant to injection mold manufacturing:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes | Best Use Case |

|---|---|---|---|---|---|

| Aluminum (6061) | 15–20 | 167 | 10,000 – 100,000 | Anodizing, Polishing | Prototypes, Low-volume production |

| Steel (P20) | 28–32 | 28–36 | 500,000 – 1,000,000 | Chrome, Polishing | Medium to high-volume production |

| Steel (H13) | 48–52 | 30–35 | 1,000,000+ | Nitriding, Coating | High-temperature, high-wear |

| Titanium (Grade 5) | 35–40 (equivalent) | 7.2 | 1,000,000+ (specialized) | TiN coating, Polishing | Corrosive environments, Aerospace |

At Wuxi Lead Precision Machinery, we work closely with engineering teams to match material and finish specifications to your production goals, ensuring optimal performance, longevity, and cost-efficiency in every custom mold system.

Manufacturing Process & QC

Precision-Driven Production Process for Injection Mould Excellence

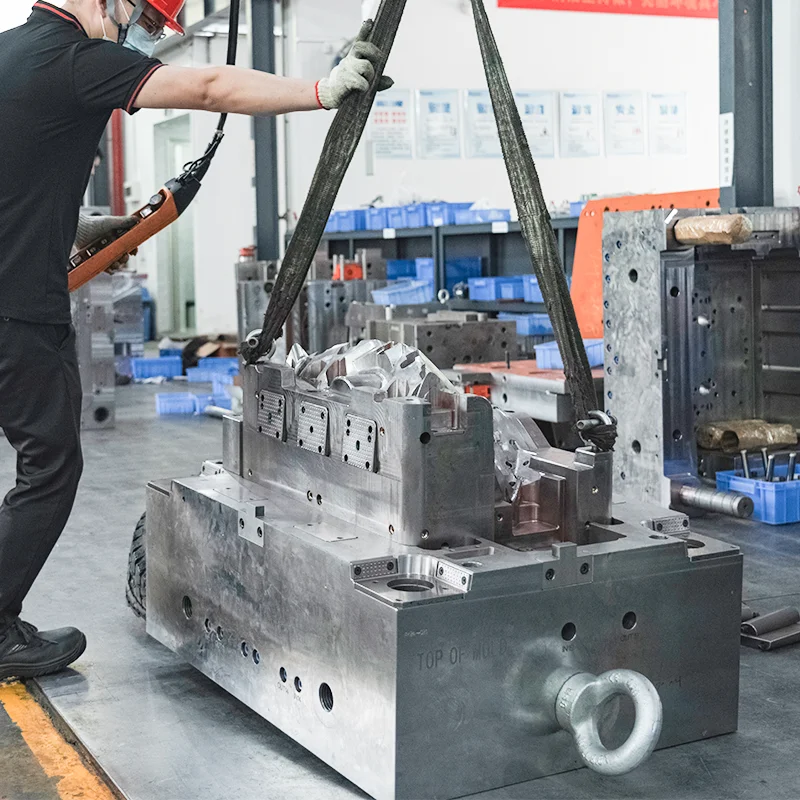

At Wuxi Lead Precision Machinery, we understand that flawless plastic injection moulding begins long before the first pellet melts. Our integrated production process, engineered for zero defects, transforms conceptual designs into high-volume production reality through three rigorously controlled phases. This methodology ensures your moulds deliver consistent part quality, extended service life, and maximum uptime, directly impacting your operational profitability and reputation for excellence.

The journey commences with collaborative Design Engineering. Our senior engineers partner with your team to scrutinize part geometry, material flow dynamics, and ejection strategies using advanced simulation software. We focus on manufacturability, optimizing cooling channels, gate locations, and structural integrity to prevent warpage, sink marks, or stress points inherent in complex plastic components. This phase establishes the critical foundation; tolerances are defined, material specifications are finalized, and potential failure modes are mitigated computationally, eliminating costly revisions later. Precision is not an afterthought but the core design principle.

Prototyping validates the virtual model against physical reality. Utilizing our state-of-the-art multi-axis CNC machining centres and wire EDM systems, we produce a functional prototype mould core and cavity set. This stage is not merely about form; it is rigorous validation under production-intent conditions. We conduct initial mould trials with your specified polymer, meticulously measuring part dimensions, surface finish, and cycle times against the simulation predictions. Any micro-discrepancy triggers immediate corrective action within our engineering loop. This critical step ensures the final mould design is perfected before committing to full production tooling, guaranteeing the path to zero defects is proven.

Mass Production leverages the validated design and prototype data for flawless execution. Our dedicated production cells, operating under stringent ISO 9001 protocols, employ statistical process control (SPC) from the first cavity. Every machining operation, heat treatment cycle, and assembly step is monitored in real-time. Sub-micron precision is maintained through environmental controls and continuous calibration. We implement 100% in-process dimensional verification for critical features and final comprehensive metrology using coordinate measuring machines (CMMs). This relentless focus on process stability and measurement ensures every mould component meets exacting specifications, delivering the consistent, high-integrity tooling required for your zero-defect manufacturing goals.

Critical Mould Performance Specifications Achieved

| Parameter | Standard Capability | High-Precision Capability | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.002 mm | CMM, Optical Comparator |

| Surface Roughness (Cavity) | Ra 0.20 µm | Ra 0.05 µm | Profilometer |

| Core/Cavity Hardness | 50-52 HRC | 54-56 HRC (Custom) | Rockwell Hardness Tester |

| Parallelism/Flatness | 0.005 mm/m | 0.002 mm/m | Laser Interferometer |

| Lead Time (Prototype) | 15-20 Days | 10-15 Days (Priority) | Project Management System |

This seamless integration of design insight, empirical prototyping validation, and statistically controlled mass production forms the backbone of Wuxi Lead’s commitment to zero-defect tooling. We deliver moulds engineered not just to perform, but to exceed the demanding requirements of modern high-volume plastic injection manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand the critical role precision-engineered metal components play in the success of plastic injection moulding operations. Our mission is to serve as a trusted extension of your manufacturing capability, delivering high-integrity parts that meet the exacting standards of modern injection moulding systems. Whether you require custom mould bases, core and cavity supports, ejector systems, or fully assembled mould subcomponents, our engineering team combines deep technical knowledge with advanced CNC manufacturing to ensure every component performs flawlessly in your production environment.

We specialize in producing custom metal components from a wide range of materials, including P20, 718, H13, S136, and other tool steels commonly used in the injection moulding industry. Our in-house capabilities span precision milling, turning, grinding, EDM, heat treatment, and surface finishing—ensuring complete process control from raw material to final inspection. Every part is manufactured to tight tolerances, with surface finishes optimized for durability, wear resistance, and seamless integration into your mould assemblies.

Our clients across Europe, North America, and Southeast Asia rely on us not just for quality, but for reliability and responsiveness. We operate under ISO 9001-certified processes and utilize state-of-the-art CMM and 3D scanning technology to verify dimensional accuracy. Our engineering team works closely with your design specifications, offering DFM feedback to optimize manufacturability, reduce lead times, and lower total production costs.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a long-term manufacturing ally committed to your operational success. We support low-volume prototyping, high-volume production runs, and everything in between, with scalable capacity and consistent quality.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope (mm) | 1200 × 800 × 600 |

| CNC Milling Centers | 5-axis, 4-axis, 3-axis (Fanuc & Siemens controls) |

| CNC Lathes | Multi-axis turning with live tooling |

| EDM | Wire-cut and sinker EDM available |

| Materials | P20, 718, H13, S136, 420SS, Aluminum 7075, and custom alloys |

| Finishing Options | Hardening, nitriding, chrome plating, texturing |

| Quality Assurance | CMM, 3D scanning, first-article inspection, PPAP support |

We invite plastic injection moulders seeking a high-performance manufacturing partner to contact us today. Let our team help you achieve greater precision, faster cycle times, and improved mould longevity through superior component engineering.

For technical inquiries, quotations, or engineering collaboration, email us at [email protected]. Our engineers respond within 12 hours and are prepared to review drawings, discuss material selections, and provide detailed manufacturing plans tailored to your needs. Partner with Wuxi Lead Precision Machinery—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.