Technical Contents

Engineering Guide: Off Road Metal Fabrication Parts

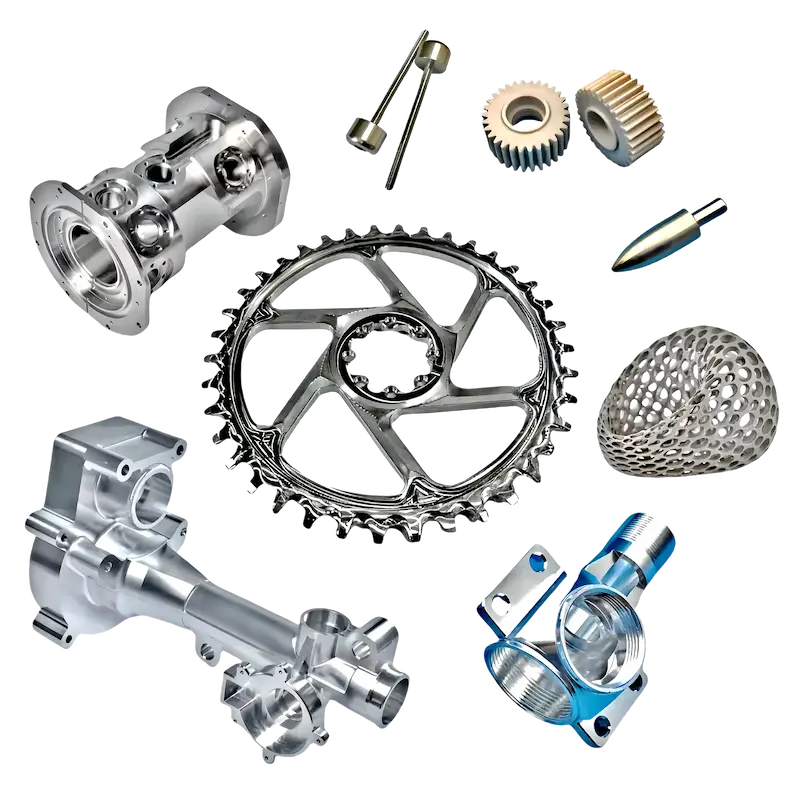

Engineering Insight: Off-Road Metal Fabrication Parts

In the demanding world of off-road machinery and heavy-duty vehicle systems, metal fabrication parts must meet uncompromising standards of durability, fit, and performance. These components—ranging from chassis subframes and suspension mounts to protective skid plates and hydraulic enclosures—are subjected to extreme stress, vibration, and environmental exposure. As such, precision in fabrication is not merely a quality benchmark; it is a functional necessity. At Wuxi Lead Precision Machinery, we understand that even a tolerance deviation of ±0.1 mm can lead to catastrophic field failure under off-road conditions. Our engineering-first approach ensures every part is designed and manufactured to withstand real-world rigors while maintaining seamless integration within complex assemblies.

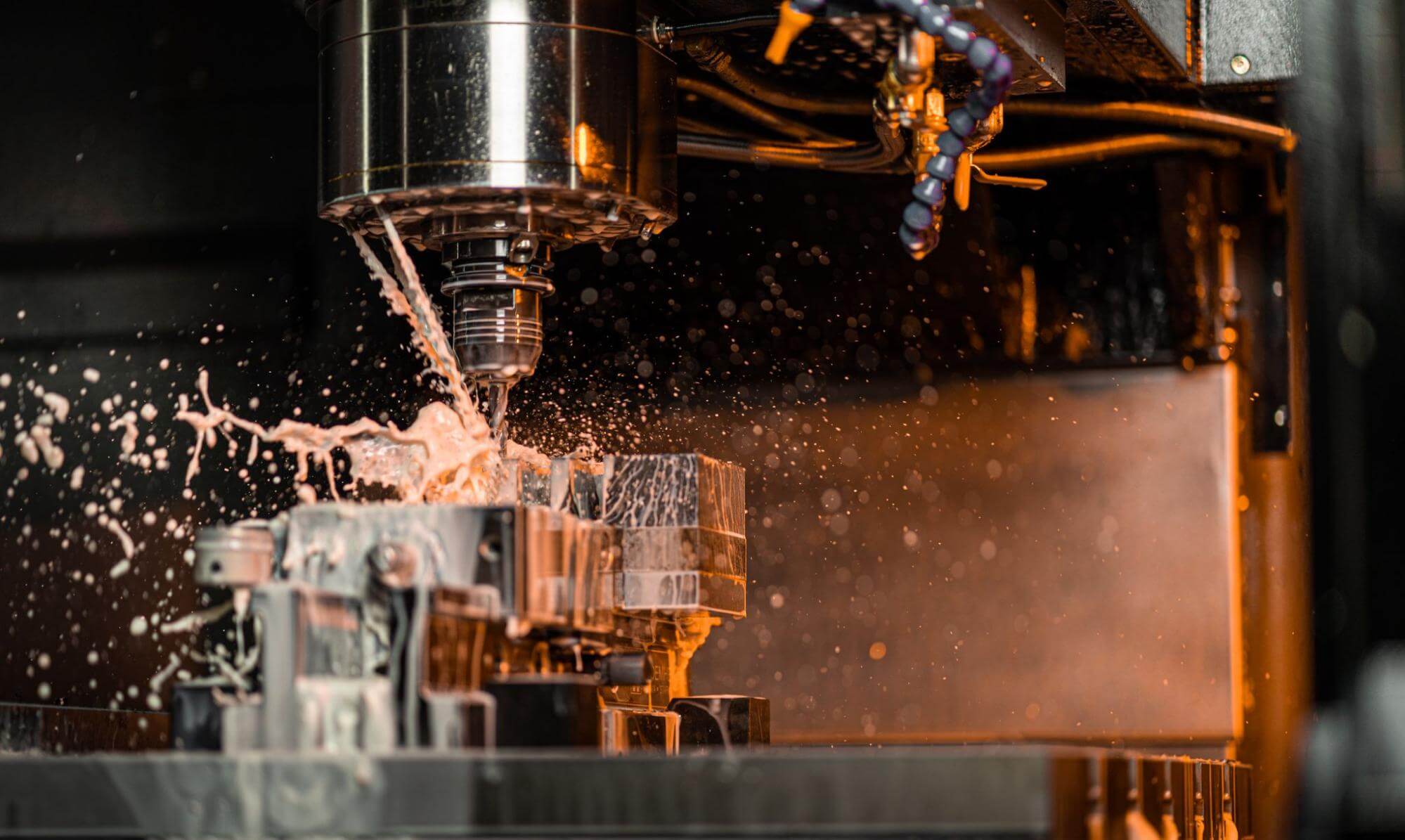

Precision in off-road metal fabrication begins with material selection and extends through every stage: laser cutting, CNC bending, welding, and surface treatment. High-strength steel alloys such as DOM, AR400, and 4130 chrome-moly are commonly used, each requiring specific thermal and mechanical handling to preserve structural integrity. Our advanced fiber laser cutting systems achieve kerf tolerances within ±0.05 mm, ensuring clean, burr-free edges that enhance weld quality and reduce post-processing. CNC press brakes with real-time feedback systems guarantee angular accuracy to ±0.25°, critical for multi-plane assemblies found in suspension linkages and roll cage structures.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in high-reliability fabrication, having supported projects with Olympic-standard equipment manufacturers and military vehicle contractors. This pedigree has instilled a culture of zero-defect engineering, where every weld is inspected per ISO 5817 standards and every dimensional check is traceable via our QMS (Quality Management System). Our team applies DFMA (Design for Manufacturability and Assembly) principles early in the development cycle, reducing part count, minimizing assembly time, and enhancing long-term serviceability—key considerations for OEMs operating in remote deployment environments.

The following table outlines typical fabrication specifications we maintain for off-road applications:

| Parameter | Standard Tolerance | High-Precision Option | Notes |

|---|---|---|---|

| Laser Cutting Accuracy | ±0.1 mm | ±0.05 mm | Fiber laser, up to 25 mm steel |

| CNC Bending Angle | ±0.5° | ±0.25° | With real-time angle compensation |

| Dimensional Flatness | 0.5 mm per 1 m² | 0.2 mm per 1 m² | For large structural panels |

| Weld Penetration | 100% required | 100% + NDT validation | X-ray or ultrasonic testing available |

| Surface Coating Thickness | 50–75 µm (powder coat) | 75–120 µm (polyurethane) | Salt spray tested to 1,000+ hours |

| Assembly Fit-Up Tolerance | ±0.3 mm | ±0.15 mm | Critical for bolt-on modular systems |

Our work with mission-critical sectors has taught us that reliability cannot be inspected in—it must be engineered in from the start. Whether supporting prototype development or high-volume production, Wuxi Lead Precision Machinery delivers off-road fabrication solutions where precision, strength, and consistency are non-negotiable.

Precision Specs & Tolerances

Technical Capabilities for Off-Road Metal Fabrication

Wuxi Lead Precision Machinery delivers engineered metal fabrication solutions specifically hardened for the extreme demands of off-road vehicle and equipment manufacturing. Our integrated sheet metal and precision machining capabilities focus on producing complex structural components, chassis elements, protective housings, and hydraulic system parts where failure is not an option. Central to our process is a modern fleet of multi-axis CNC machining centers, including advanced 5-axis milling systems. These platforms enable the precise, single-setup fabrication of intricate geometries found in differential carriers, suspension linkages, and custom bracketry, eliminating cumulative error from multiple fixtures and significantly reducing lead times for complex parts. Material versatility is critical in off-road applications; we routinely process high-strength low-alloy (HSLA) steels, abrasion-resistant (AR) plate, stainless alloys, and aluminum grades up to 150mm thick, ensuring components withstand impact, vibration, and corrosive environments.

Quality assurance is non-negotiable in safety-critical off-road systems. Every critical dimension and geometric feature undergoes rigorous validation using state-of-the-art Coordinate Measuring Machines (CMM) operating under ISO 17025 accredited protocols. Our inspection process utilizes calibrated touch-probe and optical scanning technologies, generating comprehensive GD&T reports traceable to international standards. This systematic approach verifies conformance to stringent customer specifications and internal quality benchmarks, providing documented evidence of part integrity before shipment. Our quality engineers work proactively with client design teams during the manufacturability phase to identify potential tolerance stack-up issues and recommend optimizations for robust, field-proven performance.

The following table details our standard achievable tolerances for machined and fabricated off-road components, reflecting the precision required for reliable assembly and operation under harsh conditions. These values represent typical capabilities for production runs; tighter tolerances are achievable for critical features with appropriate process planning.

| Feature | Capability | Standard Reference |

|---|---|---|

| Linear Dimension | ±0.05 mm (±0.002 in) | ISO 2768-mK |

| Angular Tolerance | ±0.1° | ISO 2768-c |

| Positional Tolerance | ±0.10 mm (±0.004 in) | ISO 2768-fH |

| Flatness | 0.10 mm per 100 mm (0.004 in) | ISO 2768-f |

| Surface Roughness | Ra 1.6 µm (63 µin) typical | ISO 1302 |

| Hole Concentricity | ±0.08 mm (±0.003 in) | ISO 1101 |

Our technical infrastructure extends beyond core machining and inspection. We integrate precision laser cutting for complex blanks, high-tonnage press braking for accurate forming of thick sections, and robotic welding cells for repeatable, high-integrity joins on structural assemblies. This vertically integrated capability allows us to manage the entire fabrication workflow for demanding off-road applications—from raw material sourcing through final assembly and testing—ensuring consistent quality and accountability. We understand that off-road component failure carries significant operational and safety risks; our processes are engineered not just to meet specifications, but to deliver uncompromising reliability in the field, reducing downtime and lifecycle costs for our partners in construction, mining, and agricultural machinery. Partner with Wuxi Lead for fabrication where precision meets ruggedness.

Material & Finish Options

Material selection is a critical phase in the development of off-road metal fabrication parts, where performance, durability, and environmental resistance directly impact operational reliability. At Wuxi Lead Precision Machinery, we specialize in precision sheet metal fabrication for demanding off-road applications, including construction, mining, and agricultural machinery. Our expertise ensures that material and finish choices align with mechanical requirements, weight constraints, and exposure conditions.

Aluminum is widely used in off-road components due to its high strength-to-weight ratio and excellent corrosion resistance. Grade 6061-T6 is particularly favored for structural brackets, housings, and enclosures exposed to moisture and temperature fluctuations. Its weldability and machinability make it ideal for complex assemblies requiring tight tolerances. However, aluminum’s lower hardness compared to steel necessitates design considerations in high-impact zones.

Steel remains the backbone of rugged off-road fabrication. Mild steel (A36) offers high tensile strength and cost-effective formability, making it suitable for frames, chassis supports, and protective guards. For enhanced durability, alloy steels such as 4140 provide superior toughness and wear resistance in drivetrain and suspension components. While steel is prone to oxidation, proper finishing mitigates this limitation effectively.

Titanium, specifically Grade 5 (Ti-6Al-4V), is selected for mission-critical parts where extreme strength, corrosion resistance, and weight reduction are paramount. Used in high-performance off-road racing and specialized military vehicles, titanium withstands thermal cycling and aggressive chemical exposure. Though more expensive and challenging to fabricate, its lifecycle advantages justify use in high-stress, low-maintenance applications.

Surface finishing plays a pivotal role in extending part life. Anodizing is the preferred treatment for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear and corrosion resistance. Type II (sulfuric acid) anodizing offers good protection with dyeing capability for identification, while Type III (hard anodizing) provides a harder, thicker coating suitable for moving parts subject to abrasion. Anodized surfaces also maintain electrical insulation and dimensional stability, critical in electronic enclosures and sensor mounts.

Below is a comparative overview of key materials used in off-road fabrication:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | High | Brackets, housings, lightweight frames | Anodizing (Type II/III) |

| Mild Steel A36 | 400–550 | 7.8 | Low (requires finish) | Frames, guards, structural supports | Powder coating, galvanizing |

| Alloy Steel 4140 | 655 | 7.85 | Moderate | Axles, gears, high-stress components | Black oxide, plating |

| Titanium Ti-6Al-4V | 900 | 4.43 | Very High | High-performance suspension, racing parts | Passivation, bead blasting |

At Wuxi Lead, we guide clients through material and finish selection based on application dynamics, environmental exposure, and lifecycle costs. Our precision fabrication processes ensure that every part meets the structural and aesthetic standards required in modern off-road engineering.

Manufacturing Process & QC

Design Phase: Engineering for Extreme Conditions

Our off-road metal fabrication process begins with collaborative design engineering focused on operational resilience. Wuxi Lead Precision Machinery integrates client specifications with material science expertise to optimize part geometry for high-impact, vibration-prone environments. We prioritize fatigue-resistant structures using ASTM A572 Grade 50 steel or titanium-grade aluminum alloys, validated through finite element analysis (FEA) for stress distribution under 200% overload scenarios. Design for Manufacturability (DFM) reviews eliminate weld weaknesses and ensure laser-cut tolerances align with robotic bending capabilities, reducing inherent defect risks before physical production commences.

Prototyping: Validation Under Simulated Field Stress

Critical prototypes undergo accelerated life testing replicating 5,000+ hours of off-road operation. Each component is subjected to hydraulic shock loading, thermal cycling (-40°C to 120°C), and abrasive particulate exposure in our ISO 17025-certified lab. Dimensional accuracy is verified via Zeiss coordinate measuring machines (CMM) with 2.5μm repeatability, while robotic weld seams undergo 100% ultrasonic testing. Only when prototypes exceed SAE J1401 durability standards do we approve the production blueprint, ensuring zero compromise on structural integrity.

Mass Production: Closed-Loop Zero Defect Execution

Serial production leverages automated cells with real-time SPC (Statistical Process Control) monitoring. Fiber laser cutters maintain ±0.1mm positional accuracy across 3m sheets, while robotic welding cells use AI-driven seam tracking to prevent porosity. Every 50th part undergoes inline CMM verification against the golden prototype dataset, with automatic machine recalibration triggered by 0.05mm deviation thresholds. Final assemblies pass through multi-axis vibration tables and salt spray chambers per ASTM B117 before shipment.

Off-Road Fabrication Performance Specifications

| Process Stage | Key Parameters | Validation Method | Zero Defects Safeguard |

|---|---|---|---|

| Design | Material: ASTM A572 Gr50 / 6061-T6 | FEA simulation (ANSYS 2023) | DFM sign-off by lead stress engineer |

| Prototyping | Load: 200% rated capacity | SAE J1401 accelerated testing | 3 consecutive pass/fail cycles |

| Mass Production | Tolerance: ±0.1mm (bent features) | Inline CMM + 100% weld UT | Real-time SPC with auto-recalibration |

This integrated workflow—grounded in AS9100 aerospace-grade process discipline—delivers certified defect-free components for excavators, agricultural machinery, and military vehicles. By embedding quality at every phase rather than inspecting post-production, Wuxi Lead ensures your off-road systems achieve 99.98% field reliability, eliminating costly downtime in the world’s harshest operating environments.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for your off-road metal fabrication needs and gain a strategic advantage in durability, precision, and delivery performance. As a leading sheet metal fabrication specialist based in Wuxi, China, we serve global OEMs and Tier-1 suppliers in the off-highway, construction, agriculture, and mining sectors. Our engineering-first approach ensures that every fabricated component meets the rigorous demands of extreme environments—where strength, resistance to wear, and long service life are non-negotiable.

Our advanced manufacturing capabilities are built around high-precision laser cutting, CNC punching, robotic bending, and MIG/TIG welding, all supported by in-house design validation and DFM analysis. We specialize in low-to-medium volume, high-mix production runs that require tight tolerances, complex geometries, and materials ranging from high-strength low-alloy (HSLA) steel to abrasion-resistant (AR) plate and stainless alloys. With ISO 9001:2015 certification and full traceability protocols, we ensure consistency across every batch—no matter the complexity.

At Lead Precision, we don’t just manufacture parts—we co-engineer solutions. Our engineering team collaborates directly with your design and R&D departments to optimize manufacturability, reduce assembly time, and lower total cost of ownership. From prototype to full-scale production, we provide rapid turnaround, real-time progress reporting, and full documentation including first article inspection (FAI) reports, material certifications, and 3D inspection data upon request.

Our strategic location in the Yangtze River Delta gives us seamless access to global logistics networks, enabling reliable delivery to North America, Europe, and Asia within compressed timelines. Whether you’re upgrading an existing component or launching a new machine platform, we scale with your project—delivering flexibility without compromising quality.

Consider the following technical capabilities that define our off-road fabrication expertise:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Max. Laser Cutting Area | 4000 mm × 2000 mm |

| CNC Press Brake Capacity | 300 tons, up to 6 meters |

| Tolerance Accuracy | ±0.1 mm (standard), ±0.05 mm (precision) |

| Welding Processes | MIG, TIG, Spot, Robotic Welding |

| Finishing Options | Powder coating, sandblasting, passivation, galvanizing |

| Quality Standards | ISO 9001:2015, First Article Inspection, GD&T Compliance |

| Lead Time (Typical) | 15–25 days, depending on complexity and volume |

When performance is paramount, trust a partner who understands the demands of off-road applications. Contact us today at [email protected] to discuss your next project with our engineering team. Let Wuxi Lead Precision Machinery become your trusted extension in precision sheet metal fabrication—where engineering excellence drives every cut, bend, and weld.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.