Technical Contents

Engineering Guide: Plastic Injection Mold Brand

Engineering Insight: The Non-Negotiable Role of Precision in Plastic Injection Mold Brands

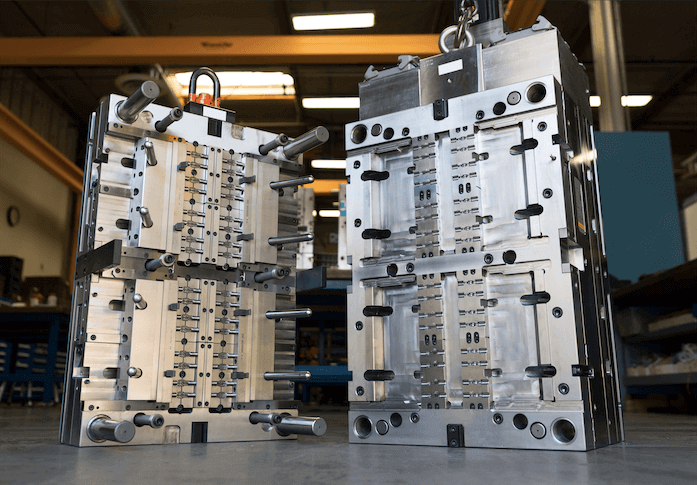

In high-stakes plastic injection molding, the mold brand is not merely a component—it is the foundational determinant of part integrity, production efficiency, and long-term profitability. Sub-micron deviations in mold geometry cascade into catastrophic part defects: flash, sink marks, or dimensional instability. For industries like aerospace, medical devices, or automotive, where tolerances are measured in thousandths of a millimeter, such failures trigger costly recalls, production halts, and reputational damage. Precision engineering transcends tooling accuracy; it encompasses thermal management, material science, and predictive lifecycle validation. A mold brand’s commitment to metrology-backed tolerances directly dictates a manufacturer’s ability to meet stringent regulatory standards and maintain competitive throughput.

Wuxi Lead Precision Machinery operates at this critical intersection of uncompromising precision and industrial reliability. Our CNC-engineered molds consistently achieve ±0.002mm tolerances—validated through ISO 17025-certified metrology labs—because we treat mold fabrication as mission-critical engineering, not commodity production. This discipline was rigorously proven in projects supporting Olympic-grade sporting equipment and defense logistics systems. For a Tier-1 military contractor, we delivered molds for composite armor components requiring zero-defect production under extreme thermal cycling. Similarly, molds for precision athletic gear endured validation at -40°C to 150°C without dimensional drift, ensuring athlete safety at international competitions. These engagements demanded adherence to MIL-STD-810G and ASTM F3125 Grade 8 specifications, where failure was never an option.

The table below outlines core precision metrics that distinguish elite mold brands from standard suppliers. These are not theoretical targets but validated outputs from our production floor:

| Specification Category | Lead Precision Standard | Industry Typical | Validation Method |

|---|---|---|---|

| Linear Tolerance (per ISO 2768) | ±0.002 mm | ±0.01 mm | CMM (ZEISS CONTURA) |

| Surface Roughness (Ra) | 0.05 µm | 0.8 µm | Profilometer (Mitutoyo SJ-410) |

| Thermal Stability (ΔT=100°C) | ≤ 0.005 mm distortion | ≤ 0.05 mm | Thermal Imaging + CMM |

| Steel Hardness Uniformity | ±1 HRC across cavity | ±3 HRC | Rockwell Tester (Qness 550) |

| Mold Life Cycle Validation | 1M+ cycles (documented) | 500k cycles | In-press fatigue testing |

This precision ecosystem—integrating Swiss CNC machining, aerospace-grade H13/420 stainless tool steels, and AI-driven deformation simulation—eliminates guesswork. We embed quality at the design phase through mold flow analysis calibrated to your polymer’s rheology, ensuring gate balance and cooling uniformity before metal is cut. The result is reduced scrap rates, accelerated ramp-up, and molds that perform identically at cycle 1 versus cycle 500,000.

For B2B manufacturers, selecting a mold brand is a strategic risk assessment. Partner with an engineer, not a vendor. At Wuxi Lead, our Olympic and defense pedigrees are not accolades—they are proof that our precision protocols deliver under the most unforgiving operational demands. Your production continuity depends on it.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing, delivering high-precision components for demanding applications in the plastic injection mold industry. Our technical capabilities are built around advanced machinery, expert engineering, and a rigorous quality assurance framework designed to meet the exacting standards of global OEMs and mold makers. Central to our production excellence is our investment in 5-axis CNC machining technology, which enables us to produce complex geometries with superior accuracy, surface finish, and repeatability.

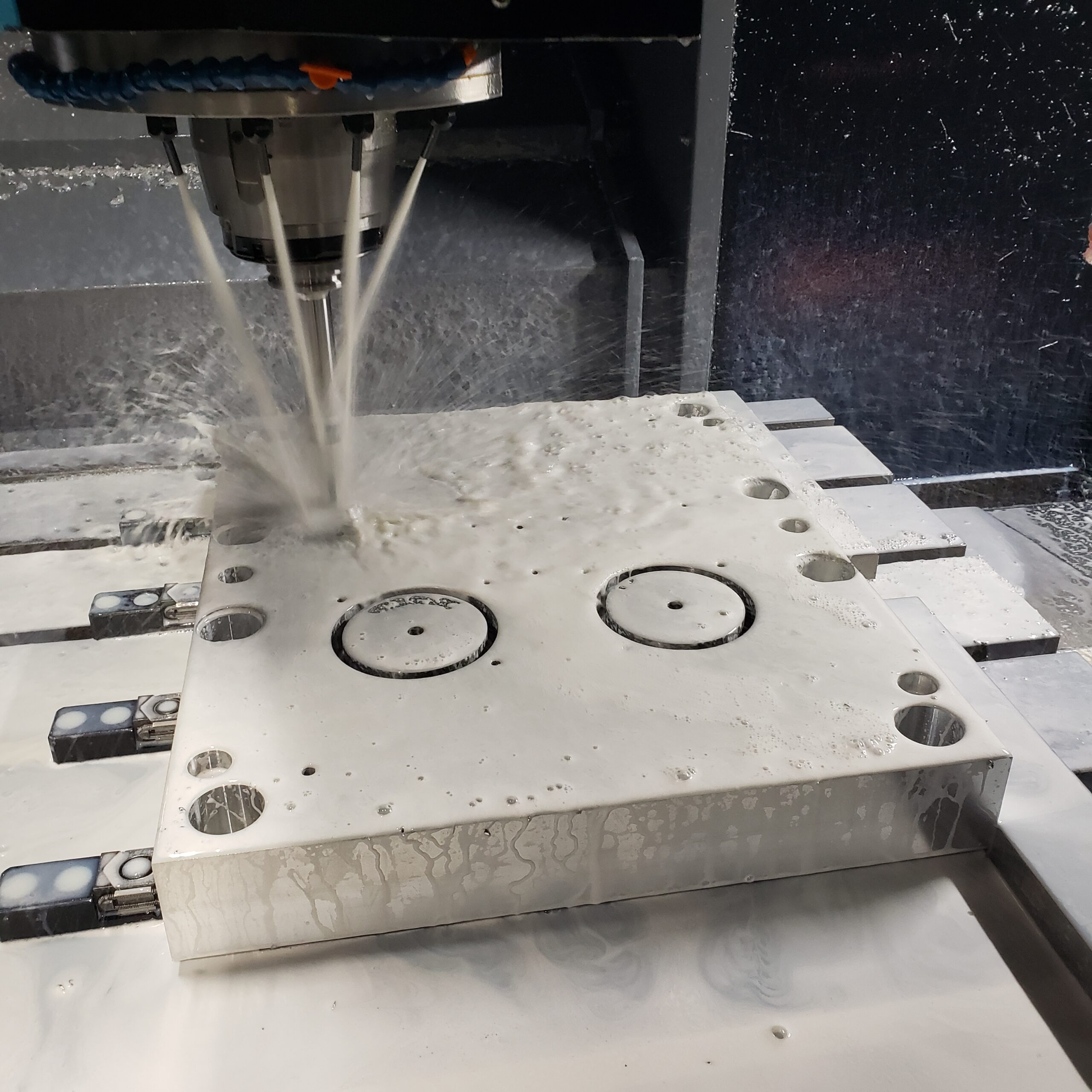

Our 5-axis CNC machining centers provide simultaneous multi-axis movement, allowing for intricate contouring and undercuts that are often required in mold cores, cavities, and inserts. This capability reduces the need for multiple setups, minimizing human error and improving dimensional consistency. With high-speed spindles and dynamic tool path optimization, we achieve tight tolerances and fine surface finishes critical to mold performance and longevity. Materials such as P20, 718H, S136, and other tool steels are machined with precision, ensuring optimal thermal stability and wear resistance in final mold applications.

Quality control is fully integrated into every stage of production. Our metrology lab is equipped with state-of-the-art Coordinate Measuring Machines (CMM) that perform comprehensive dimensional inspections using 3D scanning and tactile probing. Each component undergoes first-article inspection and in-process checks to verify compliance with design specifications. All inspection data is documented and traceable, supporting full audit readiness for regulated industries.

We maintain strict environmental controls in our machining and inspection areas to eliminate thermal distortion, ensuring measurement accuracy down to the micron level. Our team of certified metrologists and CNC programmers work in close collaboration to validate tool paths, optimize machining strategies, and confirm final part conformity.

The following table outlines the standard tolerances we consistently achieve across various machining and inspection parameters:

| Parameter | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 300 mm; ±0.01 mm for larger features |

| Positional Tolerance | ±0.008 mm | Critical for hole patterns and core alignment |

| Surface Roughness (Ra) | 0.2 – 0.8 µm | Achieved without secondary polishing in most cases |

| Flatness | 0.005 mm per 100 mm | Verified via CMM and optical flat measurement |

| Circular Runout | 0.003 mm | Typical for rotating mold components |

| Angular Accuracy | ±0.05° | For complex 5-axis features and undercuts |

| Repeatability (Batch) | ±0.003 mm | Confirmed through statistical process control |

Our technical capabilities are reinforced by a culture of continuous improvement and adherence to international standards. Wuxi Lead Precision Machinery is committed to delivering mold components that not only meet but exceed customer expectations in performance, precision, and reliability.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the optimal mold material is a critical strategic decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we emphasize that material choice must align precisely with your specific application requirements, production volume, resin characteristics, and budget constraints. Understanding the core properties and trade-offs between Aluminum, Steel, and Titanium is fundamental to achieving maximum mold performance and longevity.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for rapid prototyping, low-to-medium volume production, and applications demanding exceptional thermal conductivity. Their faster machining times reduce initial tooling costs and lead times substantially. Aluminum efficiently draws heat from the molded part, potentially shortening cycle times for thermally sensitive resins. However, aluminum’s lower hardness and wear resistance limit its suitability for abrasive filled materials or high-volume runs exceeding 100,000 cycles, where surface degradation becomes a concern.

Tool steels remain the dominant choice for high-volume, production-critical molds. P20 pre-hardened steel provides a robust balance of machinability, polishability, and moderate wear resistance for medium runs. For demanding applications involving abrasive fillers (glass, minerals), corrosive resins (PVC, flame retardants), or very high cycle counts exceeding 500,000 parts, hardened steels like H13, S7, or stainless variants (420SS, 17-4PH) are essential. These offer superior hardness, wear resistance, and thermal fatigue resistance, ensuring consistent part quality over millions of cycles despite the higher initial material and machining costs.

Titanium alloys represent a specialized solution for extreme conditions. Their exceptional strength-to-weight ratio, outstanding corrosion resistance against highly aggressive chemicals, and superior thermal stability make them suitable for niche applications like medical molding with harsh sterilization cycles or aerospace components requiring ultra-pure environments. The significantly higher material cost and complex machining requirements generally restrict titanium use to scenarios where its unique properties provide indispensable operational benefits that outweigh the investment.

Anodizing is a vital surface treatment primarily applied to aluminum molds. This electrochemical process creates a dense, hard, corrosion-resistant oxide layer integral to the base metal. Type II (sulfuric acid) anodizing enhances wear resistance and provides a base for dyeing, while harder Type III (hardcoat) anodizing significantly increases surface durability for moderate production runs. Anodizing improves release characteristics and protects against resin corrosion, extending the functional life of aluminum tooling.

Key Mold Material Properties Comparison

| Property | Aluminum (7075-T6) | P20 Steel | H13 Steel | Titanium (Ti-6Al-4V) |

|---|---|---|---|---|

| Typical Hardness | 150 HB | 28-32 HRC | 48-52 HRC | 36 HRC |

| Thermal Conductivity | Very High (130 W/mK) | Moderate (36 W/mK) | Moderate (34 W/mK) | Low (7 W/mK) |

| Corrosion Resistance | Moderate (Anodizing Essential) | Good (Stainless better) | Good | Excellent |

| Typical Mold Life | 10,000 – 100,000 cycles | 100,000 – 500,000 cycles | 500,000+ cycles | Highly Application Specific |

| Machinability | Excellent | Good | Moderate | Poor |

| Primary Use Case | Prototyping, Low/Med Volume | Medium Volume Production | High Volume, Abrasive/Corrosive Resins | Extreme Corrosion, Weight Critical |

Wuxi Lead Precision Machinery leverages decades of experience to guide clients through this complex selection process. Our engineering team collaborates closely with you to analyze resin properties, part geometry, volume requirements, and surface finish needs, ensuring the chosen material and any necessary surface treatments like anodizing deliver optimal performance and lifecycle value for your specific plastic injection molding application.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom plastic injection molds is engineered to deliver precision, consistency, and zero-defect performance. Rooted in advanced manufacturing principles and decades of industry expertise, we execute a seamless transition from concept to mass production, ensuring every component meets the highest global standards.

The process begins with Design, where our engineering team collaborates closely with clients to translate product requirements into detailed 3D CAD models. Utilizing industry-leading software such as UG, SolidWorks, and AutoCAD, we conduct comprehensive mold flow analysis, structural validation, and thermal simulation. This stage is critical for identifying potential defects such as warpage, sink marks, or air traps before physical production begins. Design for manufacturability (DFM) reviews are conducted to optimize part geometry, gate location, cooling channels, and ejection systems, ensuring long-term mold durability and part consistency.

Following design approval, we move into Prototyping. A functional prototype is produced using CNC machining, EDM, or rapid tooling techniques, depending on the complexity and material requirements. This phase allows for real-world testing of form, fit, and function. Prototypes undergo rigorous dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify tolerances within ±0.002 mm. Any necessary design refinements are implemented at this stage, minimizing risk during full-scale production. Materials used in prototyping match those intended for mass production, ensuring accurate performance evaluation.

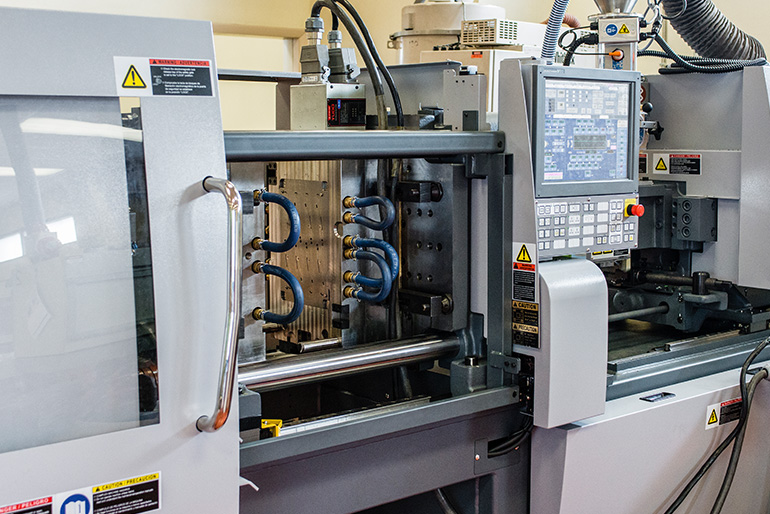

Once the prototype is validated, we initiate Mass Production using state-of-the-art CNC machining centers, high-precision EDM systems, and automated injection molding lines. Our facility is equipped with real-time monitoring systems that track critical parameters such as injection pressure, temperature, and cycle time. Every mold is subjected to a minimum of 50,000 test cycles before delivery to confirm reliability and wear resistance. Our quality management system complies with ISO 9001 standards, and each production batch undergoes 100% visual inspection and statistical process control (SPC) sampling.

Our commitment to Zero Defects is enforced through a closed-loop feedback system, where data from production is continuously analyzed to preempt deviations. This proactive approach ensures long-term repeatability, reduced downtime, and maximum return on investment for our clients.

The following table outlines key specifications of our production capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Mold Life | 500,000 to 1,000,000 cycles |

| Materials Supported | P20, 718, 2738, S136, H13, 420 Stainless, etc. |

| Maximum Mold Size | 1200 x 1000 x 800 mm |

| Surface Finishes | Polished, Textured, EDM, Mirror, SPI, VDI |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–50 days |

| Quality Standards | ISO 9001, SPC, FAI, PPAP |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery ensures every plastic injection mold delivers flawless performance across its operational lifecycle.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineering Precision for Demanding Mold Brands

In the high-stakes world of plastic injection molding, your mold brand’s reputation hinges on uncompromising precision and reliability. Sub-micron tolerances, complex geometries, and extended production lifecycles are non-negotiable. Generic manufacturers cannot consistently deliver the engineered excellence your clients demand. Wuxi Lead Precision Machinery bridges this gap, providing custom metal solutions engineered specifically for tier-one mold brands. We transform your most challenging designs into high-performance mold bases, cavities, cores, and precision components—backed by rigorous quality validation and deep industry expertise.

Our technical capabilities are built for the exacting standards of modern mold manufacturing. The table below details our core production specifications, reflecting investments in advanced CNC technology and metrology systems calibrated to international standards.

| Capability | Specification Range | Key Technology Used |

|---|---|---|

| Mold Base Fabrication | Up to 2000 x 1500 x 800 mm | 5-Axis Horizontal Machining Centers |

| Cavity/Core Precision | ±0.002 mm tolerance (critical surfaces) | High-Speed Machining (HSM) |

| Surface Finish | Ra 0.05 µm (mirror grade) | Electro-Discharge Machining (EDM) |

| Material Expertise | P20, 718H, S136, NAK80, Stainless Steels | Vacuum Hardening & Stress Relief |

| Quality Validation | Full CMM reporting, GD&T analysis | Zeiss CONTURA CMM Systems |

What differentiates Lead Precision is our engineer-led partnership model. We engage early in your design phase—not as a vendor, but as an extension of your technical team. Our CNC engineers analyze manufacturability, material behavior under cyclic stress, and thermal management requirements to preempt production failures. Every component undergoes multi-stage inspection: pre-machining material certification, in-process laser probing, and final validation against your 3D CAD models. This systematic approach eliminates costly rework and accelerates time-to-market for your mold projects.

With 15+ years serving global mold brands, we understand that precision isn’t optional—it’s foundational. Our ISO 9001-certified facility in Wuxi integrates lean manufacturing principles without sacrificing attention to detail. When your client demands a mold that runs 1 million cycles with zero drift, we deliver the metal foundation that makes it possible.

Your next mold project requires a partner who speaks the language of tolerances, not just timelines. Contact us today to discuss how Lead Precision can elevate your brand’s engineering credibility. Send your specifications to [email protected] for a technical consultation within 24 hours. Let’s build molds that outperform—reliably, repeatedly. Your reputation depends on it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.