Technical Contents

Engineering Guide: Pick Your Parts Pc

Engineering Insight: The Critical Role of Precision in Custom Metal Components for Pick Your Parts PC Systems

In the development of high-performance computing platforms such as pick your parts PC systems, the integration of custom metal components demands an uncompromising commitment to precision engineering. These systems, designed for modularity, thermal efficiency, and structural integrity, rely heavily on the dimensional accuracy and repeatability of their constituent parts. Even minor deviations in tolerances can lead to misalignment, compromised cooling performance, or long-term mechanical failure—issues that are unacceptable in mission-critical or high-end consumer applications.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a manufacturing specification—it is a foundational principle. With over 15 years of experience serving industries where failure is not an option, including defense and Olympic-grade equipment manufacturing, our engineering standards reflect the highest levels of reliability and performance. Our work on components for military-grade communication systems and precision frames used in Olympic training technology underscores our capability to deliver parts that meet exacting global benchmarks.

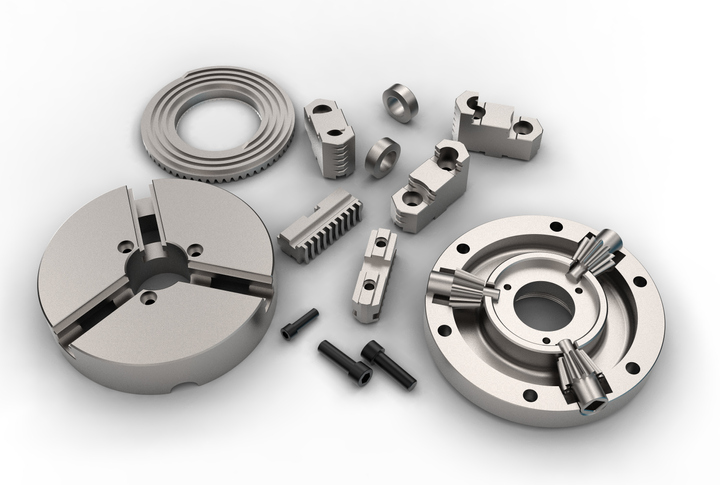

Custom metal components such as chassis brackets, heat sink mounts, and I/O shielding in a pick your parts PC system must be manufactured to micron-level tolerances. These parts interface with sensitive electronics and require consistent thermal conductivity, electromagnetic shielding, and mechanical stability. Achieving this consistency demands advanced CNC machining, rigorous quality control, and material science expertise. At Lead Precision, we utilize 5-axis CNC milling, high-precision turning, and automated inspection systems—including CMM (Coordinate Measuring Machine) validation—to ensure every component conforms to design intent across production batches.

Our experience in high-stakes environments directly translates to superior outcomes in commercial applications. For instance, the same tolerance control applied to a titanium mounting bracket in a satellite communication array is applied to an aluminum chassis component in a modular PC system. This cross-industry rigor ensures that each part not only fits perfectly but also performs reliably under thermal cycling, vibration, and long-term use.

Below are key specifications that define our manufacturing capabilities for custom metal components in PC system applications:

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum 6061, 7075; Stainless Steel 304, 316; Brass; Titanium; Copper |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry and material) |

| Surface Finish | Ra 0.8 µm standard; down to Ra 0.2 µm with polishing |

| Max Part Size | 800 mm × 500 mm × 400 mm |

| Machining Processes | 5-axis CNC milling, CNC turning, Swiss machining, EDM |

| Quality Standards | ISO 9001:2015, GD&T compliant, Full inspection reports available |

| Lead Time | 7–15 days for prototypes; 15–25 days for production runs |

Precision in custom metal manufacturing is not a luxury—it is a necessity for systems where performance, scalability, and reliability converge. At Wuxi Lead Precision Machinery, we bring military and elite engineering standards to the world of high-end computing, ensuring that every component we produce enables the next generation of modular, user-configurable PC platforms.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical metal components through integrated advanced manufacturing and metrology systems. Our core strength lies in mastering geometric complexity while maintaining strict adherence to dimensional tolerances, ensuring seamless integration into high-performance assemblies. This capability is foundational for aerospace, medical, and semiconductor clients where failure is not an option.

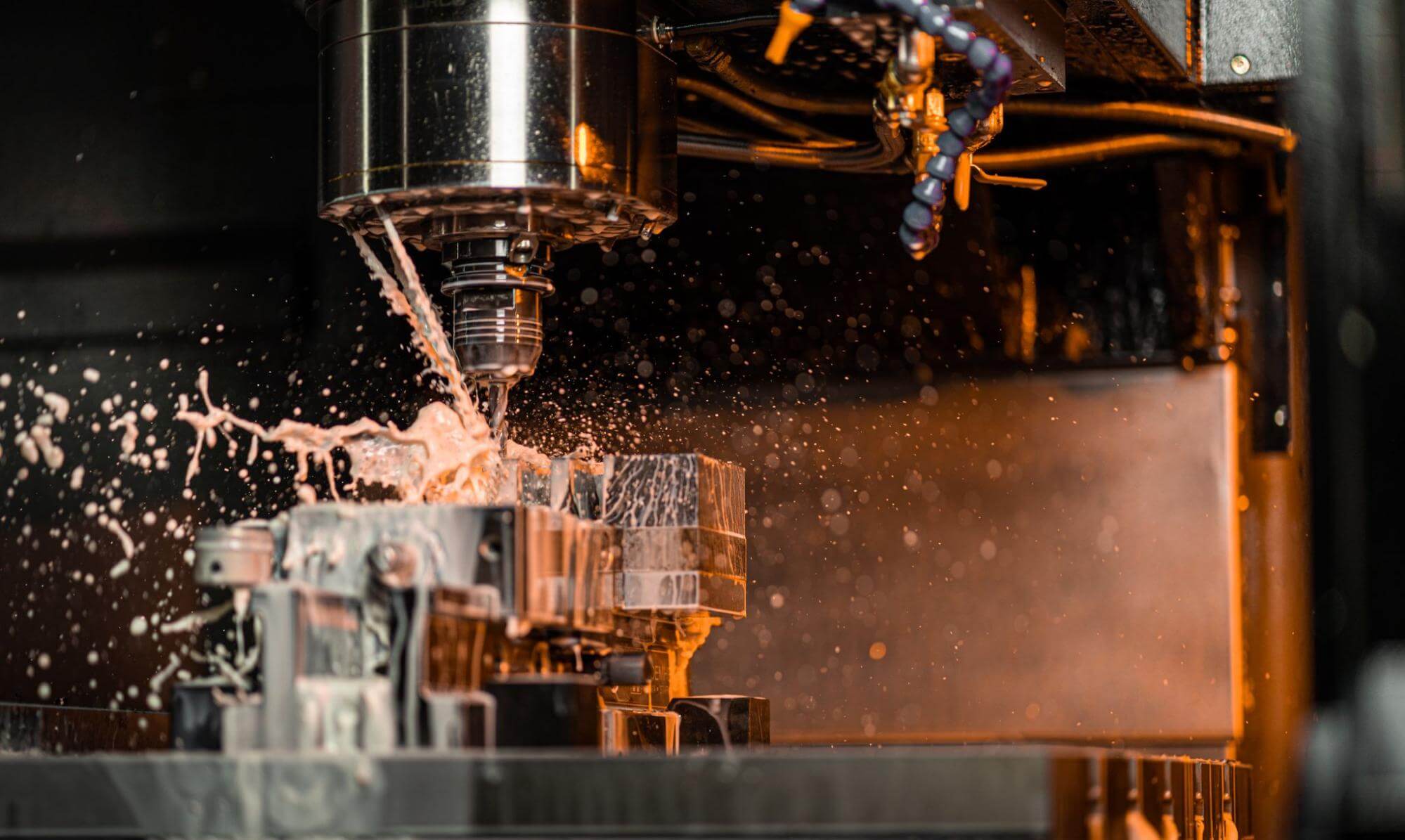

Our 5-axis CNC machining centers eliminate cumulative error from multiple setups, achieving intricate contours, deep cavities, and undercuts in a single operation. Utilizing high-rigidity machines with thermal compensation systems, we maintain ±0.005mm positional accuracy across multi-faceted parts. This reduces lead times by up to 40% compared to 3-axis alternatives while enhancing surface integrity for fatigue-critical applications. Material versatility spans titanium alloys, Inconel, aluminum 7075, and hardened steels up to 65 HRC, processed with optimized toolpaths that minimize micro-vibration and thermal distortion.

Quality assurance is embedded at every stage, anchored by Zeiss CONTURA CMMs operating in a climate-controlled ISO 17025-accredited lab. Every critical feature undergoes full 3D inspection against CAD models, with GD&T analysis validating form, profile, and positional tolerances. Real-time SPC monitoring during machining triggers automatic tool wear compensation, preventing non-conformances before they occur. Comprehensive traceability links each part to raw material certs, machine logs, and inspection reports via our digital MES platform, providing full audit trails for regulated industries.

Tolerance performance is rigorously defined by part geometry and material. The following table reflects achievable standards under controlled conditions for features ≤300mm:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025mm | ±0.005mm | Up to 150mm; ±0.01mm beyond 150mm |

| Hole Diameter | ±0.015mm | ±0.003mm | Reamed/ground finishes only |

| Positional Accuracy | ±0.020mm | ±0.008mm | Relative to primary datums |

| Surface Flatness | 0.025mm | 0.005mm | Over 100mm² area; per ISO 1101 |

| Profile of Surface | 0.030mm | 0.010mm | Complex contours; per ISO 1101 |

These specifications assume stable materials and geometries not prone to deformation. Actual tolerances are collaboratively validated during Design for Manufacturability reviews, where our engineers identify opportunities to balance precision with cost efficiency. Tighter tolerances incur no hidden premiums when justified by functional requirements—we transparently quote based on measurable process parameters.

By converging 5-axis machining agility with closed-loop quality validation, Wuxi Lead transforms design intent into physically perfect components. This technical discipline ensures your parts meet not just drawings, but the operational realities of high-stress environments. We partner with you to define achievable precision—no over-engineering, no compromises.

Material & Finish Options

Material Selection for High-Performance Custom Metal Components

Selecting the appropriate material for custom metal components is critical to ensuring optimal performance, durability, and cost-efficiency in precision manufacturing. At Wuxi Lead Precision Machinery, we specialize in delivering high-tolerance CNC-machined parts tailored to the specific mechanical, thermal, and environmental demands of your application. Among the most widely used materials in our production are aluminum, steel, and titanium—each offering distinct advantages depending on the use case.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, automotive, and consumer electronics applications where weight reduction is a priority without sacrificing structural integrity. Our standard aluminum alloys include 6061-T6 and 7075-T6, with the latter offering higher strength for more demanding environments.

Steel, particularly in its stainless and alloy forms, provides superior strength, wear resistance, and thermal stability. Stainless steel grades such as 304 and 316 are commonly selected for medical devices, food processing equipment, and marine applications due to their outstanding corrosion resistance and compliance with stringent hygiene standards. For components requiring high tensile strength and durability under load, we offer alloy steels like 4140 and tool steels processed to precise hardness specifications.

Titanium, though more costly, delivers an unmatched combination of high strength, low density, and exceptional resistance to extreme temperatures and corrosive environments. It is the material of choice in aerospace, defense, and high-end motorsport applications where performance under stress and long-term reliability are non-negotiable. Grade 5 (Ti-6Al-4V) is our most frequently machined titanium alloy, known for its excellent fatigue resistance and biocompatibility.

Surface finishing plays a crucial role in enhancing both functionality and aesthetics. Anodizing is a widely used electrochemical process for aluminum components, significantly improving surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing allows for color dyeing and is ideal for decorative or moderately exposed parts. For harsher environments, Type III (hardcoat) anodizing provides a thicker, more durable oxide layer capable of withstanding abrasive and high-wear conditions.

Below is a comparative overview of key material properties to assist in your selection process.

| Material | Typical Alloy | Tensile Strength (MPa) | Density (g/cm³) | Key Benefits | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Lightweight, corrosion resistant, easy to machine | Aerospace, electronics, automotive |

| Aluminum | 7075-T6 | 570 | 2.8 | High strength, excellent fatigue resistance | Defense, racing, structural parts |

| Stainless Steel | 304 | 505 | 8.0 | Corrosion resistant, hygienic, weldable | Medical, food processing, marine |

| Stainless Steel | 316 | 570 | 8.0 | Superior corrosion resistance, chloride resistant | Marine, chemical processing |

| Alloy Steel | 4140 | 655 | 7.85 | High toughness, good fatigue strength | Industrial machinery, tooling |

| Titanium | Ti-6Al-4V | 950 | 4.43 | High strength-to-density, extreme environment resistance | Aerospace, motorsport, medical |

At Wuxi Lead Precision Machinery, we support material certification, lot traceability, and custom finishing to meet your exact project requirements. Partner with us to ensure your component design is optimized from material selection through to final surface treatment.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero Defect Shipment

Precision engineering begins with rigorous design validation. At Wuxi Lead Precision Machinery, our Design Phase integrates deep manufacturing expertise directly into your CAD models. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis, identifying potential production risks like inadequate tool access, problematic wall thickness, or unachievable tolerances before metal is cut. We collaborate closely with your design team to optimize geometry for CNC machining, sheet metal fabrication, or additive processes, ensuring manufacturability without compromising functional intent. This proactive review eliminates fundamental flaws early, establishing the critical foundation for zero defects. All models undergo strict geometric dimensioning and tolerancing (GD&T) verification against your specifications, confirming feasibility within our process capabilities.

Prototyping transitions validated designs into physical reality under controlled conditions. We utilize dedicated high-precision CNC machining centers and coordinate measuring machines (CMM) for rapid prototype creation. Each prototype undergoes First Article Inspection (FAI) per AS9102 or customer-specific standards, verifying every critical dimension, surface finish, and material property. Crucially, this phase validates not just the part, but the process: fixture design, tool paths, and inspection routines are rigorously tested and refined. Material certifications and full traceability are established. Only after successful prototype validation and your formal sign-off do we advance to mass production, ensuring the manufacturing system is proven capable.

Mass Production executes with systematic discipline to guarantee zero defects. We deploy Statistical Process Control (SPC) on all critical dimensions, continuously monitoring machining parameters and output via real-time data acquisition. Every component undergoes 100% critical feature verification using calibrated CMMs, vision systems, or custom gauges at defined process stages. Full material traceability—from raw stock heat number to final shipment—is maintained. Our production cells operate under strict environmental controls, with tool wear monitored and compensated automatically. Final inspection includes comprehensive functional testing where applicable and full documentation package assembly. This integrated approach, combining advanced technology with rigorous procedural adherence, ensures consistent output meeting the most demanding aerospace, medical, and semiconductor specifications.

Key Process Specifications

| Phase | Tolerance Capability | Primary Materials | Lead Time (Typical) | Key Validation Step | Standards Compliance |

|---|---|---|---|---|---|

| Design | ±0.005 mm (Model) | All CAD Formats | 3-5 Business Days | DFM Report & GD&T Review | ISO 1101, ASME Y14.5 |

| Prototyping | ±0.005 mm | Aluminum, Steel, Ti, Brass | 7-10 Business Days | Full FAI Report | AS9102, PPAP Level 3 |

| Mass Production | ±0.002 mm (Critical) | Certified Aerospace/Medical Alloys | 15-25 Days (Lot) | SPC Charts + 100% CMM | ISO 9001, IATF 16949, NADCAP |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your project demands precision, reliability, and technical mastery in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery is the strategic decision that sets your business apart. As a leader in high-end CNC machining and custom fabrication, we specialize in delivering mission-critical components for industries where performance cannot be compromised—automotive, aerospace, medical devices, industrial automation, and advanced electronics. Our commitment is not just to meet your specifications, but to exceed them consistently, on time, every time.

At Lead Precision, we understand that your supply chain is only as strong as its weakest link. That’s why we’ve engineered our entire operation—from raw material sourcing to final inspection—to uphold the highest standards of quality and repeatability. Our state-of-the-art facility in Wuxi, China, spans over 15,000 square meters and is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and automated inspection systems powered by CMM and optical measurement technology. With in-house capabilities in milling, turning, grinding, and sheet metal fabrication, we offer a single-source solution for complex, high-tolerance parts.

Our engineering team works collaboratively with your design and procurement staff from initial concept through production scaling. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing model ensures rapid turnaround without sacrificing precision. We support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, copper, and specialty engineering plastics, all processed under strict ISO 9001:2015 certified procedures.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling; CNC turning; Swiss machining |

| Tolerances | ±0.005 mm (±0.0002″) for critical features |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Copper, Inconel, PEEK |

| Max Work Envelope | 1200 x 800 x 650 mm (47 x 31.5 x 25.6 in) |

| Surface Finishes | As-machined, anodizing (Type II & III), powder coating, passivation, polishing, plating |

| Quality Control | Full CMM reporting, first article inspection (FAI), PPAP documentation, SPC monitoring |

| Lead Times | Prototypes: 5–7 days; Production: 10–20 days (varies by complexity) |

Every component we produce is a testament to our philosophy: precision is not an outcome—it’s a process. Our clients rely on us not just as a vendor, but as an extension of their engineering team, providing DFM feedback, cost-optimization insights, and long-term supply assurance.

If you’re building high-performance systems where component integrity is non-negotiable, it’s time to partner with a manufacturer who shares your standards. Contact us today at [email protected] to discuss your next project. Let Lead Precision be the foundation of your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.