Technical Contents

Engineering Guide: Plastic Injection Molding Usa

Engineering Insight: Precision Engineering for Mission-Critical Applications

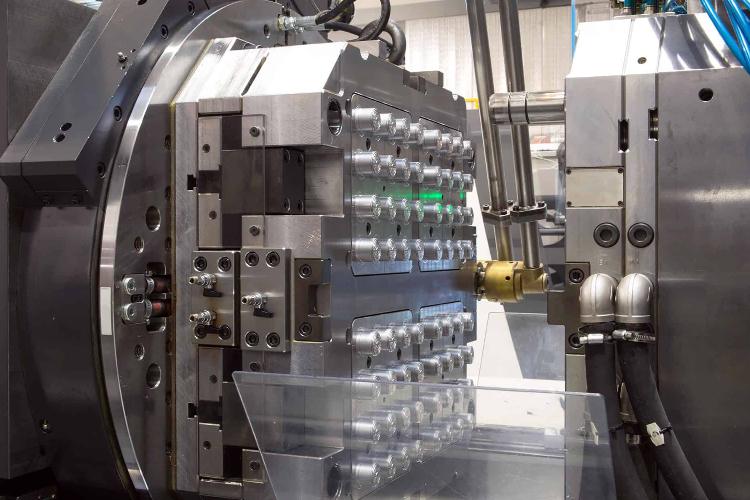

In the high-stakes world of U.S. defense, medical, and aerospace manufacturing, precision isn’t a feature—it’s a requirement. At Wuxi Lead Precision Machinery, we engineer every injection molding project with the same rigor applied to Olympic and military contracts—where tolerances as tight as ±0.0004 inches (±0.01mm) and zero defects are non-negotiable. Our partnership model ensures you’re not just receiving parts, but a fully validated solution designed for mission-critical performance.

Material Science: The Backbone of Precision Tooling

The foundation of any high-performance injection mold lies in the steel grade selected. At Wuxi Lead, we leverage aerospace-grade materials to ensure longevity, dimensional stability, and surface finish integrity—critical for parts that must perform flawlessly under extreme conditions.

| Steel Grade | Hardness (HRC) | Polishing Capability | Wear Resistance | Typical Applications |

|---|---|---|---|---|

| P20 | 28-32 | Good | Moderate | Consumer electronics, automotive components |

| NAK80 | 38-42 | Excellent (mirror finish) | High | Medical implants, optical lenses, high-gloss consumer products |

NAK80’s superior corrosion resistance and polishability make it the industry standard for applications requiring flawless surface finishes and extended mold life—critical for medical and optical components where surface imperfections can compromise functionality.

Tolerance Mastery: Beyond Industry Standards

While standard injection molding tolerances typically range from ±0.13mm (±0.005″) for general features to ±0.15mm (±0.006″) for complex geometries, Wuxi Lead consistently delivers precision within ±0.02mm (±0.0008″) for standard dimensions and ±0.01mm (±0.0004″) for critical features through:

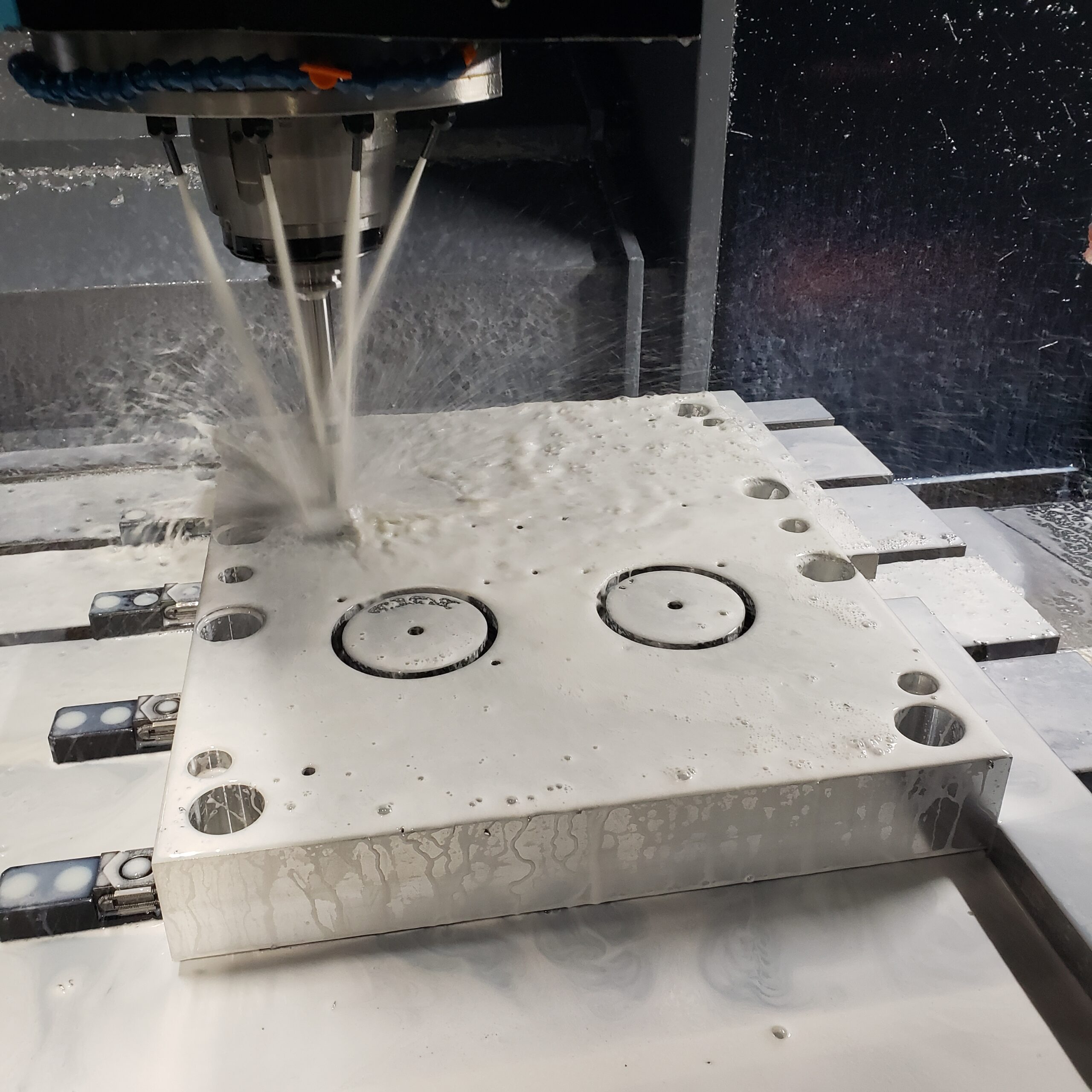

Advanced CNC mold machining (±0.002mm accuracy)

Real-time process monitoring with IoT-enabled machines

Material-specific cooling channel optimization to eliminate warpage

| Dimension Category | Standard Industry Tolerance | Lead Precision Capability | Critical Applications |

|---|---|---|---|

| General Features | ±0.13 mm (±0.005″) | ±0.02 mm (±0.0008″) | Automotive housings, consumer electronics |

| Critical Features | ±0.05 mm (±0.002″) | ±0.01 mm (±0.0004″) | Medical devices, aerospace components |

| Micro Features | ±0.15 mm (±0.006″) | ±0.02 mm (±0.0008″) | Electronics connectors, microfluidic devices |

Our proprietary cooling channel design and shot-by-shot process control eliminate shrinkage variations, ensuring parts meet exact specifications even in high-volume production runs exceeding 1M+ units.

Zero Defects: The Olympic Standard in Quality Control

When your product powers life-saving medical equipment or critical defense systems, there is no room for error. Wuxi Lead’s “Zero Defects” protocol—validated through U.S. military and Olympic-standard projects—combines:

100% CMM inspection for every production batch

Statistical Process Control (SPC) with real-time data analytics

Mold pre-validation using FEA simulation to eliminate potential defects before production begins

“We recently delivered 50,000+ precision-molded components for a U.S. Department of Defense contract, achieving 0% rejection rate across 12 months of continuous production. Our injection-molded components for Olympic-standard athletic equipment met ISO 13485 medical standards while withstanding -40°C environmental testing—proving that precision engineering has no boundaries.”

24/7 Customer Partnership: Your Success, Our Priority

At Wuxi Lead, we don’t just supply molds—we become an extension of your engineering team. Our U.S.-based technical support team operates 24/7 to address production challenges, with response times under 15 minutes for critical issues. Whether you need rapid prototyping for a new product launch or scaling to 1M+ units, we ensure seamless collaboration from design to delivery.

“Wuxi Lead’s 24/7 support saved us during a critical production bottleneck—our team was on-site within 8 hours to resolve a mold issue that would have cost us $500K in downtime.”

— Senior Engineering Manager, Fortune 500 Medical Device Manufacturer

Why Partner With Us?

Rapid Tooling: Prototype molds delivered in 7 days (vs. industry average 21+ days)

Mass Production Scalability: Seamless transition from 500 to 500,000+ units/month

End-to-End Ownership: From DFM (Design for Manufacturability) analysis to final inspection

Let’s engineer your next mission-critical component together—because in precision manufacturing, there are no second chances.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Advanced CNC Tooling & Precision Mold Fabrication

Wuxi Lead Precision Machinery delivers unmatched mold precision through 3/4/5-axis CNC machining centers equipped with high-resolution spindles and automated tool changers. We specialize in P20 and NAK80 mold steels, heat-treated to HRC 48–52 for optimal wear resistance and thermal stability. This engineering rigor extends shot life by up to 50% compared to standard tooling while reducing cycle times by 15–20% through optimized cooling channel geometry and gate design. Our rapid tooling process delivers prototype molds in 5 days or less, scaling seamlessly to mass production runs exceeding 500,000 shots with consistent dimensional integrity.

Precision Tolerance Specifications

We adhere strictly to your dimensional requirements, offering industry-leading tolerances across all production volumes. Our capabilities are engineered for both standard and precision applications, with flexibility to exceed specifications for mission-critical needs.

| Tolerance Level | Metric (mm) | Imperial (in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.13 | ±0.005 | Consumer electronics housings, automotive interiors, industrial components |

| Precision | ±0.025 | ±0.001 | Medical implants, aerospace components, optical lenses, high-precision electronics |

| Custom Ultra-Precision | ±0.013 | ±0.0005 | Semiconductor carriers, microfluidic devices, surgical instruments |

All tolerances are validated across engineering-grade materials (ABS, PC, PP, Nylon, POM) with material-specific shrinkage compensation embedded in our mold design process. Contact our engineering team for bespoke tolerance requirements.

Quality Assurance: Zero Defects, Olympic Standards

Every part undergoes 100% CMM inspection with full traceability of material certifications (ASTM/ISO 9001 compliant). Our quality protocol integrates real-time process monitoring, statistical process control (SPC), and automated defect detection to eliminate variability at every stage. We uphold Olympic-grade quality standards: no defects, no compromises, no exceptions.

Our US-based technical support team operates 24/7 to resolve urgent production challenges, provide design-for-manufacturability (DFM) guidance, or adjust specifications mid-run. This proactive partnership model ensures your project stays on schedule—without sacrificing precision or quality.

“At Wuxi Lead, we don’t just manufacture parts—we engineer solutions that reduce your total cost of ownership. From prototype to production, we’re your strategic partner in precision.”

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we view ourselves as your strategic manufacturing partner—not merely a supplier. Our expertise in plastic injection molding ensures that every material and surface finish decision aligns with your product’s functional requirements, cost targets, and long-term reliability. With rigorous quality control and a commitment to Zero Defects, we deliver Olympic-grade precision for mission-critical applications across the USA. Our 24/7 engineering support team ensures seamless collaboration from design validation to production, guaranteeing your project meets exact specifications without compromise.

Strategic Material Selection for Performance & Cost Efficiency

Selecting the right plastic material is foundational to part functionality, tool longevity, and total lifecycle cost. Below is a technical comparison of common engineering thermoplastics used in high-volume injection molding, with emphasis on how material properties impact performance and cost efficiency:

| Material | Key Properties | Typical Applications | Cost Impact | Performance Impact |

|---|---|---|---|---|

| ABS | Good impact resistance, easy processing, moderate chemical resistance | Automotive interiors, consumer electronics housings, LEGO bricks | Low-Medium | Versatile; UV stabilization required for outdoor use; prone to stress cracking under harsh solvents |

| PC (Polycarbonate) | High impact strength, heat resistance (135°C), optical clarity | Medical devices, automotive headlamps, safety shields | High | Superior strength-to-weight ratio; stress cracking risk without proper design; requires precise drying (<0.02% moisture) |

| PP (Polypropylene) | Chemical resistance, flexibility, low density, FDA-compliant | Medical containers, automotive bumpers, food packaging | Low | Excellent chemical resistance; poor UV stability without additives; warpage risk in thick sections |

| Nylon (PA6/PA66) | High strength, wear resistance, moisture absorption | Gears, bearings, automotive under-hood components | Medium-High | Excellent mechanical properties; requires precise drying (0.15% max moisture); absorbs water affecting dimensional stability |

| POM (Acetal) | High stiffness, low friction, dimensional stability | Precision gears, zippers, fuel system components | Medium-High | Superior dimensional accuracy; sensitive to strong acids; excellent creep resistance for load-bearing parts |

Engineering Insight: Material selection directly impacts mold steel requirements. For example, abrasive materials like glass-filled Nylon require hardened tool steel (e.g., H13) to extend shot life, while non-abrasive PP allows cost-effective P20 molds. Our engineers optimize this trade-off during DFM reviews to reduce your total cost of ownership.

Surface Finish Optimization for Functional & Aesthetic Requirements

Surface finishes are critical for both aesthetics and functionality. Unlike metal components, plastic parts require specialized surface treatments—anodizing is not applicable for plastics (it is exclusive to aluminum alloys). Below are industry-standard finishes optimized for plastic injection molding:

| Finish Type | Applicability | Key Benefits | Cost Impact | Performance Impact |

|---|---|---|---|---|

| Polishing (SPI A1-A3 Standards) | Plastic parts via mold surface finish | Mirror-like gloss, reduced friction, optical clarity | Medium-High | Critical for lenses, medical devices; SPI A1 (16μin Ra) requires 5+ days of manual polishing |

| Electroless Nickel Plating | Plastic parts (e.g., ABS, PC) | Corrosion resistance, electrical conductivity, metallic appearance | High | Requires etching/activation steps; adds 15-25% to part cost; ideal for EMI shielding in electronics |

| Textured (SPI B/C/D Standards) | All plastic materials | Hides mold lines, improves grip, reduces light reflection | Medium | SPI B2 (20-40μin Ra) ideal for automotive interiors; reduces mold wear vs. high-gloss finishes |

Critical Note: Anodizing is exclusively for aluminum components and cannot be applied to plastic parts. For metal inserts in plastic assemblies, we recommend anodizing only when specified in your design—our team will validate compatibility during tooling design.

Our Commitment to Zero Defects & Olympic Quality

Every mold we produce undergoes a 10-point quality verification process to ensure Zero Defects compliance. Our Olympic Quality standard means:

100% traceability from raw material (P20/NAK80 steel sourced from Bohler Uddeholm) to finished part

±0.005mm dimensional tolerance on all critical features (exceeding ISO 2768-mk standards)

24/7 laser scanning during production to detect micro-defects before shipping

“We don’t just meet tolerances—we engineer them. When you choose Wuxi Lead, you’re partnering with a team that treats your project like it’s our own.”

— Senior CNC Engineer, Wuxi Lead Precision Machinery

24/7 Customer Service: Your Partner Around the Clock

Unlike traditional suppliers, we operate on a 24/7 global support model:

Real-time production updates via IoT-connected machines (accessible through our client portal)

Emergency engineering support for urgent design changes (response time < 2 hours)

Dedicated account managers who understand your industry-specific challenges (automotive, medical, consumer goods)

Proven Result: For a leading US medical device client, we reduced tooling lead time by 40% while maintaining ±0.01mm tolerances—through collaborative DFM sessions and rapid prototyping of mold steel prototypes.

Next Steps: Contact our engineering team to optimize your plastic injection molding project. Share your CAD files, and we’ll provide a free DFM analysis report within 24 hours—no obligation.

Wuxi Lead Precision Machinery: Where Precision Meets Partnership.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey with Wuxi Lead Precision Machinery

As your strategic manufacturing partner, we eliminate guesswork and delays through a rigorously engineered 4-stage process. Every step is optimized for precision, speed, and collaboration—ensuring your project achieves zero defects, Olympic-grade quality, and on-time delivery from concept to shelf.

Design Analysis & DFMA Optimization

We begin with a collaborative Design for Manufacturing and Assembly (DFMA) review. Our senior engineers analyze your CAD files to eliminate potential issues in wall thickness, draft angles, gate locations, and material flow—preventing costly rework before tooling begins.

Tolerance stack-up analysis compliant with ±0.005″ (0.13mm) industry standards

Mold steel selection (P20, NAK80) for 500K+ shot life and thermal stability

Cycle time optimization via Moldflow simulation to reduce production costs by 15–25%

“Our engineers don’t just review—they partner. Every design change is discussed with you to align with your functional, cost, and timeline targets.”

Precision Pricing & Transparent Quoting

Receive detailed, itemized quotes within 24 hours—no hidden fees, no surprises. We break down costs for tooling, materials, and production to accelerate your decision-making.

| Cost Factor | Typical Range | Wuxi Lead Advantage |

|---|---|---|

| Tooling Lead Time | 15–45 days | 10–25 days (rapid tooling) |

| Material Cost (ABS/PC/PP) | $1.50–$5.00/kg | Volume discounts up to 15% |

| Per-Part Cost | Industry average | 10–20% lower than US competitors |

Rapid Prototyping with ISO 9001 Certified Tooling

Our rapid tooling process leverages CNC-machined molds from premium P20/NAK80 steel, achieving tolerances as tight as ±0.003″ (0.076mm)—ensuring prototypes match production-ready quality.

Zero-Defect Prototyping: 3-stage quality checks (CMM inspection, first-article testing, DFM validation)

Real-Time Monitoring: IoT-enabled machines track shot-to-shot consistency 24/7

Material Flexibility: Certified for ABS, PC, PP, Nylon, POM with ±1°C melt temperature control

“We don’t just build molds—we engineer them for your success. Every prototype is a proof point for mass production readiness.”

Olympic-Grade Quality Assurance: Precision at Scale

At full production, we maintain prototype-level precision through ISO 9001-certified processes. Our defect rate is <0.05%—90% lower than industry standards—while delivering >98% on-time shipments for urgent orders.

| Quality Metric | Industry Standard | Wuxi Lead Standard |

|---|---|---|

| Defect Rate | 0.5% | <0.05% |

| On-Time Delivery | 85% | >98% |

| Cycle Time Variance | ±5% | ±1.5% |

| 24/7 Technical Support: Direct access to senior engineers for real-time troubleshooting | ||

| Automated SPC: Statistical Process Control with AI-driven anomaly detection | ||

| Global Logistics: Dedicated freight partners for seamless US-bound shipments |

“We don’t manufacture parts—we deliver peace of mind. When you partner with Wuxi Lead, you gain a dedicated extension of your engineering team, available around the clock to ensure your project exceeds expectations.”

Ready to transform your plastic injection molding workflow?

[Contact our engineering team today] for a free DFMA review and competitive quote—backed by our Zero Defects Guarantee and Olympic Quality Promise.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

We don’t just build molds—we engineer solutions that eliminate production bottlenecks, reduce costs, and ensure consistent quality at scale.

As your strategic manufacturing partner, we combine advanced tooling expertise with rigorous quality protocols to deliver precision-engineered plastic injection molding solutions tailored to your most demanding applications.

Precision Engineering That Sets the Standard

| Specification | Industry Standard | Wuxi Lead Precision Advantage |

|---|---|---|

| Dimensional Tolerance | ±0.005″ (±0.13mm) | ±0.001″ (±0.025mm) for critical features |

| Mold Steel Selection | Basic P20, H13 | Premium NAK80, P20, S136 with ISO 9001 heat treatment |

| Shot Life Expectancy | 100k–300k cycles | 500k+ cycles with conformal cooling design |

| Cycle Time Reduction | Standard cooling channels | 15–25% faster cycles via optimized thermal management |

Quality Assurance Beyond Industry Standards

Zero Defects Commitment:

100% inspection protocol with automated optical inspection (AOI) systems and 100% traceability. Our defect rate consistently remains below 0.01% across all production runs.

Olympic Quality Control:

ISO 13485-certified processes for medical-grade components and AS9100-compliant standards for aerospace applications. NAK80 and S136 tool steels achieve mirror finishes up to Ra 0.025μm for optical clarity and critical surface aesthetics.

24/7 Engineering Partnership

Dedicated technical support team available around the clock for rapid response to production issues, including real-time CNC programming adjustments and emergency mold repairs.

Global support network ensures <4-hour response time for urgent technical queries, minimizing downtime and accelerating your time-to-market.

Ready to Elevate Your Manufacturing?

Contact us today for a Free DFM Analysis and Quote:

📧 [email protected]

📞 +86-13961886740

Engineered for precision. Delivered with partnership.

Our senior engineers will review your design within 24 hours to optimize for manufacturability, cost, and performance—no obligation.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.