Technical Contents

Engineering Guide: Online Cnc Cutting Service

Engineering Insight: The Critical Role of Precision in Online CNC Cutting Services

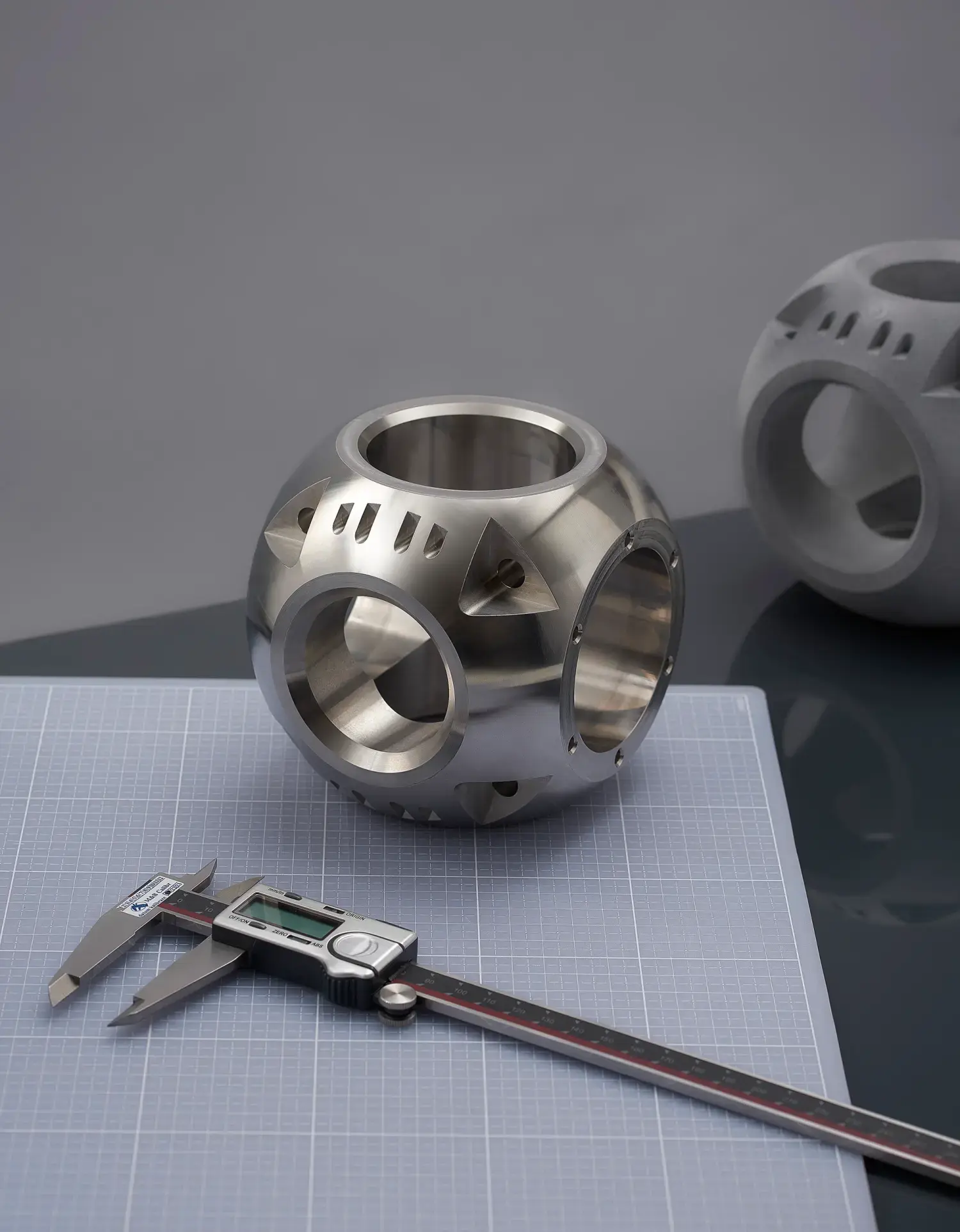

In high-end manufacturing, precision is not merely a performance metric—it is the foundation of reliability, safety, and operational success. When sourcing an online CNC cutting service, the margin for error is effectively zero, especially in industries such as aerospace, defense, medical devices, and advanced robotics. At Wuxi Lead Precision Machinery, we understand that precision transcends tight tolerances; it encompasses consistency, material integrity, and geometric accuracy across every production run.

Our engineering team approaches each CNC cutting project with a philosophy rooted in disciplined process control. From initial CAD/CAM programming to final inspection, every step is optimized to maintain micron-level accuracy. This level of control is not achieved through equipment alone, but through decades of accumulated expertise, rigorous quality protocols, and a deep understanding of material behavior under high-speed machining conditions.

Wuxi Lead Precision Machinery has been entrusted with mission-critical components for applications where failure is not an option. Our involvement in supporting infrastructure for Olympic venues and precision subsystems for military-grade equipment underscores our capability to meet the most stringent requirements. These projects demanded more than technical proficiency—they required traceability, documentation, and adherence to international standards such as ISO 9001 and AS9100. Such experience informs every online CNC cutting service we deliver, ensuring clients receive parts that are not only dimensionally accurate but also functionally reliable under extreme conditions.

Our CNC machining centers are equipped with high-resolution probing systems, in-process inspection tools, and thermal compensation algorithms that mitigate environmental variables. These technologies, combined with our engineers’ ability to interpret complex GD&T callouts, allow us to consistently achieve tolerances down to ±0.005 mm. Whether working with titanium alloys, hardened steels, or exotic composites, our processes are designed to preserve material properties while achieving the required geometry.

We recognize that clients utilizing online CNC cutting services often require rapid turnaround without sacrificing quality. Our digital workflow enables seamless integration from design upload to production scheduling, supported by real-time monitoring and automated quality checkpoints. This digital thread ensures transparency and traceability, critical for regulated industries.

Below are key performance specifications that define our CNC cutting capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance Range | Standard: ±0.01 mm, Precision: ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass |

| CNC Equipment Types | 3-axis, 4-axis, 5-axis milling, High-speed cutting |

Precision in CNC cutting is not an isolated attribute—it is the result of integrated engineering excellence. At Wuxi Lead Precision Machinery, we bring proven experience, advanced technology, and unwavering commitment to every component we produce.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision CNC Machining

Wuxi Lead Precision Machinery delivers industry-leading precision through our integrated suite of advanced manufacturing and quality assurance systems. Our core strength lies in mastering complex geometries and stringent tolerances demanded by aerospace, medical, energy, and high-tech industrial sectors. Central to this capability is our modern fleet of 5-axis CNC machining centers, featuring知名品牌 like DMG MORI and MAZAK. These machines enable simultaneous multi-directional cutting, eliminating the need for multiple setups and significantly reducing part handling errors. This translates to superior surface finishes, intricate internal features, and consolidated operations on challenging materials including titanium, Inconel, hardened steels, and advanced composites. The inherent rigidity and thermal stability of our equipment ensure consistent dimensional accuracy throughout extended production runs, directly impacting your component reliability and assembly performance.

Quality is not an afterthought but an engineered process at Wuxi Lead. Every critical dimension undergoes rigorous validation using state-of-the-art Coordinate Measuring Machines (CMMs), including蔡司 CONTURA and Hexagon GLOBAL systems. Our inspection protocols are designed for full traceability and compliance with AS9100, ISO 13485, and customer-specific standards. CMM inspection provides statistically validated data on form, position, and critical features, generating comprehensive inspection reports with GD&T analysis. This meticulous approach guarantees that every component leaving our facility meets or exceeds your engineering specifications, minimizing downstream assembly issues and scrap costs. Our quality engineers work proactively during process development to identify potential variation sources, implementing robust controls before full production begins.

Our machining precision is quantifiable and consistently achieved across diverse projects. The following table details our standard and achievable tolerance capabilities, reflecting our commitment to dimensional integrity. Note that specific tolerances are always evaluated considering part geometry, material properties, and feature complexity during the quoting phase.

| Tolerance Class | Linear Dimensions (mm) | Linear Dimensions (inches) | Geometric Tolerances (GD&T) | Typical Applications |

|---|---|---|---|---|

| Standard | ± 0.05 | ± 0.002 | ± 0.05 | Non-critical brackets, housings, prototypes |

| Precision | ± 0.01 | ± 0.0004 | ± 0.01 | Hydraulic components, precision fixtures, optical mounts |

| Ultra-Precision | ± 0.005 (achievable) | ± 0.0002 (achievable) | ± 0.005 (achievable) | Aerospace actuators, medical implants, semiconductor tooling |

This documented capability, combined with our 5-axis machining efficiency and rigorous CMM validation, ensures Wuxi Lead delivers components that perform flawlessly in your most demanding applications. We transform complex designs into reality with the precision your engineering team requires, accelerating your time-to-market while safeguarding quality. Partner with us for CNC cutting services where technical capability meets uncompromising quality assurance.

Material & Finish Options

Material selection is a critical step in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy online CNC cutting services, supporting industrial clients with expert guidance on material and finish selection. The most widely used metals in our production include aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific engineering demands.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly ideal for aerospace, automotive, and consumer electronics applications where lightweight components are essential. Grade 6061-T6 is a common choice due to its weldability and moderate strength, while 7075-T6 offers higher strength for more demanding structural uses. Aluminum’s natural oxide layer provides some protection, but for enhanced surface durability and aesthetics, anodizing is recommended.

Steel remains the backbone of heavy-duty industrial applications. Its high tensile strength, wear resistance, and affordability make it suitable for tooling, machinery components, and structural parts. We commonly machine stainless steel grades such as 304 and 316, which offer excellent corrosion resistance and are widely used in medical, food processing, and marine environments. For applications requiring extreme hardness, alloy steels like 4140 or tool steels can be precision cut to tight tolerances.

Titanium, though more challenging to machine, delivers an unmatched strength-to-density ratio and exceptional resistance to heat and corrosion. Grade 5 (Ti-6Al-4V) is the most prevalent in aerospace, defense, and medical implant manufacturing. Despite higher material and machining costs, titanium’s long-term reliability in extreme environments justifies its use in mission-critical components.

Surface finishing plays a pivotal role in enhancing functionality and appearance. Anodizing, particularly for aluminum, is a widely adopted electrochemical process that thickens the natural oxide layer, improving wear and corrosion resistance. It also allows for color coding through dye integration, supporting both branding and functional identification. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hard anodizing) delivers a thicker, harder coating for industrial wear applications.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications |

|---|---|---|---|---|

| Aluminum | 290–570 | 2.7 | 6061-T6, 7075-T6 | Aerospace, electronics, automotive |

| Stainless Steel | 505–900 | 7.9–8.0 | 304, 316, 17-4PH | Medical, food processing, marine |

| Titanium | 900–1100 | 4.5 | Ti-6Al-4V (Gr 5) | Aerospace, defense, medical |

Selecting the right material and finish requires balancing performance requirements, environmental exposure, and production costs. Wuxi Lead Precision Machinery supports global clients with advanced CNC cutting capabilities and engineering consultation to ensure optimal material utilization and part longevity. Contact our team to discuss your next precision machining project.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero Defects Fulfillment

Precision begins long before the spindle engages. At Wuxi Lead Precision Machinery, our production process is engineered for absolute reliability, transforming your design into flawless physical reality through three rigorously controlled phases. This integrated workflow ensures every component meets the most demanding aerospace, medical, and industrial specifications, delivering true zero defects performance.

The journey starts with meticulous design validation. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis on your CAD models, identifying potential tolerance stack-up issues, material constraints, or tool access challenges. We collaborate closely with your engineers to optimize geometries for CNC efficiency without compromising functional intent. This proactive review eliminates costly revisions later, ensuring the digital model is perfectly aligned with physical production realities and your exact performance requirements. Material selection is validated against application stress, environmental exposure, and regulatory standards during this critical stage.

Prototyping is not merely a sample step; it is a full-scale process validation. Utilizing the same production-grade CNC machines and certified materials destined for your final run, we manufacture functional prototypes. These undergo rigorous metrology, including CMM inspection against your original CAD data and application-specific functional testing. Dimensional accuracy, surface finish, and material properties are verified to ISO 2768-mK or tighter standards. This phase provides tangible proof of process capability and design integrity, allowing for final micro-adjustments before committing to volume. Client sign-off on prototype validation is mandatory, confirming we have achieved the required quality baseline.

Mass production leverages the validated process under stringent statistical process control (SPC). Every machine operates within monitored environmental conditions, with tool wear compensated in real-time via integrated sensors. In-process inspections at critical stages, coupled with final 100% dimensional verification using calibrated CMMs and optical comparators, ensure consistency. Material traceability is maintained from raw stock to finished part. Our closed-loop quality system analyzes inspection data continuously, triggering immediate process adjustments if trends approach tolerance limits, guaranteeing every single component in your order meets the zero defects standard. Production efficiency is maximized through optimized toolpaths and automated material handling, without sacrificing the uncompromising quality your application demands.

Core Production Capabilities

| Parameter | Specification | Relevance to Zero Defects |

|---|---|---|

| Positioning Accuracy | ±0.002 mm (ISO 230-2) | Ensures micron-level feature alignment |

| Repeatability | ±0.001 mm | Guarantees consistent part-to-part quality |

| Max Work Envelope | 2000 x 1000 x 800 mm (Milling) | Accommodates complex, large assemblies |

| Surface Finish | Ra 0.2 µm achievable (Milling) | Meets critical sealing & functional needs |

| Standard Tolerance | ISO 2768-mK (Tighter available) | Exceeds typical industry requirements |

| In-Process Control | Real-time SPC, CMM validation | Prevents defect escape, ensures consistency |

This seamless transition from validated design through proven prototyping to controlled mass production forms the backbone of our zero defects commitment. Wuxi Lead Precision Machinery delivers not just parts, but guaranteed performance, engineered for your success from the first prototype to the final shipment. Your vision, realized without compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Cutting Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in today’s competitive manufacturing landscape. As a global leader in high-end CNC machining, we offer advanced online CNC cutting services tailored to meet the exacting demands of industries ranging from aerospace and medical devices to automotive and industrial automation. When you partner with Lead Precision, you’re not just outsourcing a machining task—you’re gaining a strategic manufacturing ally committed to quality, consistency, and on-time delivery.

Our state-of-the-art facility in Wuxi, China, is equipped with a comprehensive range of CNC technologies, including 3-axis, 4-axis, and 5-axis milling, precision turning, wire EDM, and high-speed laser cutting. Every process is governed by ISO 9001:2015 standards, ensuring that each component meets the tightest tolerances and highest surface quality requirements. Our engineering team works closely with clients during the design-for-manufacturability phase, providing expert feedback to optimize part geometry, reduce lead times, and lower overall production costs.

What sets us apart is our seamless digital workflow. Our online CNC cutting service platform allows you to upload CAD files, receive instant quotations, and track production progress in real time—all from anywhere in the world. Whether you need rapid prototyping or high-volume production runs, our agile manufacturing system adapts to your schedule without compromising on precision.

We specialize in working with a broad spectrum of materials, including aluminum alloys, stainless steel, titanium, brass, PEEK, and other high-performance composites. Our quality assurance protocols include full first-article inspection reports (FAIR), coordinate measuring machine (CMM) verification, and material certification upon request.

For engineering teams and procurement managers seeking a dependable, transparent, and technically advanced manufacturing partner, Lead Precision delivers results you can trust. We pride ourselves on clear communication, technical depth, and a customer-first approach that ensures your project succeeds—from concept to delivery.

Explore the full capabilities of our precision CNC services through the specifications below.

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning, wire EDM, laser cutting |

| Tolerance | Up to ±0.005 mm |

| Materials | Aluminum, stainless steel, titanium, brass, copper, PEEK, Delrin, polycarbonate |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), 2000 x 1000 mm (laser cutting) |

| Surface Finish | As low as Ra 0.4 µm (polished), with various coatings available |

| Lead Time | As fast as 5 days for prototypes, 10–20 days for production |

| Certifications | ISO 9001:2015, RoHS compliant, full traceability documentation |

Ready to elevate your manufacturing outcomes? Contact us today at [email protected] to discuss your project, request a quote, or schedule a virtual tour of our facility. Let Wuxi Lead Precision Machinery be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.