Technical Contents

Engineering Guide: Plastic Injection Machine Parts

Engineering Insight: The Critical Role of Precision in Plastic Injection Machine Parts

In the realm of industrial manufacturing, plastic injection molding stands as one of the most efficient and scalable methods for producing high-volume, complex components. At the core of every high-performance injection molding system lies a suite of precision-engineered metal parts—components that must operate under extreme pressures, temperatures, and cyclic loads. The reliability, longevity, and output quality of an injection molding machine are directly tied to the dimensional accuracy, material integrity, and surface finish of these critical parts. Any deviation—even at the micron level—can result in part defects, machine downtime, or premature wear.

At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is a requirement. With over 15 years of experience in custom metal manufacturing, we specialize in producing mission-critical components for the plastic injection machine sector. Our engineering team applies advanced CNC machining, grinding, and surface treatment technologies to deliver parts that meet the strictest tolerances and performance standards. This expertise has been validated through our work with high-demand sectors, including defense and Olympic-grade equipment manufacturing, where failure is not an option.

Our involvement in military-grade projects has instilled a culture of zero-defect manufacturing, rigorous quality control, and traceable material accountability. Similarly, our contribution to equipment used in Olympic competitions required components that perform flawlessly under peak stress and tight operational windows. These experiences have directly informed our approach to producing injection machine components such as tie bars, screw tips, check rings, nozzle shut-off valves, and barrel liners—parts that demand repeatable accuracy and resistance to wear and corrosion.

Precision in these components translates directly into machine efficiency. For example, a tie bar manufactured within ±0.002 mm tolerance ensures even clamping force distribution, preventing mold misalignment and flash formation. Similarly, a screw tip with exact concentricity maintains consistent melt homogeneity, directly influencing the quality of the final plastic product. At Lead Precision, every component undergoes full dimensional inspection, hardness testing, and, where applicable, non-destructive testing to ensure compliance with international standards.

We combine deep metallurgical knowledge with state-of-the-art machining capabilities to serve global OEMs who demand reliability at scale. Our facility is equipped for both prototype development and high-volume production, with a supply chain optimized for fast turnaround without compromising quality.

Below are representative specifications for a commonly requested component:

| Specification | Detail |

|---|---|

| Component Type | Injection Screw Tip |

| Material | Nitrided 4140 Alloy Steel |

| Tolerance | ±0.002 mm |

| Hardness | 58–62 HRC |

| Surface Finish | Ra 0.4 µm |

| Process | CNC Turning, Grinding, Nitriding |

| Inspection | CMM, Roundness Tester, Hardness Tester |

Precision is not achieved by chance—it is engineered. At Wuxi Lead Precision Machinery, we bring military-grade discipline and Olympic-level performance to every component we manufacture, ensuring that your injection machines operate at peak efficiency, cycle after cycle.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Injection Molding Systems

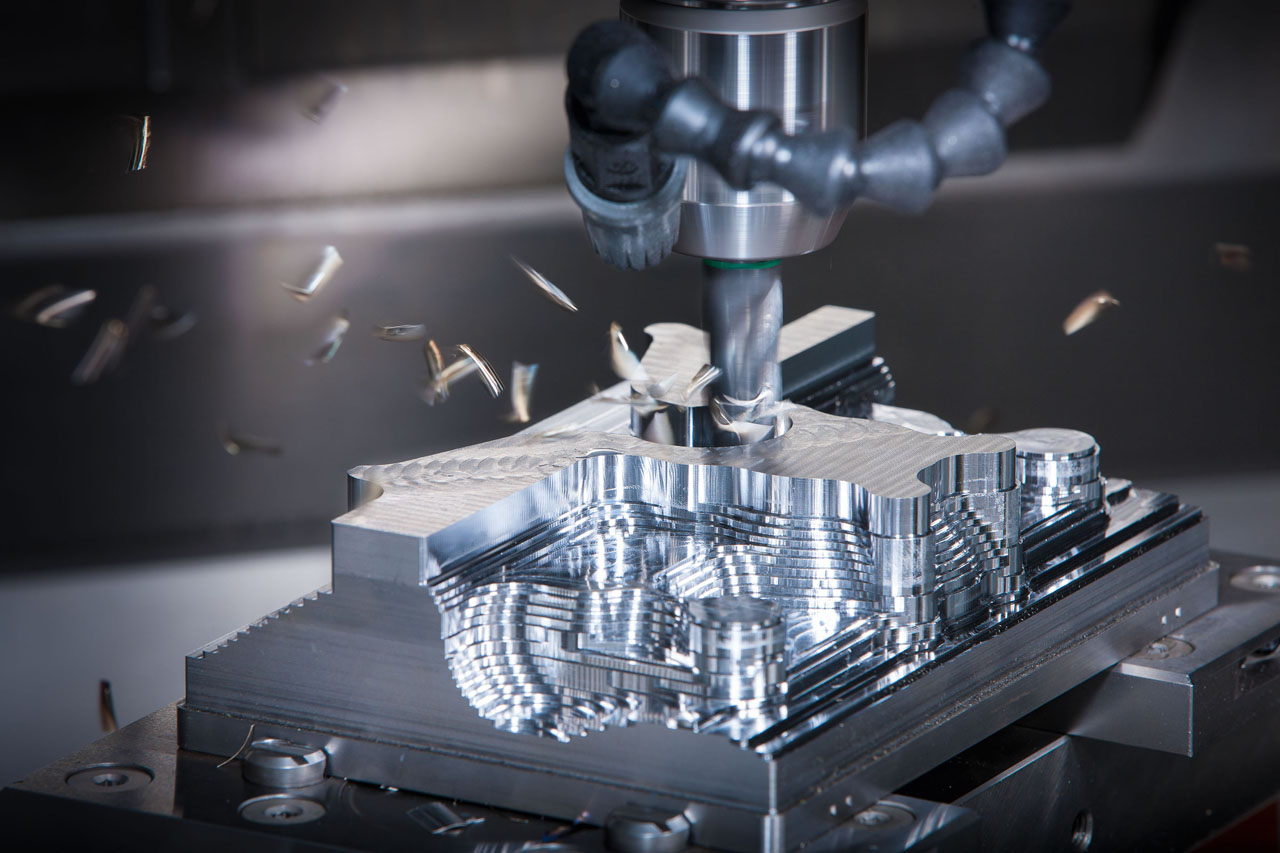

Wuxi Lead Precision Machinery delivers uncompromising accuracy for critical plastic injection machine components through advanced multi-axis CNC machining and rigorous quality validation. Our specialization in complex metal parts—such as manifolds, nozzles, tie bars, and mold cavity interfaces—ensures seamless integration into high-pressure molding environments where dimensional stability directly impacts part quality and machine uptime. Central to our process is a dedicated fleet of 5-axis CNC machining centers, enabling single-setup fabrication of geometrically intricate features. This eliminates cumulative error from multiple fixturing stages, critical for components requiring tight positional alignment across compound angles, such as hydraulic manifold sealing surfaces or cooling channel arrays within hot runner systems. Simultaneous 5-axis motion achieves undercuts, organic contours, and deep cavities without secondary operations, preserving micron-level consistency across all critical surfaces.

All production adheres to ISO 13083 standards for mold component manufacturing, with real-time process monitoring ensuring thermal stability and tool wear compensation. However, precision is only validated through systematic inspection. Every component undergoes comprehensive metrology via calibrated Coordinate Measuring Machines (CMM), programmed to ASME Y14.5-2018 GD&T standards. Our CMM protocols verify not only linear dimensions but also form tolerances—flatness, cylindricity, and profile—that dictate sealing integrity and wear resistance in dynamic molding applications. Data from each inspection is traceable to NIST-certified standards and integrated into our digital quality ledger, providing full transparency for customer audits.

The following table details achievable tolerance benchmarks for common injection machine part features, reflecting our standard production capability under controlled environmental conditions. Actual tolerances may be refined based on specific material properties and geometric complexity.

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Linear Dimensions (Critical) | ±0.005 mm | CMM (Volumetric Compensation) |

| Hole Diameter (Sealing) | H6 / -0.006 mm | Air Gaging / CMM |

| Flatness (Mating Surfaces) | ≤ 0.003 mm | CMM / Optical Flat |

| True Position (Holes) | ≤ 0.010 mm | CMM (GD&T Analysis) |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | Profilometer |

| Angular Features | ±0.001° | CMM / Sine Bar |

Material selection is optimized for performance demands, with common substrates including H13 tool steel (hardened to 48-52 HRC), P20 pre-hardened steel, and corrosion-resistant stainless alloys like 17-4PH. Post-machining treatments—including stress relieving, vacuum hardening, and precision grinding—are executed in-house to maintain dimensional integrity. This integrated approach ensures components withstand cyclic thermal loads and abrasive polymer flows while maintaining micron-level repeatability over extended production cycles. For mission-critical applications, we implement first-article inspection reports (FAIR) and PPAP documentation, providing engineering validation that directly supports your machine reliability and end-part consistency.

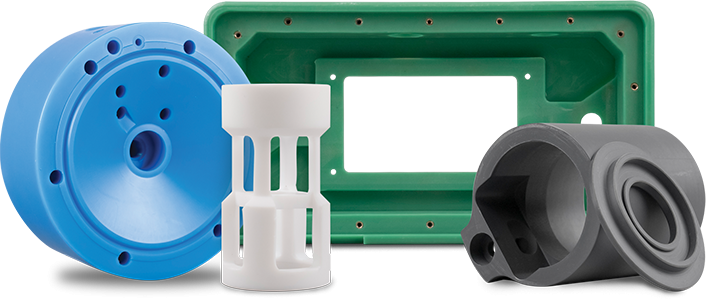

Material & Finish Options

Material selection is a critical determinant in the performance, longevity, and cost-efficiency of plastic injection machine components. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal parts tailored to the demanding operational conditions of modern injection molding systems. The choice between aluminum, steel, and titanium depends on factors such as mechanical load, thermal exposure, wear resistance, and production volume. Each material offers distinct advantages, and pairing the right alloy with an appropriate surface finish—such as anodizing—further enhances functional reliability.

Aluminum is widely used for mold bases, inserts, and support structures due to its excellent strength-to-weight ratio and thermal conductivity. It enables faster cooling cycles, improving production throughput. 6061-T6 and 7075-T6 are preferred grades for their machinability and structural integrity. While aluminum is less wear-resistant than steel, it is ideal for prototyping and low- to medium-volume production runs. When combined with hard anodizing, aluminum components achieve significantly improved surface hardness and corrosion resistance, extending service life in humid or chemically aggressive environments.

Steel remains the standard for high-volume, high-precision mold cores, cavities, and ejector components. Tool steels such as P20, H13, and S136 offer superior hardness, abrasion resistance, and thermal stability. These alloys maintain dimensional accuracy under repeated thermal cycling and high injection pressures. Stainless variants like 420SS and S136 are particularly suited for applications requiring corrosion resistance, such as molds processing PVC or other corrosive resins. While heavier and more costly to machine than aluminum, steel’s durability ensures long-term return on investment in mass production settings.

Titanium, though less common due to its high cost, is selected for specialized components requiring extreme strength, minimal weight, and outstanding corrosion resistance. Grade 5 (Ti-6Al-4V) is frequently used in high-performance ejector pins, guide columns, and wear plates where fatigue resistance and non-magnetic properties are essential. Titanium’s low thermal conductivity can be a limitation in thermal cycling applications, but its performance in aggressive chemical environments and high-stress conditions makes it indispensable in niche industrial applications.

Anodizing is a key surface treatment for aluminum parts, forming a durable, insulating oxide layer that resists wear and corrosion. Hard anodizing (Type III) can achieve surface hardness up to 60 HRC, rivaling some steels. This finish also allows for color coding and improved lubricity, beneficial in dynamic mold components.

Below is a comparative overview of key material properties for plastic injection machine parts:

| Material | Typical Grades | Tensile Strength (MPa) | Hardness (HRC) | Key Advantages | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 15–30 | Lightweight, high thermal conductivity | Mold bases, prototypes, inserts |

| Steel | P20, H13, S136 | 900–1300 | 28–52 | High wear resistance, durability | Cores, cavities, ejector systems |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1000 | 35–40 | High strength-to-weight, corrosion resistant | Guide pins, wear plates, fasteners |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on application demands, lifecycle requirements, and cost targets. Our engineering team ensures every component meets the highest standards of precision and reliability in injection molding environments.

Manufacturing Process & QC

Production Process: Achieving Zero Defects in Plastic Injection Machine Components

At Wuxi Lead Precision Machinery, our commitment to Zero Defects begins with a rigorously defined production process for custom plastic injection machine parts. This methodology, honed over years serving global OEMs, ensures unparalleled precision and reliability from initial concept to final shipment. We integrate advanced engineering controls at every stage, eliminating variability and guaranteeing components meet the exacting demands of high-speed, high-pressure molding environments.

Design Phase

The foundation is meticulous engineering design. Our team collaborates closely with client specifications, utilizing 3D CAD software with embedded GD&T standards to define critical geometries and functional interfaces. Finite Element Analysis (FEA) is mandatory for structural components like tie bars, platens, and ejector systems, simulating real-world thermal and mechanical stresses. This phase identifies potential failure points early, ensuring manufacturability and performance validation before any material is cut. Tolerances are defined to ISO 2768-mK or tighter, specifically aligned with the dynamic requirements of injection molding machinery.

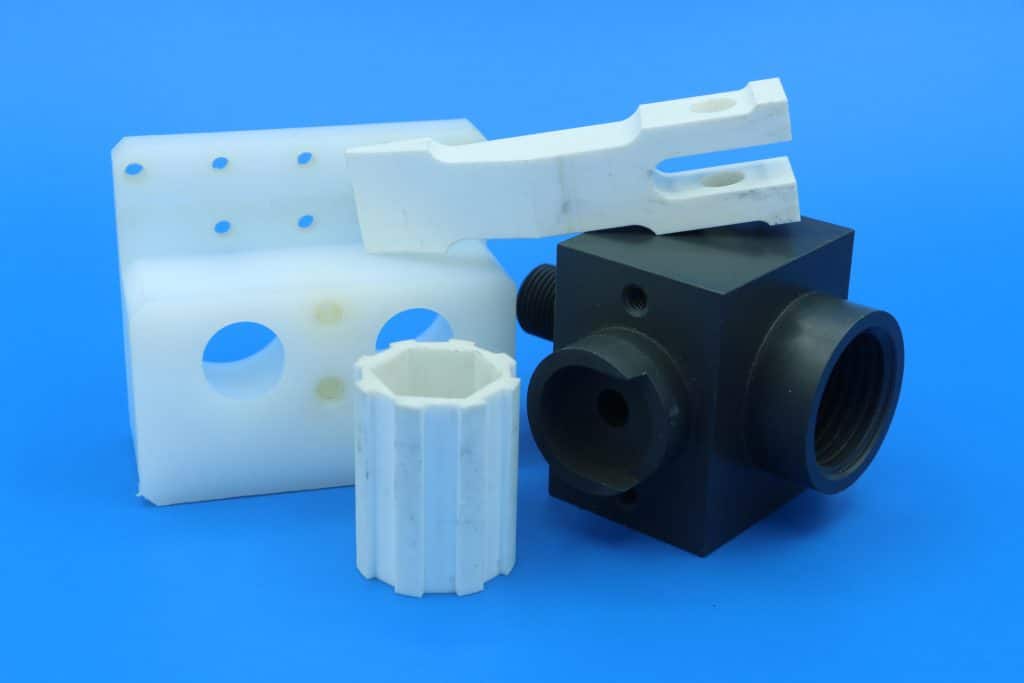

Prototyping Phase

Rapid, high-fidelity prototyping is non-negotiable for Zero Defects validation. We employ multi-axis CNC machining centers (5-axis milling, turning-milling) to produce functional prototypes from the exact grade of tool steel, stainless steel, or specialty alloy specified for mass production. Each prototype undergoes comprehensive metrology: CMM inspection against nominal CAD data, surface roughness verification, and non-destructive testing (NDT) where applicable. Crucially, prototypes are subjected to client-specific functional testing within actual machine sub-assemblies. This step confirms dimensional integrity, material behavior under load, and seamless integration, providing irrefutable evidence of design correctness before committing to tooling.

Mass Production Phase

Transitioning to volume production, Zero Defects is maintained through statistical process control (SPC) and embedded quality gates. Each machining cell operates under documented work instructions derived from validated prototypes. In-process inspections occur at critical control points: raw material certification, pre-machining geometry, post-heat treatment distortion analysis, and final dimensional verification. Our closed-loop SPC system continuously monitors key parameters like tool wear and thermal drift, automatically triggering adjustments to maintain conformance. Every finished component undergoes 100% critical dimension inspection using calibrated optical comparators and CMMs, with full traceability from raw material heat number to final shipping documentation.

The following table details the core precision specifications consistently achieved across our mass production runs for critical plastic injection machine components:

| Parameter | Typical Specification | Measurement Method | Control Limit (±) |

|---|---|---|---|

| Geometric Tolerance | ISO 2768-mK / ISO 1302 | CMM, Optical Comparator | 0.005 mm |

| Surface Roughness | Ra 0.4 – 0.8 µm | Profilometer | Ra 0.1 µm |

| Dimensional Accuracy | Critical Features | CMM (Calibrated to ISO 17025) | 0.002 mm |

| Material Hardness | As per ASTM E18 | Rockwell/Brinell Tester | Within Spec Range |

| Flatness (Platens) | ≤ 0.02 mm/m² | Laser Interferometer | 0.005 mm |

This disciplined, closed-loop process—where design integrity is proven in prototyping and relentlessly controlled in manufacturing—ensures Wuxi Lead delivers plastic injection machine parts that perform flawlessly, cycle after cycle, eliminating costly downtime for our partners. Zero Defects is not an aspiration; it is our engineered reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Plastic Injection Machine Components

At Wuxi Lead Precision Machinery, we understand that the performance and reliability of plastic injection molding machines depend directly on the precision and durability of their core components. As a leading custom metal manufacturing partner based in China, we specialize in delivering high-tolerance, engineered-to-last parts tailored to the demanding requirements of modern injection molding systems. When you choose to collaborate with us, you’re not just sourcing components—you’re gaining a strategic manufacturing ally committed to quality, innovation, and on-time delivery.

Our advanced CNC machining centers, supported by a team of seasoned engineers and metallurgy experts, enable us to produce complex machine elements such as tie bars, toggle pins, ejector plates, barrel housings, and nozzle tips with micron-level accuracy. Every part is manufactured using premium-grade materials, including hardened alloy steels, stainless steels, and wear-resistant tool steels, ensuring exceptional resistance to fatigue, corrosion, and thermal stress. We adhere strictly to international quality standards, including ISO 9001:2015, and implement comprehensive in-process inspections and final QA testing to guarantee conformity and performance.

What sets Wuxi Lead Precision Machinery apart is our end-to-end engineering approach. We work closely with OEMs and system integrators from the design phase through to production, offering DFM analysis, material optimization, and rapid prototyping to accelerate time-to-market. Whether you require a single prototype or high-volume production runs, our scalable manufacturing infrastructure ensures consistent quality and cost-efficiency across all order sizes.

We serve clients across North America, Europe, and Southeast Asia, supporting industries ranging from automotive and medical device manufacturing to consumer electronics and industrial automation. Our commitment to technical excellence and customer satisfaction has made us a trusted supplier to tier-one machinery builders who demand nothing less than perfection.

Below are key specifications that define our manufacturing capabilities for plastic injection machine components:

| Specification | Capability |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 800 mm |

| Tolerance Control | ±0.005 mm |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (precision grinding) |

| Materials Processed | 42CrMo, P20, H13, 40Cr, SS304/316, Tool Steel, Aluminum Alloys |

| Heat Treatment | Quenching & Tempering, Nitriding, Induction Hardening |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports (FAIR) |

| Lead Times | 15–25 days (production), expedited options available |

Partnering with Wuxi Lead Precision Machinery means securing a supplier who combines technical depth with responsive service. We are fully equipped to handle OEM confidential designs and provide full traceability, documentation, and post-delivery support.

For engineering inquiries or to request a quote, contact us today at [email protected]. Let us help you build injection machine systems that lead in performance, precision, and reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.