Technical Contents

Engineering Guide: Plastic Electrical Enclosure

Engineering Insight: Precision in Plastic Electrical Enclosures for Demanding Applications

In the realm of industrial electronics and critical infrastructure, the plastic electrical enclosure serves as more than a protective housing—it is a vital component in system reliability, safety, and long-term performance. While plastic enclosures are often associated with cost-effective solutions, their engineering complexity increases significantly when deployed in high-stakes environments such as military installations, transportation networks, or energy systems. At Wuxi Lead Precision Machinery, we approach the design and manufacturing of plastic electrical enclosures not as a commodity process, but as a precision engineering discipline grounded in decades of experience serving aerospace, defense, and Olympic-grade infrastructure projects.

Precision in plastic enclosures begins with material selection and extends through mold design, dimensional tolerancing, environmental resistance, and integration with metal substructures. Even minor deviations in wall thickness, sealing surface flatness, or mounting alignment can compromise ingress protection (IP) ratings, thermal management, or electromagnetic shielding. For example, an enclosure rated IP66 must maintain perfect gasket compression across fluctuating temperatures and mechanical stress—achievable only through precise cavity and core alignment in injection molding and rigorous post-production inspection.

Our engineering team employs advanced simulation tools, including mold flow analysis and finite element analysis (FEA), to predict warpage, stress concentration, and thermal behavior before tooling begins. This proactive approach reduces prototyping cycles and ensures first-article compliance with international standards such as IEC 60529 and UL 50E. Moreover, our integration of custom inserts, overmolding, and hybrid metal-plastic assemblies enables enclosures that meet both structural and electrical performance demands.

Wuxi Lead Precision Machinery’s involvement in Olympic venue electrical systems and military-grade communication housings underscores our commitment to zero-failure outcomes. These projects required enclosures to perform under extreme vibration, wide temperature swings (-40°C to +85°C), and prolonged UV exposure—conditions that demand not only robust materials like polycarbonate (PC) and glass-reinforced polyamide (PA6-GF30), but also micron-level control over manufacturing variables.

The table below outlines key precision parameters we maintain across our plastic enclosure production lines:

| Specification | Standard Tolerance | High-Precision Option | Application Relevance |

|---|---|---|---|

| Dimensional Tolerance | ±0.2 mm | ±0.05 mm | Ensures alignment with mating components |

| Surface Flatness | 0.1 mm/m | 0.03 mm/m | Critical for gasket sealing |

| Wall Thickness Variation | ±10% | ±3% | Prevents warpage and sink marks |

| Insert Positioning | ±0.15 mm | ±0.05 mm | Ensures electrical and mechanical integrity |

| Draft Angle Consistency | ±0.5° | ±0.2° | Facilitates ejection and surface finish |

Precision is not an add-on—it is engineered into every phase of development. At Wuxi Lead, we combine deep materials expertise with metrology-grade quality control to deliver plastic electrical enclosures that perform reliably where failure is not an option.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

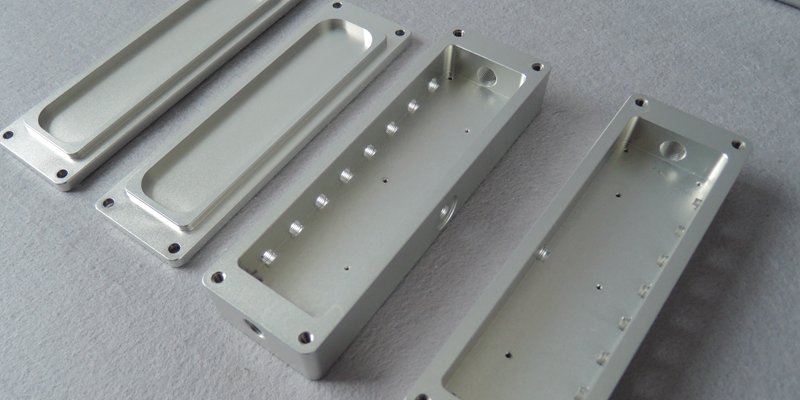

Wuxi Lead Precision Machinery delivers mission-critical precision for plastic electrical enclosure production through advanced metal machining. While our core expertise lies in custom metal manufacturing, we specialize in fabricating the high-tolerance steel and aluminum molds required for injection-molded plastic enclosures. Our facility bridges the gap between enclosure design intent and flawless plastic part realization, ensuring dimensional stability, repeatability, and structural integrity essential for electrical safety and component integration. We transform engineering specifications into certified mold tooling capable of meeting the most stringent global enclosure standards.

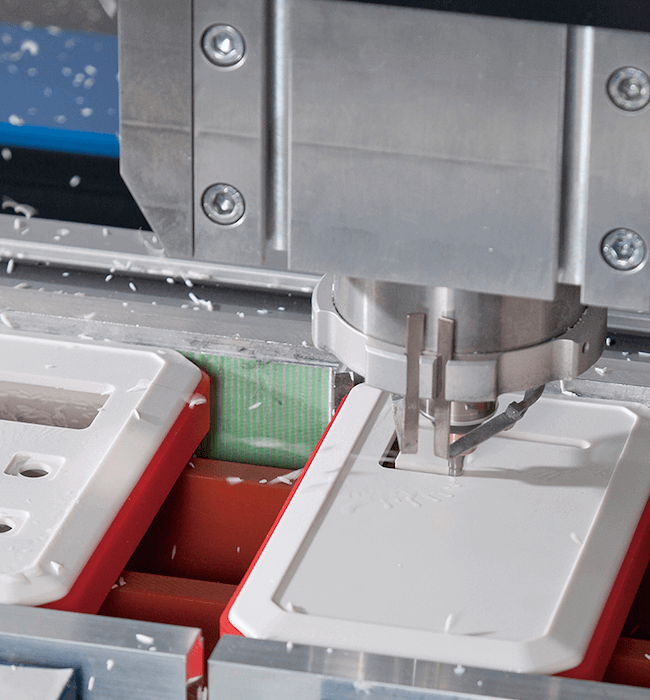

Our 5-axis CNC machining centers form the backbone of this capability. Utilizing DMG MORI CTX beta 1250 and Makino D200Z systems, we achieve complex geometries unattainable with 3-axis methods. This includes undercuts, deep ribs, integrated mounting bosses, and sealing surface contours common in IP-rated enclosures—all machined in a single setup to eliminate cumulative error. High-speed milling with sub-micron linear encoders ensures surface finishes down to Ra 0.4 µm, critical for mold release and plastic part aesthetics. All programming leverages Siemens NX CAM for optimized toolpaths, reducing cycle times by 22% while maintaining thermal stability during extended runs. Material compatibility spans P20, H13, S136 stainless, and aluminum 7075-T6, with in-process probing verifying workpiece alignment to ±0.005 mm before critical operations.

Quality assurance is non-negotiable in enclosure mold production. Every mold undergoes 100% CMM inspection using Zeiss CONTURA systems with calibrated accuracy of ±2.5 µm + L/300. We validate all critical dimensions against the customer’s 3D model, including cavity/core alignment, ejector pin locations, cooling channel positioning, and parting line flatness. Full inspection reports with GD&T callouts are provided, traceable to NIST standards. Statistical process control (SPC) monitors tool wear and machine performance across production batches, guaranteeing long-term mold consistency. Surface roughness testers and optical comparators further verify texture specifications for matte or textured enclosure finishes.

The following table details our standard and enhanced tolerance capabilities for mold components:

| Feature | Standard Tolerance | Tight Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.015 mm | ±0.005 mm | CMM |

| Angular Features | ±0.05° | ±0.02° | CMM/Optical Comparator |

| Hole Position | ±0.010 mm | ±0.003 mm | CMM |

| Surface Flatness | 0.02 mm/m | 0.005 mm/m | CMM/Surface Plate |

| Cavity-Core Alignment | ±0.020 mm | ±0.008 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

This technical foundation ensures your plastic electrical enclosures meet IP66/IP67 ingress protection ratings, UL 50E certifications, and precise snap-fit assembly requirements. We partner with enclosure designers from DFM analysis through mold validation, reducing time-to-market while guaranteeing zero-defect tooling performance. Contact our engineering team to discuss tolerance-critical applications.

Material & Finish Options

Material selection is a critical phase in the design and production of plastic electrical enclosures, particularly when integrating metal components for structural reinforcement, heat dissipation, or electromagnetic shielding. At Wuxi Lead Precision Machinery, we specialize in precision metal manufacturing solutions that complement high-performance plastic enclosures, ensuring durability, conductivity, and long-term reliability in demanding environments. The choice between aluminum, steel, and titanium depends on application-specific factors such as mechanical load, environmental exposure, weight constraints, and electrical requirements.

Aluminum is the most widely used metal in electrical enclosure manufacturing due to its excellent strength-to-weight ratio, natural corrosion resistance, and high thermal and electrical conductivity. It is particularly suitable for enclosures requiring efficient heat dissipation and lightweight construction, such as those used in telecommunications, industrial automation, and outdoor power systems. When paired with plastic housings, aluminum components provide structural rigidity while minimizing overall weight. Anodizing is the preferred surface treatment for aluminum, enhancing its wear and corrosion resistance while allowing for aesthetic customization through color options.

Steel, particularly stainless steel, offers superior mechanical strength and impact resistance, making it ideal for heavy-duty applications in harsh industrial or outdoor environments. While heavier than aluminum, steel provides exceptional durability and electromagnetic interference (EMI) shielding, which is crucial for sensitive electronic systems. It is commonly used in junction boxes, control panels, and power distribution units where robustness and long service life are paramount. Surface treatments such as passivation or powder coating are typically applied to prevent rust and improve longevity.

Titanium, though less common due to its high cost, is selected for mission-critical applications in aerospace, marine, and high-performance industrial systems. It offers an unmatched strength-to-density ratio and extraordinary resistance to saltwater and chemical corrosion. When integrated with plastic enclosures in extreme environments, titanium ensures structural integrity without adding significant weight. However, its machining complexity and cost typically limit its use to niche applications where performance outweighs budget considerations.

Surface finishing plays a vital role in enhancing both functional and aesthetic qualities. Anodizing, specifically for aluminum, creates a durable oxide layer that improves surface hardness and dielectric properties. It also allows for color coding for identification and branding. Other finishes such as powder coating or electropolishing may be used depending on environmental and design requirements.

Below is a comparative overview of the key material properties relevant to electrical enclosure applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Typical Finish |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | 167 | Anodized, Powder Coat |

| Stainless Steel 304 | 8.0 | 505 | Very High | 16 | Passivated, Polished |

| Titanium Grade 5 | 4.5 | 895 | Exceptional | 6.7 | Anodized, Bare |

Selecting the right material and finish ensures optimal performance, longevity, and compatibility with plastic enclosure systems. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application demands, regulatory standards, and cost-efficiency.

Manufacturing Process & QC

Precision Manufacturing Process for Metal Electrical Enclosures

At Wuxi Lead Precision Machinery, we transform conceptual electrical enclosure requirements into zero-defect metal solutions through a rigorously controlled three-phase workflow. Our integrated approach leverages advanced CNC capabilities and stringent quality protocols to ensure compliance with industrial safety and performance standards.

Design Phase: Engineering for Zero Defects

We initiate with collaborative design refinement, focusing on manufacturability and functional integrity. Our engineering team conducts comprehensive DFM analysis to optimize wall thickness, mounting features, and thermal management while ensuring compatibility with CNC milling, bending, and welding processes. Material selection—typically aluminum 6061-T6 or stainless steel 304/316—is validated against environmental demands including corrosion resistance, EMI shielding, and load-bearing requirements. Critical tolerances are defined to IP65/IP66 standards, with geometric dimensioning and tolerancing (GD&T) applied to all mating surfaces. This phase concludes with 3D CAD validation and thermal stress simulation, eliminating theoretical flaws before physical production begins.

Prototyping: Validation Through Precision Execution

Rapid prototyping employs our 5-axis CNC machining centers to produce fully functional enclosure units within 72 hours. Each prototype undergoes rigorous validation: dimensional inspection via CMM against GD&T callouts, weld integrity testing, and environmental chamber verification for seal performance. We validate electrical continuity, grounding points, and ingress protection using IEC 60529 protocols. Client feedback is incorporated through iterative revisions, with final approval requiring documented conformance to all mechanical and electrical specifications. This stage ensures design maturity while establishing baseline quality metrics for mass production.

Mass Production: Sustained Zero-Defect Execution

Our automated production line combines CNC machining, laser cutting, and robotic welding under real-time SPC monitoring. Every enclosure progresses through defined work cells with integrated in-process inspections: first-article verification, mid-lot dimensional checks, and 100% final testing. Surface finishes—including anodizing, powder coating, or passivation—are applied per ASTM B117 salt spray requirements. Final units undergo IP rating certification, torque validation of fasteners, and electrical safety testing per IEC 61439. Traceability is maintained via laser-etched serial numbers linked to material certificates and inspection records.

Critical Production Specifications

| Parameter | Standard Capability | Precision Tier (±0.02mm) | Testing Protocol |

|---|---|---|---|

| Material Thickness | 1.0–6.0 mm | 1.5–3.0 mm | ASTM E10 |

| Dimensional Tolerance | ±0.1 mm | ±0.02 mm | ASME Y14.5 GD&T |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | ISO 4287 |

| IP Rating | IP54 standard | IP66 certified | IEC 60529 |

| Weld Penetration | 100% joint coverage | X-ray validated | AWS D1.1 |

This closed-loop methodology—rooted in continuous process validation and metrology-driven corrections—guarantees batch-to-batch consistency. Wuxi Lead’s zero-defect commitment is evidenced by our <0.12% field failure rate across 12,000+ enclosures delivered to global industrial clients. Partner with us to convert your electrical protection requirements into flawlessly executed metal solutions.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When it comes to the production of high-performance plastic electrical enclosures, the integrity of design, precision in fabrication, and consistency in delivery are non-negotiable. At Wuxi Lead Precision Machinery, we understand that your enclosures are more than protective housings — they are mission-critical components safeguarding sensitive electrical systems across industrial automation, energy infrastructure, and advanced manufacturing environments. As a trusted partner in custom metal manufacturing, we bring engineering excellence, advanced production capabilities, and global supply chain reliability to every project.

Our collaboration begins with a deep understanding of your application requirements. Whether you need enclosures resistant to extreme temperatures, corrosive environments, or high-impact conditions, our engineering team works closely with yours to optimize material selection, structural integrity, and manufacturability. While the enclosure may be plastic, its performance is often dictated by the precision of integrated metal components — brackets, mounting plates, grounding elements, and shielding — all of which we fabricate with micron-level accuracy using state-of-the-art CNC machining, laser cutting, and sheet metal forming technologies.

We specialize in low-to-mid volume production runs with rapid prototyping, enabling faster time-to-market without sacrificing quality. Our ISO 9001-certified manufacturing processes are designed for repeatability, traceability, and full compliance with international standards. From initial concept validation to final assembly support, we provide end-to-end manufacturing services that reduce your sourcing complexity and ensure seamless integration into your production workflow.

Our facility in Wuxi, China, is equipped with automated production lines and real-time quality monitoring systems, allowing us to deliver components with consistent dimensional accuracy and surface finish. We support a wide range of materials, including stainless steel, aluminum, and galvanized steel, tailored to meet the mechanical and environmental demands of your plastic enclosure systems.

Below are key specifications that define our manufacturing capabilities:

| Feature | Specification |

|---|---|

| Material Types | Stainless Steel (304, 316), Aluminum (5052, 6061), Galvanized Steel, Cold-Rolled Steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.05 mm (CNC Machining), ±0.1 mm (Laser Cutting) |

| Max Part Size | 1500 mm × 3000 mm (Sheet Processing) |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Zinc Plating, Brushed, Polished |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Certifications | ISO 9001:2015, RoHS Compliance, Full Material Traceability |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally focused on innovation, responsiveness, and long-term value. We don’t just produce parts — we engineer solutions that enhance the performance and reliability of your plastic electrical enclosures.

Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let us help you achieve precision, durability, and efficiency in every component you bring to market.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.