Technical Contents

Engineering Guide: Part Machining

Engineering Insight: The Non-Negotiable Imperative of Precision in Part Machining

In the realm of custom metal manufacturing, precision transcends mere specification; it is the foundational element determining functional integrity, assembly success, and ultimate product lifespan. Dimensional deviations, even measured in microns, cascade into system failures, accelerated wear, compromised safety, and costly field recalls. Modern engineering demands parts that perform predictably under extreme conditions—high stress, thermal cycling, vacuum, or corrosive environments. Achieving this requires machining processes governed by rigorous metrology, advanced CNC technology, and deep process understanding. Tolerances are not arbitrary targets but critical parameters derived from physics, material science, and the component’s role within a larger, often mission-critical, system. The cost of insufficient precision extends far beyond rework; it erodes brand reputation and incurs liabilities that dwarf initial manufacturing savings.

Wuxi Lead Precision Machinery operates at this demanding threshold of accuracy. Our 20+ years of specialization in high-complexity, low-volume production for aerospace, defense, and advanced industrial sectors is defined by unwavering commitment to precision. We have engineered components for Olympic venue infrastructure requiring flawless integration under stringent timelines and environmental loads. Furthermore, our facility holds certifications and processes compliant with stringent military standards, producing parts where dimensional stability directly impacts national security systems. This experience instills a culture where ±0.001mm tolerances are routine, material behavior under machining stress is meticulously modeled, and every process step is validated through continuous in-process and final inspection using coordinate measuring machines (CMMs) traceable to national standards. Precision is not an add-on service; it is our core engineering discipline.

Our technical capabilities enable this standard across diverse materials and geometries. Key machining performance metrics are consistently achieved:

| Capability | Specification | Typical Application Example |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Aerospace hydraulic manifolds |

| Surface Roughness | Ra 0.2 µm (8 µin) | Medical implant interfaces |

| Geometric Accuracy | < 0.002 mm (0.00008″) | Precision optical mounts |

| Material Range | Titanium, Inconel, 17-4PH, Aluminum Alloys | Defense actuator components |

Partnering with a manufacturer possessing this depth of precision engineering expertise mitigates supply chain vulnerability for critical components. At Wuxi Lead, we translate complex engineering drawings into physically perfect metal with the repeatability demanded by high-stakes industries. Our value lies not just in operating advanced machinery, but in the decades of metallurgical knowledge, process optimization, and quality systems rigor applied to every spindle rotation. When failure is not an option, precision becomes the non-negotiable cornerstone of your manufacturing partnership. We deliver the exact part, every time, ensuring your engineering vision performs flawlessly in the real world.

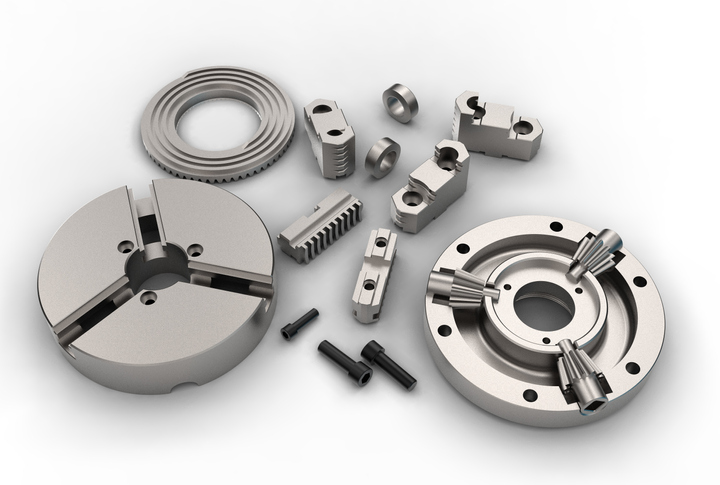

Precision Specs & Tolerances

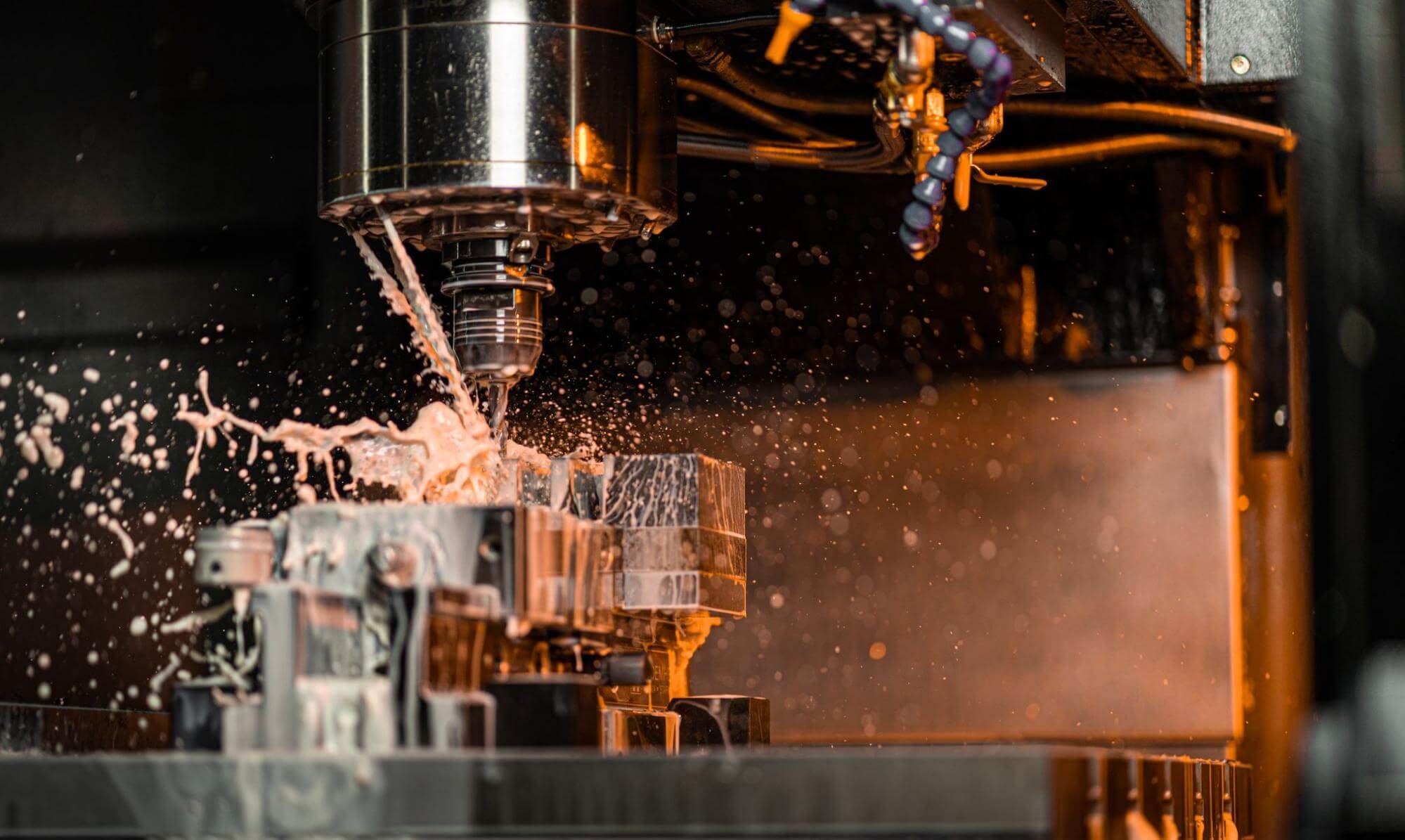

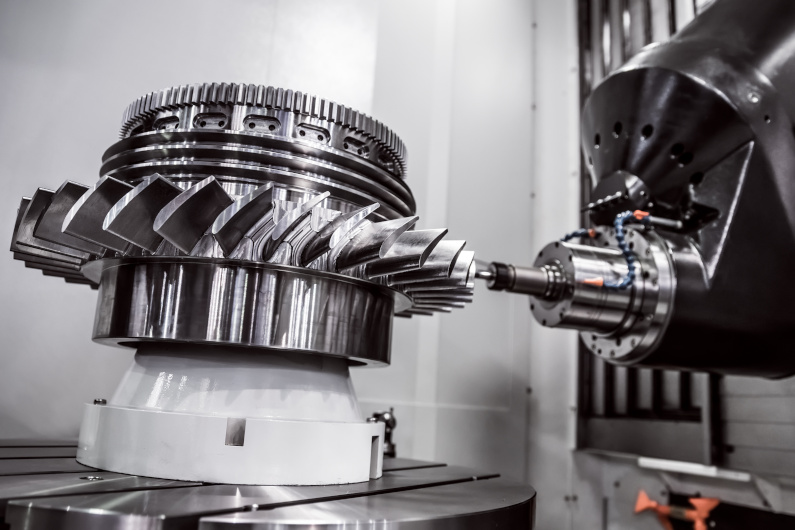

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of aerospace, medical, automotive, and industrial equipment sectors. At the core of our precision machining services is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional accuracy and surface finish. Our multi-axis systems eliminate the need for multiple setups, reducing cumulative error and cycle time while maintaining dimensional consistency across high-mix, low-volume, and full-production runs.

Our 5-axis CNC machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems. These features allow us to machine a broad range of materials—including aluminum alloys, stainless steels, titanium, Inconel, and specialty composites—with optimal efficiency and repeatability. The simultaneous movement across five axes ensures access to intricate contours and deep cavities, making our solutions ideal for components requiring tight tolerances and superior surface integrity.

Quality is embedded into every phase of production. Each machined part undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM) in our climate-controlled metrology lab. Our CMM systems provide full 3D geometric dimensioning and tolerancing (GD&T) verification, ensuring compliance with ASME Y14.5 and ISO 1101 standards. Data from inspections is documented in detailed First Article Inspection (FAI) reports and Statistical Process Control (SPC) charts, which are available to clients upon request.

We maintain full traceability from raw material to finished component, supported by digital work instructions and electronic batch records. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and process reliability.

The following table outlines the standard machining tolerances we consistently achieve under controlled conditions:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Diameter Tolerance | +0.025 / -0.010 mm | ±0.005 mm | For shafts and bores |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | As machined; can be improved with finishing |

| Angular Tolerance | ±0.1° | ±0.05° | Between features |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm | Measured via CMM |

| Runout | 0.03 mm | 0.01 mm | Total indicated runout (TIR) |

These capabilities are supported by advanced CAM programming using Siemens NX and Mastercam, ensuring optimized toolpaths and minimal thermal deformation. Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality control, and engineering expertise to deliver machined components that meet the highest standards of performance and reliability.

Material & Finish Options

Strategic Material Selection for Precision Machined Components

Material choice fundamentally dictates the performance, manufacturability, and lifecycle cost of precision machined parts. At Wuxi Lead Precision Machinery, we guide clients through this critical decision by aligning material properties with application demands, environmental exposure, and production efficiency. Selecting the optimal alloy and finish ensures parts meet stringent functional requirements while maximizing yield and minimizing waste during CNC machining.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and consumer electronics due to their exceptional strength-to-weight ratio and inherent corrosion resistance. 6061 offers excellent weldability and moderate strength, making it ideal for structural brackets and housings. 7075 provides superior strength, approaching some steels, but is less corrosion resistant and more challenging to machine. Aluminum’s high thermal conductivity aids heat dissipation but requires sharp tools and optimized feeds to prevent built-up edge and achieve fine surface finishes. Anodizing is frequently specified to enhance wear resistance and provide electrical insulation.

Stainless steel variants, especially 304 and 17-4 PH, are essential for medical devices, food processing, and marine applications demanding high corrosion resistance and strength. 304 offers excellent formability and weldability for complex geometries but work-hardens significantly during machining, requiring rigid setups and controlled parameters. 17-4 PH provides superior strength through heat treatment, making it suitable for high-stress components like valve bodies and surgical instruments, though its machinability is lower than 304. Passivation is standard post-machining to maximize corrosion resistance, while electropolishing enhances surface smoothness for critical applications.

Titanium alloys, primarily Ti-6Al-4V (Grade 5), are indispensable in aerospace and biomedical sectors where extreme strength-to-weight ratio, biocompatibility, and corrosion resistance in harsh environments are non-negotiable. Its low thermal conductivity and high chemical reactivity pose significant machining challenges, including rapid tool wear and potential for galling. Success requires specialized tooling, lower cutting speeds, higher feed rates, and meticulous coolant application to manage heat and prevent contamination. Anodizing titanium is less common than aluminum but can be used for specific color coding or minor surface property adjustments.

Anodizing remains the premier surface treatment for aluminum components. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and accepts dyes for identification. Type III (Hardcoat) anodizing delivers significantly thicker, harder, and more wear-resistant layers essential for high-abrasion environments like hydraulic pistons or firearm components. Proper masking and racking are critical to ensure uniform coverage and meet dimensional tolerances.

The following table summarizes key properties for common precision machining alloys:

| Material | Key Alloys | Yield Strength (MPa) | Density (g/cm³) | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 240-503 | 2.7 | Good to Fair | Aerospace frames, automotive parts, enclosures |

| Stainless Steel | 304, 17-4 PH | 205-1200 | 8.0 | Fair to Poor | Medical implants, valves, marine hardware |

| Titanium | Ti-6Al-4V | 880 | 4.4 | Poor | Aircraft landing gear, surgical implants |

Selecting the right material and finish is not merely a technical specification; it is a strategic investment in part performance and production economics. Wuxi Lead Precision Machinery leverages deep metallurgical expertise and advanced CNC capabilities to navigate these complexities, ensuring your critical components exceed expectations. Consult our engineering team early in the design phase for optimal material and process recommendations.

Manufacturing Process & QC

From Design to Zero-Defect Mass Production: The Wuxi Lead Precision Machining Process

At Wuxi Lead Precision Machinery, we engineer precision metal components through a rigorously controlled production pipeline designed for reliability, repeatability, and zero-defect outcomes. Our process integrates advanced engineering with disciplined manufacturing protocols, ensuring every part meets exacting international standards. The journey begins with design collaboration and culminates in scalable, high-accuracy mass production.

The process starts with comprehensive design analysis. Our engineering team reviews customer CAD models, material specifications, and functional requirements to validate manufacturability. We conduct Design for Manufacturability (DFM) assessments to identify potential inefficiencies, optimize tolerances, and recommend material or geometry improvements. This phase ensures that the design is not only feasible but also optimized for precision machining, reducing cycle times and minimizing waste.

Once the design is finalized, we proceed to prototyping. Utilizing multi-axis CNC machining centers, we produce functional prototypes within 7–14 days, depending on complexity. These prototypes undergo full dimensional inspection using coordinate measuring machines (CMM) and surface roughness testers to verify conformance to specifications. This stage allows for real-world testing, fit checks, and design validation before committing to full-scale production. Feedback loops with the client are maintained to ensure alignment on performance and quality benchmarks.

Upon prototype approval, we transition to mass production under a documented Quality Control Plan. Our production floor operates with ISO 9001-certified workflows, where every machining parameter is monitored in real time. We employ automated tool wear compensation, in-process gauging, and SPC (Statistical Process Control) to maintain dimensional stability across batches. Each operator is trained in lean manufacturing principles and defect prevention techniques, reinforcing our zero-defect philosophy.

Traceability is embedded at every stage. Raw materials are certified and logged, machining parameters are recorded per batch, and final inspection reports are archived for full auditability. Our facility supports production volumes from 100 to over 100,000 units annually, with scalability maintained through flexible manufacturing cells and robotic part handling.

The table below outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Alloy Steels |

| Tolerances | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Max Part Size | 800 mm × 600 mm × 500 mm |

| Prototyping Lead Time | 7–14 days |

| Production Lead Time | 15–30 days (depending on volume) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

| Inspection Equipment | CMM, Optical Comparator, Micrometers, Calipers, Roughness Testers |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts — we deliver engineered confidence. From concept to mass production, our process is built on precision, accountability, and an unwavering commitment to zero defects.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In high-stakes industries like aerospace, medical technology, and energy, the margin for error in precision machining is nonexistent. Partnering with a manufacturer that combines engineering rigor with unwavering process control isn’t merely advantageous—it’s foundational to product integrity and market success. At Wuxi Lead Precision Machinery, we operate at the intersection of German-engineered technology and Chinese manufacturing excellence, delivering solutions where micron-level tolerances directly impact performance and safety. Our facility in Wuxi, Jiangsu, serves as a strategic hub for global clients seeking to mitigate supply chain risk without compromising on quality or innovation.

We specialize in transforming complex geometries from raw material to certified component, leveraging multi-axis CNC machining centers, Swiss-type lathes, and advanced metrology systems. Our capabilities span titanium alloys, Inconel, stainless steel, and aluminum, with strict adherence to AS9100 and ISO 9001 standards. Below outlines our core technical specifications for critical applications:

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Tolerance Precision | ±0.001 mm (micron-level) | ISO 2768-mK, ASME Y14.5 |

| Material Range | Titanium, Inconel, Stainless, Aluminum | AMS, ASTM, EN, JIS |

| Max Work Envelope | Ø 600 mm x 1,200 mm (Milling) | Customizable per project |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm | ISO 1302, ASME B46.1 |

| Quality Documentation | Full PPAP, FAIR, CMM Reports | AIAG, SAE |

What distinguishes Lead Precision is our closed-loop quality management system. Every component undergoes real-time in-process inspection via Zeiss CMMs and optical comparators, ensuring deviations are corrected before completion. Our engineering team collaborates from DFM analysis through first-article approval, reducing time-to-market by up to 30% while eliminating costly rework. For clients in regulated sectors, our traceability protocols meet FDA 21 CFR Part 820 and NADCAP requirements, providing auditable confidence at every production stage.

The decision to partner with a precision manufacturer extends beyond technical specs—it demands a commitment to shared risk mitigation and continuous improvement. Wuxi Lead Precision Machinery operates transparently, offering dedicated project management, biweekly progress reviews, and rapid prototyping iterations. We understand that your reputation hinges on the reliability of every thread, contour, and surface finish we produce.

Initiate Your Precision Manufacturing Partnership Today

Contact our engineering team directly at [email protected] to discuss your next critical project. Include your component drawings or specifications for a tailored capability assessment within 24 business hours. Let us demonstrate how Lead Precision becomes an extension of your engineering vision—delivering not just parts, but proven performance. Your complex geometries demand nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.