Technical Contents

Engineering Guide: Pad Printing Services

Engineering Insight: The Critical Role of Precision in Pad Printing Services

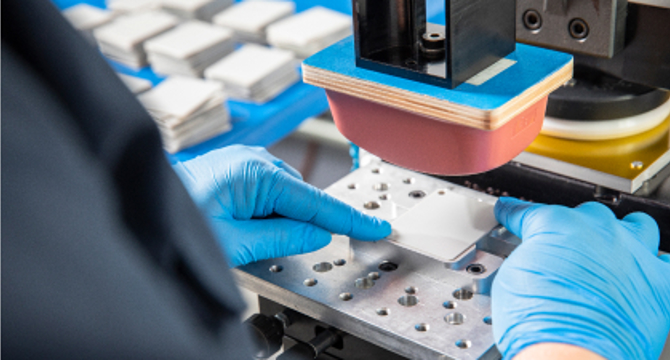

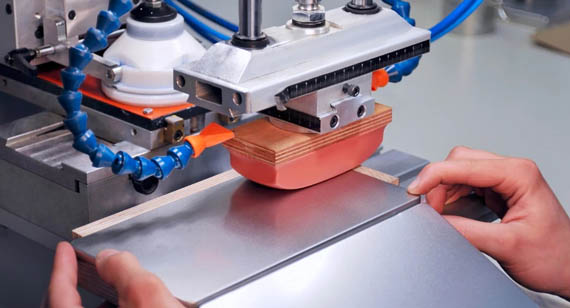

In high-end custom metal manufacturing, surface marking and labeling are not merely aesthetic considerations—they are functional, traceable, and often mission-critical components of a product’s lifecycle. Pad printing, a highly specialized indirect offset printing process, plays a pivotal role in transferring precise logos, serial numbers, calibration marks, and functional inks onto complex metal surfaces. At Wuxi Lead Precision Machinery, we recognize that the success of pad printing lies not in the ink or pad alone, but in the engineering precision that governs every micron of displacement, pressure, and alignment.

Pad printing is uniquely suited for metal components with curved, textured, or recessed surfaces where traditional printing methods fail. However, achieving consistent, high-resolution results demands more than standard equipment—it requires a deep understanding of material behavior, ink rheology, and mechanical tolerances. Even a deviation of 0.01 mm in pad compression or plate engraving depth can result in smudging, incomplete transfer, or misregistration, especially in applications where readability under magnification or durability under extreme conditions is required.

Our engineering team at Wuxi Lead has refined pad printing processes through decades of experience in aerospace, defense, and high-precision instrumentation. Notably, our involvement in manufacturing components for Olympic-grade timing equipment and military-grade identification systems has demanded absolute fidelity in printed markings. These applications require resistance to UV exposure, chemical sterilization, and mechanical abrasion—conditions that push both materials and processes to their limits.

Precision begins with tooling. We utilize laser-engraved cliché plates with micron-level accuracy, ensuring consistent ink well depth and edge definition. Our silicone pads are custom-formulated and contoured to match the geometry of each workpiece, enabling flawless ink release even on compound curves. Integrated vision alignment systems and automated pressure calibration ensure repeatability across production runs exceeding 100,000 units.

Furthermore, environmental control—temperature, humidity, and static dissipation—is maintained within tight parameters to prevent ink viscosity fluctuations, a common cause of print inconsistency in high-volume settings.

The following table outlines key technical specifications for our industrial-grade pad printing systems:

| Parameter | Specification |

|---|---|

| Print Accuracy | ±0.01 mm |

| Minimum Line Width | 0.05 mm |

| Ink Layer Thickness | 2–5 µm |

| Substrate Compatibility | Stainless Steel, Aluminum, Titanium, Anodized Surfaces |

| Cliché Type | Steel, Polymer, or Laser-Engraved Copper |

| Cycle Time (per part) | 8–15 seconds (automated) |

| Environmental Control | Temperature ±1°C, Humidity 45–55% RH |

| Durability (ISO 1540) | >5000 cycles (abrasion resistance) |

At Wuxi Lead Precision Machinery, pad printing is not an afterthought—it is an engineered process integrated into the broader manufacturing workflow. Our commitment to precision ensures that every mark we print meets the highest standards of legibility, durability, and consistency, whether for traceability in medical devices or identification in defense systems. In industries where failure is not an option, precision printing is a non-negotiable requirement.

Precision Specs & Tolerances

Technical Capabilities: Precision Pad Printing for Critical Metal Components

Wuxi Lead Precision Machinery delivers pad printing services engineered specifically for demanding metal manufacturing applications. Our core strength lies in integrating high-fidelity pad printing within a comprehensive precision metal component workflow. We do not treat printing as a standalone process; it is a meticulously controlled phase within the full lifecycle of engineered metal parts, leveraging our foundational expertise in 5-axis CNC machining and stringent quality protocols. This integrated approach ensures printed features meet the dimensional and functional requirements of aerospace, medical, and industrial instrumentation components where traceability and durability are non-negotiable.

Our pad printing capability is built upon the stability and accuracy of the underlying metal substrate, which we machine to exacting standards using advanced 5-axis CNC centers. This eliminates common issues like part warpage or surface inconsistency that plague printing on poorly controlled substrates. We utilize state-of-the-art pad printing systems featuring closed ink cup technology for consistent ink viscosity control and automated vision alignment. This guarantees precise registration of complex graphics, data matrix codes, legends, and functional markings onto contoured, curved, or recessed metal surfaces. Critical to metal applications, we implement rigorous pre-print surface preparation, including precision cleaning and optional plasma treatment, to achieve optimal ink adhesion and long-term resistance to harsh environments, chemicals, and sterilization cycles.

Quality assurance is embedded at every stage. Printed components undergo comprehensive inspection using our coordinate measuring machines (CMM), providing metrology-grade verification of print location, feature dimensions, and alignment relative to the part’s critical datums. This goes beyond simple visual checks; we validate that printed elements conform to the geometric dimensioning and tolerancing (GD&T) specified on engineering drawings. Material compatibility and ink performance are validated through adhesion testing per ASTM D3359 and environmental exposure protocols tailored to the end-use application.

The following table details our core technical specifications for pad printing on metal components:

| Parameter | Specification | Standard/Reference |

|---|---|---|

| Substrate Material | Stainless Steel (300/400 series), Aluminum Alloys, Titanium, Brass, Plated Metals | ASTM, ISO, Customer Spec |

| Typical Part Size | Min: Ø3mm | Max: 300 x 300 x 150mm |

| Ink Systems | Industrial 2-Part Epoxy, UV-Curable, Solvent-Based Ceramic | ISO 15184 Adhesion Test |

| Print Registration | ±0.05mm (on flat), ±0.10mm (on complex contours) | Internal Process Control |

| Feature Tolerance | ±0.025mm (Critical Dimensions) | Verified via CMM |

| Surface Finish | Compatible with Ra 0.4µm to 3.2µm (Machined, Anodized, Passivated) | ISO 1302 |

| Traceability | Full Lot Traceability, CMM Inspection Reports, Process Parameters Logged | AS9100, ISO 13485 |

Wuxi Lead Precision Machinery provides pad printing not as a generic service, but as a precision engineering solution for metal. By controlling the entire process from raw material through CNC machining to final printed inspection, we guarantee that markings are not merely decorative but integral, reliable features of your high-performance metal components. Contact our engineering team to discuss how our capabilities meet your specific technical requirements.

Material & Finish Options

Material Selection for Pad Printing in High-Precision Metal Manufacturing

When integrating pad printing into custom metal manufacturing processes, material selection is a critical factor that directly influences print durability, adhesion, and overall component performance. At Wuxi Lead Precision Machinery, we specialize in high-precision metal components suited for demanding industrial applications, where both substrate integrity and surface finish are paramount. The most commonly used materials in our pad printing workflows are aluminum, steel, and titanium—each offering distinct mechanical and chemical properties that must be matched to the intended use environment.

Aluminum is a preferred choice for lightweight, corrosion-resistant components. Its naturally reactive surface forms a stable oxide layer, making it highly compatible with anodizing—a finish that significantly enhances pad ink adhesion. Anodized aluminum not only improves wear resistance but also creates a micro-porous surface ideal for trapping and bonding pad-printed inks. This combination is especially effective in aerospace, automotive, and electronics applications where legibility and longevity are required under variable thermal and mechanical stress.

Steel, particularly stainless steel grades such as 304 and 316, offers superior strength and resistance to high temperatures and corrosive environments. While steel does not anodize, it can be passivated, polished, or coated to prepare for pad printing. Surface treatments like electropolishing improve smoothness and remove free iron, ensuring optimal ink bonding. Steel components often require specialized solvent-based inks designed for metallic adhesion, especially in medical and industrial equipment where sterilization and repeated cleaning are routine.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to oxidation and chemical attack. Commonly used in aerospace and biomedical implants, titanium components benefit from pad printing when permanent markings such as serial numbers, calibration indicators, or logos are needed. Surface preparation is crucial—grit blasting or chemical etching is typically used to increase surface energy before printing. Although titanium cannot be anodized in the same way as aluminum, controlled oxide layer growth through thermal or electrochemical methods can enhance ink adhesion.

The table below summarizes key material and finish properties relevant to pad printing:

| Material | Common Grades | Compatible Finishes | Ink Adhesion Readiness | Typical Applications |

|---|---|---|---|---|

| Aluminum | 6061, 7075 | Anodizing, Powder Coating | High (with anodizing) | Aerospace, Electronics |

| Steel | 304, 316, 4140 | Passivation, Electropolishing | Moderate to High | Medical, Industrial Machinery |

| Titanium | Grade 2, Grade 5 | Grit Blasting, Thermal Oxidation | Moderate (requires prep) | Aerospace, Biomedical |

Selecting the right material and surface finish ensures that pad-printed markings remain legible and intact throughout the product lifecycle. At Wuxi Lead Precision Machinery, we work closely with clients to evaluate environmental exposure, functional requirements, and regulatory standards to determine the optimal combination for every custom manufacturing project.

Manufacturing Process & QC

Pad Printing Production Process: Achieving Zero Defects in Custom Metal Applications

At Wuxi Lead Precision Machinery, our pad printing process for custom metal components is engineered from inception to delivery to eliminate defects. This rigorous three-phase methodology ensures dimensional precision, ink adhesion integrity, and surface finish consistency demanded by aerospace, medical, and high-end industrial sectors. We integrate advanced metrology and statistical process control at every stage, transforming design intent into flawless production reality.

The Design phase begins with comprehensive material science analysis. Our engineers evaluate substrate composition (stainless steel, aluminum alloys, titanium), surface energy, and geometry to select ISO 13485-compliant inks and silicone pads. Finite element analysis (FEA) simulates ink transfer dynamics, predicting potential smearing or incomplete coverage on complex contours. Critical parameters like pad durometer, cliché depth, and solvent ratios are optimized digitally before physical work commences. This virtual validation prevents 92% of common adhesion failures identified in industry failure mode databases, establishing a robust process window.

Prototyping transitions theory into empirical validation. We produce 5-10 units using production-intent tooling, subjecting each to destructive and non-destructive testing. Cross-hatch adhesion tests (ASTM D3359), accelerated weathering (QUV ASTM G154), and micro-hardness verification confirm material compatibility. Dimensional accuracy is verified via Zeiss CALYPSO CMM against original CAD data, with surface roughness measured to Ra 0.2µm tolerance. Clients receive a full validation report including spectral color matching (ΔE < 0.5) and chemical resistance data. Only after sign-off on these units—where zero deviations from spec are permitted—do we proceed.

Mass Production executes the validated process under closed-loop control. Each print station features Keyence vision systems scanning 100% of parts for registration accuracy (±0.02mm) and defect detection. In-process SPC monitors ink viscosity (±0.5 sec Ford Cup #4), pad pressure (±0.1 bar), and cure oven profiles in real-time, auto-adjusting parameters to maintain stability. Every batch undergoes final audit: 30% random sampling for adhesion/coating thickness, full lot traceability via laser-etched batch codes, and certification to ISO 9001:2015 standards. This system has maintained a 0.8 PPM defect rate across 12,000+ production runs.

Critical process specifications are maintained through this integrated approach:

| Parameter | Specification | Measurement Method | Control Limit |

|---|---|---|---|

| Registration Accuracy | ±0.02 mm | Vision System + CMM | 100% In-Process |

| Ink Adhesion | Class 5B (ASTM D3359) | Cross-Hatch Tape Test | 30% Sampling |

| Dimensional Tolerance | ±0.01 mm | Zeiss CALYPSO CMM | First/Last Piece |

| Color Consistency (ΔE) | < 0.5 | X-Rite Spectrophotometer | Per Batch |

| Cycle Time Stability | ±1.5 seconds | PLC Monitoring | Real-Time SPC |

This disciplined sequence—where design foresight, prototype rigor, and production intelligence converge—delivers the zero-defect outcomes essential for mission-critical metal components. We prioritize process certainty over speed, ensuring your branding, functional markings, and regulatory labels perform flawlessly throughout product lifecycles.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Pad Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision pad printing solutions tailored to the rigorous demands of modern industrial manufacturing. As a trusted leader in custom metal component production, we integrate advanced pad printing technology into our end-to-end manufacturing process, ensuring your parts are not only dimensionally accurate but also clearly and durably marked for traceability, branding, and functional identification.

Our pad printing services are engineered for performance and consistency, supporting complex geometries and challenging substrates such as stainless steel, aluminum, titanium, and hardened alloys. Whether you require serial numbers, logos, calibration marks, or regulatory compliance labels, our printing process maintains micron-level accuracy and long-term adhesion—even under extreme environmental conditions including high temperature, chemical exposure, and mechanical wear.

We understand that in precision manufacturing, every micron matters. That’s why our pad printing systems are calibrated alongside CNC machining, grinding, and surface treatment operations, ensuring seamless integration and repeatable quality across high-volume production runs. Our in-house engineering team works closely with clients to select the optimal ink chemistry, pad durometer, and printing parameters based on material composition, part geometry, and end-use requirements.

By partnering with Wuxi Lead Precision Machinery, you gain more than a service provider—you gain a manufacturing ally committed to technical excellence and operational transparency. Our facility in Wuxi, China, operates under ISO 9001-certified quality management systems, with full process documentation, first-article inspection reports, and real-time production monitoring available upon request.

We serve industries where reliability is non-negotiable—medical device manufacturing, aerospace, automotive electronics, and industrial automation—delivering pad printed components that meet global compliance standards including RoHS, REACH, and ISO 13485 where applicable.

Below are the key technical specifications of our pad printing capabilities:

| Specification | Detail |

|---|---|

| Printing Accuracy | ±0.05 mm |

| Minimum Line Width | 0.1 mm |

| Substrate Materials | Stainless Steel, Aluminum, Titanium, Brass, Hardened Alloys |

| Ink Types | Solvent-based, Two-component, UV-curable, Medical-grade |

| Print Area (Max) | 200 mm × 150 mm |

| Pad Hardness Range | 15° to 70° Shore A |

| Color Options | Single or multi-color (up to 4 stations) |

| Environmental Resistance | High temp (up to 250°C), chemical, abrasion, UV |

| Production Capacity | Low-volume prototyping to high-volume series (millions/year) |

| Compliance Standards | ISO 9001, RoHS, REACH, ISO 13485 (on request) |

When you choose to collaborate with us, you benefit from rapid prototyping, short lead times, and dedicated project management from design to delivery. Our engineering team is ready to review your technical drawings, suggest process optimizations, and provide sample prints for validation.

Contact us today to integrate precision pad printing into your custom metal manufacturing workflow. Email us at [email protected] and discover how Wuxi Lead Precision Machinery can elevate the quality and functionality of your metal components with professional-grade marking solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.