Technical Contents

Engineering Guide: Plastic Injection Mold Solution

Engineering Insight: The Critical Role of Precision in Plastic Injection Mold Solutions

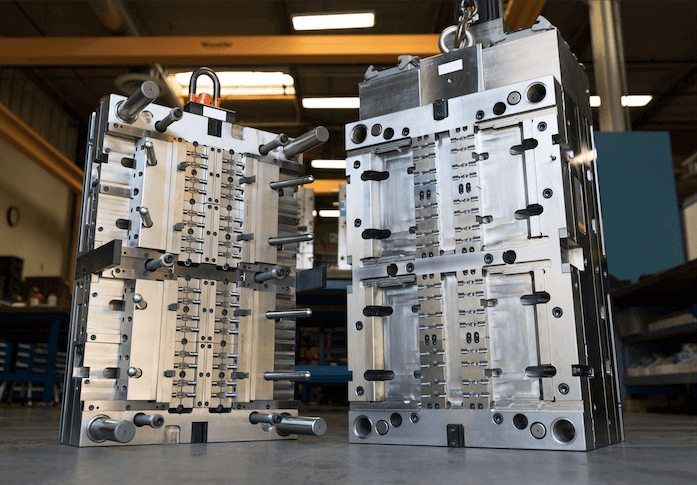

In the realm of custom metal manufacturing, the success of a plastic injection mold solution hinges on one foundational principle: precision. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in mold design or fabrication can lead to significant downstream consequences—ranging from part defects and production delays to increased tooling wear and costly rework. For industries where consistency, reliability, and performance are non-negotiable, such as aerospace, defense, and high-performance consumer goods, precision is not merely a metric—it is a standard.

Our engineering approach begins with a deep analysis of the end-use application. Whether producing molds for complex medical devices or ruggedized military components, we integrate material science, thermal dynamics, and structural integrity into every phase of development. This holistic methodology ensures that molds not only meet dimensional tolerances but also sustain performance across thousands, if not millions, of cycles. Our in-house design team utilizes advanced simulation software to model flow behavior, cooling efficiency, and stress distribution, minimizing trial-and-error and accelerating time-to-market.

Wuxi Lead Precision Machinery brings over a decade of specialized experience in delivering mission-critical mold solutions. Our portfolio includes precision tooling for Olympic-grade sporting equipment and components used in defense systems—applications where failure is not an option. These projects demand adherence to international quality standards, including ISO 9001 and AS9100, and require materials capable of withstanding extreme environments. Our ability to consistently meet these challenges reflects our commitment to engineering excellence and operational discipline.

We leverage state-of-the-art CNC machining centers, wire EDM, and high-speed milling technologies, all calibrated to maintain tolerances within ±0.002 mm. This level of accuracy ensures perfect part replication, optimal gate performance, and minimal flash—key indicators of a high-performance mold. Furthermore, our surface finishing processes, including mirror polishing and texturing, are executed with the same rigor, enhancing both functionality and aesthetics.

The result is a plastic injection mold solution that delivers repeatability, longevity, and operational efficiency. For global manufacturers seeking to reduce waste, improve cycle times, and ensure part conformity, partnering with a precision-focused manufacturer is essential.

Technical Specifications Overview

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Maximum Mold Size | 2000 x 1500 x 1200 mm | — |

| Minimum Wall Thickness | 0.6 mm | ±0.005 mm |

| Dimensional Accuracy | High-precision CNC & EDM | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.02 µm (mirror finish) | ±0.003 µm |

| Mold Life Expectancy | Up to 1,000,000 cycles (depending on material) | — |

| Materials Supported | P20, 718, H13, S136, 420 Stainless, Aluminum | — |

| Lead Time (Average) | 4–8 weeks (varies by complexity) | — |

Precision is not an added feature—it is the core of every mold we engineer. At Wuxi Lead Precision Machinery, we combine technical mastery with real-world application insight to deliver plastic injection mold solutions that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Injection Molds

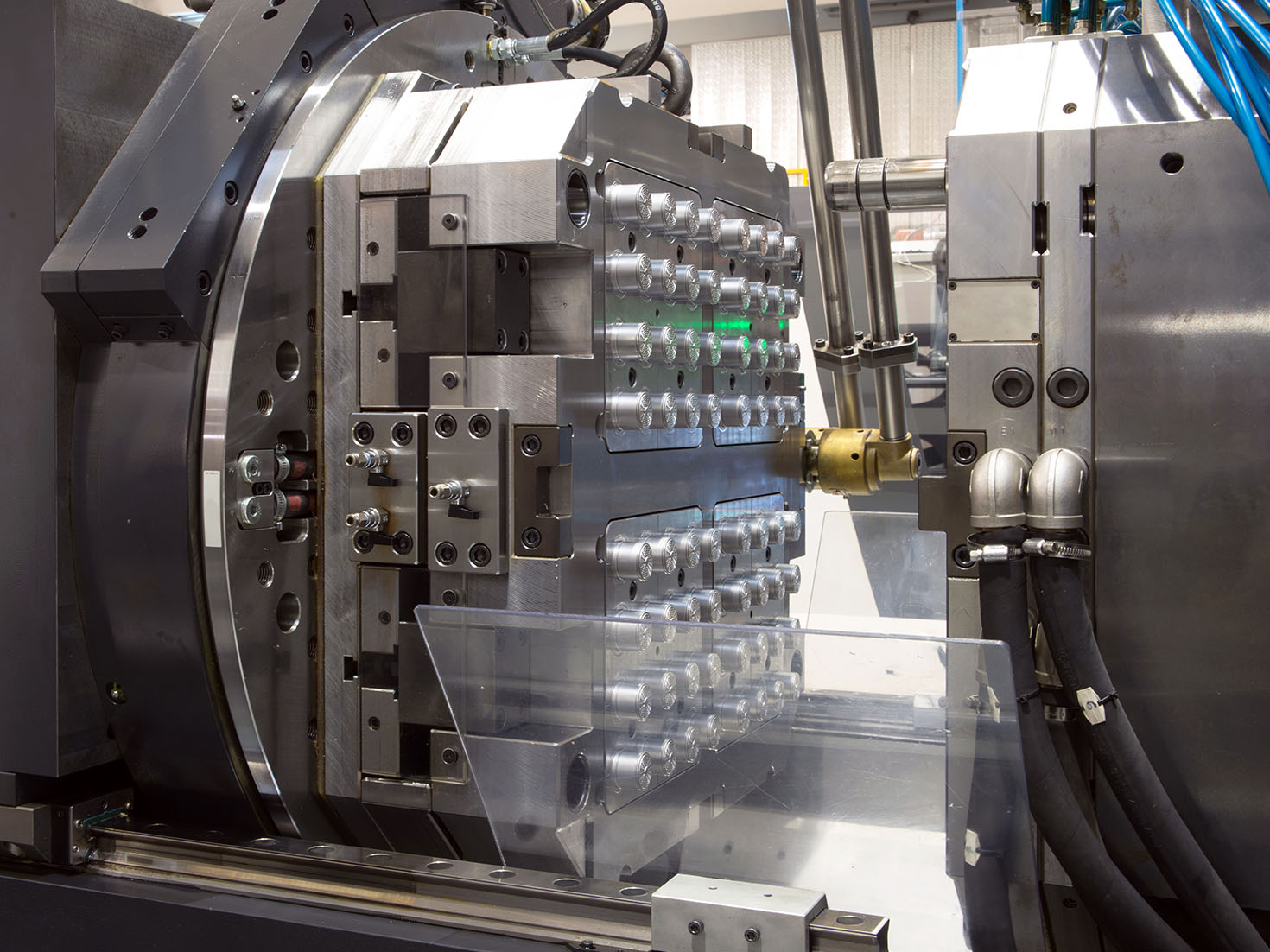

Wuxi Lead Precision Machinery delivers unmatched technical execution for complex plastic injection mold solutions, leveraging advanced manufacturing infrastructure and rigorous quality control. Our core competency lies in transforming intricate mold designs into high-performance tooling capable of sustained production excellence. Central to this capability is our comprehensive suite of 5-axis CNC machining centers. These state-of-the-art systems provide the simultaneous multi-directional movement essential for crafting complex mold cores, cavities, sliders, and intricate lifters with exceptional geometric fidelity. The elimination of multiple setups inherent in 5-axis processing significantly reduces cumulative error, ensures superior surface finish critical for part ejection and aesthetics, and dramatically shortens lead times by consolidating operations. This technology is indispensable for molds requiring undercuts, deep ribs, or organic contours common in automotive lighting, medical devices, and consumer electronics.

Precision is non-negotiable in mold manufacturing, where micron-level deviations directly impact part quality, cycle time, and tool longevity. Our machining processes are governed by stringent environmental controls and executed by highly skilled technicians with deep expertise in mold steel behaviors and thermal management. Every critical component undergoes comprehensive dimensional and geometric verification using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems, operating within certified metrology labs, provide traceable, high-accuracy data for complex 3D profiles, flatness, parallelism, and critical bore alignments. This systematic inspection protocol, integrated directly into our production workflow, ensures conformity to the most demanding specifications before mold assembly and validation.

The achievable precision of our manufacturing and quality systems is consistently demonstrated across diverse mold projects. The following table outlines our standard and high-precision tolerance capabilities for critical mold features:

| Feature Category | Standard Capability (mm) | High-Precision Capability (mm) | Applicable Standard/Notes |

|---|---|---|---|

| Dimensional (Linear) | ±0.010 | ±0.005 | ISO 2768-mK / Critical features |

| Positional (Holes/Pins) | ±0.015 | ±0.008 | Relative to datums, critical alignment points |

| Flatness / Parallelism | 0.015 / 100mm | 0.008 / 100mm | Critical parting line & sealing surfaces |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined cores/cavities (as-machined) |

| Bore Roundness | 0.010 | 0.005 | Critical bushings, guide pillars |

These capabilities are not theoretical targets but proven benchmarks consistently achieved across our production floor. We integrate metrology data directly back into the machining process for real-time adjustments, ensuring final mold performance meets the exacting demands of high-cavitation, tight-tolerance plastic injection molding. Wuxi Lead Precision Machinery provides the technical foundation for molds that deliver exceptional part consistency, extended service life, and optimal production efficiency for our global clientele. Our commitment is to precision realized, not merely promised.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of plastic injection molds. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that align material properties with production demands. The primary materials used in mold construction—aluminum, steel, and titanium—each offer distinct advantages depending on application requirements such as cycle volume, part complexity, and thermal performance.

Aluminum is widely used for prototype and low-to-medium volume production molds due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall production time during trial runs and short runs. While aluminum lacks the wear resistance of harder metals, modern alloys such as 7075-T6 and 6061-T6 offer improved strength and longevity. Aluminum is particularly suitable for applications where rapid turnaround and cost efficiency are prioritized over extended tool life.

Steel remains the standard for high-volume production molds. Tool steels like P20, H13, and S136 provide superior hardness, wear resistance, and dimensional stability under prolonged use. These properties ensure consistent part quality across hundreds of thousands—or even millions—of cycles. Stainless tool steels also offer corrosion resistance, making them ideal for molding medical or food-grade components. While steel molds require longer lead times and higher initial investment, their longevity and precision justify the cost in large-scale manufacturing operations.

Titanium is less common but increasingly considered for specialized applications where extreme strength-to-density ratio and corrosion resistance are paramount. Though not typically used for full mold bases due to cost and machining complexity, titanium alloys can be integrated into critical mold components such as inserts or cores where high stress and thermal fatigue are concerns. Its biocompatibility also makes it a candidate for medical molding applications requiring stringent material standards.

Surface finish selection further enhances mold performance and part quality. Anodizing, particularly hard anodizing, is a key finishing process for aluminum molds. It increases surface hardness, improves wear and corrosion resistance, and provides electrical insulation. Type III anodizing (hard coat) can achieve layer thicknesses from 25 to 50 µm with hardness values exceeding 60 HRC, significantly extending the service life of aluminum tools. For steel molds, alternatives such as nitriding, chrome plating, or PVD coatings are typically preferred, though anodizing may still be applied selectively in hybrid systems.

The table below summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Mold Life (Cycles) |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Prototypes, low-volume production | 10,000 – 100,000 |

| P20 Steel | 28–32 | 30 | Medium to high-volume production | 500,000 – 1,000,000 |

| H13 Steel | 48–52 | 35 | High-stress, high-temperature molding | 1,000,000+ |

| Titanium Ti-6Al-4V | 35–40 (substrate) | 7 | Critical inserts, corrosive environments | Component-specific |

Understanding the interplay between material selection and surface treatment ensures optimal mold performance. Wuxi Lead Precision Machinery supports clients in making informed decisions based on production goals, regulatory needs, and lifecycle costs.

Manufacturing Process & QC

Integrated Production Process: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our plastic injection mold solution process is engineered for uncompromising quality and efficiency, rigorously structured to achieve Zero Defects from initial concept through to high-volume delivery. This integrated methodology ensures client specifications are met with absolute precision, minimizing risk and maximizing return on investment.

The foundation is our advanced Design phase. Our engineering team conducts comprehensive mold flow analysis and detailed DFM (Design for Manufacturability) reviews using Siemens NX and Moldflow software. This critical step identifies potential weaknesses like weld lines, sink marks, or filling imbalances before metal is cut. We collaborate closely with clients to optimize part geometry, gate locations, cooling channels, and material selection, ensuring the mold design inherently supports dimensional stability and surface finish requirements. This proactive approach eliminates costly revisions later, establishing the blueprint for defect-free production.

Prototyping is not merely a validation step; it is a vital quality gate. Utilizing our high-precision CNC machining centers and EDM equipment, we produce functional prototype molds or initial cavities/core sets. These undergo rigorous testing on our in-house injection molding presses with the client-specified material. Every prototype part is subjected to full First Article Inspection (FAI) per AS9102 or client-specific standards, measuring critical dimensions with Zeiss CMMs and verifying mechanical properties. Mold performance data—pressure curves, cycle times, cooling efficiency—is meticulously analyzed. Only when prototype parts consistently meet all specifications, and the mold process is fully stabilized and documented, do we approve progression to mass production. This phase is non-negotiable for verifying the Zero Defects capability of the tooling system.

Mass Production leverages the validated process with stringent, real-time controls. Molds run on our state-of-the-art, monitored presses within a climate-controlled facility. Automated in-process inspection systems, including vision checks and laser micrometers, provide continuous feedback on critical dimensions. Statistical Process Control (SPC) charts track key parameters like cavity pressure and part weight, triggering immediate intervention if trends approach specification limits. Every production shift begins with a full setup verification, and finished lots undergo final inspection against the approved FAI report. Our integrated ERP system ensures full traceability from raw material batch to finished part, providing auditable proof of consistent quality. This closed-loop system, built on the robust foundation of design and prototyping, is how we guarantee Zero Defects at scale.

The following table outlines key specifications maintained across our production phases:

| Phase | Typical Tolerance Capability | Lead Time Focus | Primary Inspection Method | Key Quality Control Output |

|---|---|---|---|---|

| Design | ±0.005mm (Theoretical) | Optimization | Mold Flow Simulation | Validated DFM Report, Mold Design |

| Prototyping | ±0.025mm to ±0.05mm | Validation | Full FAI (CMM, Visual) | Approved Sample, Process Window |

| Mass Production | ±0.025mm (Consistent) | Stability | SPC, Automated In-Process | PPAP, Lot Traceability, Zero PPM |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for a True End-to-End Plastic Injection Mold Solution

When precision, reliability, and speed define your manufacturing success, partnering with Wuxi Lead Precision Machinery is not just a choice—it’s a strategic advantage. As a leading provider in custom metal manufacturing, we specialize in delivering comprehensive plastic injection mold solutions tailored to the exacting demands of global industries including automotive, medical devices, consumer electronics, and industrial equipment. Our engineering-driven approach ensures that every mold we produce meets the highest standards of dimensional accuracy, durability, and repeatability.

At Lead Precision, we understand that mold performance directly impacts your production efficiency and product quality. That’s why we integrate advanced CNC machining, EDM, and precision polishing technologies with rigorous quality control protocols throughout every phase of development. From initial concept and 3D design validation to mold trials and final delivery, our team of seasoned engineers and toolmakers collaborates closely with clients to transform ideas into high-performance tooling solutions.

Our facility in Wuxi, China is equipped with state-of-the-art machinery and operates under ISO 9001-certified processes, enabling us to consistently deliver molds with tight tolerances and complex geometries. Whether you require single-cavity prototypes or multi-cavity production molds for high-volume runs, we offer scalable solutions backed by decades of technical expertise and a customer-first philosophy.

Below are key technical capabilities that define our mold manufacturing excellence:

| Specification | Detail |

|---|---|

| Mold Base Materials | LKM, FUTABA, DAIDO, or customer-specified |

| Steel Types | P20, 718, 2738, S136, H13, 420SS, and other hardened or pre-hardened steels |

| Maximum Mold Size | 1200 mm × 800 mm × 900 mm (L×W×H) |

| Tolerance | ±0.005 mm for critical dimensions |

| Surface Finishes | SPI #A1–#D3, texture, mirror polish, EDM finish |

| Lead Time | 4–8 weeks depending on complexity |

| Molding Machine Compatibility | Up to 1600 tons clamping force |

| Quality Assurance | Full First Article Inspection (FAI), CMM reports, mold flow analysis available |

We don’t just build molds—we build long-term manufacturing partnerships. Our clients benefit from transparent communication, real-time project updates, and post-delivery support to ensure seamless integration into their production lines. With competitive pricing, scalable capacity, and a proven track record serving North America, Europe, and Asia, Wuxi Lead Precision Machinery is positioned to be your trusted offshore mold solution partner.

Take the next step toward precision, efficiency, and reliability in your injection molding operations. Contact us today at [email protected] to discuss your project requirements and discover how Lead Precision can deliver a custom mold solution engineered for performance and built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.