Technical Contents

Engineering Guide: Pcbway Sheet Metal

Engineering Insight: The Critical Role of Precision in PCBWay Sheet Metal Fabrication

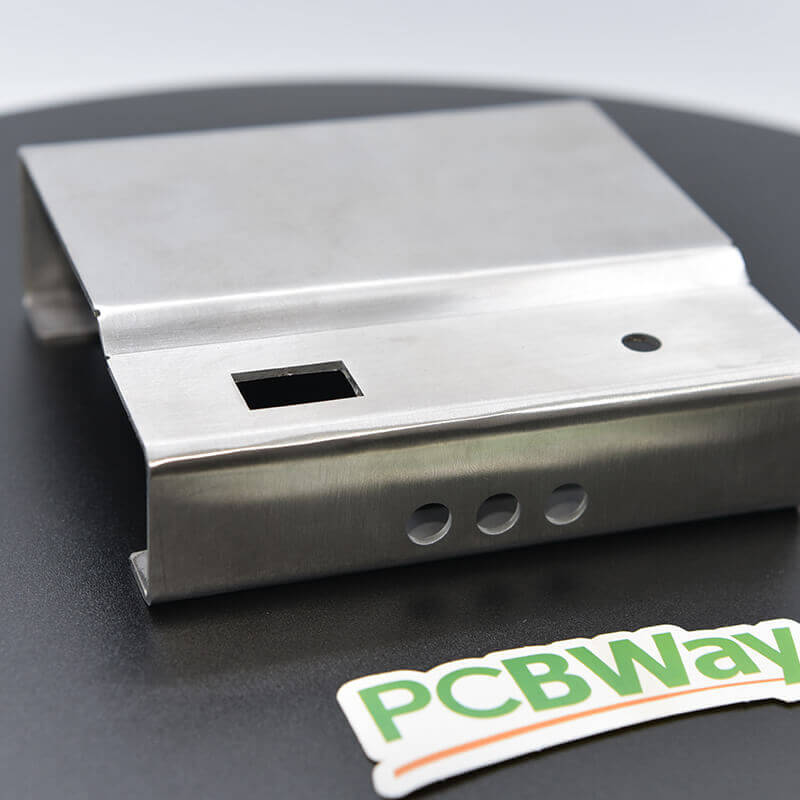

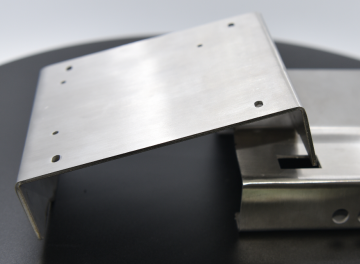

In the realm of high-performance manufacturing, precision is not merely a target—it is the foundation upon which reliability, functionality, and compliance are built. This is especially true in sheet metal fabrication for integrated electronic systems, where components must align flawlessly with printed circuit boards and embedded assemblies. At Wuxi Lead Precision Machinery, we understand that the dimensional accuracy, edge quality, and geometric consistency of sheet metal enclosures directly influence the performance and longevity of the final product. Even deviations measured in microns can lead to assembly misalignment, compromised EMI shielding, or thermal inefficiencies—failures that are unacceptable in mission-critical applications.

Our engineering philosophy centers on achieving micron-level tolerances through advanced CNC punching, laser cutting, and automated bending technologies. These processes are not operated in isolation; they are guided by comprehensive CAD/CAM integration and real-time quality verification systems. When producing sheet metal housings for PCB integration—commonly referred to in industry as PCBWay-compatible structures—our focus extends beyond raw fabrication. We ensure that mounting points, cutouts, and grounding features align perfectly with PCB layouts, minimizing assembly time and reducing field failure risks.

Wuxi Lead Precision Machinery brings over two decades of experience in high-integrity manufacturing, serving sectors where failure is not an option. Our work has supported infrastructure for Olympic Games broadcast systems, where environmental durability and rapid deployment were paramount. We have also supplied precision enclosures for military communication units, meeting stringent MIL-STD-810 and IP67 requirements. These projects demanded not only exacting tolerances but also full traceability, material certification, and repeatable production runs—benchmarks we now apply to every PCBWay sheet metal order.

Our facility operates under ISO 9001 and ISO 14001 standards, with in-house metrology labs equipped with coordinate measuring machines (CMM) and laser trackers. This infrastructure allows us to validate every critical dimension, ensuring that each component meets the design intent without compromise.

Below are key fabrication capabilities that support high-precision PCBWay sheet metal solutions:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1° / ±0.1 mm |

| Minimum Hole Diameter | 1.0 mm (steel) |

| Surface Roughness (Laser Cut) | Ra ≤ 3.2 μm |

| Max Working Area | 1500 mm × 3000 mm |

| Supported Materials | SPCC, SUS304, SGCC, AL5052, Copper Alloy |

Precision in sheet metal is not an incremental advantage—it is the defining factor in system integration success. At Wuxi Lead Precision Machinery, we combine technical excellence with proven field experience to deliver enclosures that perform as seamlessly as the electronics they protect.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication for Demanding Applications

Wuxi Lead Precision Machinery serves as the strategic manufacturing partner for PCBWay’s premium sheet metal solutions, delivering uncompromising precision for mission-critical electronics enclosures, chassis, and structural components. Our integrated facility in Wuxi, China, combines advanced machinery with rigorous quality protocols to ensure every part meets the exacting standards of aerospace, medical, and high-frequency communication sectors. Central to our capability is the deployment of multi-axis CNC technology, enabling complex geometries that conventional stamping or laser cutting alone cannot achieve. This eliminates secondary operations, reduces lead times, and maintains critical feature alignment across intricate assemblies.

Our 5-axis CNC milling and turning centers process materials including aluminum alloys (6061-T6, 7075), stainless steels (304, 316L), and copper alloys with micron-level repeatability. Simultaneous 5-axis motion allows undercuts, compound angles, and integrated mounting features to be machined in a single setup, preserving dimensional integrity and minimizing handling-induced errors. This capability is essential for RF shielding components requiring seamless seams or thermal management systems demanding precise fin geometries. All machining programs undergo virtual simulation and first-article validation to confirm toolpath accuracy before production release.

Quality assurance is non-negotiable. Every critical dimension is verified using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with 2.5μm + L/300 μm accuracy, traceable to NIST standards. Our inspection protocol includes full first-article reports (FAIR), in-process checks at defined production intervals, and final batch certification. Statistical process control (SPC) data is maintained for all high-volume runs, ensuring process stability and enabling proactive correction of drift. Surface finish, flatness, and hole positional accuracy are validated against ASME Y14.5 GD&T standards, with raw material certifications and heat-treat documentation provided upon request.

The following table defines our standard tolerance capabilities for sheet metal fabrication processes, reflecting achievable precision under controlled conditions with appropriate material selection and design collaboration:

| Process | Material Range | Thickness Range | Tolerance | Measurement Method |

|---|---|---|---|---|

| Laser Cutting | Steel, Aluminum, Copper, Brass | 0.5mm – 6.0mm | ±0.05mm | CMM / Optical Comparator |

| CNC Punching | Steel, Aluminum | 0.8mm – 3.0mm | ±0.08mm | CMM |

| Press Brake Bending | Steel, Aluminum, Stainless | 0.5mm – 4.0mm | ±0.1° / ±0.05mm | CMM / Angle Gauge |

| MIG/TIG Welding | Steel, Aluminum, Stainless | 0.8mm – 6.0mm | ±0.2mm (distortion) | CMM / Fixture Check |

| 5-Axis CNC Machining | All sheet-compatible alloys | N/A | ±0.01mm | CMM / Micrometer |

These capabilities translate directly to client success: reduced assembly scrap, higher field reliability, and accelerated time-to-market. We collaborate early in the design phase to optimize manufacturability, leveraging DFM expertise to balance precision with cost efficiency. For PCBWay clients, this means receiving fully validated, ready-to-integrate components where dimensional accuracy directly supports electronic performance and system longevity. Contact our engineering team to discuss tolerance-critical applications—we provide detailed process capability studies (Cp/Cpk) for mission-specific requirements.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a critical step in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we specialize in high-tolerance manufacturing for demanding industrial and commercial applications. Our expertise enables clients to make informed decisions when choosing between aluminum, steel, and titanium—three of the most widely used metals in modern fabrication.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is particularly suitable for aerospace, electronics enclosures, and transportation components where weight reduction is a priority. Grade 6061-T6 is a common choice due to its weldability and machinability, while 5052-H32 offers superior formability for complex bends and deep draws. Aluminum’s natural oxide layer provides inherent protection, but when enhanced surface properties are required, anodizing is recommended.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, durability, and cost-effectiveness. Cold-rolled steel (CRS) and galvanized steel are frequently used in structural enclosures, machinery frames, and electrical cabinets. While steel offers superior mechanical performance, it is susceptible to oxidation. Therefore, proper surface finishing—such as powder coating or zinc plating—is essential for long-term reliability in harsh environments.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. Its exceptional strength-to-density ratio, resistance to high temperatures, and immunity to corrosion in saline or acidic environments make it ideal for aerospace, medical devices, and marine applications. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are commonly fabricated in sheet form, though special tooling and techniques are required due to its low thermal conductivity and high reactivity at elevated temperatures.

Anodizing: Enhancing Aluminum Performance

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, significantly improving surface hardness, wear resistance, and corrosion protection. It also allows for color coding through dye integration, which is beneficial for product identification and aesthetics. Type II (sulfuric acid) anodizing is standard for most industrial applications, providing a durable coating between 8–25 µm. For extreme environments, Type III (hardcoat) anodizing produces layers up to 50 µm with Rockwell hardness exceeding 60 HRC. At Wuxi Lead, we ensure precise control over coating thickness and uniformity, meeting ASTM B580 and MIL-A-8625 standards.

Below is a comparative overview of key material properties:

| Material | Typical Grades | Density (g/cm³) | Tensile Strength (MPa) | Common Applications | Key Advantages |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 290–320 | Enclosures, heat sinks | Lightweight, corrosion resistant |

| Steel | CR1018, Galv. DX51D | 7.85 | 340–550 | Frames, cabinets | High strength, economical |

| Titanium | Grade 2, Grade 5 | 4.5 (Grade 2) | 345–1000 | Aerospace, medical implants | Extreme environment resilience |

Choosing the right material and finish ensures long-term reliability and performance. At Wuxi Lead Precision Machinery, we support clients through every phase of material selection, leveraging decades of fabrication experience and strict quality control to deliver precision-engineered sheet metal solutions.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: From Concept to Zero Defect Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for uncompromising quality and efficiency, transforming client specifications into flawless components. We rigorously implement a three-stage workflow—Design, Prototyping, Mass Production—integrated with Zero Defects methodology to eliminate waste and ensure consistent, high-integrity output for demanding PCBWay applications.

The Design phase is foundational. Our engineering team conducts exhaustive Design for Manufacturability (DFM) analysis using SolidWorks and CATIA, scrutinizing every bend, cut, and feature against material properties and process capabilities. We identify potential stress points, tooling conflicts, or tolerance stack-ups before metal is cut, collaborating closely with clients to optimize geometry for both performance and producibility. This proactive digital validation prevents 90% of potential defects at the source, ensuring the design blueprint is inherently robust and manufacturable to exacting standards.

Prototyping transitions the validated design into physical reality for critical assessment. Utilizing our high-speed laser cutting and CNC turret systems, we produce functional prototypes within 3-5 business days. Each prototype undergoes rigorous dimensional inspection against the original CAD model using Zeiss CMMs and optical comparators. This stage validates form, fit, function, and assembly compatibility with PCB components, allowing for rapid, cost-effective design refinement. Physical validation against the digital twin confirms process stability and identifies any micro-adjustments needed prior to full-scale launch, ensuring the production process is de-risked.

Mass Production leverages the perfected parameters from prototyping within our fully integrated, IoT-connected production cell. Every stage—laser cutting, bending, welding, finishing—is monitored in real-time via SPC (Statistical Process Control) systems. Automated vision inspection checks critical features after each operation, while inline CMMs perform periodic high-accuracy verification. Material traceability is maintained from coil to finished part, and our closed-loop feedback system instantly corrects any deviation from target tolerances. This relentless focus on process control, executed by our certified technicians, guarantees sustained zero-defect output at scale.

Our core capabilities enable this precision, as defined by the following specifications:

| Parameter | Capability | Standard Tolerance |

|---|---|---|

| Material Thickness | 0.5mm to 6.0mm | ±0.05mm |

| Max Part Size | 3000mm x 1500mm | ±0.1mm |

| Hole Positioning | Critical Features | ±0.03mm |

| Bend Angle | All Operations | ±0.5° |

| Surface Finish | Deburred, Anodized, Powder Coat | Ra ≤ 0.8µm |

This integrated approach—where design integrity, prototype validation, and statistically controlled mass production converge—ensures Wuxi Lead delivers sheet metal components meeting PCBWay’s exacting requirements with absolute reliability. Zero Defects is not an aspiration; it is the measurable outcome of our disciplined engineering process.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end manufacturing. As a trusted leader in sheet metal fabrication, we specialize in delivering engineered solutions that meet the rigorous demands of industries such as telecommunications, automation, medical equipment, and advanced electronics. When you partner with us, you’re not just outsourcing production—you’re aligning with a team of experts committed to your project’s success from concept to completion.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems, enabling us to handle complex geometries with tight tolerances and exceptional repeatability. We process a wide range of materials including stainless steel, aluminum, galvanized steel, and copper alloys, ensuring optimal performance for every application. With decades of combined engineering experience and a customer-first approach, we provide tailored solutions that balance cost-efficiency with uncompromised quality.

What sets us apart is our end-to-end service model. From DFM analysis and prototyping to high-volume production and surface finishing, every stage is managed in-house under strict ISO 9001-certified processes. Our quality control protocols include first-article inspection, in-process checks, and final product validation using precision measuring instruments such as CMMs and laser scanners. This ensures every component meets your exact specifications and industry standards.

We pride ourselves on responsiveness and transparency. Our engineering team collaborates directly with your design staff to resolve potential manufacturability issues early, reducing lead times and minimizing costly revisions. Whether you require low-volume custom enclosures or scalable production runs, we adapt to your timeline and volume needs without sacrificing precision.

Below are key capabilities that define our sheet metal fabrication services:

| Specification | Detail |

|---|---|

| Material Thickness | 0.5 mm – 6.0 mm |

| Maximum Processing Size | 3000 mm × 1500 mm |

| Tolerance | ±0.1 mm (standard), tighter upon request |

| Cutting Methods | Fiber Laser, CNC Punching |

| Bending | CNC Press Brake, up to 300 tons |

| Welding | TIG, MIG, Spot Welding |

| Finishing Options | Powder Coating, Anodizing, Plating, Brushing |

| Quality Standards | ISO 9001:2015, RoHS Compliant |

Your success is our benchmark. By integrating advanced technology with deep manufacturing expertise, we deliver components that perform, every time. If you’re evaluating partners for your next sheet metal project, we invite you to experience the Lead Precision difference.

Contact us today at [email protected] to discuss your requirements, request a quote, or schedule a factory audit. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.