Technical Contents

Engineering Guide: Online Laser Cutting Service

Precision as the Non-Negotiable Foundation of Online Laser Cutting Services

In high-stakes sheet metal fabrication, precision transcends specification sheets; it is the absolute cornerstone of component functionality, assembly integrity, and final product performance. For industries like aerospace, medical device manufacturing, and advanced electronics, tolerances measured in hundredths of a millimeter directly impact safety, regulatory compliance, and operational lifespan. An online laser cutting service promising rapid quoting and digital convenience must deliver uncompromising dimensional accuracy and edge quality as its fundamental promise. Sub-millimeter deviations are not merely cosmetic flaws; they cascade into costly assembly rework, field failures, and reputational damage. True precision requires more than a high-wattage laser source—it demands integrated engineering rigor across the entire production ecosystem.

At Wuxi Lead Precision Machinery, we engineer our online laser cutting service around this principle of uncompromised accuracy. Our approach integrates state-of-the-art fiber laser technology with meticulous process control systems honed over decades. We understand that the digital interface facilitating your upload and order is merely the entry point; the critical value lies in the physical execution within our facility. Every cut path is optimized using advanced nesting software that minimizes thermal distortion while maximizing material yield, but the real differentiator is the calibration and monitoring infrastructure operating beneath the surface. Our machines undergo rigorous daily verification against traceable standards, and real-time process monitoring systems actively adjust parameters to counteract minor environmental fluctuations, ensuring the first part matches the hundredth.

This commitment to precision is validated not just in certifications, but in the demanding applications our components serve. We have supplied mission-critical sheet metal parts for infrastructure supporting the Olympic Games, where structural integrity and exact fit under extreme public use were paramount. Similarly, our processes meet the stringent documentation and repeatability requirements for select military subcontractors, where failure is not an option. This experience shapes our entire online service model—we treat every customer order, regardless of size, with the same scrutiny applied to these high-profile projects.

The technical capability enabling this consistency is reflected in our core machine specifications, representing the baseline performance you receive:

| Parameter | Specification | Application Impact |

|---|---|---|

| Laser Source | 6kW Fiber | Clean cuts on materials up to 25mm stainless steel |

| Positioning Accuracy | ±0.02 mm | Critical for multi-part assemblies |

| Repeatability | ±0.01 mm | Ensures batch-to-batch consistency |

| Kerf Width Control | ±0.05 mm tolerance | Maintains precise internal features |

| Edge Perpendicularity | < 0.1° | Eliminates secondary finishing for critical surfaces |

| Nesting Optimization | > 95% material yield | Reduces cost without sacrificing quality |

Precision in online laser cutting is not an automated transaction; it is a managed engineering outcome. Wuxi Lead Precision Machinery leverages its deep industrial heritage, particularly proven in Olympic and defense applications, to transform the convenience of digital ordering into a guarantee of physical perfection. When your design moves from screen to metal, the margin for error must be zero—we ensure it is. This is the engineering insight that defines our service.

Precision Specs & Tolerances

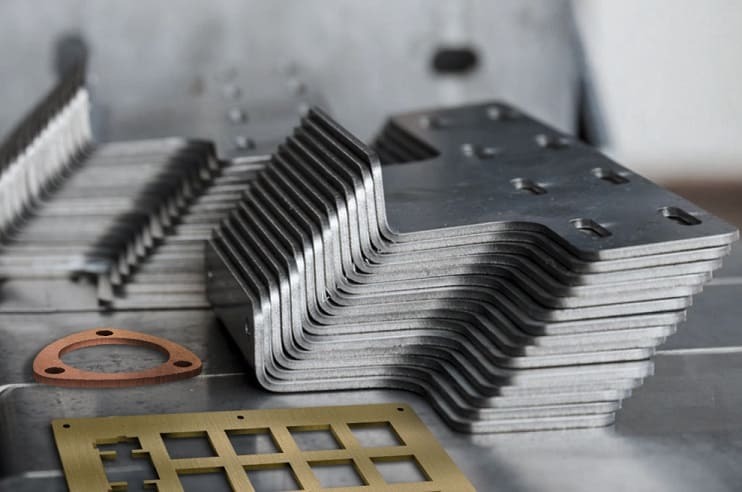

Wuxi Lead Precision Machinery delivers advanced online laser cutting services engineered for high-precision sheet metal fabrication. Our technical capabilities are anchored in state-of-the-art 5-axis CNC laser systems, enabling us to process complex geometries with exceptional accuracy and repeatability. These multi-axis platforms provide superior flexibility, allowing for beveled cuts, compound angles, and intricate contours that standard 2D laser cutting cannot achieve. By integrating 5-axis motion control, we eliminate the need for secondary operations in many cases, reducing lead times and improving part consistency across production runs.

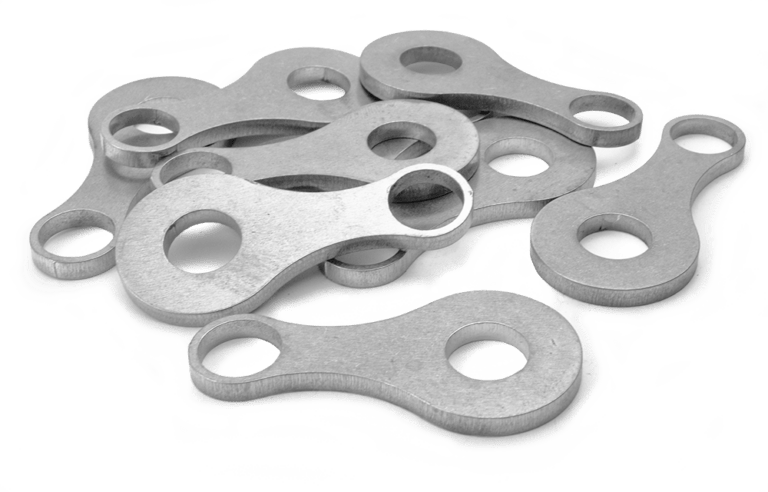

Our laser cutting systems support a wide range of conductive and non-conductive sheet metals, including stainless steel, carbon steel, aluminum, brass, and copper. Material thicknesses from 0.5 mm up to 25 mm can be processed with precision, depending on the alloy and application requirements. High-powered fiber laser sources ensure clean, dross-free cuts with minimal heat-affected zones, preserving material integrity and enabling tight-tolerance downstream fabrication. The integration of automated material handling and real-time process monitoring further enhances throughput and quality assurance across both prototyping and high-volume production.

Quality is central to our manufacturing philosophy. Every laser-cut component undergoes rigorous inspection using Coordinate Measuring Machine (CMM) technology. Our Zeiss and Hexagon CMM systems provide micron-level verification of critical dimensions, geometric features, and positional tolerances. Full inspection reports are available upon request, ensuring complete traceability and compliance with ISO 9001 standards. In-process checks, first-article inspections, and final QA audits are standard procedures across all production batches.

The following table outlines the standard tolerance specifications achievable through our online laser cutting service:

| Parameter | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimension (up to 100 mm) | ±0.1 mm | ±0.05 mm | Achieved with CMM validation |

| Linear Dimension (100–500 mm) | ±0.15 mm | ±0.1 mm | Dependent on material flatness |

| Linear Dimension (500–1000 mm) | ±0.2 mm | ±0.15 mm | Stress-relieved materials recommended |

| Hole Diameter (mechanical) | +0.1 / -0.05 mm | +0.05 / -0.02 mm | For diameters < 10 mm |

| Angular Cuts (5-axis) | ±0.5° | ±0.25° | Bevel and taper cuts |

| Edge Perpendicularity | 0.1 mm per 10 mm height | 0.05 mm per 10 mm height | Measured from base to top edge |

| Feature Position | ±0.1 mm | ±0.05 mm | Relative to datum or reference edge |

All tolerances are achievable under standard production conditions and may be tightened further with controlled material preparation and post-processing. Wuxi Lead Precision Machinery combines advanced 5-axis laser technology with metrology-grade quality control to deliver precision sheet metal components for aerospace, medical, automation, and high-end industrial applications. Our online service platform enables seamless file uploads, instant quoting, and real-time production tracking—bringing factory-grade precision to global engineering teams.

Material & Finish Options

Material Selection Guide for Precision Laser Cutting Services

Selecting the optimal material for laser cutting is critical to balancing performance, cost, and manufacturability. At Wuxi Lead Precision Machinery, our industrial-grade fiber laser systems (up to 12kW) process diverse alloys with micron-level accuracy, but material properties directly impact cut quality, edge finish, and secondary operations. Below we detail key considerations for aluminum, steel, and titanium—focusing on real-world fabrication efficiency.

Aluminum Alloys dominate lightweight applications but require precise parameter control. Avoid 6061-T6 for thick-section cutting (>6mm) due to thermal distortion risks; instead, specify 5052-H32 for superior weldability and consistent edge quality in enclosures or brackets. Anodizing compatibility is non-negotiable: ensure material is 6063 or 7075 for uniform dye absorption. Note that laser-cut aluminum edges may show slight oxidation—our post-process tumbling eliminates this prior to anodizing, preventing finish defects.

Carbon and Stainless Steel offer cost-effective strength but demand alloy-specific approaches. For structural components under 25mm, 304 stainless provides ideal corrosion resistance with minimal dross when cut with nitrogen assist gas. Avoid 316 for non-marine applications—its molybdenum content increases cost without benefit and complicates laser parameters. Mild steel (A36/SS400) excels in high-volume runs but requires immediate deburring; our automated edge finishing reduces post-cut labor by 40%. Critical note: laser-cut steel edges must be passivated before powder coating to prevent under-film corrosion.

Titanium (Grade 2/5) delivers unmatched strength-to-weight ratios but presents unique challenges. Its low thermal conductivity demands pulsed laser modes to prevent heat-affected zone (HAZ) embrittlement. Crucially, titanium must be cut under argon shielding to avoid oxygen-induced surface hardening—a capability few Chinese workshops offer. We enforce strict inert gas protocols, ensuring parts meet ASTM F67 standards for aerospace or medical use. Anodizing titanium requires specialized electrolytes; specify voltage requirements upfront to avoid color inconsistency.

Material Performance Comparison

| Material | Max Thickness (mm) | Laser Assist Gas | Anodizing Compatibility | Critical Pre-Processing Step |

|---|---|---|---|---|

| Aluminum 5052 | 20 | N₂ | Excellent (6063/7075) | Alkaline degreasing |

| Stainless 304 | 30 | N₂ | Not applicable | Pickling to remove scale |

| Titanium Grade 5 | 15 | Ar | Limited (color anodizing) | Vapor honing for HAZ removal |

Material choice directly impacts your total landed cost. Suboptimal selections trigger costly rework: improper steel grades cause coating failures, while uncontrolled titanium cutting leads to scrap rates exceeding 30%. Wuxi Lead’s engineering team validates material certifications (MTRs) and laser parameters against your GD&T requirements—eliminating guesswork. For anodized parts, we integrate chemical pre-treatment into our workflow, ensuring adhesion and color consistency per MIL-A-8625. Partner with us to transform material specifications into flawless, production-ready components.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal fabrication begins with meticulous design engineering. Our online laser cutting service integrates advanced CAD/CAM workflows to transform client concepts into manufacturable designs. Engineers utilize industry-standard software including SolidWorks, AutoCAD, and Autodesk Inventor to generate 2D and 3D models that adhere to geometric dimensioning and tolerancing (GD&T) standards. Each design undergoes rigorous DFM (Design for Manufacturability) analysis to identify potential material waste, structural weaknesses, or laser path inefficiencies. This proactive optimization ensures that components are not only dimensionally accurate but also cost-effective to produce at scale. Clients receive real-time design feedback through our secure online portal, enabling rapid iterations and approval cycles before any metal is cut.

Prototyping: Validating Accuracy and Functionality

Once the design is finalized, we proceed to prototype development using our high-precision fiber laser cutting systems. Prototyping serves as a critical validation phase, allowing clients to verify form, fit, and function before committing to full-scale production. Our laser cutters operate with ±0.1 mm positional accuracy and are paired with automated material handling systems to ensure consistency across prototype batches. Each prototype undergoes first-article inspection (FAI), including CMM (Coordinate Measuring Machine) verification and visual quality checks per ISO 9001:2015 protocols. This stage minimizes downstream risks by catching discrepancies early, reducing rework, and accelerating time-to-market. Clients receive comprehensive inspection reports and physical or digital samples for approval, ensuring complete alignment with technical and aesthetic requirements.

Mass Production: Zero Defects Through Process Control

With prototype approval, Wuxi Lead transitions seamlessly into high-volume manufacturing. Our production floor is equipped with state-of-the-art 5-axis fiber laser cutting machines, capable of processing materials from 0.5 mm to 25 mm in thickness across carbon steel, stainless steel, aluminum, and specialty alloys. The entire production run is governed by a closed-loop quality management system that monitors cutting parameters in real time—laser power, assist gas pressure, and focal position—to maintain micron-level repeatability. Every component is traceable via barcode tracking, and statistical process control (SPC) charts are used to detect and correct deviations before they impact output. Final inspection includes 100% visual checks and random sampling for dimensional conformance.

The following table outlines key capabilities of our online laser cutting service:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (IPG Photonics) |

| Cutting Thickness Range | 0.5 mm – 25 mm (material-dependent) |

| Positional Accuracy | ±0.1 mm |

| Repeatability | ±0.05 mm |

| Max Cutting Speed | 60 m/min |

| Supported Materials | Carbon Steel, Stainless Steel, Aluminum, Brass |

| Standard Tolerances | ISO 2768-m (can achieve ISO 2768-f on request) |

| Lead Time (Mass Production) | 7–15 days (depending on order volume) |

Through integrated design validation, precision prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers zero-defect sheet metal components—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

Precision manufacturing demands more than just advanced equipment it requires a strategic partner committed to your project’s success from concept to delivery. At Wuxi Lead Precision Machinery we engineer partnerships that transform your sheet metal fabrication challenges into competitive advantages. With over 20 years of specialized expertise in high-tolerance laser cutting our facility in Wuxi China merges German-engineered machinery with rigorous ISO 9001-certified processes ensuring every component meets exacting global standards. We understand that delays or dimensional inaccuracies in critical parts can cascade through your production line. That is why our online laser cutting service eliminates traditional supply chain friction through seamless digital workflows real-time production tracking and dedicated engineering support.

Our technical capabilities are built for mission-critical applications across aerospace automotive and medical device manufacturing. The table below details our core laser cutting specifications engineered for repeatability and throughput.

| Specification | Capability |

|---|---|

| Laser Types | Fiber CO₂ Hybrid Systems |

| Material Thickness | 0.5 mm – 25 mm (Mild Steel Stainless) |

| Max Cutting Area | 3000 mm × 1500 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.02 mm |

| Supported File Formats | DXF DWG STEP IGS |

| Lead Time | 3–7 Days (Standard Production) |

| Surface Finish | Burr-Free Edge (Ra ≤ 3.2 μm) |

What distinguishes Lead Precision is our integrated engineering approach. Unlike transactional vendors we assign a dedicated project engineer to review your CAD files for manufacturability optimize nesting to minimize material waste and validate first-article approvals against your GD&T requirements. Our facility operates 24/7 with redundant power systems and climate-controlled metrology labs ensuring dimensional integrity regardless of order volume. Clients consistently achieve 99.2% first-pass yield rates reducing scrap costs by up to 18% compared to regional alternatives.

When you partner with us you gain a transparent extension of your engineering team. We provide digital work-in-progress reports including in-process inspection data and final CMM reports accessible via our secure client portal. This level of visibility—coupled with our zero-defect shipment guarantee—makes us the preferred supplier for Tier-1 manufacturers who cannot afford supply chain disruptions.

Initiate your precision workflow today. Email Contact [email protected] with your technical drawings material specifications and target deadline. Our engineering team will respond within 4 business hours with a detailed quotation process timeline and DFM analysis. Specify “B2B Laser Partnership” in your subject line to expedite review. Let us demonstrate how precision manufacturing—delivered with accountability and technical rigor—can elevate your production outcomes. Wuxi Lead Precision Machinery where your specifications become our commitment.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.