Technical Contents

Engineering Guide: Plastic Injection Molding Tooling

Engineering Insight: Precision as the Foundation of Plastic Injection Molding Tooling

In high-volume plastic injection molding, tooling precision is not merely a specification—it is the economic and functional cornerstone of production. A tolerance deviation of 0.02mm can cascade into part warpage, assembly failures, or accelerated mold wear, directly impacting scrap rates, cycle times, and total cost of ownership. At Wuxi Lead Precision Machinery, we engineer molds where micron-level accuracy is non-negotiable, ensuring consistent part replication across millions of cycles. This discipline transforms tooling from a production cost into a strategic asset for our clients.

Our approach integrates advanced CNC micro-machining, laser texturing, and real-time thermal compensation systems to achieve dimensional stability under extreme thermal cycling. This capability is validated through rigorous in-house metrology, including CMM and optical contour scanning, ensuring every cavity, core, and ejection system adheres to ISO 2768-fine standards. The result? Zero concession on critical features like sealing surfaces, snap-fit geometries, or optical clarity—where even sub-micron variations compromise performance.

Wuxi Lead’s precision pedigree is forged in mission-critical applications. We engineered molds for Olympic-grade athletic equipment components demanding flawless aerodynamic symmetry and military-grade communication housings requiring EMI shielding integrity under vibration and temperature extremes. These projects demanded tolerances tighter than 0.01mm and surface finishes unattainable through conventional methods—proof that our processes thrive where failure is not an option.

The table below outlines the precision benchmarks we consistently deliver for complex plastic injection molds:

| Specification | Our Standard | Industry Typical | Impact on Production |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.02 mm | Eliminates post-mold machining; ensures part interchangeability |

| Surface Roughness (Ra) | 0.025 μm | 0.8 μm | Critical for optical parts; reduces friction in moving assemblies |

| Thermal Stability (ΔT) | ±0.5°C across mold | ±3.0°C | Prevents warpage; stabilizes cycle times by 15-20% |

| Hardness (Core Components) | HRC 52-54 | HRC 48-50 | Extends mold life 2x in abrasive polymer applications |

| Parallelism/Flatness | 0.002 mm/m | 0.01 mm/m | Ensures uniform clamping force; prevents flash |

This precision translates directly to client profitability. Tighter tolerances reduce material waste by up to 12% and accelerate time-to-market by eliminating iterative mold corrections. For medical device manufacturers, our tooling achieves Class VI biocompatibility without secondary finishing. For automotive Tier 1s, it guarantees zero leaks in fluid system components across 100,000+ thermal cycles.

At Wuxi Lead, we understand that your product’s success is machined into the tool itself. We don’t just build molds—we engineer the foundation for your production excellence. Let our Olympic-tested precision become your competitive advantage.

Precision Specs & Tolerances

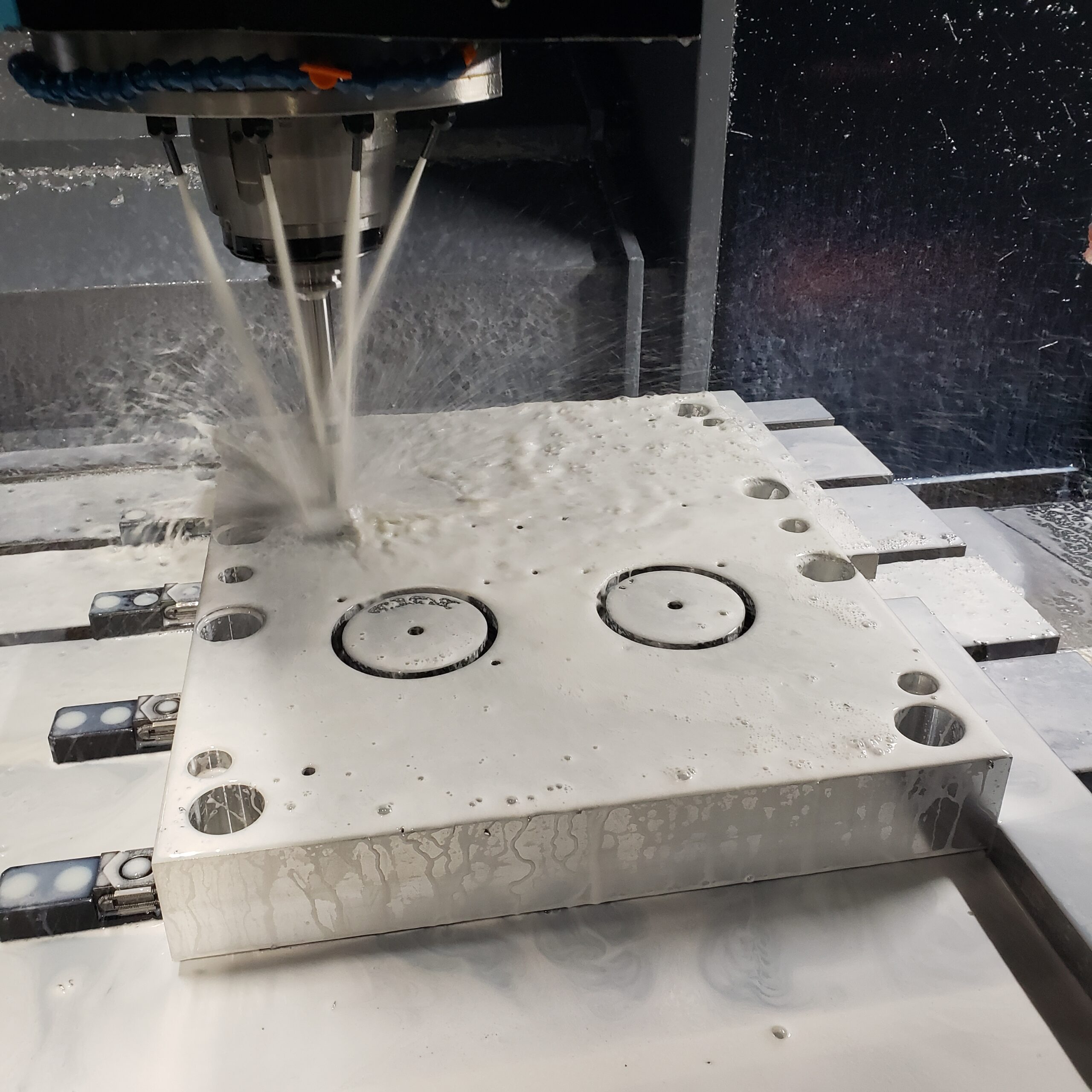

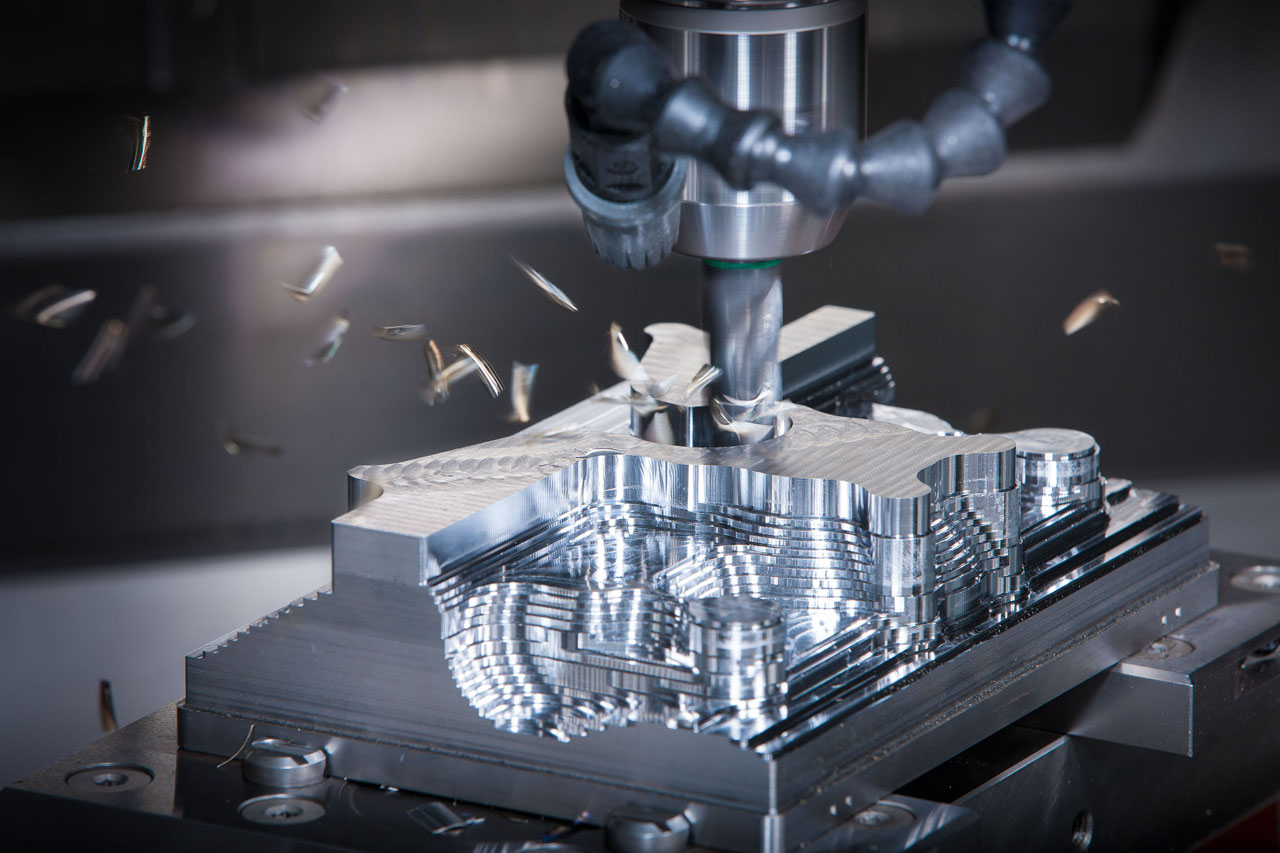

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic injection molding tooling for global industrial clients. Our engineering infrastructure is built around state-of-the-art 5-axis CNC machining systems, enabling us to produce complex mold geometries with superior accuracy, surface finish, and dimensional consistency. These multi-axis platforms allow for simultaneous movement across five planes, minimizing setup changes and significantly reducing human error. This results in faster production cycles and tighter tolerances—critical for molds used in automotive, medical, and consumer electronics applications where repeatability and reliability are paramount.

Our 5-axis CNC centers are operated by certified machinists with over a decade of experience in mold-making, supported by integrated CAD/CAM software that ensures seamless translation from design to physical part. We utilize high-speed machining techniques to achieve fine details and intricate cooling channels, which enhance mold performance and prolong service life. Materials are carefully selected based on application requirements, including hardened tool steels (such as H13, P20, and S136), aluminum alloys for prototypes, and stainless steels for corrosion-resistant environments. Each machining phase is monitored in real time to maintain process stability and part integrity.

To guarantee the highest level of precision, every mold component undergoes comprehensive quality control using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This metrology-grade system provides non-contact and tactile probing with micron-level resolution, ensuring that all critical dimensions, hole positions, and profile deviations are verified against the original 3D CAD model. Full inspection reports are generated for each project, including GD&T analysis, and are available to clients upon request. Our QC protocols follow ISO 10360 standards, and our facility maintains a climate-controlled inspection room to eliminate thermal distortion during measurement.

We understand that precision in mold tooling directly impacts part quality, cycle time, and production yield. That is why we define our machining performance through measurable, repeatable specifications.

| Feature | Specification |

|---|---|

| Positional Accuracy (5-axis CNC) | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Minimum Feature Size | 0.1 mm radius |

| Dimensional Tolerance (mold bases) | ±0.01 mm |

| Dimensional Tolerance (cavities & cores) | ±0.005 mm |

| CMM Measurement Uncertainty | ±0.0025 mm (at 95% confidence) |

| Lead Time (Average) | 15–25 days, depending on complexity |

All tooling solutions are manufactured to meet or exceed international standards, with full traceability from raw material to final assembly. Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality assurance, and deep domain expertise to deliver injection molding tools that perform consistently in high-volume production environments.

Material & Finish Options

Material Selection for High-Performance Injection Molding Tooling

Selecting the optimal material for injection molding tooling is a critical engineering decision impacting part quality, production efficiency, tool longevity, and overall project economics. At Wuxi Lead Precision Machinery, we leverage decades of precision manufacturing expertise to match material properties precisely to your application’s thermal, mechanical, and economic demands. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages and limitations within the demanding environment of plastic injection molding.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity (approximately 130-170 W/m·K) significantly reduces cycle times by enabling faster heat extraction from the molded part. This translates directly to higher throughput during initial production runs or for less abrasive polymers. Aluminum’s machinability also allows for faster, more cost-effective tool fabrication. However, its lower hardness (typically 95-150 HB) makes it susceptible to wear, galling, and deformation when processing glass-filled or highly abrasive resins, or under high-volume production. Aluminum tooling is generally unsuitable for extended high-cavitation molds.

Tool steels remain the dominant choice for high-volume, production-critical applications. Pre-hardened steels like P20 (28-32 HRC) offer a balanced combination of machinability, moderate wear resistance, and cost-effectiveness for many standard applications. For demanding scenarios involving abrasive fillers, high temperatures, or stringent wear requirements, hardened tool steels such as H13 (48-52 HRC for cavities/cores) or stainless grades like 420 (48-52 HRC) are essential. H13 provides exceptional hot hardness and thermal fatigue resistance, crucial for molds running engineering plastics at elevated temperatures. Stainless steels are mandatory for medical or food-contact applications requiring superior corrosion resistance. While steel fabrication and heat treatment incur higher initial costs and longer lead times than aluminum, the extended tool life under production conditions delivers superior long-term value.

Titanium alloys find specialized use where extreme corrosion resistance is paramount, such as molding highly corrosive polymers like PVC or certain liquid crystal polymers (LCPs). Its exceptional strength-to-weight ratio and corrosion immunity are advantageous, but very high material and machining costs, coupled with lower thermal conductivity than aluminum, limit its application primarily to highly corrosive niche scenarios. Surface treatments like anodizing are critical for aluminum tooling. Type II (Sulfuric Acid) anodizing provides a standard wear and corrosion-resistant layer, while hardcoat Type III anodizing delivers significantly enhanced surface hardness (up to 600 HV), dramatically improving abrasion resistance for aluminum molds running mildly abrasive materials, thereby extending service life.

The following table summarizes key comparative specifications:

| Material | Hardness Range | Thermal Conductivity (W/m·K) | Relative Cost Factor | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 95-150 HB | 130-170 | Low | Prototyping, low-volume, fast cycle time needs |

| P20 Tool Steel | 28-32 HRC | 28-36 | Medium | General production, medium volumes |

| H13 Tool Steel | 48-52 HRC (Hardened) | 24-30 | High | High-temp resins, abrasive fills, high volume |

| 420 Stainless | 48-52 HRC (Hardened) | 20-25 | High | Corrosive resins, medical, food-grade |

| Titanium Grade 5 | 33-38 HRC | 7-8 | Very High | Extreme corrosion resistance (specialized) |

Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients during the design phase to analyze resin characteristics, part geometry, expected volumes, and surface finish requirements. This ensures the optimal material and potential surface treatment—such as precision hardcoat anodizing for aluminum—are selected, maximizing your tooling investment’s performance and lifecycle cost efficiency. Contact our specialists for a tailored material recommendation.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless plastic injection molding tooling begins with precision engineering in the design phase. Our team of senior tooling engineers collaborates closely with clients to translate product concepts into manufacturable, high-performance molds. Utilizing advanced CAD/CAM software such as Siemens NX, SolidWorks, and Autodesk Moldflow, we conduct comprehensive mold flow analysis to predict material behavior, optimize gate locations, and eliminate potential defects like warpage, sink marks, or air traps. Every design is evaluated for thermal efficiency, ejection dynamics, and structural durability under high-cycle production conditions. We adhere strictly to international standards, including ISO 9001 and DIN 16901, ensuring dimensional accuracy and long-term reliability. Design for manufacturability (DFM) reviews are conducted in-house to validate part geometry, draft angles, wall thickness, and tolerances—typically holding ±0.005 mm on critical features—before any metal is cut.

Prototyping: Validating Performance Before Scale

Once the mold design is finalized, we proceed to prototype tooling using high-speed CNC machining and precision EDM techniques. Prototypes are manufactured in P20 or 718H hardened tool steels, enabling real-world validation under actual injection parameters. This phase is critical for achieving zero-defect readiness. We conduct rigorous trial runs using client-specified resins—ranging from ABS and PC to high-temperature PEEK and LCP—monitoring fill patterns, cycle times, and part consistency. Each prototype undergoes full metrological inspection using Zeiss coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to design intent. Any deviations are corrected through iterative mold adjustments, ensuring optimal balance between cavity pressure, cooling uniformity, and part ejection. The result is a fully validated tool capable of repeatability across millions of cycles.

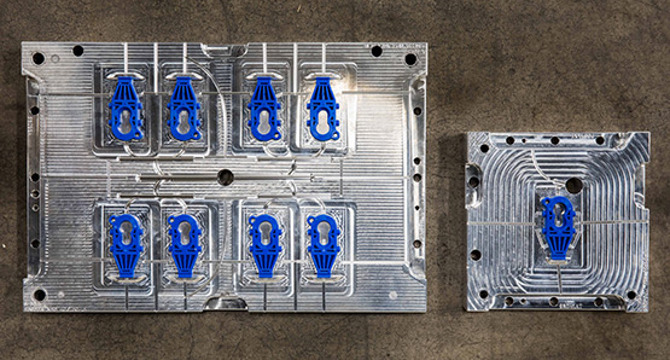

Mass Production: Consistency at Scale with Zero Defects

With design and prototyping complete, we transition seamlessly into high-volume production. Our automated molding cells, equipped with robotic part handling and in-line vision inspection systems, maintain continuous process control. Real-time monitoring tracks key parameters such as melt temperature, injection pressure, and cooling time, ensuring every molded component meets exact specifications. Preventive maintenance schedules and tool wear tracking are integrated into our production management system, minimizing unplanned downtime and preserving mold integrity over extended runs. We implement Six Sigma methodologies and Statistical Process Control (SPC) to detect and correct variations before they impact output quality.

The following table outlines key specifications and capabilities across our injection molding tooling process:

| Parameter | Specification |

|---|---|

| Tooling Materials | P20, 718H, H13, S136, 420 Stainless, Titanium Coatings |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on part size) |

| Mold Life Expectancy | 500,000 to 1,000,000+ cycles |

| Lead Time (Design to Prototype) | 4–8 weeks (based on complexity) |

| Surface Finishes | SPI, VDI, Textured, Mirror Polish, EDM Finish |

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Injection Press Range | 50–2000 Tons |

At Wuxi Lead Precision Machinery, our end-to-end control over the production process—spanning design, prototyping, and mass manufacturing—ensures that every plastic injection mold delivers zero-defect performance, on time and to the highest global standards.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Uncompromising Injection Molding Tooling

Securing a strategic manufacturing partner for complex plastic injection molding tooling demands more than standard supplier capabilities. It requires a deep integration of advanced engineering, rigorous process control, and unwavering commitment to your project’s success from concept through high-volume production. At Wuxi Lead Precision Machinery, we operate at the pinnacle of custom metal manufacturing, specifically engineered to deliver the precision, durability, and repeatability your most demanding molding applications demand. Our facility in Wuxi, China, is not merely a production shop; it is a center of excellence where German-inspired precision engineering meets scalable Asian manufacturing efficiency, governed by stringent international quality protocols.

Our technical foundation is built upon state-of-the-art equipment and meticulously validated processes. We specialize in multi-cavity, family, and hot runner systems requiring micron-level accuracy and exceptional longevity. The table below outlines core capabilities directly impacting your tooling performance and project timeline.

| Specification Category | Wuxi Lead Precision Capability |

|---|---|

| Maximum Mold Weight | 30,000 kg |

| Typical Tolerance Range | ±0.002 mm (Sub-5μm achievable for critical features) |

| Standard Steel Grades | NAK80, S136, 2738, 2344, H13, Custom Alloys |

| Lead Time (Complex Mold) | 8-14 Weeks (Validated by Project Scope) |

| Surface Finish (Cavity/Core) | SPI A1, VDI 3400 Class A (Ra ≤ 0.025 μm) |

| Quality Certification | ISO 9001:2015, IATF 16949 (Automotive Focus) |

Partnering with Lead Precision translates to tangible operational advantages. We proactively mitigate risks inherent in complex tooling through comprehensive Design for Manufacturability (DFM) analysis conducted by our senior tooling engineers, significantly reducing costly iterations and delays. Our closed-loop manufacturing processes, utilizing high-precision CNC machining centers, wire EDM, and optical measurement systems, ensure dimensional integrity is maintained throughout production. This precision directly correlates to reduced part scrap rates, minimized machine downtime on your production floor, and extended mold service life – critical factors for your cost-per-part and overall equipment effectiveness (OEE). We understand that your reputation hinges on part consistency; our tooling is engineered and validated to deliver it, batch after batch.

The true value of a partnership lies in collaborative problem-solving and shared objectives. We engage early in your development cycle, providing actionable engineering insights to optimize both the tool and the final plastic component. Our dedicated project management team ensures transparent communication, real-time progress tracking, and swift resolution of any technical challenges, eliminating the uncertainty often associated with offshore manufacturing. This proactive, engineering-led approach minimizes project risk and accelerates your time-to-market.

Do not compromise your production goals with tooling that fails to meet the highest standards of precision and reliability. Elevate your injection molding capability with Wuxi Lead Precision Machinery. Initiate a technical consultation to discuss your specific project requirements, material challenges, and performance targets. Contact our engineering sales team directly at [email protected]. Provide your part drawings or specifications, and we will respond within 24 business hours with a preliminary assessment and actionable next steps. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.