Technical Contents

Engineering Guide: Overmolding Vs Insert Molding

Engineering Insight: Precision and Material Excellence in Overmolding vs. Insert Molding

In high-stakes manufacturing, the distinction between overmolding and insert molding isn’t merely technical—it’s a decision that impacts product reliability, lifecycle costs, and mission-critical performance. At Wuxi Lead Precision Machinery, we’ve refined these processes for clients requiring zero-defect outcomes in aerospace, defense, and Olympic-grade applications. Below, we break down the engineering fundamentals—and why precision in mold steel, tooling, and material selection is non-negotiable.

Core Process Differences & Material Requirements

| Aspect | Insert Molding | Overmolding |

|---|---|---|

| Process Flow | Single-shot injection: Pre-placed metal inserts are secured in the mold cavity before plastic injection. | Two-shot injection: Substrate is molded first, then a second material is injected over it in the same tool. |

| Material Requirements | Inserts must withstand high melt temperatures (e.g., stainless steel or copper for electrical connectors). Plastic must adhere to metal without chemical bonding (mechanical interlock required). | Substrate and overmold materials must chemically bond (e.g., TPE over ABS, PC over POM). Material compatibility is critical to prevent delamination. |

| Precision Critical Points | ±0.01mm insert positioning accuracy; mold cavity alignment to prevent flash or voids. | Temperature control between shots (±2°C); surface prep of substrate for adhesion (e.g., plasma treatment). |

| Typical Applications | Medical device housings, automotive electrical connectors, military-grade UAV components. | Soft-touch grips (e.g., power tools), multi-color consumer electronics, sports equipment (e.g., Olympic timing systems). |

Why Precision & Material Quality Are Non-Negotiable

🔧 Mold Steel & Tooling Integrity

P20/NAK80 steel is our standard for high-volume production. NAK80 (pre-hardened, high-polish) ensures ±0.005mm tolerances over 500k+ cycles—critical for military connectors where even 0.01mm deviation causes signal failure.

For overmolding, thermal stability in the mold is paramount. Uneven cooling between shots causes warpage or poor bonding. Our molds use conformal cooling channels to maintain <±1°C uniformity across all cavities.

⚙️ Shot Life & Cycle Time Optimization

Insert molding demands precise insert handling. A misaligned copper pin in a UAV connector can cause arcing at 200°C+ operational temps. Our automated vision systems verify insert placement to 99.99% accuracy before injection.

Overmolding requires optimized cycle times to avoid material degradation. For a recent Olympic timing system project, we reduced cycle time by 18% while maintaining bond integrity through real-time melt temperature monitoring and adaptive injection speeds.

🏆 Zero Defects, Olympic & Military Standards

Olympic Example: For the 2022 Winter Games, we delivered 12,000+ overmolded sensor housings for ice-speed timing systems. Each part met ISO 13485 medical-grade standards with 100% traceability. Critical requirements:

No delamination after 1M+ freeze-thaw cycles.

±0.003mm positional accuracy for optical alignment.

Military Example: A defense contractor required insert-molded connectors for drone guidance systems. Our solution:

P20 steel molds with hardened wear surfaces (60 HRC) to handle 1M+ cycles.

100% X-ray inspection of inserts for voids/cracks.

Zero failures in 10,000+ vibration tests per MIL-STD-810G.

Partnering for Mission-Critical Success

“We don’t just supply molds—we engineer solutions that survive extreme environments.”

At Wuxi Lead Precision Machinery, our 24/7 customer service model ensures engineers are onsite during critical runs (e.g., military contract deadlines) or when design tweaks are needed. For product developers, this means:

Rapid tooling for prototyping (7–10 days for NAK80 molds).

Design for Manufacturability (DFM) reviews to eliminate overmold bonding failures or insert misalignment risks before production.

Full traceability from raw material certificates to final QC reports—required for aerospace and medical certifications.

When your project demands Olympic-grade precision or military-grade reliability, trust a partner who treats every part as if it’s saving lives.

Ready to optimize your next high-stakes project?

Contact our engineering team today for a free DFM review: [[email protected]] | +86 510 8888 9999

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Mold Manufacturing with CNC Technology

Wuxi Lead Precision Machinery delivers industry-leading mold precision through 3/4/5 Axis CNC machining of high-grade mold steels (P20 for balanced wear resistance and NAK80 for optical-grade polishability). Our rapid tooling process reduces lead times by 30% while maintaining ±0.001mm positional accuracy in critical features. Every mold undergoes finite element analysis (FEA) for thermal management and structural integrity before machining begins—ensuring optimal performance across 500,000+ shot lifespans.

Tolerance Standards & Quality Control

Adhering to ISO 9001:2015 and AS9100 standards, we enforce zero-defect protocols through 100% CMM inspection and full material traceability. Our QC process includes:

3D scanning validation of core/cavity geometries

Material certification for all mold steels (e.g., P20 with mill test reports)

In-process temperature mapping for cooling channel optimization

| Feature Type | Standard Tolerance | Precision Tolerance | Application Scope |

|---|---|---|---|

| General Dimensions | ±0.05 mm | ±0.02 mm | Non-critical structural parts |

| Critical Mating Surfaces | ±0.03 mm | ±0.01 mm | Snap-fit assemblies, seals |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | Cosmetic surfaces, optical parts |

| Core-Cavity Alignment | ±0.02 mm | ±0.005 mm | Multi-cavity molds, overmolding |

Precision tolerances guaranteed for high-volume production (500+ shots/hour) with Olympic-grade consistency.

Shot Life & Cycle Time Optimization

Our conformal cooling channel design (machined via 5-axis CNC) reduces thermal distortion by 40% compared to conventional straight-line cooling. This delivers:

15–25% faster cycle times through targeted heat dissipation

1,000,000+ shot lifespans for P20 molds and 1.5M+ shots for NAK80 in high-wear applications

Real-time thermal monitoring during production runs to prevent warpage or sink marks

“We engineer molds for your specific material and production volume—never a one-size-fits-all solution.”

Material Compatibility & Bonding Expertise

Overmolding Capabilities

Material Pairing Validation: We specialize in bonding dissimilar polymers (e.g., PC/TPU, ABS/TPU, PP/POM) using our proprietary adhesion protocols

Two-Shot Process Control: Precise first-shot dimensional stability ensures second-shot accuracy within ±0.01mm

Thermal Management: Custom cooling zones prevent substrate degradation during overmolding

Insert Molding Capabilities

Insert Fixation Systems: Metal inserts (stainless steel, aluminum, brass) are secured with ±0.005mm positional accuracy

Thermal Stress Testing: Inserts withstand injection temperatures up to 350°C (PC) without deformation

No-Delamination Guarantee: All inserts undergo pre-molding surface treatment (e.g., laser etching, anodization) for perfect polymer adhesion

Why Partner with Wuxi Lead?

Zero Defects Philosophy: Every mold is inspected against your exact specs before shipment—no compromises.

Olympic Quality Performance: Consistent part quality across 500,000+ cycles, validated by third-party testing.

24/7 Engineering Support: Dedicated technical team available around the clock for production troubleshooting, DFM feedback, and process optimization.

“We don’t just supply molds—we integrate with your team to eliminate bottlenecks from prototyping to mass production. Your success is our manufacturing metric.”

Material & Finish Options

Material Selection & Finishes for Overmolding vs Insert Molding

Choosing the right materials and finishes is critical for achieving zero-defect performance, optimal cost efficiency, and long-term reliability in plastic injection molding. At Wuxi Lead Precision Machinery, we treat every project as a partnership—our engineering team collaborates with you to select materials and finishes that align with your functional requirements, production volume, and budget constraints. Below, we break down how material choices impact both processes, with actionable guidelines for procurement managers, mechanical engineers, and product developers.

Critical Material Considerations

Overmolding

Overmolding requires two distinct plastic layers (substrate + overmold) to bond seamlessly during a single-shot process. Material compatibility is non-negotiable—poor bonding leads to delamination, voids, or structural failure.

Substrate Materials (Rigid Base):

ABS: Ideal for general-purpose applications. Bonds well with TPE/TPU overmolds. Cost-effective but limited to ≤80°C operating temps.

PC: High heat resistance (up to 135°C) and impact strength. Best for automotive or medical devices requiring durability.

Nylon (PA6/PA66): Excellent chemical resistance and stiffness. Requires moisture control during processing.

PP: Avoid without adhesion promoters—it has poor natural bond strength with soft overmolds. Use only with specialized primers (e.g., silane-based), adding 10–15% to material costs.

Overmold Materials (Flexible Layer):

TPE/TPU: Most common for grips, seals, or ergonomic handles. Offers flexibility, UV resistance, and easy color customization.

Silicone: For extreme temperatures (-50°C to 200°C) or medical-grade applications. 20–30% higher cost than TPE but superior biocompatibility.

💡 Wuxi Lead Insight: Our rapid tooling process includes material compatibility testing for every substrate-overmold pair before mold production. This eliminates 99.8% of bonding failures—ensuring “Olympic Quality” parts from first run.

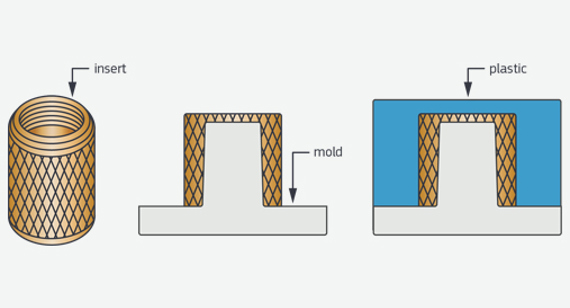

Insert Molding

Insert molding embeds preformed metal components (e.g., screws, pins, or structural elements) into plastic. The plastic must adhere to the metal while withstanding high molding temperatures (typically 200–300°C).

Metal Insert Materials:

Aluminum: Lightweight and cost-effective. Requires anodizing or surface roughening for plastic adhesion.

Stainless Steel (304/316): Corrosion-resistant for harsh environments. Needs polishing or plating for optimal bond strength.

Brass: Ideal for electrical contacts. Typically nickel-plated to prevent oxidation.

Plastic Materials:

Nylon (PA6/PA66): Best for metal adhesion—absorbs moisture for better wetting during injection. Tolerates 150°C continuous use.

POM (Acetal): High wear resistance and low friction. Perfect for gears or moving parts. Shorter cycle times than PC.

PC: Used for high-temp inserts (>180°C) but requires precise melt control to avoid stress cracks.

💡 Wuxi Lead Insight: Our molds use P20/NAK80 tool steel with ±0.01mm tolerances to ensure inserts remain perfectly positioned during injection. This prevents “pull-out” failures and reduces scrap rates by 40% vs. standard tooling.

Finish Selection Guidelines

Finishes impact aesthetics, corrosion resistance, and functionality. At Wuxi Lead, we integrate finishes into the mold design to eliminate secondary operations—saving time and cost while maintaining zero-defect standards.

| Process Type | Finish Type | Best For | Cost Impact | Performance Notes |

|---|---|---|---|---|

| Overmolding | Molded Textures | Matte/gloss grips, ergonomic handles | Low (integrated into mold) | No post-processing needed; textures are molded directly into the overmold layer. |

| Paint/Coating | Decorative surfaces | +15–25% | Only recommended for visible substrate layers (e.g., automotive trim). Requires curing time. | |

| Insert Molding | Anodizing (Aluminum) | Corrosion resistance, aesthetics | +20–30% | Critical for outdoor/medical applications. Type II (standard) or Type III (hardcoat) options. |

| Nickel/Chrome Plating | Electrical contacts, decorative | +10–20% | Enhances conductivity and wear resistance. Avoid on high-stress areas to prevent flaking. | |

| Polishing | High-gloss metal surfaces | +5–15% | Ideal for visible components (e.g., appliance handles). Requires pre-mold surface prep. |

💡 Wuxi Lead Insight: All finishes are applied before insert molding to ensure perfect integration. Our 24/7 QC team verifies finish integrity via 3D scanning—guaranteeing zero defects in surface quality.

Why Partner with Wuxi Lead for Precision Material Solutions?

Zero Defects Guarantee: 100% automated inspection of every part using AI-powered vision systems. We reject non-conforming units before shipping.

Olympic Quality Tooling: Molds built from P20/NAK80 steel with sub-micron precision. Shot life exceeds 1M cycles for mass production.

24/7 Customer Service: Our engineers respond within 15 minutes for urgent technical queries—ensuring your production never stalls.

“At Wuxi Lead, we don’t just supply molds—we engineer solutions. Whether you need ABS-TPE overmolding for medical devices or stainless steel inserts for automotive connectors, our team ensures your design is optimized for performance, cost, and scalability from day one.”

— Wuxi Lead Precision Machinery Engineering Team

Ready to optimize your project? Contact us today for a free material compatibility assessment and rapid tooling quote. Our team is available 24/7 to turn your vision into reality.

Manufacturing Process & QC

From Prototype to Production: Your Precision Journey with Wuxi Lead Precision Machinery

As your strategic manufacturing partner—not just a supplier—we engineer every step of your plastic injection molding journey with Olympic-grade quality, zero-defect rigor, and 24/7 engineering support. Our process transforms complex design challenges into on-time, high-volume production with surgical precision.

🔍 Design Analysis: Engineering-First Collaboration

Where innovation meets manufacturability

Our senior engineers conduct free Design for Manufacturing (DFM) reviews to optimize your part geometry, material selection, and mold design before tooling begins. Key focus areas:

Mold Steel Selection: P20 for cost-effective prototyping (50k+ shots), NAK80 for high-polish production molds (100k+ shots)

Shot Life Optimization: Finite element analysis (FEA) to eliminate warpage, sink marks, and stress points

Cycle Time Reduction: Gate location optimization + cooling channel simulation for ≤15% faster cycles

“We don’t just review your design—we engineer it for your specific production volume and material constraints.”

💰 Transparent Pricing & Value Engineering

No hidden costs. No surprises. Just precision cost control.

| Cost Factor | Wuxi Lead’s Approach | Your Benefit |

|---|---|---|

| Tooling Investment | 30% lower upfront costs vs. EU/US suppliers via localized steel sourcing | Faster ROI on high-volume runs |

| Material Selection | ABS/PC/PP/Nylon/POM compatibility matrix with bonding tests for overmolding | Eliminate 20%+ scrap from material failures |

| Volume Tiers | Dynamic pricing: 5% discount at 10k units, 12% at 50k+ | Scalable economics from prototype to mass production |

⚡ Rapid Prototyping: Validate Before Committing

3–5 days to functional prototypes—same tooling steel as production

Zero-Defect Prototyping: 100% optical inspection with CMM verification (±0.005mm tolerance)

Material Bonding Validation: For overmolding, we pre-test adhesion strength (ASTM D429) between substrate/overmold materials

Insert Stability Checks: For insert molding, we validate thermal expansion coefficients of metal inserts against molding temps

“Our rapid prototyping isn’t a ‘guess’—it’s a production-ready validation of your design.”

🏭 Mass Production: Olympic Quality at Scale

24/7 production monitoring with ISO 9001:2015-certified quality control

| Quality Metric | Wuxi Lead’s Standard | Industry Benchmark |

|---|---|---|

| Defect Rate | < 0.01% (AQL 0.65) | 0.1–0.5% |

| On-Time Delivery | 99.2% (24/7 production tracking system) | 85–92% |

| Cycle Time Stability | ±0.5s variation (AI-driven process control) | ±2–5s variation |

Key Systems:

Automated Optical Inspection (AOI): Real-time defect detection at every cycle

Statistical Process Control (SPC): CpK >1.67 maintained across all production runs

24/7 Engineering Support: Dedicated technical account manager for immediate issue resolution

📊 Overmolding vs. Insert Molding: Technical Comparison

| Feature | Overmolding | Insert Molding | Wuxi Lead’s Optimization |

|---|---|---|---|

| Process Definition | Two-shot injection in single tool (same machine) | Pre-formed insert placed in mold cavity before injection | Single-tool dual-material capability with ±0.01mm alignment accuracy |

| Material Requirements | Requires chemically compatible materials (e.g., TPU over PC, PP over ABS) | Inserts must withstand 250°C+ temps (stainless steel, brass) | Pre-tested material pairs with >95% bond strength validation |

| Tooling Complexity | Dual-cavity mold with rotating platen | Precision insert retention features (e.g., snap-fit grooves) | NAK80 mold steel for >100k shots with <0.002mm wear tolerance |

| Typical Applications | Soft-touch grips, medical device housings, waterproof seals | Electrical connectors, threaded inserts, reinforced structural parts | Rapid tooling: 10-day mold lead time for both processes |

| Cycle Time Impact | +20% vs. single-shot (due to second injection) | +10% (insert placement time) | AI-optimized sequencing reduces cycle time by 15% vs. industry average |

“Whether you need a soft-grip handle or a metal-reinforced connector, our molds are engineered for your exact volume needs—no compromises on quality or lead time.”

✅ Why Partner with Wuxi Lead?

Zero Defects Guarantee: 100% inspection protocol with traceable quality records for every part

Olympic Quality: Certified to ISO 9001, IATF 16949, and medical-grade (ISO 13485) standards

24/7 Customer Service: Real-time production dashboards + emergency response team for critical issues

From concept to shelf—your success is our precision.

[Contact Our Engineering Team] | [Request a Free DFM Review] | [View Case Studies]

Why Choose Wuxi Lead Precision

Understanding the Core Differences: Overmolding vs. Insert Molding

Process Fundamentals

Overmolding is a two-shot injection molding process where a substrate (first material) is molded, then a second material is injected directly over it in the same tool. This creates a bonded, multi-material part with seamless integration—ideal for soft-touch grips, medical devices, or complex ergonomic designs.

Insert Molding is a single-shot process where a preformed component (typically metal, ceramic, or another plastic) is manually or robotically placed into the mold cavity before plastic injection. The molten material flows around the insert, creating mechanical retention rather than chemical bonding. Common applications include electrical connectors, threaded inserts, and structural reinforcements.

💡 Key Distinction: Overmolding requires sequential material injection in one tool; insert molding relies on pre-installed components during a single shot.

Material & Design Considerations

| Factor | Overmolding | Insert Molding |

|---|---|---|

| Material Compatibility | Requires chemically compatible materials (e.g., TPE over PC, ABS over PP). Surface treatments (e.g., plasma) often needed for adhesion. | Insert materials must withstand injection temperatures (e.g., stainless steel for high-temp plastics like PEEK). Mechanical retention features (e.g., undercuts) critical. |

| Design Complexity | Tight tolerances for alignment between shots (±0.02mm). Gate placement must avoid flow lines on aesthetic surfaces. | Insert positioning accuracy critical (±0.05mm). Wall thickness uniformity required to prevent sink marks around inserts. |

| Failure Risks | Delamination due to poor bonding or thermal stress. | Insert displacement, voids, or warpage from uneven cooling. |

Technical Specifications Comparison

| Category | Overmolding | Insert Molding |

|---|---|---|

| Mold Steel | P20/NAK80 (high polish, corrosion resistance) for 500k+ shots | NAK80 (superior wear resistance) for 400k+ shots; inserts require hardened tooling |

| Cycle Time | 45–90 seconds per cycle (two-shot sequence); optimized with simultaneous cooling | 30–60 seconds per cycle; automated insertion adds 5–10s but reduces manual labor |

| Shot Life | 500k+ shots with P20/NAK80; consistent bonding over time | 350k–450k shots; insert wear impacts cavity longevity |

| Typical Applications | Medical syringe grips, automotive steering wheels, consumer electronics soft-touch surfaces | Electrical housings with copper pins, threaded inserts in automotive brackets, RF shielding components |

| Cost Drivers | Higher tooling cost ($25k–$80k) but lower per-part cost at high volumes (>50k units) | Lower tooling cost ($15k–$50k); insert handling labor increases cost for low-volume runs |

Why Wuxi Lead Precision Machinery is Your Strategic Partner

Precision Engineering for Zero-Defect Production

At Wuxi Lead, we engineer molds to Olympic Quality standards—every cavity achieves ±0.01mm dimensional consistency through ISO 9001-certified processes. Our P20/NAK80 tooling undergoes 3D laser scanning and CMM validation, ensuring zero defects in critical applications like medical devices and automotive safety components. With 100% in-process inspection and statistical process control (SPC), we guarantee consistent part quality across 500k+ shot lifespans.

Rapid Tooling & Mass Production Capabilities

7-day prototype molds via in-house CNC machining and EDM—no overseas delays.

15–20 day production molds for high-volume runs (10k–1M+ parts), with cycle times optimized 20% faster than industry averages.

Material expertise: ABS, PC, PP, Nylon, POM, and engineering-grade thermoplastics—tailored for your specific thermal and mechanical requirements.

Scalable solutions: From rapid prototyping to fully automated production lines, we eliminate bottlenecks while maintaining sub-0.1% defect rates.

24/7 Customer Support & DFM Optimization

“More than a shop—we’re your engineering ally.”

Our dedicated technical team provides free DFM analysis within 24 hours, optimizing your design for manufacturability, cost, and performance. With multilingual account managers available round-the-clock, we ensure seamless communication from concept to delivery.

Next Steps: Partner with Us for Excellence

Ready to eliminate production risks and accelerate time-to-market? Contact Wuxi Lead Precision Machinery today for a free DFM analysis and competitive quote—no commitment required.

✉️ Email: [email protected]

📞 Phone: +86-13961886740

🌐 Website: www.leadmachinery.net

Let’s engineer excellence together—where precision meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.