Technical Contents

Engineering Guide: Online Cnc

Engineering Insight: The Non-Negotiable Imperative of Precision in Online CNC Manufacturing

In the realm of high-stakes B2B manufacturing, the term “precision” transcends mere marketing rhetoric; it represents the absolute foundation upon which product performance, safety, and longevity are built. When engaging with online CNC services, understanding the true depth of precision required – far beyond nominal tolerance ranges – is critical. Sub-micron deviations, imperceptible to the naked eye, can cascade into catastrophic system failures in aerospace hydraulics, biomedical implants, or semiconductor fabrication equipment. The cost of inadequate precision extends far beyond scrap parts; it encompasses delayed time-to-market, compromised brand reputation, and potentially severe liability in safety-critical applications. Selecting a partner capable of consistently delivering and verifying micron-level accuracy under real-world production conditions is not an option, it is a fundamental engineering requirement.

Wuxi Lead Precision Machinery operates at this uncompromising threshold daily. Our engineering ethos is forged through direct experience delivering components where failure is inconceivable. We have engineered and manufactured mission-critical parts validated under the extreme scrutiny of Olympic sporting equipment, where marginal gains determined podium finishes, and for advanced military systems adhering to stringent MIL-STD-810 and AS9100 compliance frameworks. This experience instills a profound understanding that precision is not solely about the machine’s capability, but equally about the integrated process: rigorous material certification, environmental controls, in-process metrology, and a culture of zero-defect accountability. Our online CNC platform provides transparent access to this disciplined precision ecosystem, ensuring every machined component meets the exacting standards demanded by innovators pushing technological boundaries.

The technical capability underpinning this reliability is quantifiable. Our core production equipment consistently achieves the following verified performance metrics:

| Specification Parameter | Performance Level | Industry Standard Reference |

|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±1.5 µm | ISO 230-2:2014 |

| Repeatability (3σ) | ≤ 0.8 µm | ISO 230-2:2014 |

| Volumetric Compensation | Full 3D Applied | NAS979 / ISO 10791-6 |

| Thermal Drift Control | < 2 µm/8h (20°C±0.5°C) | Custom Environmental Protocol |

| Surface Finish (Ra) | Down to 0.05 µm | Measured via Profilometry |

Partnering with Wuxi Lead Precision for online CNC machining means integrating our proven precision discipline directly into your supply chain. We translate complex engineering intent into tangible, reliable components through a seamless digital workflow backed by physical rigor. This commitment eliminates the guesswork and risk associated with standard online machining services, transforming precision from a specification on a drawing into a guaranteed outcome. For industries where performance margins are measured in microns, this level of assured precision is the only acceptable standard, directly impacting your product’s success and your organization’s competitive edge. Trust in precision engineered for consequence.

Precision Specs & Tolerances

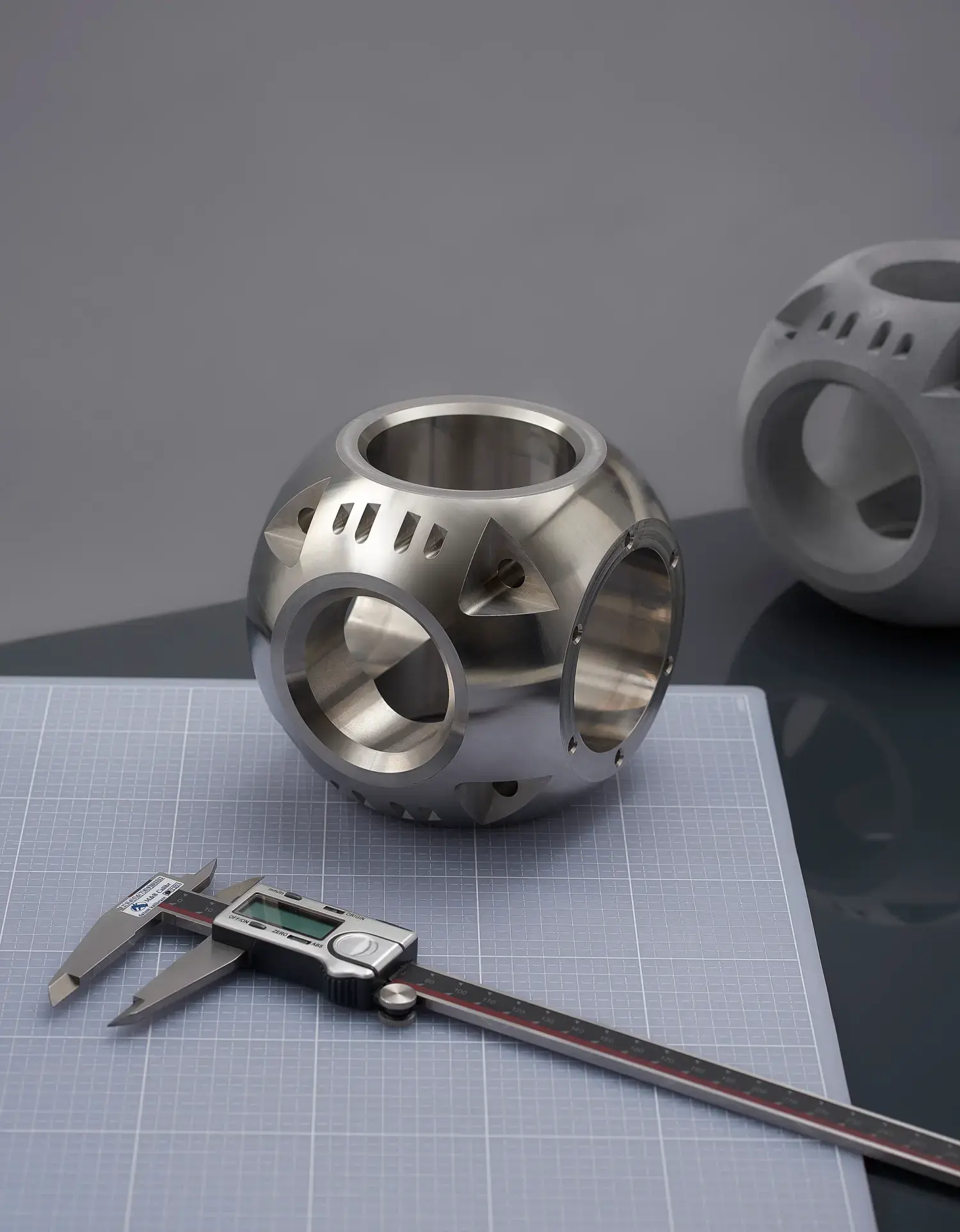

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored for high-performance industries including aerospace, medical, energy, and automation. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling the production of complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five axes, minimizing setup changes and ensuring tight alignment across intricate features. This capability is essential for manufacturing components with organic shapes, deep cavities, or compound angles—common in turbine blades, surgical instruments, and high-pressure manifolds.

Our machining centers are equipped with high-speed spindles, thermal compensation systems, and rigid toolholding technologies to maintain dimensional stability across long production runs. We support a wide range of materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics such as PEEK and PPSU. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, reduce cycle times, and ensure consistent part quality.

Quality control is integrated at every stage of production. All critical dimensions are verified using state-of-the-art Coordinate Measuring Machines (CMM) with tactile and optical probing systems. These inspection platforms provide full 3D measurement data, generating detailed reports that include geometric dimensioning and tolerancing (GD&T) analysis, surface deviation mapping, and first-article inspection (FAI) documentation per AS9102 or customer-specific requirements. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate conformance.

Our facility maintains a climate-controlled inspection environment to eliminate measurement drift due to thermal variation. All measuring equipment is recalibrated annually in accordance with ISO 17025 standards, and our quality technicians are trained in ISO 9001:2015 and IATF 16949 methodologies. This rigorous approach ensures that every component shipped meets or exceeds customer specifications.

The following table outlines the standard precision tolerances achievable across common machining processes at Wuxi Lead:

| Feature | Standard Tolerance | Typical Range | Measurement Method |

|---|---|---|---|

| Linear Dimensions (machined) | ±0.005 mm | 0.1 – 500 mm | CMM, Micrometer |

| Geometric Tolerances (GD&T) | ±0.010 mm | Position, Flatness, Runout | CMM |

| Hole Diameter (reamed) | +0.010 / -0.000 mm | 3 – 50 mm | Air Gauge, CMM |

| Surface Roughness (Ra) | 0.4 – 1.6 μm | Machined Finish | Surface Tester |

| Angular Features (5-axis) | ±0.05° | Complex 3D Surfaces | CMM, Optical Probe |

| Repeatability (batch) | ±0.003 mm | Over 100+ parts | SPC Monitoring |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade inspection to deliver components where precision is non-negotiable. Our technical capabilities are engineered to support rapid prototyping, low-volume specialty runs, and high-volume production with consistent repeatability and full traceability.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Machining

Selecting the optimal material is a critical engineering decision that directly impacts part performance, manufacturability, cost, and longevity in CNC machining. At Wuxi Lead Precision Machinery, our engineering team evaluates client requirements against material properties to ensure the final component meets stringent functional and economic targets. Aluminum, steel, and titanium represent the core structural metals for high-precision applications, each offering distinct advantages. Understanding their characteristics is essential for informed procurement.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and superior machinability. Grades like 6061-T6 and 7075-T6 provide good corrosion resistance and are easily anodized. Aluminum machining yields high feed rates, reducing cycle times and costs significantly compared to harder metals. It is the default choice where weight savings and electrical conductivity are paramount, though pure aluminum requires careful handling to avoid deformation.

Carbon and alloy steels, such as 4140, 4340, and 1018, deliver unmatched strength, hardness, and wear resistance for demanding mechanical applications. Steel is indispensable for high-stress components like shafts, gears, and tooling. Its higher density and toughness increase machining difficulty and tool wear compared to aluminum, necessitating robust CNC systems and optimized parameters. Post-machining heat treatments are often required to achieve final mechanical properties, adding process steps but enabling superior durability in structural and load-bearing roles.

Titanium, primarily Grade 5 (Ti-6Al-4V), offers an extraordinary combination of high strength, low density, and exceptional corrosion resistance, especially in saline or high-temperature environments. This makes it vital for aerospace, medical implants, and marine components. However, titanium’s low thermal conductivity and chemical reactivity pose significant machining challenges, including heat buildup and galling. Specialized tooling, rigid setups, and conservative cutting parameters are mandatory, increasing production time and cost. Its use is justified only when its unique properties are non-negotiable.

Anodizing: The Essential Aluminum Enhancement

Anodizing is a critical electrochemical finish exclusively for aluminum, creating a durable, corrosion-resistant, and electrically insulating oxide layer. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hard coat) provides superior abrasion resistance for high-wear parts. Anodizing thickness, color, and sealing method must align with environmental exposure and functional requirements. It enhances aesthetics and longevity but requires precise dimensional control during machining, as the process adds a thin layer to all exposed surfaces.

Material choice fundamentally shapes the CNC process strategy and final part value. The following table summarizes key considerations for common engineering metals:

| Material | Key Properties | Common Grades | Typical Applications |

|---|---|---|---|

| Aluminum | Lightweight, excellent machinability, good corrosion resistance, electrically conductive | 6061-T6, 7075-T6, 2024-T3 | Aerospace brackets, heat sinks, enclosures, automotive components |

| Steel | High strength, hardness, wear resistance, magnetic properties | 4140, 4340, 1018, 304/316 Stainless | Shafts, gears, tooling, structural frames, hydraulic components |

| Titanium | High strength-to-weight ratio, exceptional corrosion resistance, biocompatible | Grade 2 (CP), Grade 5 (Ti-6Al-4V) | Aircraft structural parts, medical implants, marine hardware, high-performance automotive |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced CNC systems to machine these materials to micron-level tolerances. Consult our engineering team early in the design phase to optimize material selection, finish specification, and manufacturability, ensuring cost-effective delivery of mission-critical components. Your application demands precision; we deliver the right material solution.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful production cycle begins with meticulous design engineering. Our team collaborates closely with clients to translate conceptual blueprints into manufacturable designs optimized for CNC machining. Using advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, we conduct comprehensive design reviews to ensure dimensional accuracy, material compatibility, and functional performance. Finite element analysis (FEA) and geometric dimensioning & tolerancing (GD&T) are applied to preempt stress points, minimize material waste, and enhance structural integrity. This phase includes Design for Manufacturability (DFM) feedback, ensuring that every component is not only precise but also efficient to produce at scale. All design data is securely archived and version-controlled to maintain traceability throughout the production lifecycle.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move into the prototyping stage—a critical checkpoint for quality assurance. Utilizing high-speed 3-axis, 4-axis, and 5-axis CNC milling and turning centers, we produce functional prototypes that mirror final production conditions. These prototypes undergo rigorous in-house testing, including dimensional inspection via Coordinate Measuring Machines (CMM), surface finish analysis, and material property verification. We also perform fit, form, and function evaluations in real-world assemblies to validate performance under operational stress. Client feedback is integrated at this stage, allowing for rapid iteration without impacting the production timeline. The prototype approval signifies not just design validation, but also the readiness of tooling, programming, and inspection protocols for mass production.

Mass Production: Precision at Scale with Zero Defects

With approved prototypes, Wuxi Lead initiates mass production under a fully documented and ISO 9001-certified quality management system. Our automated CNC cells operate with minimal human intervention, ensuring consistency across thousands of parts. Real-time process monitoring systems track tool wear, spindle load, and thermal drift, triggering alerts before deviations occur. Each production batch is accompanied by first-article inspection reports (FAIR), statistical process control (SPC) data, and full material certification. In-process inspections are conducted at defined intervals, and final parts are subjected to 100% visual inspection and sampling-based metrology. Our zero-defect philosophy is enforced through continuous improvement loops, root cause analysis of near-misses, and corrective action protocols.

Production Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.8 µm to 6.3 µm (customizable) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001:2015, RoHS, REACH, PPAP Level 3 |

| Lead Time (Mass Prod.) | 15–25 days after prototype approval |

From design to delivery, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of precision, reliability, and repeatability—delivering excellence on every run.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Excellence

At Wuxi Lead Precision Machinery, we engineer solutions where precision meets scalability. For over 15 years, we have served global aerospace, medical, and automotive leaders by transforming complex designs into mission-critical components. Our ISO 9001 and AS9100-certified facility in Wuxi, China, operates under stringent international quality frameworks, ensuring every part adheres to ±0.005mm tolerances and surface finishes down to Ra 0.4μm. Unlike generic suppliers, we integrate advanced 5-axis machining with in-house metallurgical analysis and first-article inspection protocols, eliminating rework cycles and accelerating time-to-market. When you partner with us, you gain not just a vendor but a co-engineering resource committed to your product’s success from prototype to full-scale production.

Our technical capabilities are built on a foundation of cutting-edge infrastructure and process rigor. The table below outlines core specifications defining our production capacity:

| Parameter | Specification Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling & turning |

| Max Work Envelope | 2000 x 1000 x 800 mm (XYZ) |

| Typical Tolerances | ±0.005 mm (standard), ±0.002 mm (tight) |

| Material Range | Aluminum, Titanium, Inconel, Stainless Steel, Plastics |

| Key Industries Served | Aerospace, Medical Devices, Semiconductor, Energy |

| Quality Documentation | FAI, PPAP, CMM Reports, Material Certs |

What differentiates Lead Precision is our closed-loop engineering approach. Our team collaborates during your design phase to optimize manufacturability, reducing costs by up to 22% while maintaining geometric integrity. Real-time SPC monitoring on every machine ensures batch consistency, and our ERP system provides full traceability—from raw material lot tracking to final inspection data accessible via client portal. For high-mix, low-volume projects demanding rapid iteration, our agile workflow accommodates rush orders without compromising quality, a critical advantage in regulated sectors where delays carry severe consequences.

Initiate your precision machining project with a partner who treats your specifications as non-negotiable. Contact us today to discuss your technical requirements, material challenges, or volume needs. Our engineering team will respond within 24 hours with a feasibility assessment and actionable timeline. Direct inquiries to [email protected]—include your part drawings or 3D models for a tailored production strategy. For urgent requests, reference “Priority Review” in your subject line. Wuxi Lead Precision Machinery: Where global standards drive Chinese manufacturing excellence. Let us prove why industry leaders trust us for components where failure is never an option.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.