Technical Contents

Engineering Guide: Online Lathe Service

Engineering Insight: The Critical Role of Precision in Online Lathe Services

In the realm of high-end manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, repeatability, and performance are built. As industries ranging from aerospace to medical devices demand tighter tolerances and superior surface finishes, the role of advanced online lathe services has become increasingly pivotal. At Wuxi Lead Precision Machinery, we understand that precision in CNC turning is not an outcome of isolated processes, but the culmination of engineering excellence, real-time monitoring, and decades of domain expertise.

An online lathe service transcends traditional CNC turning by integrating live data feedback, remote monitoring, and adaptive control systems. This enables continuous adjustment during machining, ensuring dimensional accuracy within microns and minimizing material waste. Unlike conventional setups where post-process inspection reveals deviations, online systems detect and correct variances in real time. This capability is especially critical when producing mission-critical components for sectors such as defense, energy, and high-performance automotive systems—areas where Wuxi Lead has demonstrated proven excellence.

Our engineering team brings over 15 years of specialized experience in precision CNC machining, with documented contributions to projects meeting Olympic-standard equipment requirements and military-grade specifications. These high-stakes applications demand not only micron-level accuracy but also full traceability, rigorous quality assurance, and compliance with international standards such as ISO 9001 and AS9100. Our online lathe infrastructure is calibrated to meet these benchmarks consistently, leveraging Siemens and Fanuc control systems, high-rigidity spindles, and in-process probing to maintain tight control over every machining cycle.

Material behavior, thermal expansion, and tool wear are dynamic variables in any turning operation. The advantage of an online lathe service lies in its ability to monitor these factors continuously and adjust feed rates, cutting speeds, and depth of cut accordingly. This adaptive approach ensures uniform part quality across large production runs and reduces the risk of batch rejection—crucial for OEMs operating under strict delivery and quality mandates.

At Wuxi Lead, we combine cutting-edge technology with deep engineering insight to deliver online lathe services that meet the most demanding specifications. Our facility in Wuxi, China, operates under stringent environmental controls and employs real-time SPC (Statistical Process Control) dashboards accessible to clients, ensuring full transparency and collaboration throughout production.

The future of precision machining is connected, intelligent, and responsive. By integrating online monitoring into our CNC lathe operations, we ensure that every component we produce is not just within tolerance—but consistently at the peak of dimensional and geometric accuracy.

Key Technical Specifications of Lead Precision Online Lathe Systems

| Parameter | Specification |

|---|---|

| Spindle Speed Range | 50 – 6,000 RPM |

| Maximum Turning Diameter | 500 mm |

| Maximum Turning Length | 1,200 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Control System | Siemens 840D / Fanuc 31i |

| In-Process Measurement | Touch probe with real-time compensation |

| Surface Finish (Ra) | 0.4 – 1.6 µm (achievable) |

| Materials Supported | Steel, Stainless Steel, Aluminum, Titanium, Inconel, Brass |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision and versatility for complex component manufacturing through our advanced online lathe service platform. Our core strength lies in integrating state-of-the-art multi-axis CNC technology with rigorous, data-driven quality control protocols. This ensures every part produced meets the exacting dimensional and geometric requirements of aerospace, medical, semiconductor, and high-performance industrial sectors. We specialize in transforming intricate digital designs into physical realities with exceptional repeatability and surface integrity, directly accessible through our streamlined online ordering system.

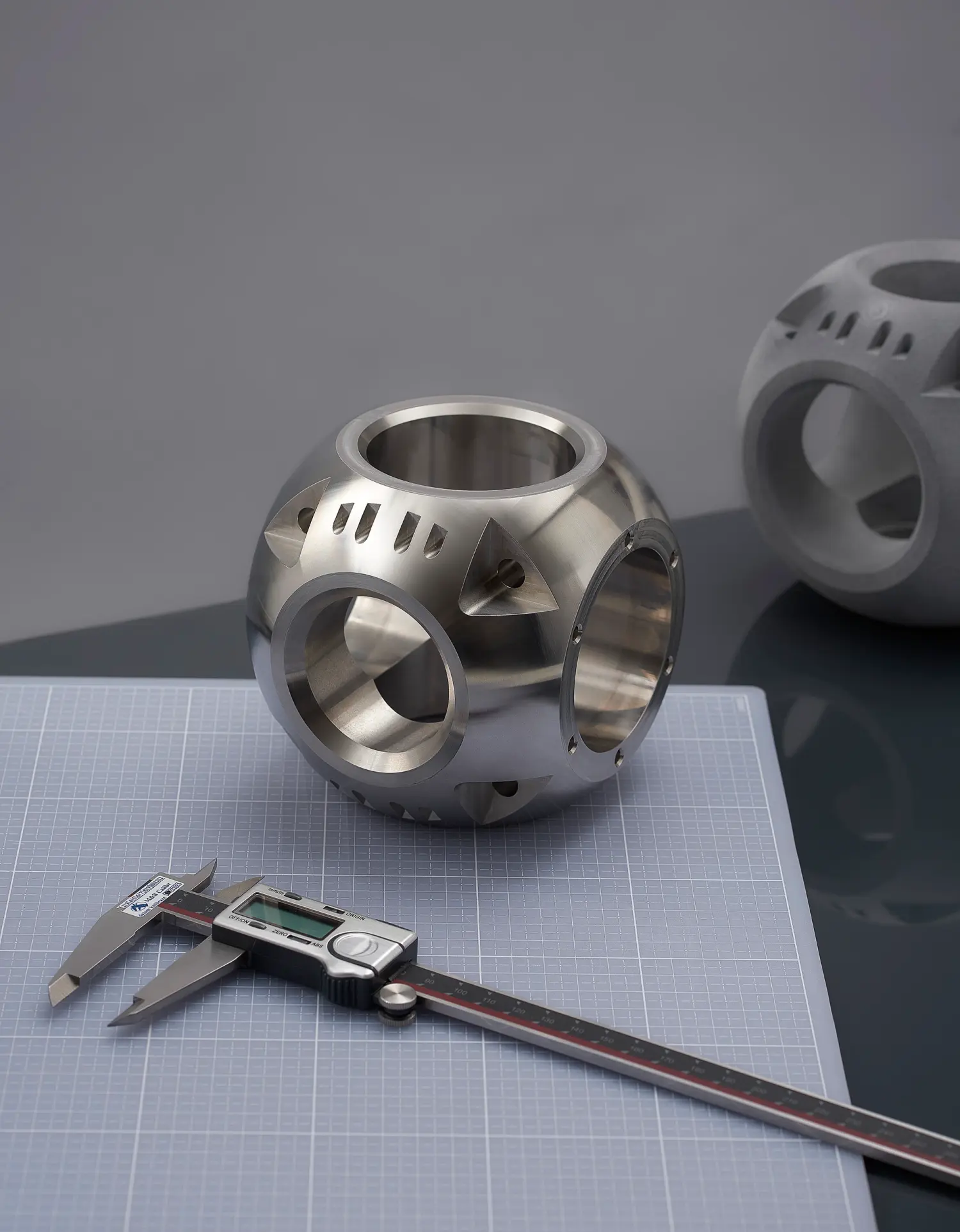

Our foundation is a modern fleet of high-torque, high-accuracy 5-axis CNC turning and milling centers. These machines, featuring live tooling, Y-axis capability, and sub-spindle functionality, enable the complete machining of complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures, significantly enhancing positional accuracy and reducing lead times. Typical machining envelopes accommodate diameters up to Ø300mm and lengths to 600mm, handling diverse materials including aerospace-grade aluminum alloys, titanium, stainless steels, Inconel, brass, and engineering plastics. Advanced coolant-through-spindle systems and optimized toolpath strategies ensure superior surface finishes and extended tool life, critical for high-integrity components.

Quality is intrinsically woven into every manufacturing step, not merely a final checkpoint. All critical features undergo comprehensive verification using calibrated Coordinate Measuring Machines (CMMs) operating under ISO 17025 guidelines. Our CMMs, equipped with high-precision probes and advanced metrology software, provide full 3D geometric dimensioning and tolerancing (GD&T) analysis, generating detailed inspection reports accessible online with each order. This closed-loop process guarantees traceability and adherence to even the most stringent specifications.

The achievable precision levels across common feature types are demonstrated below, reflecting our standard production capabilities under controlled environmental conditions. These tolerances are consistently maintained through continuous process monitoring and machine calibration.

| Feature Type | Standard Tolerance Range | Material Consideration | Typical Surface Finish (Ra) |

|---|---|---|---|

| Diameter (Machined) | ±0.002 mm to ±0.005 mm | All metals & plastics | 0.4 µm to 0.8 µm |

| Length / Face | ±0.003 mm to ±0.008 mm | All metals & plastics | 0.8 µm to 1.6 µm |

| Concentricity | Ø0.003 mm to Ø0.008 mm | Critical for shafts | N/A |

| Positional Tolerance | ±0.005 mm | Hole patterns, slots | N/A |

| Angular Features | ±0.001° to ±0.005° | Complex geometries | 0.8 µm to 1.6 µm |

| Surface Profile | ±0.002 mm | Critical sealing faces | 0.2 µm to 0.4 µm (optional) |

This commitment to measurable precision, combined with the efficiency of our online service platform, provides global customers with a reliable, transparent, and high-performance manufacturing solution. Wuxi Lead Precision Machinery ensures your most challenging components are produced with the accuracy and consistency demanded by advanced engineering applications.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, especially when utilizing online lathe services for high-performance components. At Wuxi Lead Precision Machinery, we understand that the right material choice directly impacts part functionality, durability, and cost-efficiency. Among the most widely used materials in our CNC turning operations are aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, automotive, and electronics industries where lightweight components are essential. The most common grades we machine include 6061 and 7075 aluminum, both of which respond well to precision turning and secondary finishing processes such as anodizing. Anodizing enhances surface hardness and wear resistance while offering aesthetic versatility through color options, making it ideal for both functional and visible parts.

Steel remains the backbone of industrial applications due to its high tensile strength, durability, and affordability. We frequently work with alloy steels such as 4140 and stainless steels like 304 and 316. These materials are optimal for high-stress environments, including hydraulic systems, tooling, and structural components. While steel does not anodize like aluminum, it can be treated with passivation, plating, or coating to improve corrosion resistance and surface performance.

Titanium, though more challenging to machine, delivers unmatched performance in extreme conditions. Known for its exceptional strength-to-density ratio and resistance to high temperatures and corrosion, titanium is widely used in aerospace, medical implants, and defense applications. Grade 5 titanium (Ti-6Al-4V) is our most commonly processed variant due to its balanced mechanical properties and weldability. Specialized tooling and slower cutting speeds are required, but our advanced CNC lathes are optimized to maintain tight tolerances and surface integrity.

Below is a comparative overview of key material properties relevant to CNC turning:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Finish Compatibility |

|---|---|---|---|---|---|

| Aluminum | 180–570 | 2.7 | 6061, 7075 | Aerospace, Electronics, Automotive | Anodizing, Powder Coating |

| Steel | 400–2000 | 7.8–8.0 | 4140, 304, 316 | Industrial Machinery, Tools | Passivation, Zinc Plating |

| Titanium | 900–1200 | 4.5 | Ti-6Al-4V (Grade 5) | Aerospace, Medical, Defense | Bead Blasting, Passivation |

Selecting the appropriate material must align with the operational environment, load requirements, and lifecycle expectations of the final component. Our online lathe service platform allows engineers to upload designs and receive real-time feedback on material suitability, manufacturability, and finishing options. At Wuxi Lead Precision Machinery, we combine material expertise with state-of-the-art CNC turning to deliver precision-engineered parts that meet the highest industry standards.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our online lathe service delivers uncompromising quality through a rigorously defined production process. We integrate advanced engineering with systematic quality controls across three critical phases—Design, Prototyping, and Mass Production—to ensure every component meets exacting specifications and achieves Zero Defects. This structured approach minimizes risk, accelerates time-to-market, and guarantees repeatability for our global manufacturing partners.

The Design phase establishes the foundation for success. Our engineering team collaborates closely with clients to translate concepts into manufacturable realities using industry-leading CAD/CAM software. We meticulously analyze geometric dimensioning and tolerancing (GD&T), material properties, and machinability factors. Finite element analysis (FEA) simulates stress points and thermal behavior, while CAM programming optimizes toolpaths for efficiency and surface finish. This stage includes comprehensive feasibility reviews and material selection guidance, ensuring the design is not only precise but also optimized for high-yield CNC turning. Critical parameters are locked down before any metal is cut, preventing downstream errors.

Prototyping transforms the digital model into a physical validation step. Utilizing our high-precision CNC lathes, we produce initial sample parts under full production conditions. Each prototype undergoes rigorous First Article Inspection (FAI) against the original CAD model and client specifications. Dimensional accuracy, surface roughness, material integrity, and functional performance are verified using coordinate measuring machines (CMM), optical comparators, and surface profilometers. Client feedback is incorporated iteratively; this phase is non-negotiable for identifying and resolving potential issues early. Only after formal client sign-off on the prototype do we proceed, ensuring the path to mass production is de-risked.

Mass Production executes at scale with embedded Zero Defects methodology. Our automated CNC turning cells run under strict statistical process control (SPC), with real-time monitoring of critical parameters like tool wear, spindle load, and dimensional drift. Every batch includes in-process inspections at defined intervals, while final inspection employs 100% critical feature verification for high-risk components. Full material traceability—from raw bar stock lot to finished part—is maintained. Automated vision systems and CMMs provide objective data, feeding back into process adjustments. This closed-loop system, combined with our certified ISO 9001:2015 quality management framework, ensures consistent output meeting the most demanding aerospace, medical, and industrial standards.

Key Production Specifications for CNC Turning Services

| Parameter | Capability | Typical Tolerance Range | Materials Supported |

|---|---|---|---|

| Maximum Turning Diameter | 500 mm | Ø0.001 mm – Ø0.025 mm | Stainless Steel (303, 304, 316), Aluminum (6061, 7075), Titanium, Brass, PEEK |

| Maximum Turning Length | 1000 mm | ±0.001 mm – ±0.01 mm | Inconel, Tool Steels, Plastics |

| Surface Finish | Ra 0.2 µm – Ra 1.6 µm | Concentricity: Ø0.002 mm | |

| Secondary Operations | Milling, Threading, Drilling, Tapping | Flatness: 0.005 mm/m |

This seamless transition from Design through Prototyping to Mass Production, governed by data-driven quality protocols, is how Wuxi Lead transforms online lathe service requests into defect-free, mission-critical components. We deliver not just parts, but guaranteed performance and supply chain resilience.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Lathe Excellence

At Wuxi Lead Precision Machinery, we understand that precision, consistency, and speed are non-negotiable in modern manufacturing. As a global leader in high-end CNC machining solutions, we offer advanced online lathe services designed to meet the exacting demands of aerospace, medical, automotive, and industrial equipment sectors. Our commitment to engineering excellence and process optimization ensures that every component we produce meets the highest standards of accuracy and reliability.

Our online lathe service integrates state-of-the-art CNC turning technology with real-time monitoring and remote accessibility, enabling clients to submit designs, track progress, and receive detailed quality reports—all through a secure digital platform. This seamless integration of digital workflow and precision machining reduces lead times, minimizes human error, and enhances traceability across production cycles. Whether you require single-part prototypes or high-volume production runs, our facility in Wuxi, China, is equipped to deliver with micron-level precision and ISO-certified quality control.

We specialize in multi-axis turning, including live tooling and Swiss-type machining, allowing us to handle complex geometries and tight-tolerance components with ease. Materials we routinely process include aluminum alloys, stainless steel, titanium, brass, and engineering plastics—each machined under controlled environments to ensure dimensional stability and surface integrity.

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, providing actionable feedback to optimize part geometry, reduce costs, and accelerate time-to-market. This proactive approach not only improves manufacturability but also enhances the functional performance of the final component.

Wuxi Lead Precision Machinery operates a fully integrated smart factory with automated tool management, in-process inspection, and 24/7 production monitoring. Our quality management system is certified to ISO 9001:2015 standards, and we utilize coordinate measuring machines (CMM), optical comparators, and surface roughness testers to validate every batch.

To support global clients, we offer comprehensive logistics solutions, including consolidated shipping, customs documentation, and just-in-time delivery scheduling. Our customer portal provides full transparency, allowing you to access project timelines, inspection data, and technical certifications in real time.

Partnering with Lead Precision means aligning with a team that values precision as much as you do. We are committed to being an extension of your engineering and production capabilities—delivering not just parts, but performance-driven manufacturing solutions.

Contact us today to discuss your next project. Reach out to our engineering team at [email protected] and discover how our online lathe service can elevate your production standards.

| Specification | Capability |

|---|---|

| Maximum Turning Diameter | 400 mm |

| Maximum Turning Length | 750 mm |

| Spindle Speed | Up to 6,000 RPM |

| Axis Configuration | 2-axis to 7-axis CNC turning |

| Tolerance | ±0.005 mm |

| Surface Roughness | Ra 0.4 μm (typical) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Plastics |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP available |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.