Technical Contents

Engineering Guide: Pcb Overmolding

Engineering Insight: The Critical Role of Precision in PCB Overmolding

In high-reliability manufacturing environments, PCB overmolding is not merely an assembly technique—it is a precision engineering process that ensures long-term durability, environmental resistance, and structural integrity of electronic systems. At Wuxi Lead Precision Machinery, we approach PCB overmolding as a mission-critical operation, where micron-level accuracy directly influences product performance in aerospace, defense, medical, and industrial applications.

PCB overmolding involves encapsulating printed circuit boards with thermoplastic or thermoset materials to protect against moisture, vibration, thermal cycling, and mechanical shock. However, the success of this process hinges on the precision of mold design, material flow control, temperature regulation, and alignment. Even minor deviations in cavity dimensions or injection pressure can lead to incomplete encapsulation, delamination, or stress-induced microcracks—failures that are unacceptable in high-stakes industries.

Our engineering team leverages over 15 years of experience in custom metal manufacturing and precision molding, with direct involvement in projects supporting Olympic-standard timing systems and military-grade communication modules. These applications demand zero-defect performance under extreme conditions, reinforcing our commitment to precision at every stage. Our in-house mold design and CNC machining capabilities ensure that tooling tolerances remain within ±0.005 mm, minimizing flash and ensuring consistent part geometry across production runs.

We utilize advanced simulation software to model material behavior during injection, predicting potential warpage or air entrapment before tooling is cut. This proactive approach reduces development cycles and ensures first-time-right outcomes. Furthermore, our cleanroom molding facilities maintain ISO Class 7 standards, critical for medical and semiconductor-related overmolding where particulate contamination must be eliminated.

Material selection is equally critical. We work with high-performance polymers such as PPS, LCP, and liquid silicone rubber (LSR), each chosen for thermal stability, dielectric strength, and adhesion properties. Our process parameters are fine-tuned for each material-substrate combination, ensuring optimal bonding between the encapsulant and sensitive PCB components without damaging solder joints or passive elements.

The following table outlines key process specifications maintained at Wuxi Lead Precision Machinery for high-integrity PCB overmolding:

| Parameter | Specification |

|---|---|

| Mold Tolerance | ±0.005 mm |

| Injection Pressure Control | ±1 bar |

| Temperature Uniformity | ±2°C across mold surface |

| Cleanroom Class | ISO 7 (Class 10,000) |

| Material Shrinkage Compensation | CAD-optimized based on FEA simulation |

| Cycle Time Accuracy | ±0.5 seconds |

| Dimensional Repeatability | Cp/Cpk ≥ 1.67 |

Our track record in precision-critical sectors underscores our ability to deliver overmolded PCB assemblies that meet the most stringent reliability standards. At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer confidence into every part.

Precision Specs & Tolerances

Technical Capabilities for Precision PCB Overmolding Solutions

Wuxi Lead Precision Machinery delivers engineered excellence in custom metal manufacturing specifically for demanding PCB overmolding applications. Our integrated approach combines advanced multi-axis machining with rigorous metrology to produce housings, shields, and structural components that ensure optimal thermal management, signal integrity, and environmental protection for sensitive electronics. We understand that the success of your overmolded assembly hinges on the foundational precision of the metal component, directly impacting yield rates and long-term field reliability.

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers. This technology is essential for producing the complex geometries, tight internal features, and critical sealing surfaces required in modern PCB overmolding tooling and end-use components. The simultaneous movement across five axes allows us to machine intricate contours, deep cavities, and undercuts in a single setup. This eliminates cumulative errors from multiple fixtures, significantly enhancing part accuracy and repeatability while reducing lead times. We utilize high-stability machines with thermal compensation systems, capable of maintaining micron-level precision during extended production runs on challenging materials like aluminum alloys, stainless steels, and copper alloys commonly specified for EMI shielding and thermal dissipation.

Quality control is not an endpoint but an integrated process at Wuxi Lead. Every critical dimension and geometric feature undergoes verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection routines, developed from detailed client drawings and GD&T specifications, provide comprehensive 3D data validation. This ensures conformity to the most stringent tolerances across all axes, verifying flatness, parallelism, positional accuracy of mounting features, and the integrity of sealing surfaces vital for preventing resin bleed during the overmolding process. This metrology-driven approach provides tangible data for process validation and continuous improvement, giving you confidence in every component shipped.

The following table details our standard achievable capabilities for precision-machined components supporting PCB overmolding processes. These figures represent our routine production performance under controlled conditions; tighter tolerances are achievable for critical features upon specific engineering review and process validation.

| Specification Category | Standard Capability | Notes |

|---|---|---|

| Dimensional Tolerance (Linear) | ±0.005 mm (±0.0002″) | Standard for critical mating/sealing surfaces |

| Geometric Tolerance (Flatness) | 0.008 mm (0.0003″) per 100mm | Verified via CMM on critical mounting surfaces |

| Surface Roughness (Ra) | 0.4 μm (16 μin) | Typical machined finish; finer finishes available |

| Material Compatibility | Aluminum 6061/7075, Stainless 303/316, Copper C110 | Plus client-specified alloys; full material certs provided |

| Cavity Precision (for Tooling) | ±0.003 mm (±0.0001″) | Critical for overmold dimensional control |

| Feature Positional Accuracy | ±0.005 mm (±0.0002″) | Verified per GD&T callouts on all critical features |

This level of precision engineering ensures seamless integration with your overmolding process, minimizing flash, preventing component damage, and guaranteeing the final assembly meets exacting performance and reliability standards. Wuxi Lead Precision Machinery provides the dimensional integrity your PCB overmolding success demands.

Material & Finish Options

Material Selection for Precision PCB Overmolding Components

In high-performance PCB overmolding applications, the selection of base materials and surface finishes plays a critical role in ensuring mechanical integrity, thermal management, electrical insulation, and long-term reliability. At Wuxi Lead Precision Machinery, we specialize in custom metal components that serve as structural and functional frameworks for advanced overmolding processes. Our engineering expertise enables clients to optimize material choices based on application demands such as environmental exposure, weight constraints, strength requirements, and regulatory compliance.

Aluminum is frequently the material of choice for PCB overmolding due to its excellent strength-to-weight ratio, high thermal conductivity, and machinability. Grades such as 6061-T6 and 7075-T6 are commonly used in aerospace, automotive, and industrial electronics. Aluminum effectively dissipates heat generated by embedded circuitry, reducing thermal stress on sensitive components. Additionally, its compatibility with anodizing processes enhances surface durability and electrical isolation, making it ideal for overmolded housings where insulation and corrosion resistance are paramount.

Steel, particularly stainless steel grades like 304 and 316, offers superior mechanical strength and resistance to extreme environments. While heavier than aluminum, steel provides exceptional durability in high-vibration or high-impact applications. Its use is prevalent in medical devices, defense systems, and offshore electronics where long-term structural stability and resistance to moisture, chemicals, and sterilization processes are required. However, due to its lower thermal conductivity compared to aluminum, steel is typically selected when mechanical performance outweighs thermal management needs.

Titanium, specifically Grade 5 (Ti-6Al-4V), is employed in mission-critical applications where extreme strength, lightweight properties, and outstanding corrosion resistance are non-negotiable. Aerospace, deep-sea instrumentation, and high-end medical implants often utilize titanium overmolded enclosures. Although more challenging to machine and higher in cost, titanium’s biocompatibility and performance under extreme temperatures make it indispensable in niche, high-value sectors.

Surface finishing, particularly anodizing, is a key enhancement for aluminum components. Type II (sulfuric acid) and Type III (hardcoat) anodizing create a durable, non-conductive oxide layer that improves wear resistance and provides electrical insulation essential for overmolding. Hard anodizing, in particular, delivers a thicker coating (up to 50 µm) suitable for harsh operational environments.

The following table summarizes key mechanical and thermal properties of the primary materials used in our PCB overmolding solutions.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 167 | Anodizing (Type II/III) | Automotive, Industrial Electronics |

| Stainless Steel 316 | 8.0 | 580 | 16 | Passivation, Electropolish | Medical, Marine, Chemical |

| Titanium Ti-6Al-4V | 4.4 | 900 | 7.2 | Anodizing, Laser Etching | Aerospace, Defense, Medical |

Selecting the appropriate material and finish requires a comprehensive understanding of operational conditions and performance goals. Wuxi Lead Precision Machinery supports clients through every stage of this decision, ensuring optimal integration of metal components within the PCB overmolding process.

Manufacturing Process & QC

PCB Overmolding: Precision Engineering for Zero Defects

Our PCB overmolding process delivers absolute reliability for demanding electronics applications. Achieving zero defects requires an integrated approach spanning design, prototyping, and mass production, underpinned by Wuxi Lead Precision Machinery’s advanced CNC capabilities and rigorous quality systems. This ensures your overmolded assemblies withstand harsh environments while maintaining electrical integrity.

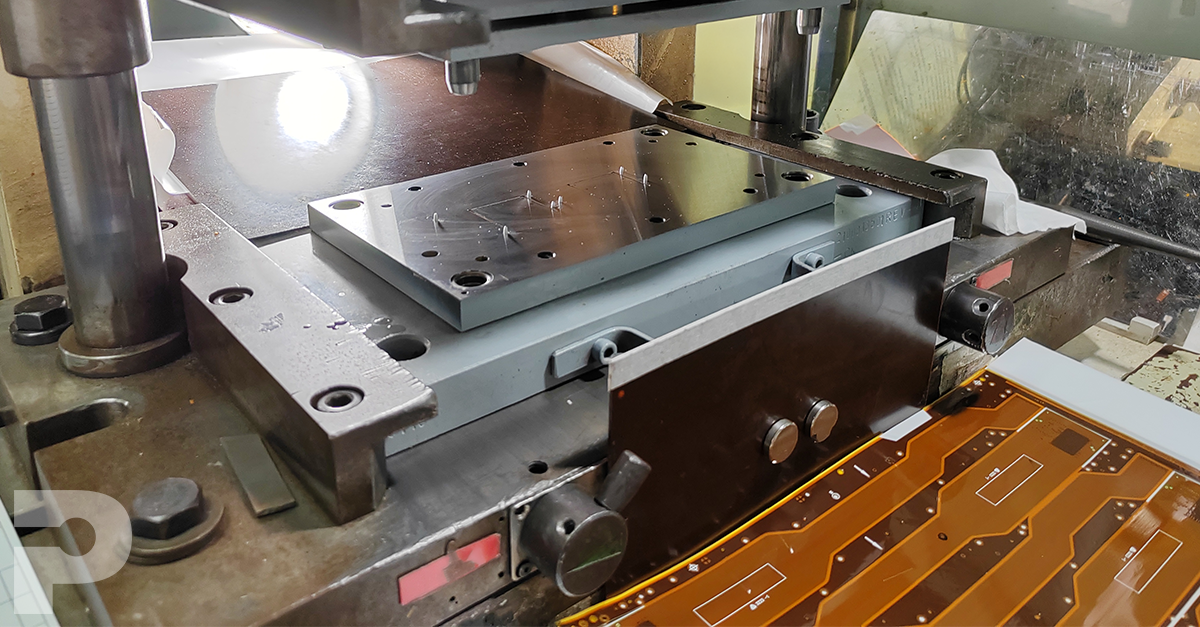

The process begins with collaborative design engineering. Our team conducts in-depth Design for Manufacturing (DFM) analysis, focusing on mold flow simulation, thermal management, and material compatibility. We optimize parting lines, gate locations, and venting to prevent voids, knit lines, or flash that compromise protection. Critical factors like coefficient of thermal expansion (CTE) matching between the PCB substrate, components, and selected thermoplastic elastomer (TPE) or liquid silicone rubber (LSR) are meticulously evaluated. This phase establishes the foundation for defect prevention by addressing potential failure modes before tooling commences.

Prototyping utilizes CNC-machined prototype molds, enabling rapid validation of the design under real-world conditions. We perform functional testing, including thermal cycling (-40°C to +125°C), moisture ingress resistance (IP67/IP68), and mechanical stress tests. Metrology-grade verification confirms dimensional accuracy and material adhesion strength. Any deviations trigger immediate design or process adjustments. This stage is non-negotiable for identifying micro-defects invisible to standard inspection, ensuring the final process window is robust.

Mass production leverages our high-precision, temperature-stabilized molding cells. Zero defects are enforced through 100% inline automated optical inspection (AOI) for surface defects, flash, and component shift. In-process Statistical Process Control (SPC) monitors critical parameters like melt temperature, injection pressure, and cure time in real-time. Every batch undergoes destructive testing per IPC-A-610 standards for adhesion, electrical isolation, and environmental resistance. Our closed-loop feedback system instantly corrects process drift, guaranteeing consistent output. Traceability from raw material lot to finished part is mandatory.

The following table details key production specifications achievable with our process:

| Parameter | Specification | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm (critical features) | CMM (ISO 10360-2) |

| Material Temperature Range | -55°C to +180°C (LSR/TPE variants) | Thermal Cycling Chamber (IEC 60068) |

| Adhesion Strength | > 8 MPa (peel test) | ASTM D903 / IPC-TM-650 2.4.8 |

| Moisture Ingress | IP68 compliant (1.5m, 30 days) | IEC 60529 Testing |

| Electrical Isolation | > 1000 MΩ @ 500V DC | Megohmmeter (IEC 60664-1) |

Wuxi Lead Precision Machinery integrates CNC excellence with disciplined process control. From initial simulation to final shipment, every step is engineered to eliminate defects, ensuring your overmolded PCBs deliver uncompromised performance and longevity in the field. Partner with us for manufacturing certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced PCB Overmolding Solutions

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing with a focus on advanced PCB overmolding technologies. As a trusted partner in the industrial automation and electronics protection sector, we deliver engineered solutions that meet the rigorous demands of aerospace, medical devices, automotive systems, and industrial controls. Our expertise lies in combining precision metal fabrication with polymer encapsulation processes to produce robust, reliable, and fully sealed electronic assemblies.

PCB overmolding is more than a protective measure—it’s a strategic enhancement that improves product durability, thermal stability, and resistance to environmental stressors such as moisture, vibration, and chemical exposure. At Lead Precision, we integrate state-of-the-art injection molding equipment with in-house tooling design and metallurgical analysis to ensure every overmolded component exceeds performance expectations. Our engineering team works closely with clients from concept through production, offering DFM analysis, material selection guidance, and rapid prototyping to accelerate time-to-market.

What sets us apart is our vertical integration model. We control every stage of production—from CNC machining and stamping to mold fabrication and cleanroom overmolding—ensuring consistency, traceability, and compliance with international quality standards. All processes are executed under ISO 9001-certified protocols, with full documentation and first-article inspection reports available upon request.

We understand that every application presents unique challenges. Whether you require overmolding for high-density SMT assemblies, flexible hybrid circuits, or ruggedized control modules, our team tailors material formulations (including LSR, PPS, PBT, and thermoplastic elastomers) and process parameters to match your operational environment. Our presses range from 50 to 350 tons, enabling production scalability from low-volume prototypes to high-volume automated runs.

For seamless integration into your supply chain, we offer turnkey services including post-molding testing, conformal coating, and final assembly. Our facility in Wuxi, China, is equipped with real-time process monitoring and automated vision inspection systems, guaranteeing dimensional accuracy and defect-free output across batches.

| Specification | Capability |

|---|---|

| Molding Press Range | 50 – 350 tons |

| Typical Tolerances | ±0.05 mm |

| Material Compatibility | LSR, PPS, PBT, TPU, PA6, PA66, PP |

| Max PCB Size | 250 x 200 mm |

| Cleanroom Class | ISO 8 (Class 100,000 optional) |

| Secondary Operations | Ultrasonic welding, potting, testing, labeling |

| Lead Time (Prototype) | 15–20 days |

| Certifications | ISO 9001, RoHS, REACH compliance |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, quality, and long-term collaboration. We don’t just produce parts—we engineer performance. Contact us today at [email protected] to discuss your PCB overmolding requirements and discover how our precision-driven approach can elevate your product reliability and market competitiveness.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.