Technical Contents

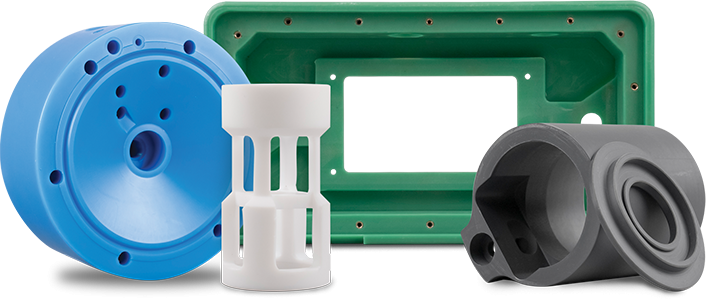

Engineering Guide: Plastic Cnc Milling

Engineering Insight Plastic CNC Milling

Precision in plastic CNC milling transcends mere dimensional accuracy; it is the foundational requirement for functional integrity, assembly reliability, and long-term performance of critical components. Unlike metals, engineering plastics exhibit significant thermal expansion coefficients, inherent material variability, and susceptibility to stress-induced warpage. Minute deviations during machining—often measured in microns—can trigger catastrophic part failure in demanding applications like medical devices, aerospace interiors, or semiconductor handling systems. Achieving true precision demands a deep understanding of polymer behavior under cutting forces and thermal loads. Material selection dictates specific strategies; machining ultra-high-molecular-weight polyethylene requires radically different toolpaths and feeds compared to rigid polycarbonate or thermally sensitive PEEK. Controlling chip evacuation is paramount to prevent re-melting or surface degradation, while minimizing clamping forces avoids distortion that manifests only after part release. Thermal management throughout the process—from spindle cooling to ambient workshop stability—is non-negotiable for holding tight tolerances consistently. Neglecting these factors results in scrapped batches, costly assembly delays, and compromised product lifespans, directly impacting a manufacturer’s bottom line and reputation.

Wuxi Lead Precision Machinery leverages over 15 years of specialized expertise in high-tolerance plastic machining to overcome these inherent challenges. Our engineering protocols are forged through rigorous production for sectors where failure is unacceptable. We routinely manufacture critical components for Olympic timing systems demanding micron-level repeatability under dynamic conditions and supply mission-essential polymer parts for military communication and avionics platforms requiring absolute reliability in extreme environments. This experience translates into proven methodologies for material-specific parameter optimization, advanced fixturing that eliminates distortion, and in-process metrology ensuring conformance at every stage. Our commitment extends beyond the machine tool; we partner with clients during design for manufacturability (DFM) reviews to preempt potential plastic-specific issues before cutting begins.

The table below outlines critical precision parameters we consistently achieve across common engineering plastics, reflecting our process capability:

| Material Category | Typical Tolerance Range | Surface Roughness (Ra) | Max Feature Complexity | Critical Process Focus |

|---|---|---|---|---|

| Rigid Thermoplastics (PC, ABS, PMMA) | ±0.025 mm | 0.8 – 1.6 µm | High (thin walls, undercuts) | Chip control, thermal stability |

| High-Performance (PEEK, PEI, PPS) | ±0.015 mm | 0.4 – 0.8 µm | Very High (precision bores, seals) | Tool wear monitoring, minimal stress |

| Soft/Slippery (UHMWPE, PTFE) | ±0.050 mm | 1.6 – 3.2 µm | Medium (bearing surfaces) | Non-marring fixturing, chip evacuation |

True precision in plastic CNC milling is a holistic discipline integrating material science, adaptive machining strategies, and unwavering process control. At Wuxi Lead Precision Machinery, our Olympic and military-grade production heritage provides the rigorous framework necessary to transform complex plastic designs into flawless, high-performance components. We deliver not just parts, but guaranteed dimensional stability and functional reliability, ensuring your end products meet the highest standards of quality and performance. Partner with us to mitigate plastic-specific risks and achieve manufacturing excellence.

Precision Specs & Tolerances

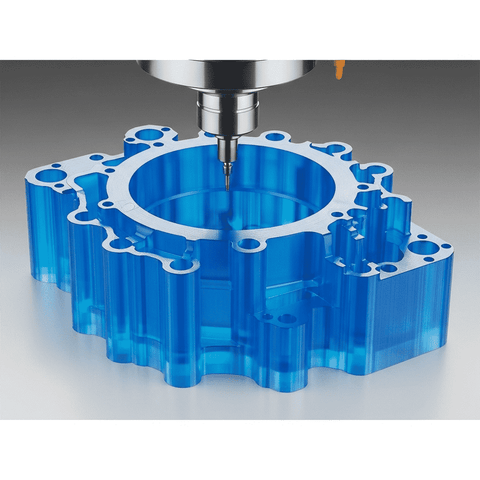

Wuxi Lead Precision Machinery delivers advanced plastic CNC milling solutions tailored for industries requiring uncompromising precision and repeatability. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional surface finish and dimensional accuracy. These multi-axis systems allow for simultaneous movement across five axes, minimizing setup changes and ensuring superior part consistency—critical when machining high-performance engineering plastics used in aerospace, medical, and semiconductor applications.

Our 5-axis CNC platforms are optimized for the unique thermal and mechanical properties of plastic materials. Unlike metals, plastics exhibit higher thermal expansion and lower rigidity, demanding refined toolpaths, specialized tooling, and controlled cutting parameters. Our engineering team employs adaptive machining strategies, including high-speed machining (HSM) and optimized spindle speeds, to reduce heat buildup and prevent material deformation. This ensures clean cuts, tight tolerances, and excellent edge definition, even in delicate or thin-walled components.

Material compatibility spans a broad range of engineering thermoplastics, including PEEK, PTFE, Ultem (PEI), Acetal (POM), Polycarbonate, and Nylon. Each material is processed under controlled environmental conditions to mitigate moisture absorption and thermal variance. Fixturing is designed to provide secure hold without inducing stress, preserving the integrity of the final component.

Quality assurance is integral to our manufacturing process. Every plastic milled part undergoes rigorous inspection using a Zeiss DuraMax Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides traceable, 3D metrology data for first-article inspections and batch validation, supporting AS9100 and ISO 13485 quality standards. In-process inspections are also conducted to detect deviations early, reducing rework and lead time.

The table below outlines our standard machining tolerances for plastic components, reflecting our capability to meet demanding engineering specifications.

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.05 mm | ±0.025 mm |

| Linear Dimensions (100–300 mm) | ±0.08 mm | ±0.04 mm |

| Linear Dimensions (300–600 mm) | ±0.10 mm | ±0.05 mm |

| Hole Diameter (Drilled) | ±0.05 mm | ±0.02 mm |

| Positional Tolerance | ±0.05 mm | ±0.03 mm |

| Flatness (per 100 mm) | 0.05 mm | 0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

Our technical expertise is further enhanced by in-house design for manufacturability (DFM) analysis, allowing us to optimize part geometry, reduce cycle time, and improve yield before production begins. This proactive engineering approach ensures that every plastic CNC milled component meets both functional and regulatory requirements. At Wuxi Lead Precision Machinery, we combine advanced equipment, material intelligence, and metrology-grade validation to deliver precision plastic components that perform in the most demanding environments.

Material & Finish Options

Precision Material Selection for CNC Milling Applications

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in high-precision CNC milling. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and geometric complexity. While plastics serve specific niches, this guide focuses on critical metal alloys where dimensional stability and mechanical resilience are paramount: Aluminum, Steel, and Titanium. Each offers distinct advantages for aerospace, medical, and industrial components demanding micron-level tolerances.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring lightweight strength and thermal conductivity. Their excellent machinability reduces cycle times and tool wear, making them ideal for complex enclosures, heat sinks, and structural frames. However, aluminum lacks the wear resistance needed for high-stress interfaces. Steel variants like 304 stainless and 4140 chrome-moly excel where hardness, fatigue resistance, and structural integrity are non-negotiable. These alloys withstand extreme loads and maintain stability in corrosive environments but demand robust tooling and slower machining parameters. Titanium Ti-6Al-4V represents the pinnacle for weight-critical, high-strength applications in aerospace and medical implants. Its exceptional strength-to-weight ratio and biocompatibility come with significant machining challenges, including low thermal conductivity and high reactivity, necessitating specialized cutting strategies and rigid machine setups to prevent work hardening.

Surface finishing, particularly anodizing, is integral to material performance. Type II (sulfuric acid) anodizing enhances aluminum’s corrosion resistance and provides a porous base for dyeing, critical for consumer-facing parts. Type III (hardcoat) anodizing delivers superior abrasion resistance for functional components like hydraulic manifolds. Note that anodizing is exclusive to aluminum; steel typically requires passivation or plating, while titanium benefits from acid etching or plasma spraying for biocompatibility.

Material selection directly impacts manufacturability and total cost. Aluminum offers the fastest throughput, while titanium requires 30–50% longer machining times due to conservative feed rates. Our engineering team evaluates your part geometry, tolerance stack-ups, and volume to recommend the most efficient material-finish combination. Below are key mechanical properties for common alloys:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Grades |

|---|---|---|---|---|

| Aluminum | 240–570 | 2.7 | Excellent (85–95) | 6061-T6, 7075-T6 |

| Stainless Steel | 505–1300 | 8.0 | Moderate (45–65) | 304, 316, 17-4 PH |

| Titanium | 900–1100 | 4.4 | Poor (20–35) | Ti-6Al-4V (Grade 5) |

Wuxi Lead Precision Machinery leverages 15+ years of metallurgical expertise to optimize your material choice. We conduct pre-production material validation and in-process inspections to ensure your components meet AS9100 and ISO 13485 standards. Consult our engineering team early in your design phase to balance performance requirements with production economics. Material is never just a substrate—it’s the cornerstone of precision.

Manufacturing Process & QC

The production process for plastic CNC milling at Wuxi Lead Precision Machinery follows a rigorous, end-to-end workflow designed to achieve zero defects and ensure repeatable precision across all stages. From initial design to final mass production, every step is engineered for accuracy, efficiency, and material integrity, tailored specifically to the unique thermal and mechanical properties of engineering-grade plastics.

Design begins with a comprehensive review of the client’s CAD models and technical specifications. Our engineering team evaluates part geometry, tolerances, wall thickness, and potential stress points, optimizing the design for manufacturability. Special attention is given to minimizing warpage and internal stress, common challenges in plastic components. Material selection is a critical phase—common choices include PEEK, Delrin, Ultem, PTFE, and polycarbonate, each selected based on thermal stability, chemical resistance, and mechanical performance. Finite element analysis (FEA) may be employed to simulate real-world performance and refine the design before any material is cut.

Prototyping follows design validation, serving as both a functional and dimensional verification step. Using high-precision 3-, 4-, and 5-axis CNC milling centers, we produce initial samples with tolerances as tight as ±0.005 mm. Each prototype undergoes full inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, material certifications, and first-article inspection (FAI) documentation are provided to the client for approval. This stage allows for rapid iteration and design refinement, ensuring that the final product meets all functional and aesthetic requirements.

Once the prototype is approved, the process transitions to mass production under a controlled, ISO-compliant manufacturing environment. Each CNC machine is calibrated daily, and tool wear is monitored in real time using advanced in-process probing systems. Automated chip removal and temperature-stabilized work cells prevent thermal deformation, a critical factor in maintaining dimensional accuracy in plastic milling. Every production run is subject to statistical process control (SPC), with random sampling and 100% inspection applied to critical features. Our zero-defect philosophy is enforced through a closed-loop quality system that detects, documents, and corrects deviations before they impact output.

All finished components are packaged in anti-static, humidity-controlled materials to prevent damage during transit. Traceability is maintained through batch coding and digital process logs, ensuring full accountability from raw material to final shipment.

Typical Plastic CNC Milling Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Axis Configuration | 3-axis, 4-axis, and 5-axis simultaneous |

| Common Materials | PEEK, Delrin, Ultem, PTFE, PC, PMMA, Nylon |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 10–20 working days (volume-dependent) |

| Quality Standards | ISO 9001:2015, SPC, FAI, CMM Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic CNC Milling Excellence

Achieving dimensional stability and surface integrity in plastic CNC milling demands far more than standard metalworking protocols. Thermoplastics like PEEK, Ultem, and acrylic exhibit unique challenges—thermal expansion, chip adhesion, and internal stress relief—that demand specialized machine dynamics, toolpath strategies, and material science expertise. Generic machining approaches result in part warpage, delamination, or scrapped batches, directly impacting your time-to-market and production costs. At Wuxi Lead Precision Machinery, we engineer solutions specifically for the inherent complexities of high-performance polymers, ensuring your critical components meet aerospace, medical, and semiconductor-grade specifications without compromise.

Our dedicated plastic milling division operates on Haas and DMG MORI 5-axis platforms modified with low-vibration spindles, cryogenic cooling integration, and closed-loop thermal management systems. Unlike conventional shops, we implement material-specific protocols: slow-feed strategies for glass-filled composites, vacuum-assisted chip evacuation for amorphous resins, and post-machining annealing cycles to eliminate residual stress. Every project begins with our material characterization lab verifying lot-specific thermal behavior, enabling us to calibrate feeds, speeds, and coolant parameters to your exact polymer grade. This scientific approach consistently delivers ±0.005mm tolerances on features as thin as 0.2mm—even in hygroscopic materials like nylon 6/6.

Critical Plastic Milling Capabilities at Wuxi Lead

| Parameter | Specification | Material Coverage |

|---|---|---|

| Tolerance Range | ±0.005mm to ±0.025mm | Engineering Plastics, Composites |

| Max Work Envelope | 1200 x 800 x 600mm | PEEK, Ultem, PPS, Acetal, PMMA, UHMW |

| Surface Finish (Ra) | 0.4μm to 3.2μm | Glass/Ceramic-Filled Grades Supported |

| Minimum Feature Size | 0.2mm wall thickness | FDA/USP Class VI Compliant Options |

| Lead Time (Prototype) | 7-10 business days | ISO 13485 & AS9100 Certified Process |

We eliminate the guesswork in plastic machining through proactive collaboration. Share your CAD model and application requirements early in the design phase. Our engineers will conduct a manufacturability review identifying potential stress points, recommending optimal material grades, and proposing fixture solutions to prevent distortion—saving you costly iterations. For mission-critical components, we provide full traceability with material certs, first-article inspection reports (FAIR), and in-process CMM validation at defined milestones. Our Wuxi facility’s strategic location within China’s industrial corridor ensures seamless logistics for global supply chains while maintaining rigorous IP protection protocols.

Do not risk project timelines with vendors treating plastics as secondary to metals. Partner with a team whose sole focus is polymer precision. Contact us today to schedule your technical consultation. Send your project specifications to [email protected]—our engineering team responds within 4 business hours with a detailed process plan and feasibility assessment. Let Wuxi Lead Precision Machinery become your trusted authority in plastic CNC milling, where material science meets manufacturing mastery. Your next breakthrough component starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.