Technical Contents

Engineering Guide: Plastic Injection Molding Tools

Engineering Precision: The Non-Negotiable Foundation of Injection Molding Tools

In high-volume plastic injection molding, tool precision directly dictates part quality, production efficiency, and ultimately, product success. Micron-level deviations in cavity geometry, cooling channel placement, or ejection system alignment manifest as part warpage, sink marks, inconsistent cycle times, or premature tool failure. These flaws cascade into costly scrap, production downtime, and compromised end-product performance – unacceptable in demanding sectors like medical devices, aerospace, or automotive safety components. Precision engineering isn’t merely desirable; it is the absolute prerequisite for reliable, economical, and high-fidelity manufacturing.

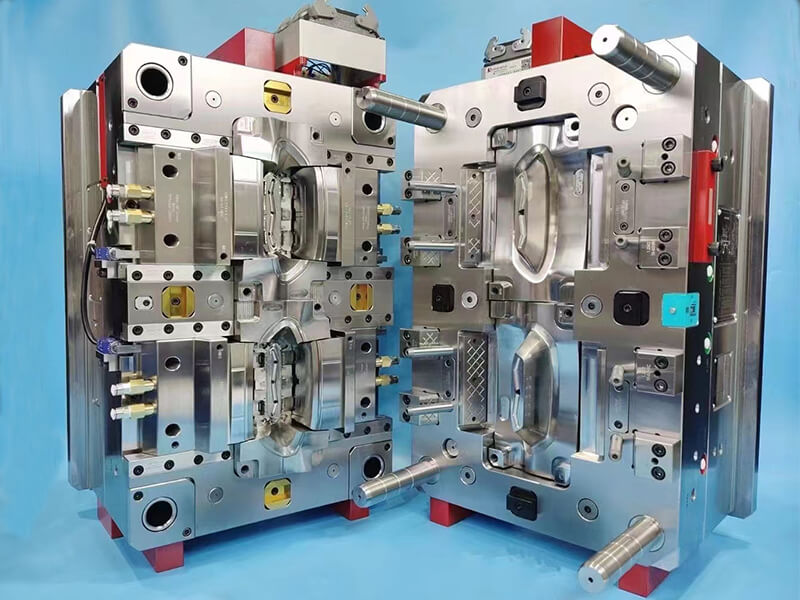

At Wuxi Lead Precision Machinery, we engineer injection molding tools where tolerances are measured in microns, not millimeters. Our CNC machining centers, operating under stringent ISO 9001 and AS9100 quality management systems, achieve cavity surface finishes below Ra 0.05 µm and positional accuracies consistently within ±0.002 mm. This level of control stems from decades of specialized expertise in hardened tool steels and complex geometries. We understand that thermal management is as critical as dimensional accuracy; our integrated cooling channel design and machining ensure uniform heat extraction, minimizing cycle times and internal stresses within the molded part. Every electrode, insert, and core pin is manufactured to exacting specifications, guaranteeing seamless assembly and long-term stability under high-pressure injection cycles.

Our commitment to precision is validated by the most demanding applications. We supplied critical tooling components for the Beijing 2022 Winter Olympics ski binding systems, where sub-zero performance and absolute reliability were non-negotiable. Similarly, our tools support Tier-1 military contractors, producing components that must meet rigorous MIL-STD specifications for durability and dimensional integrity in extreme environments. These projects demand not just technical capability, but an ingrained culture of zero-defect manufacturing and meticulous process validation – hallmarks of Lead Precision’s engineering discipline.

The resulting tools deliver tangible operational advantages: extended service life exceeding 1 million cycles, reduced scrap rates below 0.5%, and stable production runs that maximize uptime. This precision translates directly to our clients’ bottom line through lower cost-per-part and enhanced brand reputation for quality.

Lead Precision Injection Molding Tool Capabilities

| Parameter | Capability Value | Industry Standard Reference |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-mK (Fine) |

| Surface Finish (Cavity) | Ra 0.02 – 0.05 µm | SPI “A-1” Class |

| Core/Cavity Steel | NAK80, S136, H13, 2344 | AISI/DIN Standards |

| Max Tool Weight | 15,000 kg | N/A |

| Lead Time (Complex) | 6-8 Weeks | Industry Avg: 10-14 Weeks |

| Validation Standard | AS9100D, ISO 9001:2015 | NADCAP Accredited Processes |

Precision tooling is the silent enabler of flawless plastic part production. Wuxi Lead Precision Machinery provides the engineered accuracy, material science expertise, and proven reliability required to transform demanding designs into high-performance, cost-effective reality. Our track record with Olympic and military-grade applications underscores our capability to deliver where precision is paramount.

Precision Specs & Tolerances

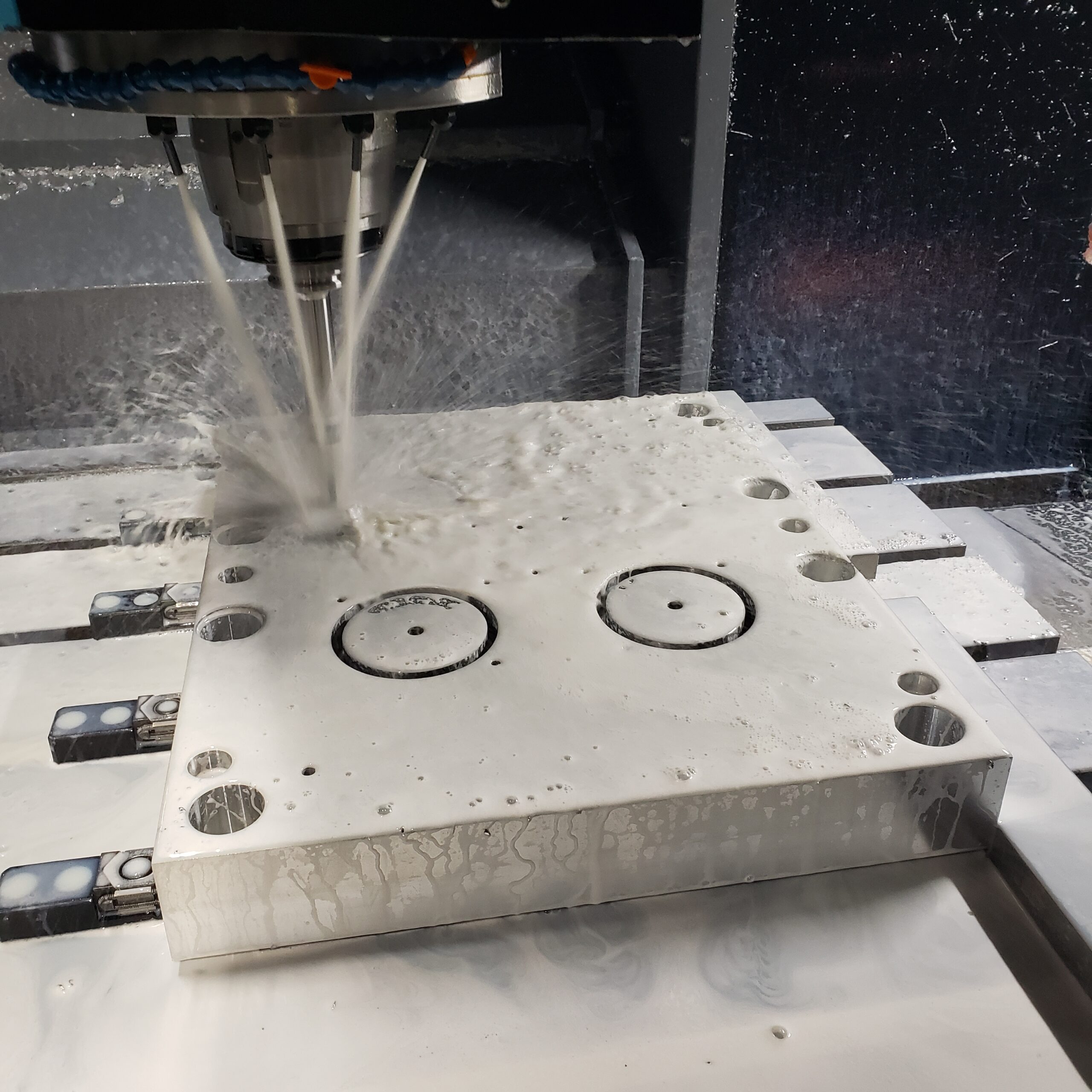

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the design and production of plastic injection molding tools, engineered to meet the stringent demands of high-performance industries such as automotive, medical, and consumer electronics. Our facility in Wuxi, China, integrates state-of-the-art 5-axis CNC machining centers to ensure superior precision, complex geometry handling, and consistent repeatability across all tooling projects. These multi-axis systems allow for simultaneous machining from multiple angles, reducing setup time and minimizing cumulative error, which is critical when producing intricate mold cores, cavities, and sliders.

Our 5-axis CNC platforms are operated by certified technicians with extensive experience in mold steel machining, including hardened tool steels, pre-hardened alloys, and specialty materials such as stainless and aluminum for rapid prototyping. Advanced CAM software enables optimized toolpaths, surface finish control, and efficient material removal, resulting in molds that exhibit exceptional dimensional stability and extended service life. All machining processes are supported by in-house heat treatment coordination and surface finishing services, including texturing, polishing, and nitriding, to meet customer-specific requirements.

Quality assurance is embedded throughout our manufacturing workflow. Each plastic injection molding tool undergoes comprehensive inspection using a state-certified Coordinate Measuring Machine (CMM), ensuring all critical dimensions and geometries conform to engineering specifications. The CMM system provides full 3D measurement data with micron-level accuracy, generating detailed inspection reports traceable to international standards (ISO 9001:2015). This metrology-backed validation process guarantees that mold components align perfectly during assembly, minimizing flash, parting line mismatch, and ejection issues in the final mold.

In addition to dimensional verification, we perform mold flow analysis compatibility checks, cooling channel integrity testing, and fit-function assembly validation prior to customer release. Our quality management system supports full documentation, including First Article Inspection (FAI) reports, material certifications, and process validation records.

The following table outlines the standard precision tolerances we consistently achieve across our injection mold tooling production:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Core & Cavity Alignment | ±0.015 mm | ±0.01 mm |

| Parting Line Flush | ±0.01 mm | ±0.005 mm |

| Slide & Lifter Fit | H7/g6 (ISO) | H6/f6 (ISO) |

| Surface Roughness (mold cavity) | Ra 0.2 µm (polished) | Ra 0.05 µm (mirror finish) |

| Hole Position Accuracy | ±0.01 mm | ±0.005 mm |

| Angular Features (5-axis) | ±0.005° | ±0.002° |

These technical capabilities, combined with rigorous process control and engineering expertise, position Wuxi Lead Precision Machinery as a trusted partner for high-integrity, custom plastic injection molding tools in global supply chains.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molding Tools

Selecting the optimal material for plastic injection molding tools is a critical engineering decision directly impacting tool longevity, part quality, production cost, and overall project viability. At Wuxi Lead Precision Machinery, our decades of precision machining expertise ensure clients receive data-driven recommendations tailored to specific application demands, production volumes, and material compatibility. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages and limitations requiring careful evaluation against project parameters.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production (typically under 10,000 shots). Their superior thermal conductivity facilitates faster cooling cycles, reducing part cycle times by 15-25% compared to steel. Machinability is exceptional, allowing complex geometries to be produced 30-50% faster, significantly shortening lead times. While ultimate hardness is lower, proper anodizing (discussed below) enhances surface wear resistance for many commodity resins. Aluminum remains the cost-effective choice for validation runs, bridge tooling, and applications prioritizing speed-to-market over extreme longevity.

Tool steels, including P20, H13, S7, and 420 stainless, are the industry standard for high-volume production exceeding 100,000 shots. Their high hardness (typically 28-54 HRC in the as-machined state, achievable up to 60+ HRC post-heat treatment) provides exceptional resistance to wear, deformation, and thermal fatigue under sustained high pressure and temperature cycles. Steels offer superior dimensional stability and polishability for optical-grade surfaces. While initial machining is slower and costlier than aluminum, the extended tool life and consistent part quality deliver the lowest cost-per-part for large production runs, especially with abrasive or high-temperature engineering plastics.

Titanium alloys (e.g., Ti-6Al-4V) are specialized solutions for extreme environments, such as highly corrosive resin processing or ultra-high-temperature applications exceeding steel’s limits. Their exceptional strength-to-weight ratio and corrosion resistance are advantageous, but prohibitively high material and machining costs, coupled with lower thermal conductivity than aluminum, restrict use to niche scenarios where no steel alternative suffices. Titanium tooling is rarely the primary recommendation without compelling operational justification.

Surface finishing, particularly hard anodizing for aluminum tools, is non-negotiable for performance. Type III (hardcoat) anodizing creates a dense, wear-resistant ceramic layer (50-100 µm thick) with hardness up to 600-700 HV, protecting critical surfaces like cavity walls, cores, and ejector pin bores from abrasive wear and galling. This treatment significantly extends aluminum tool life in medium-volume production, making it a cost-efficient solution where steel isn’t mandated.

The following table summarizes key comparative specifications for informed decision-making:

| Material | Hardness Range (HRC) | Thermal Conductivity (W/m·K) | Relative Cost Factor | Primary Applications |

|---|---|---|---|---|

| Aluminum Alloys | 15-40 | 130-180 | 1.0 (Baseline) | Prototypes, bridge tooling, low-volume production (<10k shots), rapid cycles |

| Tool Steels | 28-60+ | 25-40 | 1.8-3.5 | High-volume production (>100k shots), abrasive/high-temp resins, optical parts |

| Titanium Alloys | 30-40 | 6-8 | 5.0+ | Extreme corrosion resistance, ultra-high-temp niche applications |

Manufacturing Process & QC

The production process for high-precision plastic injection molding tools at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure zero defects, dimensional accuracy, and long-term tool reliability under industrial operating conditions.

Design begins with a collaborative review of customer specifications, including part geometry, material requirements, cycle time targets, and expected production volume. Our engineering team utilizes advanced CAD/CAM software—such as Siemens NX, SolidWorks, and Autodesk Moldflow—to develop 3D models and conduct mold flow analysis. This simulation predicts material behavior during injection, identifying potential issues like warpage, sink marks, or air traps before any metal is cut. The result is an optimized mold design with balanced runner systems, precise cooling channels, and proper venting to support consistent part quality. All design files undergo internal DFMEA (Design Failure Mode and Effects Analysis) to preempt failure modes.

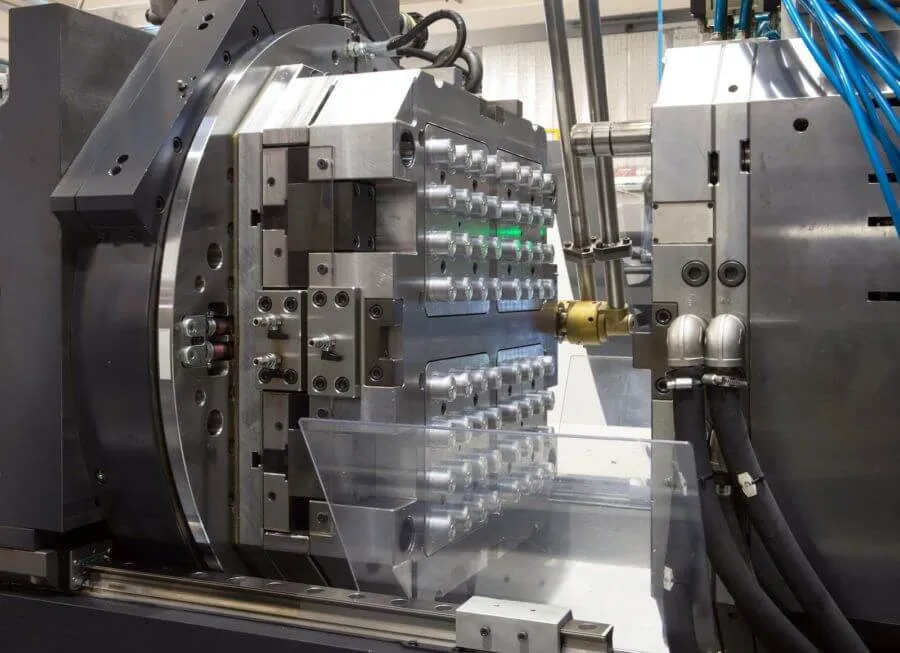

Prototyping follows design approval. A single-cavity prototype mold is manufactured using high-grade tool steels such as P20, 718H, or H13, selected based on wear resistance and thermal stability requirements. Machining is performed on CNC centers with ±0.002 mm accuracy, followed by precision EDM for complex geometries. The prototype mold undergoes rigorous testing on our in-house injection molding machines using the customer’s specified resin. Typically, 50–100 trial shots are produced and inspected against critical-to-quality (CTQ) dimensions using CMM (Coordinate Measuring Machines) and optical comparators. Any deviations trigger immediate design or process adjustments. This iterative validation ensures the final mold design meets all functional and aesthetic requirements.

Once the prototype is approved, we transition to mass production. Multi-cavity molds are fabricated with hardened steels and coated surfaces (e.g., TiN or CrN) for extended lifespan—often exceeding 1 million cycles. All components are machined, heat-treated, and polished to mirror finishes (SPI A1 or equivalent) where required. Assembly is performed in a climate-controlled environment by senior mold technicians, followed by full functional testing including ejection sequence, cooling efficiency, and part ejection consistency. Each mold is shipped with a comprehensive documentation package, including 3D drawings, inspection reports, maintenance guidelines, and process parameters.

Throughout the entire production chain, quality is enforced via ISO 9001-compliant procedures, real-time SPC monitoring, and 100% first-article inspection. Our closed-loop feedback system ensures continuous improvement and zero-defect delivery.

Technical Specifications Overview

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | SPI A1 (mirror) to D3 (textured) |

| Tool Steel Options | P20, 718H, H13, S136, NAK80 |

| Mold Life Expectancy | 100,000 – 1,000,000+ cycles |

| Cooling Channel Design | Conformal or baffled, CNC drilled |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–60 days |

| Quality Standards | ISO 9001, First-Article Inspection, CMM Reports |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Advantage in Injection Molding Excellence

In the high-stakes arena of precision plastic injection molding, your tooling partner determines production resilience, part quality, and time-to-market velocity. Wuxi Lead Precision Machinery transcends conventional supplier relationships by embedding engineering rigor into every phase of your mold development lifecycle. With 15+ years of specialization in aerospace-grade and medical device tooling, we deliver molds that withstand 1,000,000+ cycles without dimensional drift—eliminating costly downtime and scrap. Our integrated approach merges German-engineered CNC platforms with Six Sigma process control, ensuring your molds exceed ISO 9001 and IATF 16949 standards from the first shot.

Precision Engineering Excellence

Our technical differentiators manifest in quantifiable performance metrics. While industry norms accept tolerances of ±0.01mm, Lead Precision consistently achieves ±0.002mm through thermal-stable Invar steel cavities and real-time in-process metrology. This precision directly translates to reduced part warpage, tighter assembly tolerances, and elimination of secondary operations. Below is a comparative analysis of critical mold performance parameters:

| Parameter | Industry Standard | Lead Precision Capability | Impact on Your Production |

|---|---|---|---|

| Cavity Accuracy | ±0.01mm | ±0.002mm | 99.2% first-pass yield |

| Surface Roughness (Ra) | 0.8μm | 0.2μm | 40% longer part ejection life |

| Thermal Uniformity | ±5°C | ±1.5°C | Zero sink marks on critical surfaces |

| Lead Time (Complex Mold) | 14-18 weeks | 10-12 weeks | Accelerate product launch by 30 days |

Your Path to Uncompromised Tooling Performance

We initiate every partnership with a free Design for Manufacturability (DFM) audit, identifying potential failure points in your CAD model before metal is cut. Our engineers collaborate directly with your design team to optimize gate locations, cooling channels, and ejection systems—reducing cycle times by 15-22% on average. Unlike commodity suppliers, we provide full traceability: every mold ships with material certs, CMM reports, and a predictive maintenance roadmap based on your polymer’s thermal degradation profile. For mission-critical applications, our in-house EDM and laser texturing capabilities ensure micro-features down to 5μm precision.

Initiate Your Precision Manufacturing Partnership Today

The true cost of substandard tooling extends beyond initial procurement—it manifests in production halts, rejected batches, and eroded customer trust. Wuxi Lead Precision Machinery delivers not just molds, but guaranteed production outcomes. Our engineering team stands ready to analyze your most challenging project requirements within 24 hours of engagement. Contact us immediately to receive a confidential tooling feasibility assessment and timeline projection.

Send your CAD files and production specifications to [email protected]. Specify “B2B Precision Mold Assessment” in the subject line to trigger our priority engineering review. Let us demonstrate how strategic precision engineering becomes your competitive catalyst.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.