Technical Contents

Engineering Guide: Plastic 3D Printing Service

Engineering Insight: The Role of Precision in Plastic 3D Printing Services

In the realm of advanced manufacturing, plastic 3D printing services have evolved beyond prototyping to become a critical solution for producing end-use components across aerospace, medical, defense, and high-performance industrial sectors. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not just in design flexibility, but in the ability to deliver repeatable, dimensionally accurate, and functionally reliable parts. Precision is not a feature—it is the foundation.

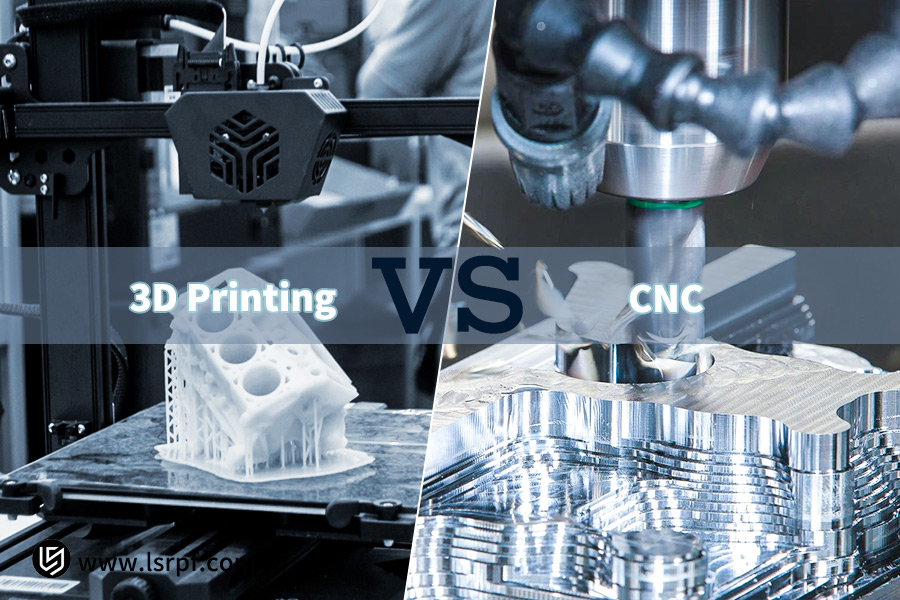

Unlike traditional plastic fabrication methods, 3D printing allows for complex geometries and internal structures that would be impossible or cost-prohibitive to machine. However, this capability introduces new challenges in maintaining tight tolerances, material consistency, and structural integrity. Without rigorous process control, even minor deviations in layer adhesion, thermal expansion, or post-processing can compromise performance. This is where engineering expertise becomes decisive.

At Lead Precision, our approach to plastic 3D printing integrates decades of precision metal manufacturing experience with state-of-the-art polymer additive systems. Our engineers apply the same stringent quality standards used in our military and Olympic-grade projects—where failure is not an option—to ensure every printed component meets exacting specifications. From material selection to environmental chamber control, every variable is monitored and optimized.

Our facility supports multiple plastic 3D printing technologies, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM) with industrial-grade systems, and Multi Jet Fusion (MJF). Each process is calibrated to maintain tolerances within ±0.1 mm for small features and ±0.2 mm for larger builds, with warpage and shrinkage actively compensated using predictive modeling. In-house metrology, including CMM and laser scanning, verifies conformity before any part is released.

Material performance is equally critical. We utilize engineering-grade thermoplastics such as Nylon 12, ULTEM™ 9085, and PEEK, selected for their strength-to-weight ratios, thermal stability, and chemical resistance. These materials are processed under controlled humidity and temperature conditions to prevent inconsistencies that could affect mechanical properties.

The integration of plastic 3D printing into mission-critical applications demands more than access to advanced machines—it requires a culture of precision engineering. At Wuxi Lead Precision Machinery, our legacy in custom metal manufacturing for defense systems and high-stakes international competitions has instilled a discipline that directly translates to our additive services. Whether producing lightweight drone housings, custom jigs for assembly lines, or non-metallic components for corrosive environments, we treat every print as a precision component, not just a prototype.

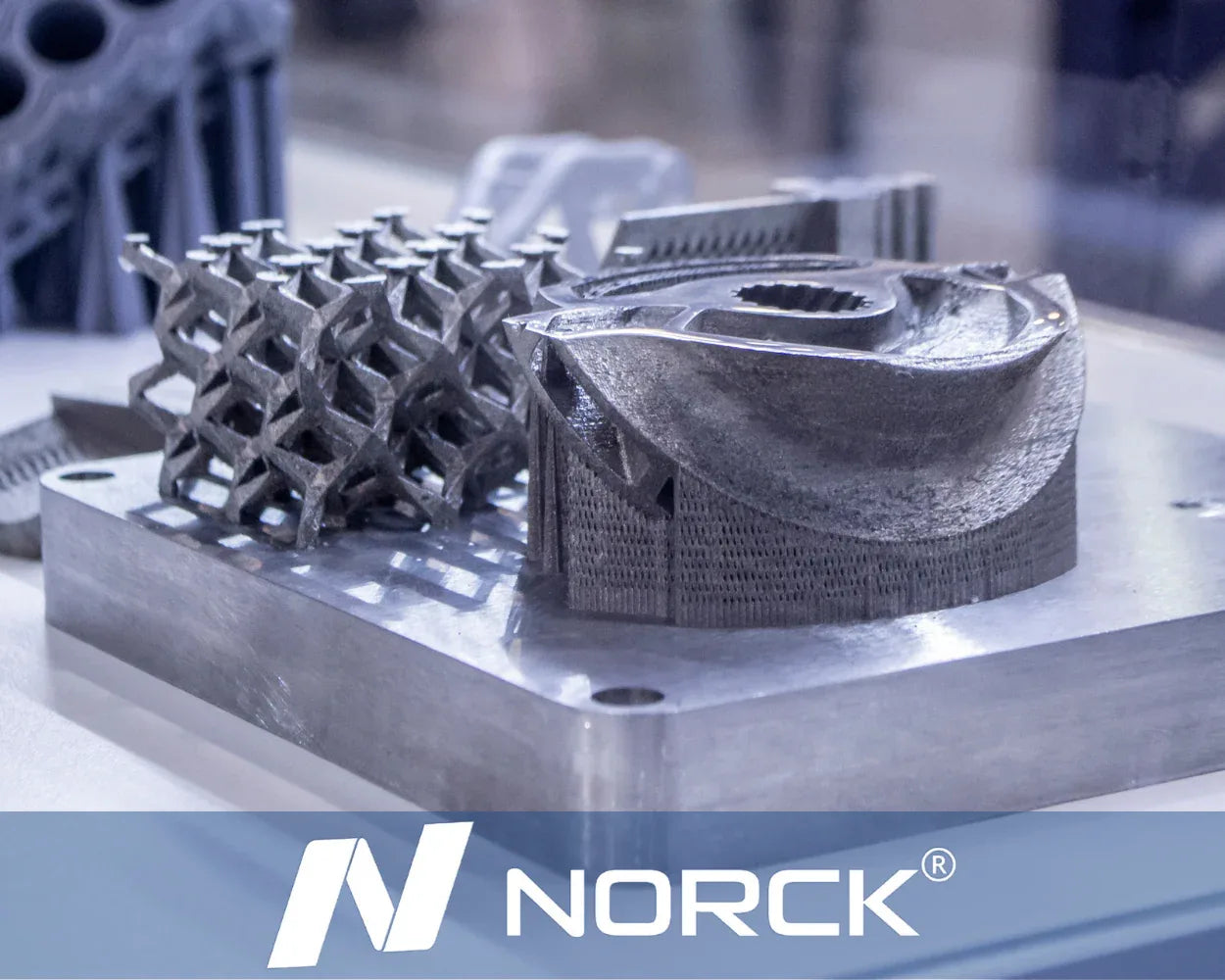

The future of manufacturing is hybrid—combining metal and polymer technologies under one quality umbrella. With Lead Precision, clients gain not just a service provider, but an engineering partner committed to accuracy, reliability, and performance.

| Parameter | Specification |

|---|---|

| Standard Tolerance | ±0.1 mm (features < 50 mm), ±0.2 mm (features > 50 mm) |

| Layer Resolution | 50 – 120 µm (adjustable by application) |

| Build Envelope (Max) | 300 x 300 x 400 mm (varies by technology) |

| Supported Materials | Nylon 12, Nylon 11, ULTEM™ 9085, PEEK, TPU, ABS-like |

| Post-Processing | Media blasting, vapor smoothing, annealing, tapping, coating |

| Quality Control | In-process monitoring, CMM verification, first article inspection |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing at Wuxi Lead Precision Machinery

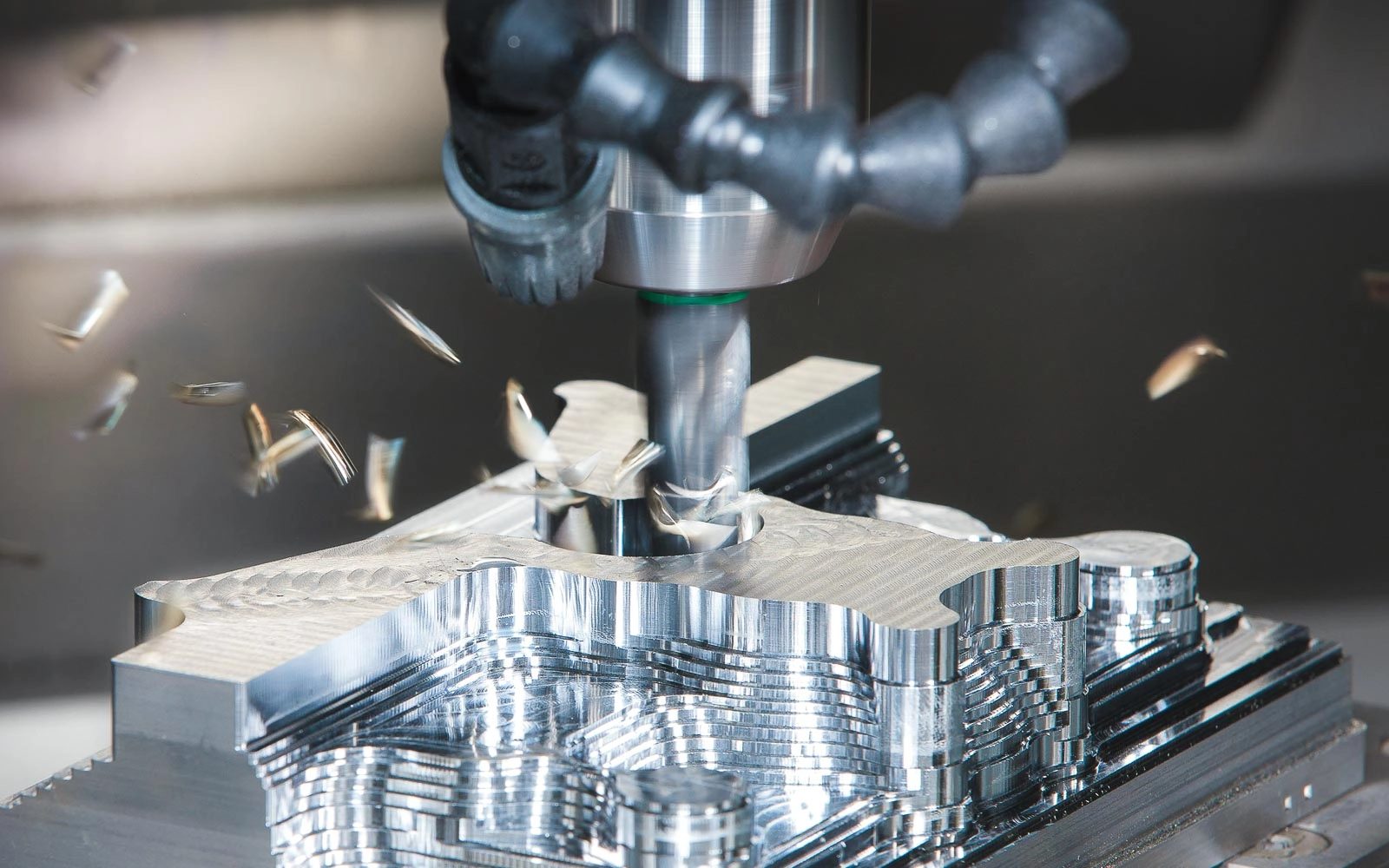

Wuxi Lead Precision Machinery specializes in high-precision custom metal manufacturing, leveraging advanced subtractive technologies to deliver components demanding exacting geometric and dimensional integrity. While additive processes like plastic 3D printing serve specific prototyping niches, our core expertise and value proposition lie in precision CNC machining for mission-critical metal parts across aerospace, medical, and industrial automation sectors. We utilize state-of-the-art 5-axis CNC machining centers, enabling complex geometries, reduced setup times, and superior surface finishes unattainable through additive methods for production-grade metal components. This capability ensures optimal material properties, structural reliability, and repeatability essential for end-use applications where plastic 3D printing lacks the necessary strength, thermal stability, or certification compliance.

Our integrated manufacturing workflow begins with rigorous material certification for aerospace-grade alloys, medical stainless steels, and high-performance engineering metals. Components are machined on HAAS and DMG MORI 5-axis platforms featuring high-speed spindles, dynamic tool compensation, and real-time thermal management. This eliminates the layer adhesion weaknesses and anisotropic properties inherent in plastic additive processes, guaranteeing isotropic mechanical behavior and dimensional stability under operational stress. Every stage adheres to AS9100 and ISO 13485 quality management systems, with full traceability from raw material lot to finished part.

Quality control is non-negotiable. All critical features undergo 100% inspection using Zeiss CONTURA and Wenzel LH87 coordinate measuring machines (CMM). These systems provide micron-level verification of complex contours, GD&T callouts, and surface textures, validated against CAD models through PolyWorks software. Statistical process control (SPC) data is continuously monitored to preempt deviations, ensuring batch consistency. This metrology-driven approach surpasses the limited in-process verification possible in plastic 3D printing, delivering certified accuracy for safety-critical assemblies.

The following table details achievable tolerances for machined metal components, reflecting our process capability under controlled environmental conditions. These specifications assume standard materials like 6061-T6 aluminum, 304/316 stainless steel, and Ti-6Al-4V, with geometry-dependent feasibility assessments provided during design review.

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / Micrometer |

| Geometric Tolerancing | ±0.020 mm | ±0.008 mm | CMM (GD&T Analysis) |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Hole Position | ±0.015 mm | ±0.007 mm | CMM / Optical Comparator |

| Flatness | 0.025 mm/m | 0.010 mm/m | CMM / Surface Plate |

Wuxi Lead’s commitment extends beyond machining to holistic value engineering. Our engineering team collaborates early in the design phase to optimize manufacturability, reduce lead times, and minimize total cost of ownership—addressing challenges where plastic 3D printing often fails in scalability, material performance, or regulatory acceptance. For applications requiring certified metal performance, our 5-axis CNC capabilities and metrology infrastructure deliver the precision, repeatability, and documentation demanded by global Tier 1 suppliers. Contact our technical sales team to discuss how our metal manufacturing expertise solves your most demanding production challenges.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, especially when integrating components designed for compatibility with plastic 3D printed assemblies. At Wuxi Lead Precision Machinery, we specialize in precision metal parts that complement advanced prototyping and end-use applications where plastic 3D printing meets high-performance metal components. The choice of material directly influences mechanical performance, environmental resistance, weight, and cost-efficiency. Aluminum, steel, and titanium represent the core alloys used in such hybrid manufacturing ecosystems, each offering distinct advantages depending on application requirements.

Aluminum is widely selected for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for aerospace, automotive, and consumer electronics applications where weight reduction is essential without sacrificing structural integrity. Grade 6061-T6 is commonly used due to its weldability and corrosion resistance, making it ideal for enclosures, brackets, and housings that interface with 3D printed plastic parts. For enhanced surface properties, anodizing is recommended. Type II and Type III (hard coat) anodizing improve wear resistance and allow for color coding, which is beneficial in assembly processes.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, offers superior strength, durability, and resistance to high temperatures and corrosive environments. These properties make steel ideal for industrial tooling, medical devices, and fixtures that must maintain dimensional stability over extended use. While heavier than aluminum, steel provides unmatched rigidity and is often used in jigs and molds that support plastic 3D printed components during production or testing phases. Secondary finishing such as passivation enhances corrosion resistance, especially in medical and food-grade applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers exceptional performance in extreme conditions. Its high strength-to-density ratio, biocompatibility, and resistance to fatigue and corrosion make it the material of choice for aerospace, defense, and medical implant applications. Although more challenging to machine, titanium’s long-term reliability justifies its use in mission-critical systems where failure is not an option. When paired with high-temperature plastic 3D printed parts, titanium components ensure structural continuity under thermal stress.

Anodizing is a key surface treatment for aluminum parts, providing both functional and aesthetic benefits. It creates a durable, non-conductive oxide layer that resists wear and corrosion while allowing for precise color control. This is particularly useful in assemblies involving plastic 3D printed components where visual alignment or branding is required.

The following table summarizes key mechanical and finishing properties of the primary materials we offer:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Available Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Anodizing (Type II/III), Powder Coat | Aerospace, Electronics, Automotive |

| Stainless Steel | 515–1300 | 7.9 | 304, 316, 17-4 PH | Passivation, Electropolishing | Medical, Industrial Tooling, Food Processing |

| Titanium | 900–1100 | 4.5 | Ti-6Al-4V (Gr 5) | Bead Blasting, Anodizing (decorative) | Aerospace, Defense, Medical Implants |

At Wuxi Lead Precision Machinery, we support engineers in selecting the optimal material and finish combination tailored to their design goals, ensuring seamless integration with plastic 3D printed systems and long-term field performance.

Manufacturing Process & QC

Precision Plastic 3D Printing: Integrated Path from Concept to Flawless Production

At Wuxi Lead Precision Machinery, our expertise in custom metal manufacturing provides the rigorous foundation for our high-precision plastic 3D printing service. We treat plastic additive processes not as isolated operations, but as integral components within a comprehensive, defect-elimination workflow designed for demanding industrial applications. This ensures seamless integration with subsequent metal fabrication or assembly stages, delivering components that meet exacting functional and dimensional requirements from the first prototype to full-scale production.

The process begins with collaborative Design for Additive Manufacturing (DfAM) engineering. Our specialists work directly with your CAD models, applying deep knowledge of material behavior, thermal dynamics, and post-processing constraints. We conduct rigorous virtual simulations to optimize part orientation, support structures, and internal stress management, preventing warpage or failure before the printer activates. This phase is critical for achieving the geometric complexity inherent in high-value industrial parts while ensuring manufacturability and adherence to your specified tolerances and surface finishes. Material selection—spanning engineering-grade nylons, ULTEM™, ABS, and specialized composites—is validated against your application’s thermal, chemical, and mechanical demands.

Prototyping transitions seamlessly into our controlled production environment. Initial builds undergo comprehensive metrology using calibrated CMMs and optical scanners, comparing as-built geometry against nominal CAD data with micron-level accuracy. Critical functional prototypes are subjected to application-specific validation tests, often alongside companion metal components we machine in-house. This integrated verification identifies potential interface issues or performance gaps early, allowing rapid design iteration without impacting the final production timeline. Every prototype build report feeds directly into refining the mass production parameters.

Mass production operates under our Zero Defects Manufacturing System. Each print job is governed by pre-validated, locked-down machine profiles stored in our centralized database. Real-time monitoring tracks chamber temperature, laser power, layer adhesion, and build platform stability, triggering automatic pauses for any parameter deviation beyond strict statistical process control limits. Post-build, components undergo a defined sequence: automated support removal, precision vapor smoothing or bead blasting as specified, and multi-stage cleaning. Final inspection employs AQL 1.0 sampling with full traceability; 100% critical feature verification is standard for high-risk components. Non-conforming parts are quarantined immediately, with root cause analysis driving continuous process refinement. This closed-loop system, honed through years of precision metal machining, guarantees consistent output meeting the most stringent industrial standards.

Key Production Specifications

| Parameter | Industrial Grade Specification | Lead Precision Standard |

|---|---|---|

| Layer Resolution | 25 – 100 microns | 20 – 80 microns |

| Dimensional Tolerance | ±0.1% (min ±0.2mm) | ±0.05% (min ±0.05mm) |

| Max Build Volume | 300 x 300 x 300 mm | 500 x 500 x 500 mm |

| Surface Roughness (As-Built) | Ra 12 – 25 µm | Ra 8 – 15 µm |

| Material Traceability | Batch Certificate | Full Lot Traceability + Cert |

| Quality Standard | ISO 9001 | ISO 9001 + PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Plastic 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in high-precision custom manufacturing solutions that bridge the gap between innovation and industrial performance. While our core expertise lies in custom metal manufacturing, we integrate advanced plastic 3D printing services as a strategic complement to our end-to-end production capabilities. This synergy enables us to deliver fully optimized components—combining the strength of machined metals with the flexibility and complexity of engineered polymers. For global OEMs, automation integrators, and high-tech engineering firms, this means faster prototyping, reduced assembly complexity, and accelerated time-to-market.

Our plastic 3D printing service leverages state-of-the-art industrial-grade equipment and a rigorous quality control framework aligned with ISO 9001 standards. We support a wide range of high-performance thermoplastics, including ULTEM, PEEK, ABS, and nylon-based composites, ensuring material properties meet demanding thermal, mechanical, and chemical resistance requirements. Whether you need functional prototypes, end-use parts for low-volume production, or complex assemblies that traditional manufacturing cannot achieve, our additive solutions are engineered for real-world application.

Each project begins with a collaborative design review, where our engineering team evaluates manufacturability, material selection, and structural integrity. We apply DfAM (Design for Additive Manufacturing) principles to maximize performance while minimizing weight and material waste. Post-processing options such as vapor smoothing, heat treatment, CNC finishing, and precision tapping ensure that every printed part meets exact dimensional and surface finish specifications.

Our facility in Wuxi, China, is equipped with automated build monitoring, environmental controls, and in-line metrology to maintain consistency across production runs. With full traceability and batch documentation, we support industries where compliance and repeatability are non-negotiable—medical device manufacturing, semiconductor equipment, aerospace subsystems, and industrial robotics.

Below are key specifications for our plastic 3D printing service:

| Parameter | Specification |

|---|---|

| Technology | Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) |

| Build Envelope | Up to 900 x 600 x 900 mm |

| Layer Resolution | 50 – 150 microns |

| Common Materials | ABS, PC, ULTEM 9085, PEEK, PA12, PA6-GF |

| Tolerance | ±0.1 mm (standard), ±0.05 mm (with post-machining) |

| Surface Finish | As-printed, sandblasted, vapor smoothed |

| Post-Processing | Annealing, CNC machining, tapping, coating |

| Lead Time | 3–7 days (prototypes), 7–14 days (production runs) |

| Quality Standards | ISO 9001 certified, full inspection reporting |

We understand that precision is not just a specification—it’s a commitment. By partnering with Wuxi Lead Precision Machinery, you gain more than a supplier; you gain a manufacturing ally focused on solving complex engineering challenges with speed, accuracy, and reliability.

To discuss your next project or request a quote, contact us today at [email protected]. Let us help you transform design concepts into high-performance reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.