Technical Contents

Engineering Guide: Parts Injection Mold

Engineering Insight Precision in Metal Injection Molding

In high-volume metal injection molding MIM the margin for error exists solely in the sub-micron realm. Unlike plastic molding metal feedstocks introduce complex variables thermal expansion differential shrinkage and powder density fluctuations. These factors demand not just tight tolerances but predictive engineering to counteract material behavior during sintering. At Wuxi Lead Precision Machinery we treat 0.002mm tolerance not as a specification but as the baseline for viable production. This precision directly dictates part functionality structural integrity and assembly compatibility especially in multi-cavity tooling where cumulative deviations can cascade into systemic failure.

The consequences of inadequate precision manifest early in the production lifecycle. Variations exceeding 0.005mm in critical features like bearing seats or fluid channels induce micro-misalignments that accelerate wear compromise seals or disrupt thermal management. In medical or aerospace applications such deviations violate regulatory thresholds rendering entire batches non-compliant. Our engineering protocols address this through closed-loop cavity pressure monitoring and AI-driven thermal profiling ensuring each shot replicates the validated sintering curve within ±1.5°C. This level of control transforms material science theory into repeatable industrial output.

Wuxi Lead’s expertise in mission-critical molding is validated through deployments where failure is not an option. We engineered MIM components for Beijing 2022 Winter Olympics timing systems operating flawlessly at -30°C and supplied hardened connectors for military-grade communication arrays subjected to MIL-STD-810G vibration testing. These projects demanded zero-defect delivery under accelerated timelines proving our capability to merge extreme precision with ruggedized performance.

Our technical benchmarks consistently exceed industry norms as demonstrated below

| Critical Parameter | Industry Standard | Wuxi Lead Precision Standard | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.005mm | ±0.002mm | CMM with 24h thermal soak |

| Cavity Pressure Stability | ±5% | ±1.2% | In-mold piezoelectric sensors |

| Sintering Density Uniformity | 95-97% | 98.3-98.7% | Archimedes principle ASTM B962 |

| Surface Roughness (Ra) | 0.8-1.2μm | 0.3-0.5μm | Stylus profilometry ISO 4287 |

This rigor originates from our integrated approach where tooling design material science and process validation operate as a unified system. We collaborate with clients during DFM to preempt shrinkage-related defects through finite element analysis of sintering distortion. The result is first-article compliance rates exceeding 92% eliminating costly trial-and-error iterations. For sectors where component reliability dictates operational safety or brand reputation Wuxi Lead delivers the dimensional certainty that transforms design intent into field-proven performance. Partner with us to convert precision engineering into your competitive advantage.

Precision Specs & Tolerances

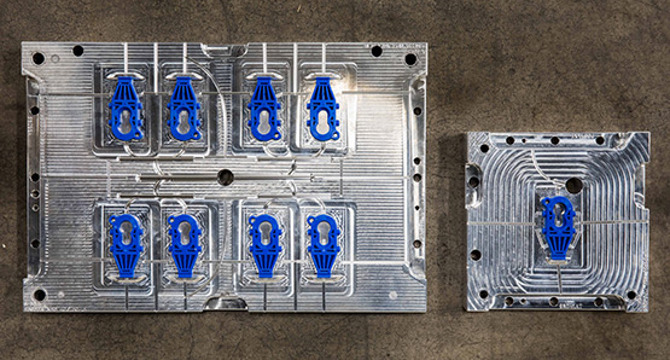

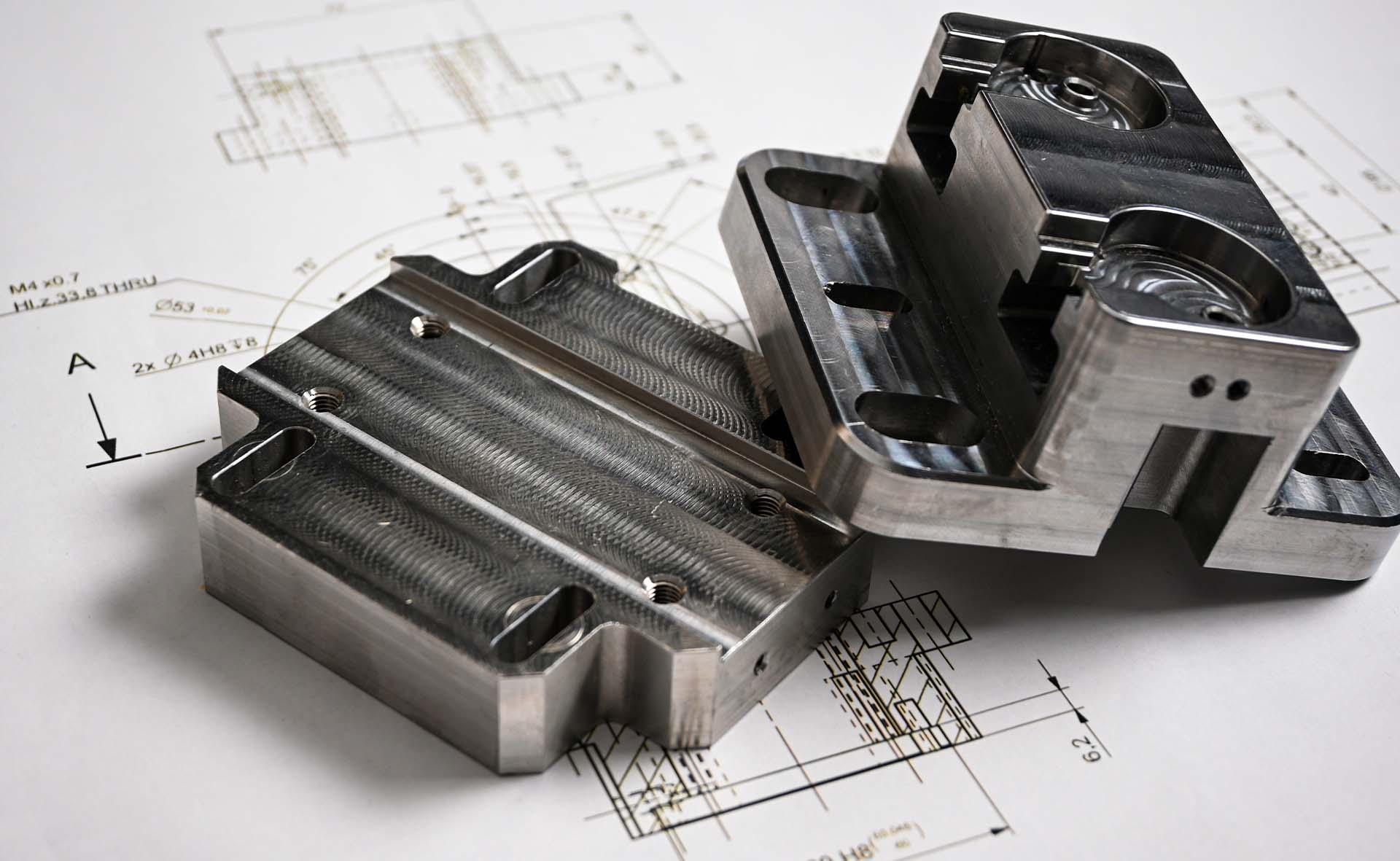

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in precision-engineered components for injection mold applications. Our facility integrates state-of-the-art 5-axis CNC machining technology to produce complex geometries with exceptional accuracy and surface finish. This multi-axis capability enables simultaneous machining from five different directions, minimizing setup changes and ensuring superior part consistency. By leveraging high-speed, high-torque spindles and advanced toolpath strategies, we achieve intricate contours and tight tolerances essential for mold cores, cavities, ejector systems, and cooling channels.

All machining operations are supported by a robust quality control infrastructure, anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology validation, ensuring every component conforms to the original CAD specifications. Each part undergoes comprehensive dimensional analysis, including geometric dimensioning and tolerancing (GD&T), flatness, parallelism, and positional accuracy checks. Data from CMM reports is documented and traceable, meeting stringent requirements for aerospace, medical, and automotive industries.

Our technical team combines decades of mold-making expertise with digital manufacturing workflows. From initial design review to final inspection, we apply precision engineering principles to optimize manufacturability, reduce cycle times, and extend mold life. Materials commonly processed include P20, H13, S136, 718HH, and other tool steels, as well as aluminum and stainless steel alloys. All components are machined in a climate-controlled environment to minimize thermal distortion and maintain dimensional stability.

Advanced CAM software enables adaptive machining strategies that enhance tool life and surface integrity, critical for mold surfaces requiring mirror polishing or texturing. We also integrate in-process probing for real-time tool wear compensation and first-article verification, reducing scrap rates and improving throughput.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Value |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.010 mm |

| Geometric Tolerance (Flatness, Parallelism) | ±0.008 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Angular Tolerance | ±0.05° |

| Maximum Work Envelope (5-Axis) | 1200 × 800 × 750 mm |

| Repeatability (CMM Measurement) | ±0.002 mm |

| Material Hardness Range | Up to 60 HRC (pre-hardened steels) |

Wuxi Lead Precision Machinery is committed to delivering injection mold components that meet the highest standards of precision and reliability. Our investment in 5-axis CNC technology and metrology-grade inspection ensures consistent quality, on-time delivery, and long-term performance in the most demanding production environments.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection mold cores, cavities, and critical components is fundamental to achieving production efficiency, part quality, and mold longevity. At Wuxi Lead Precision Machinery, we prioritize material properties that directly impact resistance to wear, thermal fatigue, corrosion, and dimensional stability under high cavity pressures and repeated thermal cycling. The choice between Aluminum, Tool Steel, and Titanium hinges on specific application demands, production volume, and part geometry complexity. Understanding these trade-offs ensures your mold investment delivers maximum return.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping, low-to-medium volume production, and molds requiring rapid heat dissipation. Their lower hardness compared to steels makes them faster and more economical to machine, accelerating time-to-market. However, aluminum’s susceptibility to wear under abrasive resins or high-volume runs necessitates careful application. Tool Steels, including P20, H13, and S136, form the backbone of high-volume, production-critical molds. These materials provide exceptional hardness, wear resistance, and polishability, maintaining tight tolerances over millions of cycles. Premium grades like S136 offer superior corrosion resistance for molding PVC or other aggressive materials. Titanium alloys, while less common due to cost and machining complexity, excel in highly corrosive environments or where extreme weight reduction is critical, offering a unique strength-to-weight ratio and outstanding corrosion resistance, though thermal conductivity is lower than aluminum.

Anodizing is a critical surface enhancement process primarily applied to aluminum mold components. This electrolytic passivation significantly increases surface hardness and wear resistance, extending mold life in demanding applications. It also provides excellent adhesion for subsequent coatings and enhances corrosion protection. Type II (Sulfuric Acid) anodizing is standard for general wear improvement, while Type III (Hard Anodizing) delivers a much thicker, harder, and more abrasion-resistant layer suitable for higher volume production on aluminum molds. It is essential to note that anodizing is specific to aluminum; steel components utilize nitriding, PVD/CVD coatings, or specialized plating, while titanium benefits from anodizing for color coding or mild corrosion enhancement, not primary wear resistance.

The following table summarizes key material properties relevant to injection mold performance:

| Material | Typical Hardness (HRC) | Key Strengths | Primary Limitations | Best Suited For |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | Rapid machining, Excellent thermal conductivity, Cost-effective for prototyping | Lower wear resistance, Limited for high-volume | Prototypes, Low-medium volume, Complex cores |

| P20 Tool Steel | 28-32 | Good machinability pre-hardened, Balanced toughness, Cost-effective production | Moderate wear resistance, Requires heat treatment for max performance | Medium-high volume production molds |

| H13 Tool Steel | 48-52 | Superior hot hardness, Excellent thermal fatigue resistance, High toughness | More difficult/costly to machine than P20 | High-temperature resins, High-volume production |

| S136 Stainless | 48-52 | Exceptional corrosion resistance, High polishability, Good wear resistance | Higher cost than standard tool steels | Corrosive resins (PVC), Optical clarity parts |

| Titanium Grade 5 | 32-36 | Highest corrosion resistance, Excellent strength-to-weight ratio | Very high cost, Difficult machining, Lower thermal conductivity | Extreme corrosion environments, Weight-sensitive aerospace molds |

Material selection is not merely a technical specification; it is a strategic decision impacting your entire production economics. Partner with Wuxi Lead Precision Machinery to analyze your specific resin, part geometry, volume requirements, and surface finish needs. Our engineering team will recommend the optimal material and surface treatment solution to maximize your mold’s performance and your operational ROI.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production of injection mold parts begins with an intensive design phase that integrates engineering rigor with advanced simulation technology. Our design engineers collaborate closely with clients to interpret technical drawings, 3D CAD models, and functional requirements. Utilizing industry-leading software such as Siemens NX, SolidWorks, and Autodesk Moldflow, we conduct mold flow analysis to predict material behavior, optimize gate locations, and identify potential defects before any metal is cut. This virtual validation ensures cavity balance, minimizes warpage, and enhances cycle time efficiency. Material selection is carefully matched to production volume, part geometry, and environmental exposure, with common choices including P20, 718H, S136, and H13 tool steels. Tolerances are defined to meet ISO 2768-mK or tighter, depending on application demands, setting the stage for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Following design finalization, we proceed to prototyping using high-precision CNC machining, wire EDM, and surface grinding to fabricate mold inserts and core components. This phase produces a fully functional mold capable of generating initial sample parts under real injection conditions. Prototypes are subjected to rigorous dimensional inspection via coordinate measuring machines (CMM) and 3D scanning to verify conformity to GD&T specifications. We perform mold trials with client-approved resins, evaluating fill patterns, ejection performance, and surface finish quality. Any deviations are corrected through iterative adjustments, ensuring process stability. The prototype stage is not merely a trial run—it is a critical validation gate where we confirm that the mold performs within specification across multiple cycles, achieving repeatability and reliability. Only after full sign-off from both engineering and client teams do we advance to mass production.

Mass Production: Sustained Precision at Scale

Our mass production process is built on automation, real-time monitoring, and Total Quality Management principles. Molded parts are produced on state-of-the-art electric and hybrid injection machines equipped with cavity pressure sensors and robotic part handling. Each production lot undergoes 100% visual inspection and statistical process control (SPC) sampling for critical dimensions. In-process checks are logged digitally, enabling traceability down to individual cavities and shifts. Preventive maintenance schedules ensure mold longevity and consistency, while environmental controls stabilize temperature and humidity in the production zone. We enforce a zero-defect mindset through Poka-Yoke systems and root cause analysis for any non-conformances.

Typical Production Specifications

| Parameter | Specification Range |

|---|---|

| Tolerance | ±0.005 mm to ±0.02 mm |

| Surface Finish | Ra 0.05 µm (polished) to Ra 3.2 µm (milled) |

| Tool Steel Options | P20, 718H, S136, H13, NAK80 |

| Mold Life | 100,000 to 1,000,000 cycles |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days (including mold fabrication) |

| Quality Standard | ISO 9001:2015, PPAP, FAI compliant |

From concept to volume output, Wuxi Lead Precision Machinery ensures every injection mold part meets the highest standards of precision, durability, and consistency—delivering excellence on every cycle.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Injection Mold Excellence

In high-stakes industries like aerospace, medical devices, and automotive, injection mold performance dictates production success. Substandard mold components lead to part defects, costly downtime, and compromised product integrity. At Wuxi Lead Precision Machinery, we engineer mold bases, cavities, cores, and inserts to exacting tolerances where 0.001mm deviations are non-negotiable. Our decades of specialization in custom metal manufacturing ensure your molds deliver thermal stability, longevity, and repeatable precision under extreme production cycles.

We integrate advanced 5-axis milling, wire EDM, and surface grinding with rigorous metrology protocols to eliminate common failure points. Every component undergoes CMM validation against AS9100 and ISO 13485 standards, guaranteeing dimensional accuracy and surface finishes down to Ra 0.05µm. Our engineering team collaborates from concept to validation, optimizing material selection—such as H13, S136, or custom alloys—to withstand corrosive resins and high-cavity pressures. This proactive approach reduces trial runs by up to 40% and extends mold life by 25% compared to industry averages.

Our technical capabilities are engineered for complexity:

| Capability | Specification Range | Precision Standard |

|---|---|---|

| Milling (5-Axis) | Up to Ø1,200 x 800 mm | ±0.003 mm |

| Wire EDM | Up to 400 x 300 x 250 mm | ±0.002 mm |

| Surface Grinding | Up to 1,000 x 500 mm | Flatness ≤ 0.0015 mm |

| Material Hardness Range | HRC 28–58 | Uniformity ±1.5 HRC |

| Surface Finish | Ra 0.05–0.8 µm | Mirror to textured |

Choosing Lead Precision means partnering with engineers who speak the language of tooling integrity. We prioritize your production timeline without sacrificing quality—achieving 95% on-time delivery through dedicated project management and real-time progress tracking. Our facility in Wuxi, China, operates under stringent environmental controls to maintain micron-level consistency, supported by a 24/7 technical response team for urgent production escalations.

When mold performance impacts your brand reputation and bottom line, settle for nothing less than engineered certainty. Contact our precision engineering team to initiate your project. Provide your dimensional requirements, material specifications, and volume needs, and we will deliver a feasibility assessment within 48 hours.

Initiate your precision project today:

[email protected]

Wuxi Lead Precision Machinery, Wuxi, China

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.