Technical Contents

Engineering Guide: One Fabrication

Engineering Insight: The Non-Negotiable Precision of One Fabrication

In high-stakes sheet metal fabrication, the concept of “one fabrication” transcends mere production volume. It signifies the absolute imperative that every single component, whether part of a batch of one or one million, must meet exacting specifications without exception. This zero-defect mandate is not a luxury; it is the foundational requirement for system integrity, safety, and long-term operational success in aerospace, defense, medical, and advanced infrastructure applications. Tolerances measured in microns directly impact assembly fit, structural performance, and the ultimate functionality of the final product. A single dimension outside specification can cascade into catastrophic system failure, costly field recalls, or compromised mission objectives. Precision engineering in “one fabrication” demands rigorous process control, advanced metrology, and an unwavering commitment to repeatability at the individual part level, where statistical averages are irrelevant – only the absolute conformance of that specific part matters.

Wuxi Lead Precision Machinery operates at this critical threshold daily. Our engineering philosophy is built upon the understanding that precision is non-negotiable, especially when a single component can define the success or failure of an entire system. This commitment is validated through our direct contributions to projects where failure is not an option. We have successfully delivered mission-critical sheet metal components for infrastructure supporting the Beijing Winter Olympics, where environmental resilience and absolute dimensional accuracy were paramount under extreme conditions. Furthermore, our facility adheres to stringent protocols required for certified military-grade fabrication, producing parts where tolerances directly impact national security and operational safety. These experiences are not merely credentials; they are the proving ground for our processes, demonstrating our capability to consistently achieve the highest levels of precision demanded by the world’s most exacting industries.

Achieving this level of consistency requires integrated technology and deep process mastery. Our facility leverages state-of-the-art equipment operating within tightly controlled environmental parameters, coupled with multi-stage in-process inspection protocols. The table below outlines the core precision capabilities underpinning our “one fabrication” success for critical applications.

| Specification Category | Capability | Equipment/Process Verification | Olympic/Military Project Validation |

|---|---|---|---|

| Geometric Tolerance | ±0.02 mm (Flatness/Perpendicularity) | CMM, Laser Tracker, Optical Comparator | Structural Brackets, Sensor Mounts |

| Dimensional Tolerance | ±0.05 mm (Critical Features) | In-Process Probes, Hard Gauging | Hydraulic Manifolds, Enclosures |

| Material Range | 0.5 mm – 6.0 mm Steel, SS, Al, Ti | Certified Mill Test Reports, Spectro | Lightweight Chassis, Shielding |

| Critical Process Control | Real-time Laser Power/Position Monitoring | Trumpf TruLaser Series 5000/7000 | Dynamic Load Components |

| Final Inspection | 100% First Article + Random Batch CMM | Zeiss CONTURA CMMs | All Mission-Critical Deliverables |

The true measure of a precision fabricator lies not in capability sheets alone, but in the proven ability to deliver flawless “one fabrication” results under the most demanding real-world constraints. At Wuxi Lead Precision Machinery, our Olympic and military project heritage provides the definitive validation of our engineering rigor and operational discipline. We understand that for our clients, every part is the critical part. This is the standard we engineer to, and the promise we deliver with every component we produce.

Precision Specs & Tolerances

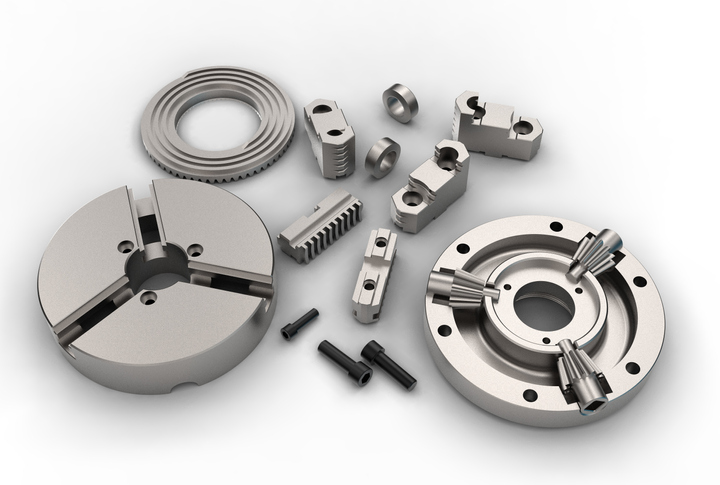

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, consistency, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable complex geometries, tight tolerances, and superior surface finishes across a broad range of metallic materials. These multi-axis platforms provide simultaneous movement across five planes, allowing for intricate contouring and reduced setup cycles. This translates into faster production times, minimized human error, and enhanced repeatability—critical factors for clients in aerospace, medical, automation, and energy sectors.

Our 5-axis CNC machining centers are integrated with high-speed spindles and advanced tooling systems, supporting materials such as aluminum alloys, stainless steel, titanium, and specialty alloys. The dynamic range of motion eliminates the need for multiple fixtures, ensuring part integrity and dimensional accuracy throughout the machining process. This capability is particularly advantageous for components requiring undercuts, deep cavities, or compound angles that are unattainable with conventional 3-axis systems. Each operation is supported by in-house CAD/CAM programming, ensuring optimal toolpaths and material efficiency.

Quality control is embedded at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), providing micron-level verification of geometric dimensions and tolerances. The CMM system operates on a temperature-controlled environment to eliminate thermal drift, ensuring measurement stability and traceability. Data from inspections are documented and archived for full process transparency, meeting ISO 9001 standards and client-specific quality requirements. This metrology-backed validation guarantees that every fabricated part conforms to design intent and performs reliably in its operational environment.

The following table outlines the standard tolerances achievable across our sheet metal fabrication and 5-axis CNC processes:

| Feature | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.02 mm | Up to 500 mm; larger dimensions ±0.1 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or precision bored |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Angular Tolerance | ±0.1° | ±0.05° | Applicable to milled features |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achieved via fine finishing passes |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm | On machined surfaces |

| 5-Axis Contour Accuracy | ±0.03 mm | ±0.01 mm | Complex freeform surfaces |

These specifications reflect our commitment to precision engineering and process control. Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality assurance, and deep technical expertise to deliver fabricated components that meet the most stringent performance criteria. Our capabilities support low-volume prototyping to high-volume production, ensuring scalability without compromise.

Material & Finish Options

Precision Material Selection for Sheet Metal Fabrication

Material selection is a foundational engineering decision in high-precision sheet metal fabrication, directly impacting component performance, manufacturability, lifecycle cost, and final finish quality. At Wuxi Lead Precision Machinery, our CNC expertise ensures optimal material utilization, but the initial choice dictates feasibility and outcome. Understanding the core properties of aluminum, steel, and titanium is critical for demanding applications across aerospace, medical, and industrial automation sectors.

Aluminum alloys, particularly 6061-T6 and 5052-H32, dominate where strength-to-weight ratio and corrosion resistance are paramount. These grades offer excellent machinability on CNC punch presses and laser cutters, coupled with high electrical conductivity. Aluminum is the preferred substrate for anodizing, enabling durable, decorative, or functional surface layers. Its natural oxide film provides good atmospheric resistance, though anodizing significantly enhances wear and corrosion protection for harsh environments.

Carbon steel, including Q235 and higher-strength Q355 variants, delivers superior structural integrity and impact resistance at a lower material cost. It is essential for heavy-duty enclosures, frames, and structural components requiring high load-bearing capacity. While inherently prone to oxidation, steel achieves robust protection through powder coating, plating, or painting. Stainless steel grades like 304 and 316 offer inherent corrosion resistance for medical or marine applications but require specialized CNC tooling and parameters due to work hardening.

Titanium Grade 2 stands unmatched for extreme environments demanding exceptional strength-to-weight ratio, biocompatibility, and resistance to corrosion from saltwater, chemicals, and high temperatures. Its use is critical in aerospace and medical implants. However, titanium’s low thermal conductivity and high chemical reactivity necessitate meticulous CNC programming, specialized tooling, and controlled environments to prevent galling and ensure precision, increasing fabrication complexity and cost.

Anodizing is the premier surface treatment for aluminum components, transforming the surface into a durable, non-conductive aluminum oxide layer. Standard sulfuric acid anodizing (Type II) provides good corrosion resistance and accepts dyes for identification. For maximum wear resistance in high-friction applications, hard anodizing (Type III) produces a significantly thicker, harder coating essential for aerospace and military specifications. Proper material preparation before anodizing is non-negotiable for adhesion and quality.

The following table summarizes key fabrication characteristics for common sheet metal materials:

| Material | Common Grades | Typical Thickness Range (mm) | Tensile Strength (MPa) | Key Fabrication Consideration | Corrosion Resistance (Base) |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 0.5 – 6.0 | 240 – 290 | Excellent machinability; ideal for anodizing | Good (Anodizing enhances significantly) |

| Carbon Steel | Q235, Q355 | 0.8 – 10.0 | 370 – 500 | Prone to oxidation; requires post-finishing | Low (Requires coating) |

| Stainless Steel | 304, 316 | 0.5 – 8.0 | 515 – 690 | Work hardens rapidly; needs sharp tooling | Excellent |

| Titanium | Grade 2 | 0.8 – 4.0 | 345 – 450 | Low thermal conductivity; requires slow feeds/speeds | Exceptional |

Selecting the optimal material requires balancing performance requirements, environmental exposure, regulatory standards, and total fabrication cost. Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients during the design phase to validate material suitability against CNC process capabilities and finish specifications, ensuring components meet exacting performance criteria while maximizing production efficiency.

Manufacturing Process & QC

From Concept to Consistency: The Zero-Defect Sheet Metal Fabrication Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we define excellence not by volume, but by precision. Our sheet metal fabrication process is engineered from the ground up to deliver zero-defect outcomes across every phase: Design, Prototyping, and Mass Production. This disciplined, integrated workflow ensures that our clients receive components that meet exacting engineering standards—consistently and reliably.

The process begins with Design for Manufacturability (DFM). Our engineering team collaborates closely with clients during the initial concept stage, using advanced CAD/CAM software to simulate real-world performance and identify potential fabrication challenges before any material is cut. This proactive approach minimizes rework, reduces lead times, and ensures that each design is optimized for both function and manufacturability. Material selection, tolerance analysis, bend allowances, and weld integrity are all evaluated at this stage, laying the foundation for defect-free production.

Next, we move to Prototyping, where precision meets validation. Utilizing our state-of-the-art CNC punching, laser cutting, and press brake forming systems, we produce functional prototypes with the same tooling and processes intended for full-scale production. This ensures that the prototype is not merely a model, but a true representation of the final part. Each prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and first-article inspection reports (FAIR) are provided for client approval. Any deviations are corrected in real time, ensuring that only validated designs advance to mass production.

The Mass Production phase leverages automated workflows, real-time monitoring, and statistical process control (SPC) to maintain consistency across high-volume runs. Our production floor integrates robotic material handling, in-process gauging, and automated welding cells to minimize human error and maximize repeatability. Every component is traceable through our ERP system, with batch records, inspection data, and process parameters stored for full auditability. Quality is not a final checkpoint—it is embedded into every operation.

Our commitment to zero defects is supported by a comprehensive quality management system certified to ISO 9001:2015 standards. From raw material inspection to final packaging, every step is documented, monitored, and optimized.

Below are key capabilities that enable our high-precision fabrication process:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 – 10 mm |

| Tolerances | ±0.05 mm (machining), ±0.1 mm (forming) |

| Laser Cutting Accuracy | ±0.03 mm |

| Max Part Size | 3000 x 1500 mm |

| CNC Punching Tonnage | Up to 30 tons |

| Welding Processes | MIG, TIG, Spot Welding |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Brushing |

| Quality Standards | ISO 9001:2015, FAIR, PPAP, SPC |

At Wuxi Lead Precision Machinery, we don’t just fabricate parts—we engineer confidence. Our end-to-end control ensures that every component meets the highest standards of quality, performance, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Path to Manufacturing Excellence

When micron-level precision meets complex geometry in sheet metal fabrication, the margin for error vanishes. At Wuxi Lead Precision Machinery, we transform this challenge into your competitive advantage. Our engineering-led partnership model ensures every component we produce aligns with your operational imperatives—zero-defect delivery, accelerated time-to-market, and uncompromised repeatability. For over 15 years, we have served Tier-1 aerospace, medical device, and semiconductor clients across North America and Europe, embedding our processes within your supply chain as a seamless extension of your engineering team.

Our commitment begins with rigorous technical collaboration. We deploy DFMA (Design for Manufacturability Analysis) upfront to optimize your designs for cost efficiency and yield, avoiding downstream rework. Coupled with real-time SPC (Statistical Process Control) monitoring across all production stages, we guarantee adherence to the most stringent industry standards—including AS9100, ISO 13485, and ITAR compliance. This disciplined approach ensures your parts arrive not merely to specification, but to the exact functional intent of your engineering team.

To validate our capability for your most demanding projects, consider our core technical benchmarks:

| Specification Category | Performance Standard | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | CMM with 0.0005 mm repeatability |

| Material Range | Aluminum 7075-T6 to Stainless 316L, Titanium Grade 5 | Certified mill test reports |

| Maximum Work Envelope | 3000 x 1500 x 1000 mm | Laser-tracked gantry systems |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Profilometer validation per ISO 4287 |

| Lead Time Consistency | ±2% variance against quoted schedule | ERP-integrated production tracking |

This precision is sustained through our integrated facility in Wuxi—a 12,000 m² smart factory housing 27 state-of-the-art CNC punch-laser combo machines, robotic bending cells, and automated welding stations. Every machine undergoes daily calibration against NIST-traceable standards, while our 45-engineer team holds ASME Y14.5 certification to interpret geometric dimensioning with unambiguous accuracy.

Your next fabrication project demands more than a vendor—it requires a technical ally who anticipates the unspoken complexities of high-mix, low-volume production. We do not merely fulfill purchase orders; we de-risk your new product introductions through concurrent engineering and shared digital twins. When your design requires tolerances tighter than industry norms or materials pushing thermal limits, our process validation protocols become your insurance policy against field failure.

Initiate your precision partnership today. Email [email protected] with your project specifications and target launch timeline. Our engineering team will respond within 4 business hours with a tailored capability assessment—including DFM feedback, risk-mitigation roadmap, and firm delivery commitment. For urgent RFQs, reference code LEAD-ENGINEERED to expedite technical review. Let us prove why global innovators trust Lead Precision as their silent partner in manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.