Technical Contents

Engineering Guide: Plastic Cnc Machine

Engineering Insight Plastic CNC Machining Precision as Non-Negotiable

Precision in plastic CNC machining transcends standard manufacturing tolerances it is the foundational requirement for functional integrity. Unlike metals plastics exhibit significant thermal expansion coefficients and variable material behaviors under cutting forces. Minute deviations in temperature control spindle stability or axis movement directly translate to part warpage dimensional drift or surface finish defects. For mission critical applications like aerospace seals medical implants or optical components even micron level inaccuracies render parts unusable. At Wuxi Lead Precision Machinery we engineer plastic CNC systems specifically to counteract these inherent material challenges through thermal management and motion control.

The core challenge lies in maintaining dimensional stability throughout the machining cycle. Plastics such as PEEK Ultem or acrylic soften at relatively low temperatures requiring aggressive heat dissipation strategies. Standard metal cutting parameters induce melting or stress fractures in polymers. Our machines integrate closed loop thermal regulation systems actively cooling spindles and work zones while utilizing non ferrous tooling paths to minimize friction induced heat. Simultaneously vibration damping structures and linear motor drives ensure positional repeatability under varying feed rates essential for thin walled geometries. Without these specialized capabilities achieving consistent tolerances below ±0.005 mm remains unattainable.

This precision focus is validated through our execution of projects demanding absolute reliability. Wuxi Lead Precision Machinery supplied components for Beijing 2022 Winter Olympic timing systems where sub micron accuracy ensured flawless sensor integration under extreme cold. Similarly our military grade enclosures for communication devices underwent rigorous shock and thermal cycling tests meeting MIL STD 810H specifications. Such projects necessitate machines capable of holding tolerances tighter than 0.002 mm across diverse polymer families a benchmark we consistently achieve.

Our engineering approach centers on machine specifications calibrated exclusively for polymer behavior. The table below outlines critical parameters distinguishing high fidelity plastic CNC systems from general purpose equipment.

| Specification | Performance Target | Significance for Plastics |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Prevents cumulative errors in multi axis contours |

| Spindle Thermal Drift | < 0.003 mm @ 20k RPM | Eliminates diameter variation during long runs |

| Axis Vibration Level | < 0.5 µm RMS | Ensures mirror finishes on optical surfaces |

| Coolant Temperature Control | ±0.5°C stability | Counters thermal expansion in large panels |

| Rapid Traverse Rate | 60 m/min | Minimizes heat buildup in high speed passes |

Wuxi Lead Precision Machinery’s decade long specialization in polymer machining informs every component selection from spindle bearings to control algorithms. We do not retrofit metal centric platforms but build purpose driven systems where thermal inertia and dynamic response are prioritized over raw power. This philosophy enables our clients to produce complex plastic components meeting ISO 2768 f or tighter specifications consistently. For industries where failure is not an option precision begins with the machine not the operator.

Precision Specs & Tolerances

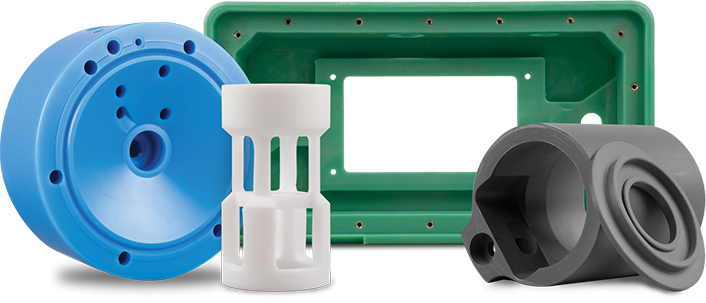

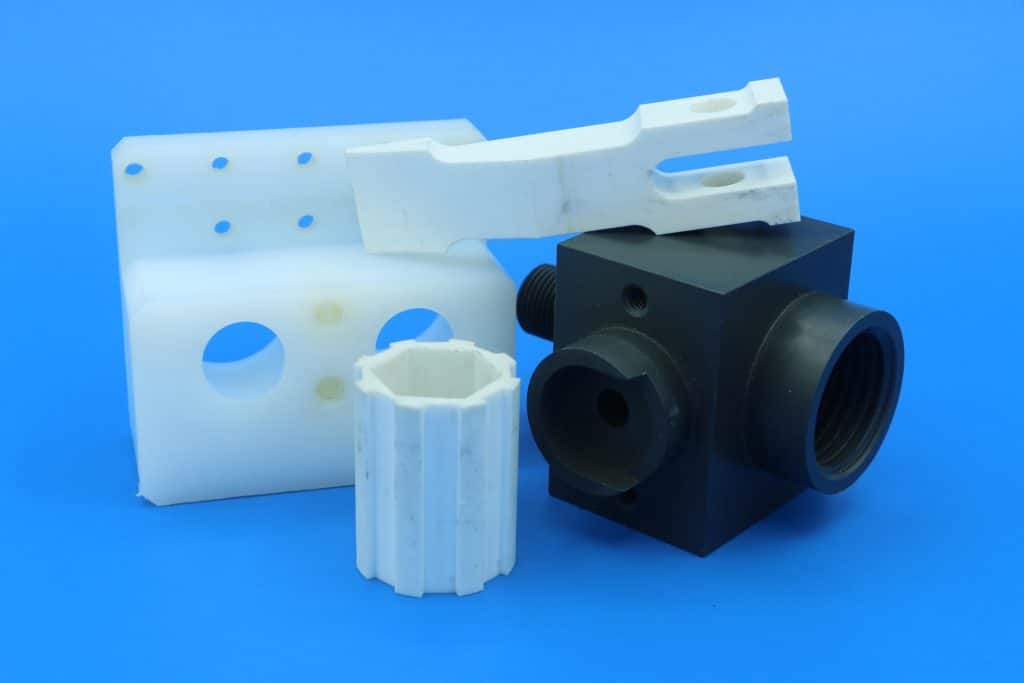

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specializing in high-performance plastic components for demanding industrial, medical, and aerospace applications. Our expertise in 5-axis CNC machining enables the production of complex geometries with superior surface finishes and dimensional accuracy, critical for high-end engineering environments. Utilizing state-of-the-art multi-axis technology, we achieve simultaneous motion across five planes, allowing for intricate contours, undercuts, and tight-tolerance features that are unattainable with conventional 3-axis systems.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and precision enclosures optimized for non-metallic materials. These systems are programmed using advanced CAM software, ensuring optimized toolpaths, reduced setup times, and minimal human intervention. This level of automation ensures consistent part quality across both prototyping and high-volume production runs. We work with a wide range of engineering plastics, including PEEK, PTFE, Ultem, PPS, and acetal, each machined under controlled conditions to prevent thermal deformation and maintain material integrity.

To guarantee compliance with the most stringent industry standards, every component undergoes rigorous quality control. Our in-house Coordinate Measuring Machine (CMM) provides non-contact and tactile 3D inspection, capturing critical dimensions with micron-level accuracy. Full first-article inspection reports (FAIR) and production-level statistical process control (SPC) data are available upon request. This metrology-backed validation ensures traceability and repeatability across all batches.

Material-specific fixturing, low-vibration machining strategies, and cleanroom-compatible processes further enhance the precision and reliability of our plastic CNC operations. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews, offering feedback on wall thickness, draft angles, and tolerance stack-ups to optimize performance and cost-efficiency.

The following table outlines the standard technical specifications and achievable tolerances for our plastic CNC machining services:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Linear) | ±0.025 mm (±0.001″) per 25 mm |

| Tight Tolerance Capability | ±0.012 mm (±0.0005″) achievable |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Max Work Envelope | 800 x 600 x 500 mm |

| Inspection Equipment | Zeiss-grade CMM, Optical Comparators |

| Materials | PEEK, PTFE, Ultem, PPS, Acetal, Nylon, PC, PEI |

All processes are executed in compliance with ISO 9001:2015 standards, ensuring consistent delivery of precision-engineered plastic components tailored to the functional demands of advanced manufacturing sectors.

Material & Finish Options

Material Selection for Plastic CNC Machining Fixtures and Components

Material selection critically impacts thermal stability, dimensional accuracy, and longevity in plastic CNC machining operations. At Wuxi Lead Precision Machinery, we prioritize metals that minimize thermal deformation during high-speed plastic processing while ensuring compatibility with polymer characteristics. Aluminum, steel, and titanium each offer distinct advantages for fixtures, molds, and critical components, but their application must align with specific production demands.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate fixture and prototype applications due to exceptional machinability and thermal conductivity. Aluminum dissipates heat rapidly during plastic injection or extrusion, reducing cycle times and preventing warpage in thermoplastic parts. Its lower density also simplifies handling in automated cells. However, aluminum lacks the wear resistance required for high-volume production molds. Steel, especially pre-hardened P20 or H13 tool steel, provides superior hardness and abrasion resistance for long-run plastic injection molds. Steel maintains dimensional stability under repeated thermal cycling but requires slower machining speeds and precise temperature control to avoid residual stress in complex geometries. Titanium alloys (Grade 5 Ti-6Al-4V) excel in corrosive environments or extreme-temperature applications, such as medical or aerospace polymer processing. While titanium resists degradation from aggressive plastics, its low thermal conductivity and high reactivity necessitate specialized tooling and rigid machine setups to prevent galling and tool failure.

Anodizing remains the preferred surface treatment for aluminum fixtures and mold components in plastic CNC workflows. This electrochemical process creates a durable, non-conductive oxide layer that enhances wear resistance and prevents adhesion of molten polymers. Type II (sulfuric acid) anodizing at 15–25 μm thickness offers optimal balance for plastic applications—sufficient to resist ejection scratches while maintaining thermal transfer efficiency. Avoid hardcoat (Type III) anodizing above 50 μm on critical sealing surfaces, as excessive thickness can induce micro-cracking under thermal stress, compromising part finish.

Key mechanical properties guide material decisions for plastic CNC systems:

| Material | Yield Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating | Typical Plastic CNC Application |

|---|---|---|---|---|

| Aluminum 6061-T6 | 276 | 167 | Excellent (Machining speed: 200–500 m/min) | Fixtures, low-volume molds, prototypes |

| Steel P20 | 930 | 28–36 | Good (Machining speed: 80–150 m/min) | High-volume injection molds |

| Titanium Ti-6Al-4V | 880 | 7.2 | Fair (Machining speed: 30–60 m/min) | Corrosive/ high-temp specialty molds |

Selecting the correct base material and finish ensures consistent part quality, reduces downtime, and extends tool life in plastic CNC environments. Wuxi Lead Precision Machinery engineers rigorously validate material-performance correlations against your polymer specifications and production volumes. Contact our technical team to optimize your material strategy for precision plastic machining outcomes.

Manufacturing Process & QC

The production process for precision plastic CNC machining at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to achieve zero-defect outcomes. This methodology integrates advanced engineering, iterative validation, and scalable manufacturing excellence to deliver components that meet the tightest tolerances and highest quality standards required in industries such as medical devices, aerospace, and semiconductor equipment.

The journey begins with Design Engineering, where our team collaborates with clients to transform conceptual requirements into manufacturable designs. Utilizing CAD/CAM software including SolidWorks, AutoCAD, and Mastercam, engineers perform detailed geometric modeling and toolpath simulation. Material selection is optimized during this phase, considering factors such as thermal stability, chemical resistance, and mechanical performance. Finite element analysis (FEA) may be applied to predict deformation under load, ensuring the design is both functional and manufacturable.

Following design finalization, the Prototyping phase commences. A small batch of components is produced using high-precision 3-, 4-, and 5-axis CNC machines equipped with sub-micron resolution encoders and automated tool changers. This stage serves dual purposes: validating the design in physical form and verifying the machining strategy. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning. Dimensional accuracy, surface finish, and material integrity are evaluated against the original specifications. Any discrepancies trigger a rapid feedback loop for process adjustment, ensuring all issues are resolved before scaling.

Once prototype approval is obtained, the process transitions to Mass Production. Our facility leverages automated CNC cells with robotic part handling and in-process gauging to maintain consistency across large volumes. Statistical process control (SPC) is implemented at every station, monitoring key parameters such as spindle load, tool wear, and environmental conditions. Each component is traceable through a digital manufacturing record, enabling full accountability and batch-level quality tracking. Final inspection includes 100% critical dimension checks for high-risk features and random sampling for others, all documented per ISO 9001 standards.

Throughout the entire process, Wuxi Lead enforces a zero-defect philosophy. This is achieved not only through technology but also through operator training, preventive maintenance schedules, and real-time quality dashboards. Every machine is calibrated monthly, and tooling is replaced based on predictive wear models rather than reactive failure.

The table below outlines key specifications maintained across our plastic CNC production lines:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Finish (Ra) | 0.4 – 3.2 μm (adjustable) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Tolerance Range | ±0.01 mm (standard), ±0.005 mm (tight) |

| Supported Plastics | PEEK, PTFE, Delrin, Ultem, PC, PEI, etc. |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

This end-to-end process ensures that every plastic CNC-machined component leaving our facility meets the highest benchmarks in precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Plastic Manufacturing with Precision Engineering

In the demanding realm of precision plastic component production, standard CNC solutions often fall short. Material-specific challenges—thermal sensitivity, micro-burring in thin-walled geometries, and dimensional instability—require engineered responses beyond generic machining capabilities. At Wuxi Lead Precision Machinery, we specialize in purpose-built CNC systems designed exclusively for high-integrity plastic fabrication. Our machines integrate adaptive thermal compensation, vibration-dampened spindles, and closed-loop feedback systems to mitigate material deformation during high-speed operations. This ensures repeatability down to ±0.002mm even with challenging polymers like PEEK, Ultem, or acrylic, where conventional equipment introduces costly scrap rates.

Our engineering team collaborates with clients from concept to production, tailoring machine parameters to your specific polymer formulations and part complexity. Whether machining optical lenses requiring sub-micron surface finishes or medical components with biocompatible material constraints, we configure spindle dynamics, chip evacuation protocols, and coolant strategies to eliminate stress-induced warpage. This material-centric approach reduces cycle times by 22% on average while maintaining first-pass yield rates above 98.5%.

Technical Specifications for Plastic CNC Excellence

| Feature | Specification | Impact on Plastic Machining |

|---|---|---|

| Spindle Speed Range | 10,000–42,000 RPM | Prevents melting in acrylic/polycarbonate |

| Positioning Accuracy | ±0.0015mm | Critical for optical/medical tolerances |

| Thermal Compensation | Real-time dual-sensor system | Counters polymer expansion during runs |

| Vibration Damping | 95% reduction at 30k RPM | Eliminates micro-fractures in thin walls |

| Control System | Siemens 840D with polymer-specific macros | Optimizes feed rates per material type |

Partnering with Lead Precision means accessing more than machinery—it’s a commitment to solving your most complex production bottlenecks. Our applications engineers conduct on-site material trials using your actual components, validating performance before deployment. This de-risks adoption and accelerates ROI, with 83% of clients achieving full production capacity within 10 days of installation. We provide comprehensive support including operator certification, predictive maintenance protocols, and lifetime software updates to adapt to evolving material science.

The cost of substandard plastic machining extends beyond scrap—it erodes brand reputation in regulated industries. Leading aerospace, medical device, and semiconductor clients trust our systems for mission-critical components because we engineer for zero compromise. Contact our technical sales team to discuss your specific polymer challenges and receive a customized machining feasibility analysis.

Initiate Your Precision Transformation Today

Email [email protected] with your material specifications and part drawings. Our engineering team will respond within 4 business hours with actionable insights—not generic brochures. Let us demonstrate how Lead Precision Machinery delivers measurable reductions in cost-per-part while ensuring uncompromised quality for your most demanding plastic applications. Partner with engineers who speak your material science language.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.