Technical Contents

Engineering Guide: Plastic Injection Mold Making

Engineering Insight: Precision as the Non-Negotiable Foundation of Plastic Injection Mold Making

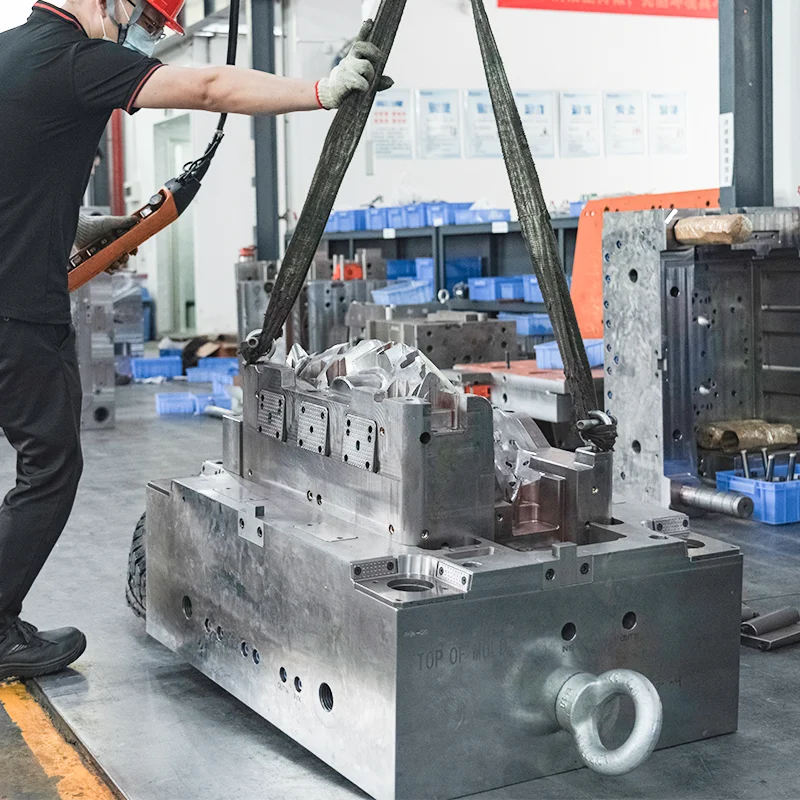

In the demanding realm of custom plastic injection molding, the mold is not merely a tool; it is the absolute determinant of part quality, consistency, and ultimately, the viability of the entire production process. At Wuxi Lead Precision Machinery, we assert with engineering conviction that precision in mold manufacturing is non-negotiable. Micron-level deviations during mold fabrication translate directly into part defects, assembly failures, shortened mold life, and unsustainable scrap rates at production scale. The complex interplay of thermal dynamics, material flow, and ejection mechanics demands that every cavity, core, runner, and gating feature adheres to exacting dimensional and geometric specifications. Compromise here cascades through the supply chain, eroding profitability and damaging brand reputation. True precision encompasses not only initial dimensional accuracy but also the thermal stability of the mold structure under repeated cycling and the flawless interaction of all moving components under high cavity pressure.

The consequences of inadequate mold precision are severe and quantifiable. Flash formation due to mismatched parting lines increases post-processing costs and risks contaminating cleanroom environments. Warpage or sink marks stem from inconsistent wall thickness control or improper cooling channel placement, directly traceable to mold geometry errors. Short shots or knit lines often originate from imprecise gate dimensions or runner balance. These are not isolated production hiccups; they represent fundamental flaws rooted in the mold’s engineering and manufacture. Achieving the required precision demands more than advanced machinery; it requires deep metallurgical understanding, sophisticated simulation validation, and an uncompromising culture of quality control at every machining and assembly stage. This is where decades of high-stakes experience become critical.

Wuxi Lead Precision Machinery operates at this pinnacle of precision manufacturing. Our engineering team possesses proven expertise in delivering molds where tolerances are measured in single-digit microns, validated through mission-critical applications. We have engineered and manufactured molds for components used in Olympic-grade sporting equipment demanding flawless aerodynamics and structural integrity, and for specialized military hardware requiring absolute reliability under extreme environmental stress. This experience is not a footnote; it is the rigorous proving ground that defines our standards. We understand that the mold must perform identically cycle after cycle, year after year, under the most demanding production conditions. Our capability is built upon state-of-the-art multi-axis CNC machining centers, wire EDM, and surface grinding, all operating within stringent environmental controls, but elevated by the engineering judgment forged in the highest accountability sectors.

The following table outlines the core precision specifications we consistently achieve and validate for critical mold components:

| Specification Category | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.01 mm | ±0.003 mm | CMM (Calibrated to ISO 17025) |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.005 mm | CMM, Optical Comparator |

| Cavity/ Core Surface Finish | Ra 0.2 µm | Ra 0.05 µm (Mirror) | Profilometer |

| Parting Line Match | ≤ 0.005 mm | ≤ 0.002 mm | Precision Gauge Blocks, CMM |

| Cooling Channel Position | ±0.02 mm | ±0.008 mm | CMM, Bore Gauging |

| Hardness (Core Materials) | HRC 48-52 | HRC 54-58 (Uniform) | Rockwell Hardness Tester |

This level of precision is not accidental. It is the direct result of integrating advanced manufacturing technology with deep engineering insight and the uncompromising standards demanded by our most rigorous projects. For manufacturers seeking zero-defect production and maximum mold longevity, partnering with an engineering-led precision mold maker like Wuxi Lead is not an expense; it is the essential investment securing product success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic injection mold making for global industrial clients. Our engineering-driven approach integrates state-of-the-art 5-axis CNC machining systems with stringent quality control protocols to produce molds that meet the most demanding specifications. These capabilities enable us to serve industries such as automotive, medical devices, consumer electronics, and industrial equipment, where precision, repeatability, and durability are paramount.

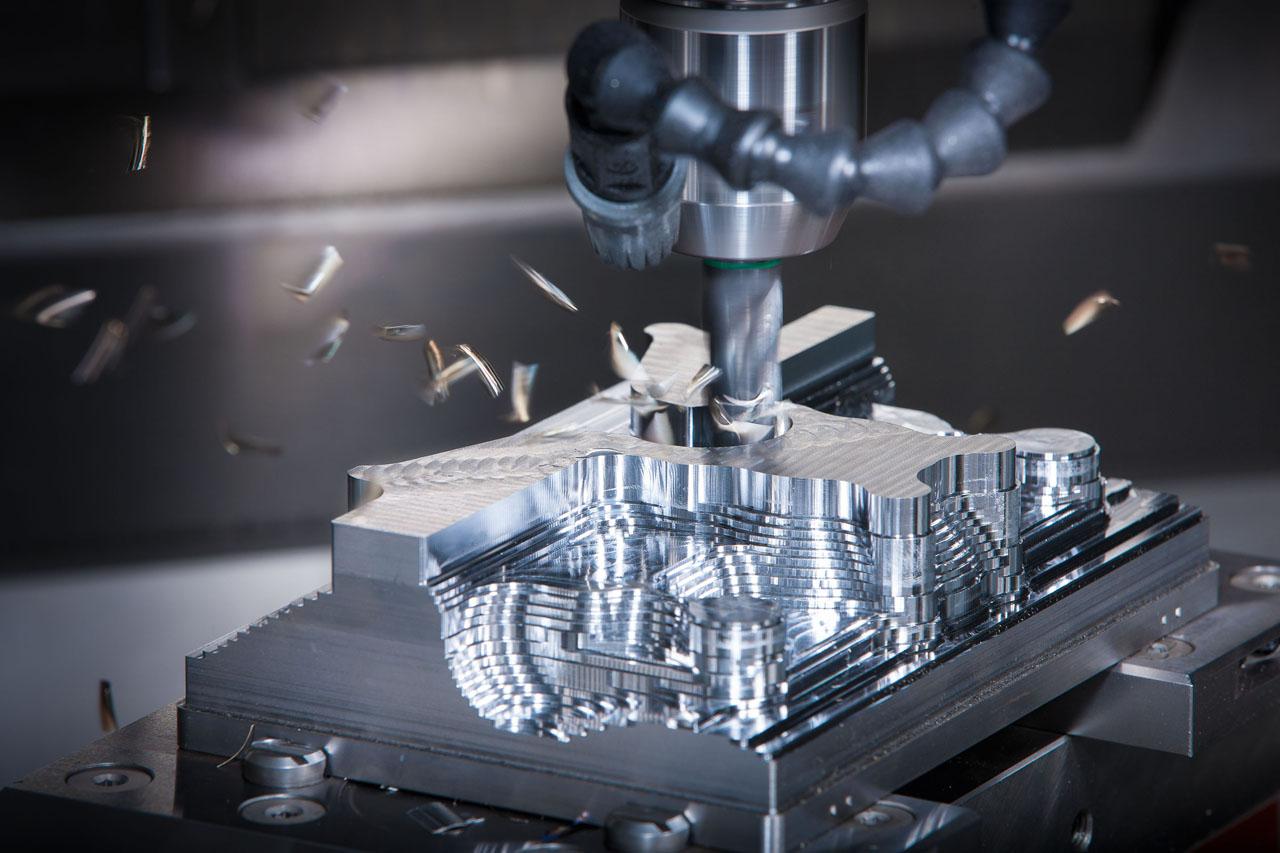

At the core of our manufacturing process is a fleet of high-performance 5-axis CNC machines, allowing for complex geometry machining in a single setup. This reduces cumulative errors associated with multiple fixturing stages and significantly enhances dimensional accuracy. The simultaneous movement across five axes enables undercuts, deep cavities, and contoured surfaces to be machined with superior surface finish and tight positional tolerances. Our skilled machinists program and operate these systems using advanced CAM software, ensuring optimal tool paths and material utilization for both prototype and production-grade molds.

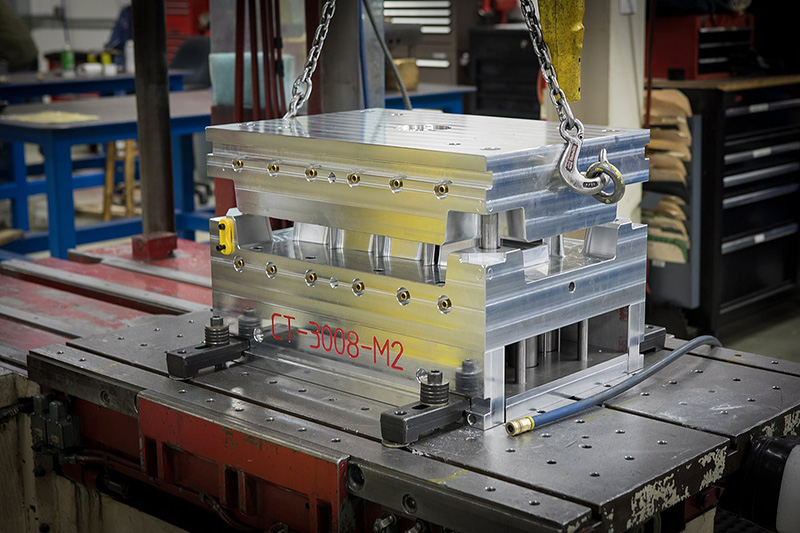

Complementing our machining excellence is a rigorous quality assurance framework centered on CMM (Coordinate Measuring Machine) inspection. Every mold undergoes comprehensive dimensional verification using蔡司 (Zeiss) and Hexagon CMM systems, capable of micron-level measurement accuracy. These inspections validate critical features such as cavity alignment, gate positioning, cooling channel placement, and parting line integrity. Full inspection reports are generated for client review, providing traceability and compliance with ISO 9001 standards.

Material selection, heat treatment, and surface finishing are also tightly controlled to ensure mold longevity and performance under high-cycle production conditions. We work with a wide range of tool steels including P20, 718H, S136, and H13, applying vacuum heat treatment and precision polishing or texturing as required. Electrode fabrication for EDM processes is performed in-house using high-accuracy graphite and copper machining techniques, further expanding our geometric flexibility.

Our technical capabilities are summarized in the table below, reflecting standard and advanced performance levels achievable across typical mold components.

| Specification | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Tolerance | ±0.01 mm | ±0.005 mm | CMM |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Surface Tester |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | CMM / Optical Flat |

| Mold Cavity Matching | ±0.01 mm | ±0.003 mm | CMM & Manual Fit Test |

Wuxi Lead Precision Machinery combines cutting-edge technology with deep process expertise to deliver injection molds that exceed functional and quality expectations. Our technical capabilities are continuously refined to support innovation and reliability in high-end manufacturing applications.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the optimal mold material is fundamental to achieving part quality, production efficiency, and total cost of ownership in plastic injection molding. At Wuxi Lead Precision Machinery, our CNC engineering expertise ensures material choices align precisely with your project’s volume, resin type, geometric complexity, and surface finish requirements. The primary contenders—aluminum, tool steel, and titanium—each offer distinct advantages under specific conditions, demanding careful technical evaluation beyond initial cost considerations.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production (under 100,000 cycles). Their superior thermal conductivity enables faster cooling cycles, reducing part cycle times significantly. Aluminum’s machinability allows for complex geometries at lower CNC processing costs. However, its lower hardness (150-200 HB) makes it susceptible to wear with abrasive resins or high-cavity pressures, limiting longevity for demanding production runs. It is the strategic choice when speed-to-market and initial cost are paramount.

Tool steels dominate high-volume manufacturing. Pre-hardened steels like P20 (28-32 HRC) offer a balance of machinability, polishability, and durability for medium runs. For extended life (500,000+ cycles) with engineering plastics or corrosive resins, hardened steels are essential. H13 (48-52 HRC) provides exceptional toughness and thermal fatigue resistance for hot-runner systems and high-temperature polymers. Stainless steels like 420 or S136 are critical for medical or optical applications requiring superior corrosion resistance and mirror polishing. Steel’s higher initial machining cost is offset by vastly superior wear resistance and dimensional stability over millions of cycles.

Titanium alloys see limited but critical application in ultra-high-corrosion environments or specialized aerospace components where weight reduction in the mold base is beneficial. Its exceptional corrosion resistance surpasses stainless steel, but high cost and challenging machinability restrict its use to niche scenarios where no steel alternative suffices. It is generally not cost-effective for standard mold cavities and cores.

Material performance characteristics are summarized below for critical comparison:

| Material | Hardness Range | Thermal Conductivity (W/m·K) | Typical Applications | Cycle Life Expectancy |

|---|---|---|---|---|

| Aluminum 7075-T6 | 150-200 HB | 130-150 | Prototypes, low-volume production | < 100,000 cycles |

| P20 Steel | 28-32 HRC | 28-36 | Medium-volume production, general purpose | 100,000 – 500,000 cycles |

| H13 Steel | 48-52 HRC | 25-30 | High-temp resins, hot runners, high wear | 500,000 – 1,000,000+ cycles |

| 420/S136 Stainless | 48-52 HRC | 20-25 | Corrosive resins, medical, optical | 500,000 – 1,000,000+ cycles |

| Titanium Grade 5 | 36-41 HRC | 6-7 | Extreme corrosion, specialized aerospace | Highly variable |

Surface finishing, particularly anodizing for aluminum molds, is integral to material performance. Type II (Sulfuric Acid) anodizing provides basic corrosion resistance and dye acceptance for identification. For production molds, hardcoat Type III anodizing is essential, creating a dense, wear-resistant ceramic layer (50-100 µm thick) that significantly extends mold life in abrasive applications. Critical dimensional tolerances must be accounted for during anodizing due to the layer’s growth outward and inward from the base metal surface. Our precision CNC processes at Wuxi Lead incorporate these tolerances, ensuring final cavity dimensions meet specifications post-finishing. Selecting the right material-finishing combination, engineered with precision manufacturing, directly translates to reduced downtime, consistent part quality, and optimized ROI for your production line.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the plastic injection mold making process begins with a meticulous design phase that integrates engineering excellence with advanced simulation technology. Our team of senior mold designers collaborates closely with clients to interpret technical drawings, 3D CAD models, and functional requirements. Using Siemens NX, Autodesk Moldflow, and SolidWorks, we conduct comprehensive mold flow analysis to predict material behavior, optimize gate locations, and minimize warpage or sink marks. This phase ensures that every design is not only manufacturable but also optimized for long-term durability and performance. Tolerances are defined down to ±0.002 mm, and material selection—such as P20, 718H, or S136 stainless steel—is aligned with production volume, part geometry, and environmental exposure. The final design undergoes internal DFMEA (Design Failure Mode and Effects Analysis) review before release, guaranteeing compliance with ISO 9001:2015 standards.

Prototyping: Validating Performance Before Scale

Once the mold design is approved, we proceed to prototype tooling using high-speed CNC machining, precision EDM, and automated polishing techniques. Prototypes are produced in small batches—typically 50 to 100 shots—using the same materials and process parameters intended for mass production. This allows us to validate part fit, function, and surface finish under real-world conditions. All prototype parts undergo full dimensional inspection via coordinate measuring machines (CMM) and 3D scanning, with results compared against nominal CAD data. Any deviations trigger an immediate root cause analysis and corrective loop, involving mold adjustments or process recalibration. This stage is critical to achieving zero defects in final production, as it uncovers potential issues in ejection, venting, cooling, or shrinkage before full-scale launch.

Mass Production: Consistency at Scale

With prototype approval, we transition to high-volume manufacturing using multi-cavity molds and fully automated injection lines. Our production cells operate under strict process control, with real-time monitoring of temperature, pressure, and cycle time. Each mold is equipped with sensor-based mold protection systems and automatic part rejection mechanisms to prevent non-conforming output. In-process quality checks occur every two hours, supported by SPC (Statistical Process Control) data tracking. Final inspection includes first-article reporting (FAI), material certification, and packaging per customer specifications. Our production process is engineered for repeatability, ensuring every component meets the exact specifications of the initial design.

Key Mold Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Mold Base Materials | P20, 718H, NAK80, S136, H13 |

| Surface Finishes | SPI A1 (Polished), B1 (Textured), VDI 3400 |

| Mold Life Expectancy | 500,000 to 1,000,000 cycles |

| Lead Time (Design to Trial) | 4 to 8 weeks (depending on complexity) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC-controlled |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers plastic injection molds that achieve zero-defect performance across global automotive, medical, and consumer electronics applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Mold Excellence

In the demanding realm of plastic injection mold making, precision engineering is non-negotiable. Wuxi Lead Precision Machinery stands as your strategic collaborator for custom metal manufacturing, delivering molds that redefine performance and longevity. Our integrated facility in Wuxi, China, merges decades of metallurgical expertise with cutting-edge CNC technology, ensuring every component meets the exacting standards of global automotive, medical, and consumer electronics sectors. We do not merely fabricate molds; we engineer solutions that optimize cycle times, reduce scrap rates, and guarantee repeatable part quality under high-volume production.

Our technical capabilities are engineered to eliminate your production bottlenecks. From complex multi-cavity systems to micro-molding applications requiring micron-level accuracy, our processes are validated through rigorous in-house metrology. The table below details our core manufacturing specifications, reflecting the infrastructure that powers your success:

| Specification | Capability Range | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.002mm (core/cavity surfaces) | Critical for zero-defect part geometry |

| Machine Capacity | Up to 1,200T clamping force molds | Supports large automotive components |

| Materials Processed | P20, H13, S136, 420SS, Titanium alloys | Ensures wear resistance & corrosion protection |

| Lead Time (Complex) | 35-45 days (from CAD to T1 samples) | Accelerates time-to-market for new products |

| Surface Finishes | SPI A1 (optical grade) to textured | Meets stringent aesthetic requirements |

This technical rigor is embedded within a partnership framework designed for transparency and agility. We initiate every project with a collaborative design review, identifying potential manufacturability risks before steel is cut. Our engineering team works synchronously with your R&D department, providing DFM feedback that reduces iterations and costly revisions. Unlike transactional suppliers, we treat your project timelines as our own operational imperatives, with dedicated project managers providing weekly progress updates via secure client portals.

When you select Wuxi Lead Precision Machinery, you gain more than a vendor—you secure a technical extension of your own manufacturing division. Our zero-defect culture is certified under ISO 9001:2015, with every mold undergoing 100% CMM validation against your CAD data. We understand that mold failure translates directly to production line stoppages; therefore, our quality protocols exceed industry benchmarks to ensure dimensional stability across 500,000+ cycles.

The competitive edge in high-volume molding lies in precision you can replicate, shift after shift. Let us demonstrate how our engineering discipline transforms your mold specifications into production assets. Contact our technical sales team today to discuss your next project’s requirements. Submit your CAD files and tolerance stack-ups to [email protected] for a confidential capability assessment. We respond to all technical inquiries within 4 business hours—a commitment reflecting our respect for your development schedules. Partner with certainty. Partner with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.