Technical Contents

Engineering Guide: Plastic Injection Molding Maker

Engineering Insight: The Critical Role of Precision in Plastic Injection Molding

In the realm of high-performance manufacturing, plastic injection molding is not merely a process—it is a science defined by exacting standards, consistent repeatability, and uncompromising precision. For industries ranging from aerospace and defense to medical and consumer electronics, the integrity of a molded component can determine the success or failure of an entire system. At Wuxi Lead Precision Machinery, we understand that precision is not an optional attribute; it is the foundation upon which reliability, performance, and innovation are built.

As a leading custom metal manufacturing partner based in China, Lead Precision specializes in the design and production of high-precision molds and tooling systems for plastic injection molding. Our engineering expertise ensures that every cavity, core, and ejection mechanism is machined to micron-level tolerances, enabling consistent part quality across high-volume production runs. The precision of the mold directly influences critical factors such as dimensional accuracy, surface finish, and material flow dynamics—each of which can impact the functionality and durability of the final product.

Our commitment to precision is validated through real-world applications in the most demanding environments. Lead Precision has contributed to projects associated with Olympic-standard equipment and military-grade systems, where failure is not an option. These high-stakes applications require not only advanced material science and thermal management but also a deep understanding of stress distribution, wear resistance, and long-term performance under extreme conditions. Our molds are engineered to withstand thousands of cycles without degradation, ensuring longevity and cost-efficiency for our clients.

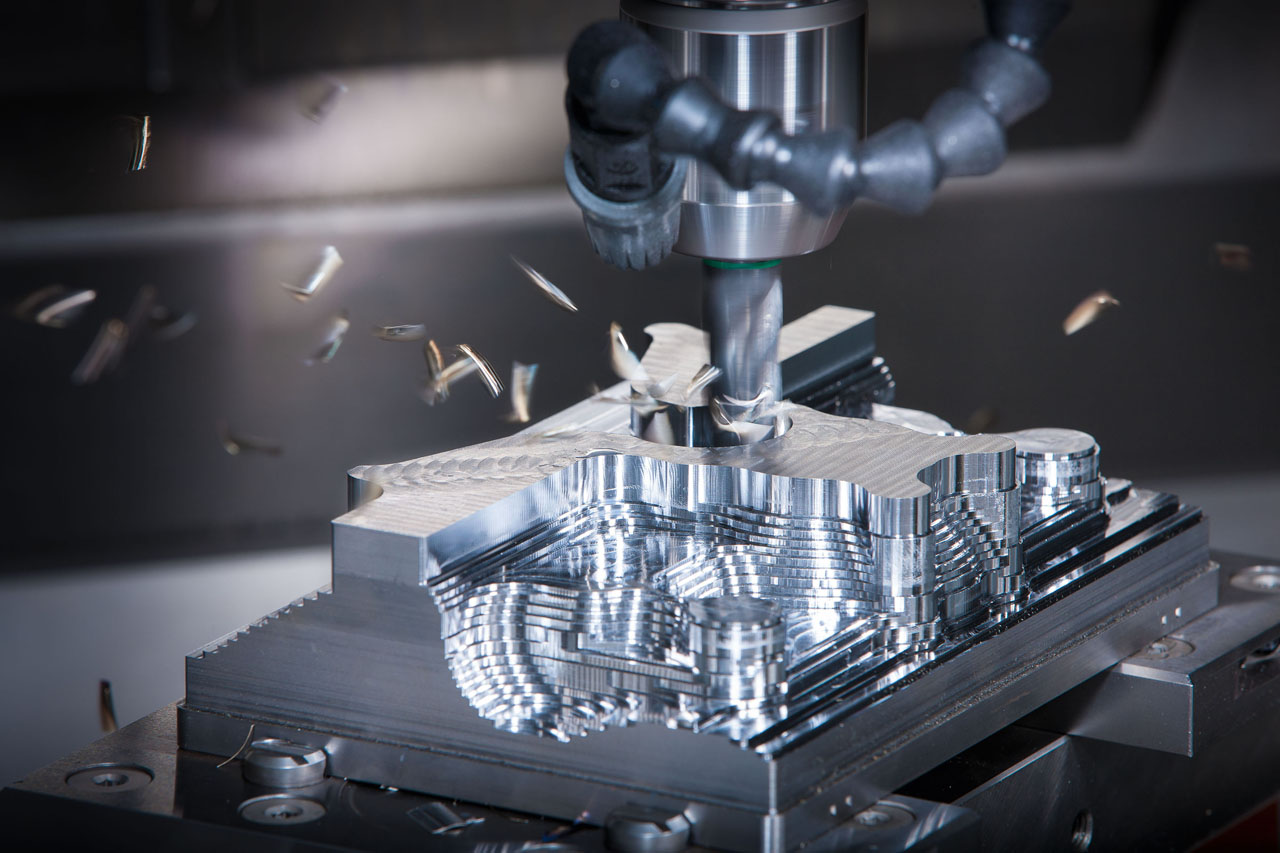

Precision begins at the design stage, where our engineers utilize advanced simulation software to model flow behavior, cooling patterns, and potential warpage. This predictive capability allows for proactive optimization, reducing trial-and-error iterations and accelerating time-to-market. Coupled with state-of-the-art CNC machining centers, wire EDM, and surface grinding technologies, we achieve tolerances as tight as ±0.002 mm—setting a benchmark in the industry.

The table below outlines key technical specifications that define our precision molding capabilities.

| Specification | Performance Value |

|---|---|

| Maximum Mold Size | 2000 x 1500 x 1200 mm |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm (mirror polish) |

| Material Compatibility | P20, 718H, S136, H13, Stainless Steel, Aluminum |

| Production Volume Capacity | 10,000 to 1,000,000+ cycles |

| Lead Time (Standard Mold) | 4–8 weeks, depending on complexity |

At Wuxi Lead Precision Machinery, we do not simply manufacture molds—we engineer solutions that meet the rigorous demands of global industries. Our experience with mission-critical applications underscores our ability to deliver precision where it matters most. For OEMs and Tier-1 suppliers, partnering with a manufacturer that combines technical excellence with proven reliability is not just strategic—it is essential.

Precision Specs & Tolerances

Technical Capabilities

Precision is non-negotiable in plastic injection mold manufacturing where microscopic deviations directly impact part quality, cycle time, and tool longevity. At Wuxi Lead Precision Machinery we engineer metal components to the exacting standards demanded by high-performance molds. Our integrated technical capabilities bridge advanced machining with rigorous metrology ensuring every mold base, cavity, core, and insert meets the functional requirements of the most challenging production environments. This commitment to dimensional integrity forms the bedrock of reliable, high-yield molding operations for our global clients.

Our core machining capability centers on state-of-the-art 5-axis CNC milling and turning centers. These systems enable the monolithic fabrication of complex mold geometries—including deep ribs, undercuts, and organic cooling channels—in a single setup. Eliminating multiple fixtures drastically reduces cumulative error potential while enhancing surface finish consistency critical for part ejection and cosmetic surfaces. We machine a wide spectrum of mold-appropriate materials including P20, H13, S136 stainless, and hardened tool steels up to 60 HRC with thermal stability protocols to prevent distortion. Advanced high-speed machining strategies optimize metal removal rates without compromising surface integrity or dimensional control essential for tight-tolerance sealing surfaces and slide interfaces.

Quality assurance is embedded within our process flow through comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical feature undergoes verification against the original CAD model using calibrated Zeiss CONTURA systems with sub-micron accuracy. Our inspection protocol covers geometric dimensioning and tolerancing (GD&T) callouts, surface profiles, positional accuracy of ejector holes and cooling lines, and critical mating surfaces. Full first-article inspection reports (FAIR) with detailed deviation maps are standard deliverables providing complete traceability. This metrology-driven approach ensures molds arrive ready for production minimising costly trial-and-error adjustments at the press.

The following table details our standard and achievable tolerance capabilities for critical mold features demonstrating our precision foundation:

| Feature Type | Standard Capability | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm |

| Flatness | 0.008 mm | 0.003 mm |

| Perpendicularity | 0.010 mm | 0.005 mm |

| Concentricity | 0.012 mm | 0.006 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Bore Diameter | H7 (±0.007 mm) | H6 (±0.005 mm) |

This level of precision execution translates directly into mold performance. Clients achieve reduced scrap rates extended tool life consistent part dimensions and faster time-to-market. Wuxi Lead Precision Machinery delivers not just components but the dimensional certainty that underpins profitable, high-volume plastic injection molding operations worldwide. Our technical infrastructure ensures your mold investment performs predictably from the first shot to the millionth cycle.

Material & Finish Options

Material selection is a critical step in the development of precision molds and tooling for plastic injection molding. At Wuxi Lead Precision Machinery, we understand that the performance, longevity, and cost-efficiency of a mold are directly influenced by the base material and surface treatment chosen. For high-performance applications, aluminum, steel, and titanium represent the most widely adopted materials, each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, such as 7075 and 6061, are favored for prototyping and low- to medium-volume production due to their excellent machinability and thermal conductivity. These properties allow for faster cooling cycles and reduced lead times during mold fabrication. While aluminum lacks the wear resistance of steel, modern surface treatments like anodizing significantly enhance its durability and corrosion resistance, making it suitable for many industrial applications.

Steel, particularly tool steels like P20, H13, and S136, remains the standard for high-volume injection molding. These alloys offer superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. Pre-hardened steels such as P20 are commonly used for molds requiring moderate durability, while H13 excels in applications involving high thermal stress. Stainless variants like S136 provide additional corrosion resistance, ideal for molding medical or food-grade plastics where hygiene is paramount.

Titanium, though less common in mold construction, is gaining traction in specialized applications where extreme strength-to-density ratio and corrosion resistance are required. Its use is typically limited to critical mold components such as inserts or cores, rather than full mold bases, due to cost and machining complexity. However, in aggressive environments or aerospace-related molding processes, titanium’s performance justifies its premium.

Surface finishing, particularly anodizing, plays a pivotal role in extending mold life and improving part quality. Anodizing creates a hard, wear-resistant oxide layer on aluminum surfaces, enhancing resistance to abrasion and chemical exposure. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior thickness and durability. While anodizing is specific to aluminum, steel molds benefit from alternative treatments such as nitriding or chrome plating to achieve similar performance gains.

The following table summarizes key mechanical and thermal properties of the primary materials used in custom mold manufacturing:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Application |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 570 | 130 | Prototyping, low-volume runs |

| P20 Steel | 28–32 | 900 | 30 | Medium to high-volume production |

| H13 Steel | 48–52 | 1,500 | 28 | High-temperature, high-wear molds |

| S136 Steel | 50–54 | 1,600 | 25 | Corrosion-resistant molds |

| Titanium Grade 5 | 35–40 | 900 | 7 | Specialized, high-strength inserts |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, environmental demands, and lifecycle cost analysis. Our engineering team ensures every mold is optimized for performance, delivering precision and reliability in every cycle.

Manufacturing Process & QC

Precision Metal Mold Manufacturing Process: Zero Defects from Concept to Volume Production

At Wuxi Lead Precision Machinery, we engineer metal molds for plastic injection molding makers with uncompromising focus on zero defects. Our integrated process transforms client specifications into flawless production assets through three rigorously controlled phases. This methodology ensures your final plastic components meet exacting dimensional, cosmetic, and functional standards at scale.

The Design Phase begins with collaborative engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, leveraging Siemens NX and Moldflow simulation to optimize gate placement, cooling channels, and ejection systems. We identify potential warpage, sink marks, or knit lines before metal is cut, reducing rework risk by 70%. Critical tolerances are validated against ISO 2768-m standards, with thermal expansion coefficients calculated for your specific polymer. Every mold cavity and core is digitally stress-tested under 150% operational pressure to eliminate structural weaknesses. Client sign-off occurs only after virtual validation of 10,000+ cycle fatigue performance.

Prototyping utilizes production-intent steel molds—not soft aluminum or 3D prints—to validate real-world behavior. We machine P20 or H13 tool steel molds to ±0.005mm accuracy, then run 500-shot trials on our all-electric Engel presses. Each prototype part undergoes CMM inspection against your CAD model, with cavity pressure sensors capturing fill/hold/pack data. Any deviations trigger immediate mold steel adjustments via our in-house EDM and high-speed CNC centers. This phase delivers statistically valid process windows (SPC CpK >1.67) and full First Article Inspection reports compliant with PPAP Level 3 requirements.

Mass Production deployment integrates our molds into your line with zero tolerance for variation. We embed IoT sensors monitoring tonnage, temperature, and cycle time in real time, feeding data to your MES. Our molds feature hardened tool steel (52-54 HRC) with mirror-polished cavities (Ra ≤0.025µm) and conformal cooling channels proven to reduce cycle times by 22%. Every 500th part undergoes automated optical inspection against master profiles, while SPC charts track critical dimensions. This closed-loop system achieves <50 PPM defect rates, with mold maintenance logs ensuring 1,000,000+ shot longevity.

Wuxi Lead’s metal manufacturing excellence guarantees that your plastic injection process starts perfect—and stays perfect.

| Critical Process Specification | Wuxi Lead Standard | Industry Baseline |

|---|---|---|

| Mold Tolerance | ±0.002 mm | ±0.01 mm |

| Surface Finish (Cavity) | Ra 0.012 µm | Ra 0.05 µm |

| Tool Steel Hardness | 54 ±1 HRC | 50 ±2 HRC |

| Cooling Channel Accuracy | ±0.003 mm | ±0.02 mm |

| First Article Inspection Depth | 100% GD&T Points | 30% Critical Points |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation define success in high-end manufacturing. As a leading custom metal manufacturing partner based in China, we specialize in delivering engineered solutions for industries where performance cannot be compromised—automotive, medical, aerospace, and consumer electronics. Our mastery in supporting plastic injection molding makers with mission-critical metal components sets us apart in a competitive global market.

Our engineering-driven approach ensures that every component we produce meets the highest standards of dimensional accuracy, surface finish, and structural integrity. Whether you require mold bases, inserts, cores, ejector systems, or fully assembled tooling solutions, our team applies decades of technical expertise to deliver parts that perform flawlessly under demanding production cycles. We leverage advanced CNC machining centers, wire EDM, grinding, and surface treatment technologies to guarantee consistency across both prototypes and high-volume production runs.

What truly differentiates Lead Precision is our commitment to collaboration. We don’t just manufacture parts—we become an extension of your engineering team. From initial design consultation to final inspection and global logistics, we align our processes with your project timelines, quality benchmarks, and cost targets. Our in-house quality control lab is equipped with CMMs, optical comparators, and hardness testers, ensuring full traceability and compliance with ISO 9001 standards.

Our clients choose us not only for our technical capabilities but also for our responsiveness and long-term partnership model. We support rapid prototyping, design for manufacturability (DFM) analysis, and iterative feedback loops that reduce time-to-market and prevent costly rework. With a focus on continuous improvement and lean manufacturing principles, we optimize every stage of production to deliver value beyond the drawing.

Below are key technical specifications that define our manufacturing capacity:

| Specification | Capability |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 1000 mm |

| Tolerance Range | ±0.002 mm |

| Surface Roughness | Ra 0.1 – 0.8 μm (polished to mirror finish) |

| Materials Processed | P20, 718, H13, S136, 420SS, Aluminum 7075/6061, Titanium, Brass |

| CNC Machining Centers | 3-axis, 4-axis, 5-axis simultaneous |

| Secondary Processes | Heat treatment, nitriding, PVD coating, texturing |

Partnering with Wuxi Lead Precision Machinery means securing a reliable, technically advanced manufacturing ally dedicated to your success. We are ready to support your next-generation plastic injection molding projects with precision-engineered metal components built to last.

Contact us today at [email protected] to discuss your requirements and discover how we can elevate your manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.