Technical Contents

Engineering Guide: Plastic Injection Molding Price

Engineering Insight: The True Cost Drivers Behind Plastic Injection Molding Price

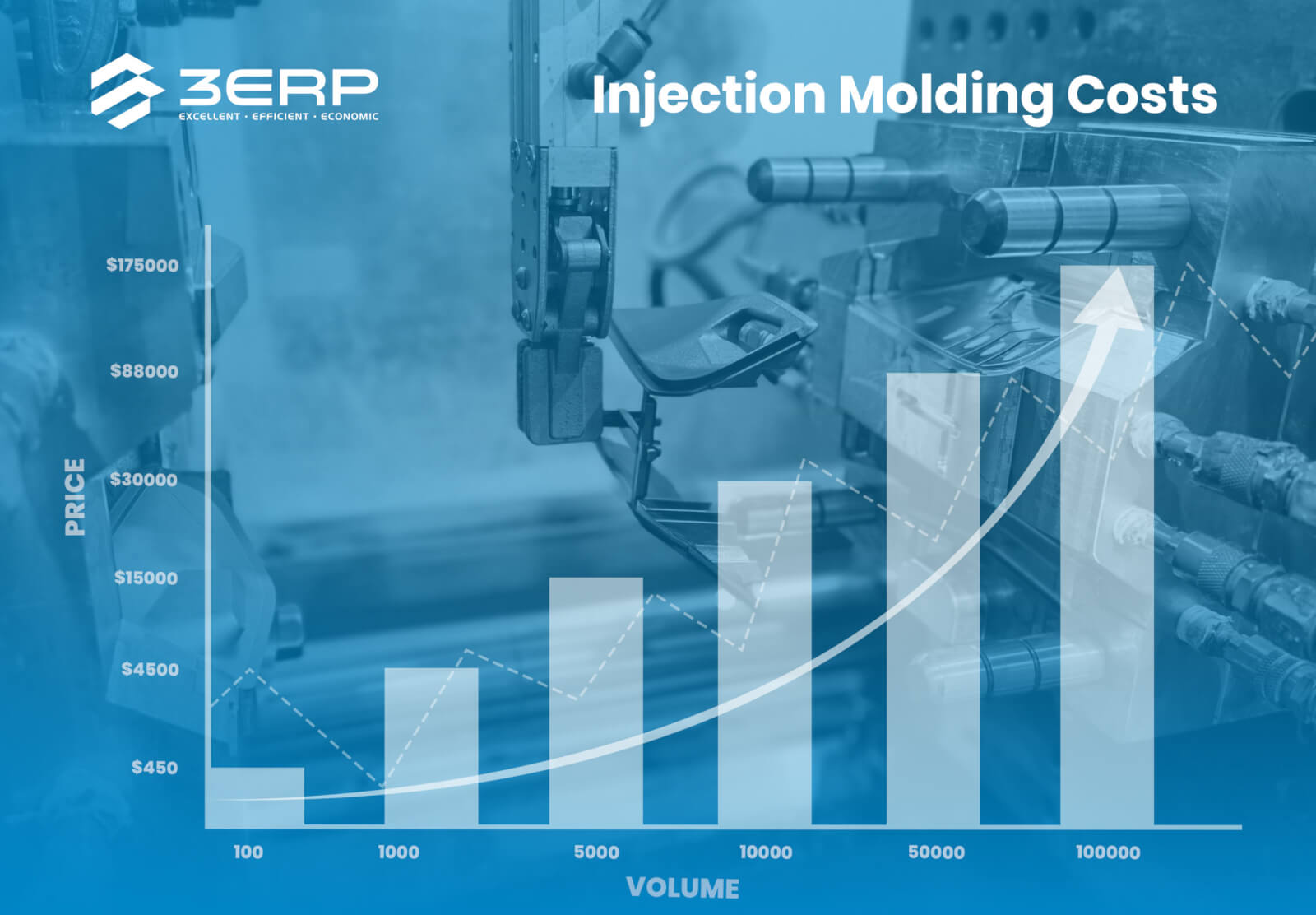

Understanding the true drivers behind plastic injection molding price is essential for manufacturers seeking high-performance, repeatable, and cost-effective production. While initial quotes may appear competitive, long-term value hinges on precision engineering, material integrity, and process consistency—factors that define the difference between acceptable parts and exceptional performance. At Wuxi Lead Precision Machinery, we approach plastic injection molding not as a commodity process, but as a high-precision engineering discipline where tolerances, repeatability, and design optimization directly influence final cost and quality.

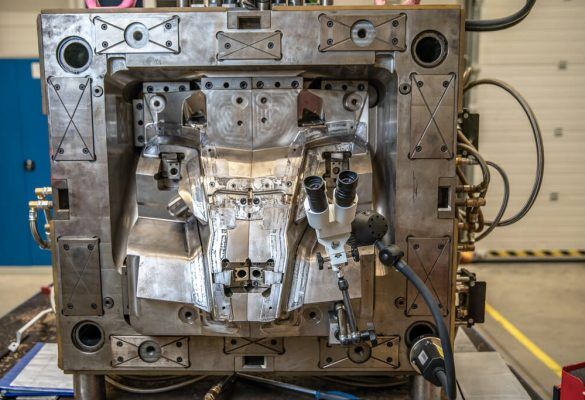

Precision in mold fabrication is the cornerstone of cost efficiency. A mold manufactured to tight tolerances ensures consistent part geometry, reduces flash and post-processing, and extends tool life—directly lowering per-unit cost over high-volume runs. Poorly machined molds may offer short-term savings but result in increased scrap rates, unplanned downtime, and frequent maintenance, ultimately inflating total ownership cost. Our in-house CNC machining centers, operating under ISO 13485 and AS9100 standards, achieve tolerances down to ±0.002 mm, ensuring that every cavity performs identically across millions of cycles.

Material selection further impacts injection molding price. Engineering-grade resins such as PEEK, PPS, and ULTEM offer superior thermal and chemical resistance but require precise temperature control and robust mold design to avoid degradation and warpage. At Wuxi Lead, our engineers conduct detailed flow analysis and thermal modeling during mold design to optimize gate locations, cooling channels, and ejection systems—minimizing cycle time and material waste while maximizing part integrity.

Our experience in mission-critical applications—including components used in Olympic-standard timing systems and military-grade communication enclosures—has refined our approach to precision molding. These projects demanded zero-defect performance under extreme conditions, reinforcing our commitment to over-engineering reliability into every mold we produce.

Below are key specifications reflecting our injection molding capabilities:

| Parameter | Specification |

|---|---|

| Maximum Mold Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tolerance Range | ±0.002 mm to ±0.02 mm (depending on part size) |

| Standard Surface Finish | SPI A1, A2, B1, B2, or custom textures |

| Materials Supported | ABS, PC, POM, PA, PEEK, PPS, PP, PE, PMMA |

| Injection Press Capacity | 100 to 2,500 tons |

| Lead Time (Standard Mold) | 25–45 days, depending on complexity |

| Quality Standards | ISO 9001, ISO 13485, AS9100 |

By integrating advanced metrology, real-time process monitoring, and decades of precision machining expertise, Wuxi Lead ensures that every mold delivers optimal performance from the first shot to the millionth cycle. When evaluating plastic injection molding price, consider not just the initial investment, but the lifecycle value of precision-engineered tooling.

Precision Specs & Tolerances

Technical Capabilities: Precision Foundation for Injection Molding Economics

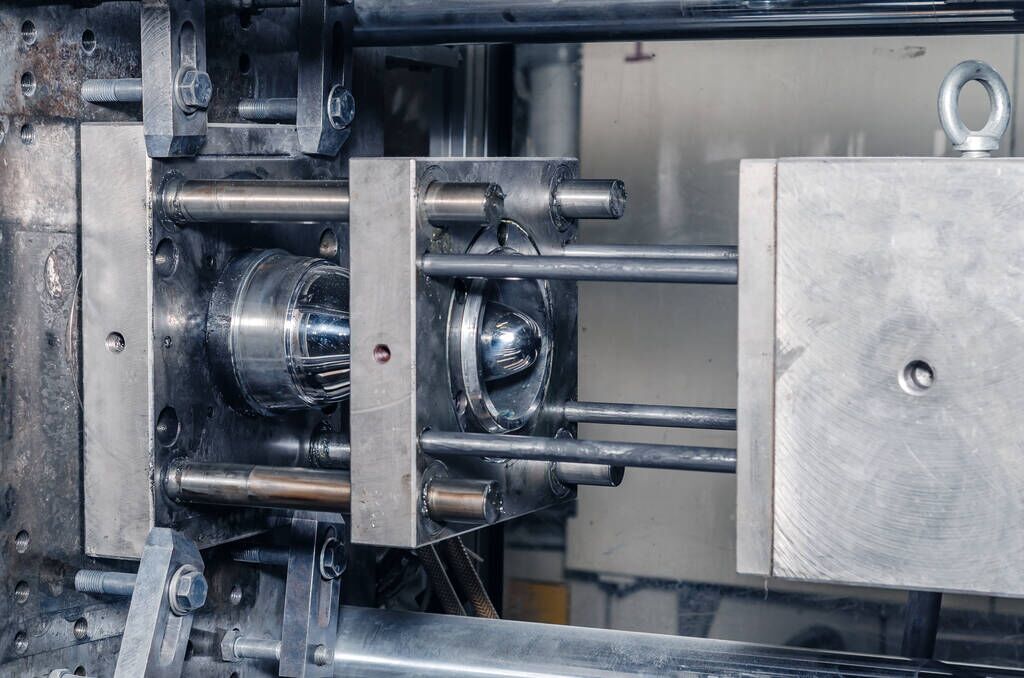

At Wuxi Lead Precision Machinery, our technical capabilities directly influence the cost structure and quality outcomes of plastic injection molding projects. We specialize in manufacturing high-precision metal components—specifically mold cores, cavities, inserts, and electrodes—that form the backbone of efficient, repeatable plastic part production. Superior mold accuracy reduces cycle times, minimizes scrap rates, and extends tool life, directly lowering per-part costs for our clients. Our integrated approach ensures every metal component meets the exacting demands of modern injection molding, transforming initial mold investment into long-term production savings.

Central to our process is a dedicated fleet of 5-axis CNC machining centers. These systems enable us to produce complex geometries with single-setup efficiency, eliminating cumulative errors from multiple fixtures. We machine hardened tool steels (P20, H13, S136), aluminum alloys, and copper EDM electrodes to micron-level precision. Multi-axis contouring ensures optimal surface finishes on critical mold surfaces, reducing polishing time and preventing flow lines or weld lines in the final plastic part. This capability is non-negotiable for molds producing medical, automotive, or optical components where dimensional stability under thermal cycling is paramount.

Rigorous quality control validates every phase of production. All critical features undergo 100% inspection using Zeiss CONTURA G2 and Wenzel LH877 coordinate measuring machines (CMM). Our CMM protocols follow ISO 10360-2 standards, measuring geometric tolerances, surface profiles, and positional accuracy against 3D CAD models. This data-driven verification ensures mold components interlock perfectly, preventing flash, short shots, or ejection failures during plastic molding. Real-time SPC analysis identifies process drift before defects occur, safeguarding your tool’s longevity and part consistency.

The table below details our standard achievable tolerances for mold components. Tighter tolerances are feasible for critical features upon engineering review, though may impact lead time and cost. Understanding these specifications is essential for accurate plastic molding price forecasting, as tolerance requirements directly correlate with machining complexity and inspection burden.

| Feature Category | Standard Capability | Impact on Plastic Molding Price |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Tighter tolerances increase machining time and scrap risk, raising mold cost but reducing part rejection rates |

| Geometric Tolerances | ±0.003 mm (±0.0001″) for flatness/profile | Ensures uniform part cooling and ejection; deviations cause warpage or sink marks requiring costly process adjustments |

| Hole Position Accuracy | ±0.002 mm (±0.00008″) | Critical for ejector pin alignment; misalignment increases flash and maintenance downtime |

| Surface Roughness (Ra) | 0.4 µm (16 µin) standard | Smoother finishes reduce part drag but extend machining/polishing time; matte finishes may lower mold cost |

Our technical execution bridges the gap between mold fabrication cost and plastic part profitability. By delivering metal components within these tolerances, we enable molders to run faster cycles with fewer adjustments, directly improving your cost-per-part equation. Partner with Wuxi Lead to transform precision metal manufacturing into a strategic advantage for your injection molding operations.

Material & Finish Options

Material Selection in Precision Injection Molding: Aluminum, Steel, and Titanium for High-Performance Tools

Selecting the appropriate base material for injection molds is critical to achieving optimal production efficiency, part quality, and tool longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand injection molding applications. Our engineering team evaluates material performance based on thermal conductivity, hardness, wear resistance, and compatibility with finishing processes such as anodizing. The three primary metals used in advanced mold construction—aluminum, steel, and titanium—each offer distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, particularly 7075 and 6061, are favored for prototyping and low-to-medium volume production due to their excellent machinability and high thermal conductivity. These properties enable faster cycle times and efficient heat dissipation during molding. While aluminum lacks the wear resistance of steel, it performs exceptionally well when enhanced with hard anodizing. This electrochemical process increases surface hardness up to 60 HRC, improves corrosion resistance, and reduces friction—making anodized aluminum molds suitable for thousands of cycles in controlled environments.

Steel remains the standard for high-volume production molds. Tool steels such as P20, H13, and S136 offer superior hardness, dimensional stability, and resistance to abrasion and thermal fatigue. These characteristics ensure long service life even under continuous operation with engineering-grade resins. While steel has lower thermal conductivity than aluminum, proper cooling channel design mitigates this limitation. Steel molds are often surface-treated through nitriding or chrome plating, though anodizing is not applicable due to steel’s composition.

Titanium and its alloys, such as Ti-6Al-4V, are emerging in specialized mold applications where extreme strength-to-density ratios and corrosion resistance are paramount. Though rarely used for full mold bodies due to cost and machinability challenges, titanium inserts are employed in areas subject to high wear or corrosive media. Titanium can be anodized to produce durable, decorative, or functional oxide layers, enhancing surface properties without compromising structural integrity.

The choice between aluminum, steel, and titanium must align with production goals, resin type, and part specifications. Each material responds differently to surface finishing, with anodizing playing a pivotal role in extending the performance of aluminum and titanium components.

Comparative Material Properties for Injection Mold Applications

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Anodizing Compatible | Recommended Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 150 HB (up to 60 HRC with hard anodizing) | 130 | Moderate (improves with anodizing) | Yes | Prototypes, low/medium volume runs |

| P20 Steel | 28–32 HRC | 30 | Low to moderate | No | High-volume production |

| H13 Steel | 48–52 HRC | 35 | Moderate | No | Hot-runner molds, high stress |

| Ti-6Al-4V | 36 HRC | 7 | Excellent | Yes | Corrosive environments, inserts |

At Wuxi Lead, we integrate material science with precision engineering to deliver molds that meet the exact demands of modern manufacturing. Our expertise ensures optimal material and finish selection for every injection molding project.

Manufacturing Process & QC

Precision Metal Mold Manufacturing: The Foundation of Cost-Effective Plastic Injection Molding

At Wuxi Lead Precision Machinery, we engineer the critical metal tooling that defines plastic injection molding economics. Our core expertise lies in manufacturing high-precision steel and aluminum molds, not the plastic components themselves. Understanding this distinction is vital for accurate cost analysis. True value in plastic injection molding pricing stems from the mold’s ability to consistently produce zero-defect parts at volume. We optimize the entire process chain—Design, Prototyping, Mass Production—around this singular objective, directly impacting your total cost of ownership. Initial mold investment is merely the starting point; the real cost driver is part failure rates during production. Our integrated approach minimizes scrap, rework, and machine downtime, delivering superior long-term economics.

The Design phase is where cost efficiency is engineered in. Our engineers collaborate closely with clients using advanced CAD/CAM and mold flow simulation software. We rigorously analyze part geometry, material selection, gate placement, cooling channel design, and ejection mechanisms. This preemptive optimization ensures the mold design inherently supports dimensional stability and structural integrity of the plastic part, eliminating potential defect sources before metal is cut. Precision cavity and core machining begins here through virtual validation, directly influencing manufacturability and final part quality. Skipping thorough design validation inevitably leads to expensive iterations later.

Prototyping transforms the digital model into a tangible reality for zero-defect validation. We employ high-speed CNC milling and precision EDM to fabricate initial mold cavities and cores using production-intent materials and processes. This functional prototype mold undergoes rigorous testing under actual production parameters. We measure critical dimensions, assess surface finish, evaluate cycle times, and identify any microscopic flaws or potential stress points. This phase is non-negotiable for risk mitigation; it allows us to refine the mold design and process parameters before committing to full-scale production tooling, preventing costly defects from propagating through thousands of parts.

Mass Production leverages the perfected design and validated prototype. Our state-of-the-art multi-axis CNC machining centers, coupled with stringent in-process metrology using CMMs and optical comparators, ensure every mold component meets exacting tolerances. Continuous process monitoring during mold manufacturing guarantees consistency. The result is a production mold engineered for longevity, thermal stability, and micron-level repeatability. This precision directly translates to zero-defect output in your injection molding operation, maximizing yield and minimizing hidden costs associated with part rejection and machine stoppages.

The table below illustrates how our precision mold manufacturing specifications directly correlate with defect prevention and cost efficiency:

| Specification Parameter | Wuxi Lead Precision Standard | Defect Rate Impact |

|---|---|---|

| Mold Steel Hardness | HRC 48-52 (Pre-hardened) | Reduces wear-induced dimensional drift |

| Cavity/Core Tolerance | ±0.005 mm | Ensures part dimensional consistency |

| Surface Finish (Cavity) | Ra 0.05 μm (Mirror Polish) | Eliminates surface defects, improves ejection |

| Cooling Channel Accuracy | ±0.01 mm positional | Prevents warpage, sink marks, cycle variation |

| Mold Base Flatness | 0.01 mm per 100 mm | Guarantees consistent parting line sealing |

Achieving zero defects in plastic part production is fundamentally dependent on the precision and reliability of the metal mold. Wuxi Lead Precision Machinery delivers molds engineered for perfection, transforming your injection molding investment into a predictable, high-yield asset. Contact us to discuss how our zero-defect mold manufacturing process optimizes your true plastic injection molding price.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Plastic Injection Molding Pricing and Custom Metal Manufacturing

When it comes to precision-driven manufacturing, especially in the highly competitive field of plastic injection molding, cost transparency, technical accuracy, and long-term reliability are non-negotiable. At Wuxi Lead Precision Machinery, we understand that your project’s success hinges not only on the final price but on the total value delivered—from material selection and mold design to production scalability and post-processing support. As a trusted leader in custom metal manufacturing based in China, we offer comprehensive solutions tailored to your exact specifications, ensuring optimal cost-efficiency without compromising on quality.

Our engineering team specializes in analyzing every variable that influences plastic injection molding price, including part complexity, material grade, tooling requirements, production volume, and surface finish. We go beyond quoting a number—we deliver a detailed cost breakdown supported by advanced simulation tools and decades of hands-on experience. This enables you to make informed decisions, avoid hidden costs, and accelerate time to market.

What sets Wuxi Lead apart is our vertical integration. We design, machine, and assemble molds in-house using premium-grade steel and cutting-edge CNC technology, reducing lead times and ensuring dimensional accuracy down to ±0.002 mm. Our facility is equipped with high-tonnage injection molding presses capable of handling both prototype and high-volume production runs, giving you seamless scalability under one roof.

We serve industries where precision matters most—automotive, medical devices, consumer electronics, and industrial automation—delivering components that meet ISO 9001 and IATF 16949 standards. Whether your project requires 1,000 prototype units or 1 million production parts, our team optimizes cycle times, minimizes waste, and ensures consistent repeatability, directly impacting your bottom line.

Below are key specifications that define our plastic injection molding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50 to 2000 Tons |

| Shot Weight Capacity | Up to 3000 grams |

| Tolerance | ±0.002 mm |

| Materials Supported | ABS, PC, PP, PA (Nylon), POM, PBT, PEEK, and engineered composites |

| Mold Base Materials | 718H, S136, NAK80, H13 |

| Surface Finishes | SPI A1, VDI 3400, texture, matte, high-gloss |

| Secondary Operations | Ultrasonic welding, insert molding, CNC trimming, assembly |

Partnering with Wuxi Lead Precision Machinery means gaining a transparent, responsive, and technically superior manufacturing ally. We don’t just manufacture parts—we engineer cost-effective solutions tailored to your production goals.

Contact us today at [email protected] to receive a detailed, no-obligation quote and let our engineers help you optimize your next plastic injection molding project for performance, quality, and cost.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.