Technical Contents

Engineering Guide: Obróbka Cnc Aluminium

Engineering Insight: obróbka CNC aluminium

In the realm of high-performance manufacturing, obróbka CNC aluminium stands as a cornerstone process for industries demanding lightweight strength, thermal efficiency, and structural integrity. At Wuxi Lead Precision Machinery, we recognize that precision in aluminium machining is not merely a technical requirement—it is an engineering imperative. Our decades of experience in CNC machining, particularly for mission-critical applications in Olympic-grade equipment and military defense systems, have solidified our understanding of what true precision entails.

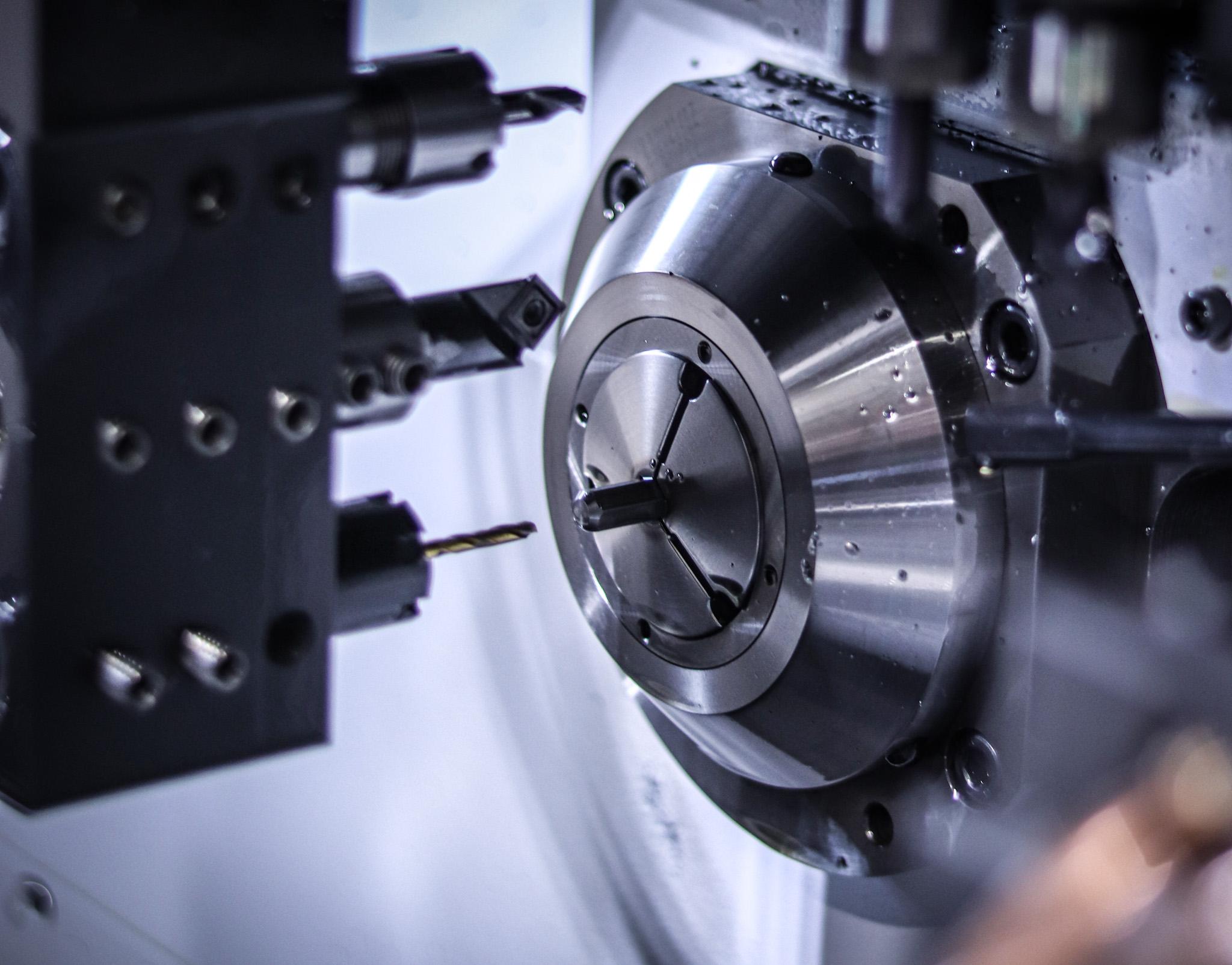

Aluminium, while inherently malleable and easier to machine than many metals, poses unique challenges in maintaining tight tolerances and surface consistency. Thermal expansion, tool deflection, and chip evacuation dynamics must be meticulously managed to achieve micron-level accuracy. At Lead Precision, we deploy advanced 5-axis CNC machining centers equipped with high-speed spindles and real-time in-process monitoring systems. These technologies, combined with our proprietary fixturing solutions, ensure dimensional stability across complex geometries and high-volume production runs.

Our work with Olympic engineering teams has demanded sub-10-micron tolerances on aerodynamic components, where even the slightest deviation impacts performance. Similarly, in military applications—ranging from UAV structural frames to fire-control system housings—our CNC aluminium machining processes adhere to MIL-STD-810 and ISO 2768 standards, ensuring reliability under extreme environmental stress. These experiences have shaped our approach: precision is not an endpoint, but a continuous process of refinement.

Material selection plays a pivotal role in achieving optimal results. We specialize in aerospace-grade alloys such as 7075-T6, 6061-T6, and 2024-T3, each selected for their strength-to-weight ratio and machinability. Our engineers conduct detailed material stress simulations prior to machining, allowing us to anticipate deformation and adjust toolpaths proactively. Furthermore, our cleanroom finishing stations enable burr-free edges and surface finishes down to Ra 0.4 µm, critical for components requiring sealing or optical clarity.

All processes are supported by comprehensive metrology, including CMM (Coordinate Measuring Machine) validation and 3D laser scanning. This ensures full traceability and compliance with AS9100 and ISO 9001:2015 standards.

Below are key technical specifications reflecting our CNC aluminium machining capabilities:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 × 800 × 650 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed (Max) | 24,000 rpm |

| Surface Finish (Typical) | Ra 0.8 – 0.4 µm |

| Tolerance Range | ±0.01 mm to ±0.002 mm (tight) |

| Supported Al Alloys | 7075-T6, 6061-T6, 2024-T3, 5052, 5083 |

| Quality Standards | ISO 9001:2015, AS9100, MIL-STD-810 |

At Wuxi Lead Precision Machinery, our mastery of obróbka CNC aluminium is built on a foundation of precision engineering, rigorous quality control, and real-world performance validation. Whether supporting elite athletic performance or national defense systems, we deliver components where failure is not an option.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Aluminum Machining

Wuxi Lead Precision Machinery delivers uncompromising precision for high-complexity aluminum components, leveraging advanced 5-axis CNC technology and rigorous quality control. Our facility specializes in machining aerospace-grade alloys including 6061-T6, 7075-T73, and 2024-T3, where thermal stability and material integrity are non-negotiable. Our integrated approach ensures geometric accuracy down to micron-level tolerances while maintaining optimal surface finishes for critical applications in aerospace, medical, and semiconductor industries.

Our core strength lies in simultaneous 5-axis CNC machining, eliminating manual repositioning and minimizing cumulative error. We deploy state-of-the-art DMG MORI CTX beta 2500 and Hermle C400 U milling centers equipped with high-frequency spindles (up to 24,000 RPM) and dynamic tool compensation systems. This enables single-setup production of intricate geometries such as impellers, hydraulic manifolds, and structural brackets with undercuts and compound angles. Advanced flood/ mist coolant delivery ensures chip evacuation and thermal management specific to aluminum’s galling tendencies, preventing work hardening and maintaining dimensional stability across extended production runs.

Quality verification is embedded at every stage through our Zeiss CONTURA G2 coordinate measuring machine (CMM) system, operating under ISO 17025-accredited protocols. Every component undergoes 100% post-process inspection against CAD models, with full traceability of measurement data including GD&T analysis, surface roughness mapping, and first-article reports. Our CMM cell validates critical features such as positional tolerances of bolt patterns within ±0.005 mm and angular alignments to 0.001°, ensuring seamless integration into final assemblies. Statistical process control (SPC) monitoring provides real-time feedback to machining parameters, guaranteeing consistency across batch sizes from prototypes to 10,000+ units.

The following table details our standard achievable tolerances for aluminum machining per ISO 2768-mK, with tighter specifications available for mission-critical features:

| Characteristic | Tolerance Range | Standard Reference |

|---|---|---|

| Linear Dimensions (0-100 mm) | ±0.01 mm | ISO 2768-mK |

| Linear Dimensions (100-500 mm) | ±0.02 mm | ISO 2768-mK |

| Angular Tolerances | ±0.05° | ISO 2768-k |

| Positional Deviation | ±0.005 mm | ISO 1101 |

| Surface Roughness (Ra) | 0.8 μm | ISO 1302 |

We consistently achieve these specifications through optimized toolpath strategies, in-process probing, and environmental controls maintaining 20±1°C workshop conditions. This capability enables clients to consolidate multi-part assemblies into single aluminum housings, reducing weight and enhancing structural reliability. For demanding sectors like unmanned aerial systems and precision optics, our process delivers leak-tight cavities, mirror-finish surfaces, and vibration-resistant geometries that exceed industry benchmarks. Partner with Wuxi Lead to transform complex aluminum designs into high-performance reality with zero compromise on precision or repeatability.

Material & Finish Options

Material Selection for High-Precision CNC Machining in Aluminum, Steel, and Titanium

Selecting the appropriate material for CNC machining is critical to achieving optimal performance, durability, and cost-efficiency in precision components. At Wuxi Lead Precision Machinery, we specialize in advanced CNC machining of aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding these materials enables engineers and procurement managers to make informed decisions aligned with functional requirements and environmental conditions.

Aluminum remains the most widely used material in precision CNC machining due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly favored for its weldability, corrosion resistance, and suitability for aerospace, automotive, and electronics applications. Its low density reduces component weight without sacrificing structural integrity, making it ideal for dynamic systems where efficiency is paramount. Additionally, aluminum responds exceptionally well to anodizing, enhancing surface hardness and wear resistance.

Steel, particularly alloy and stainless grades such as 304, 316, and 4140, provides superior strength, durability, and resistance to high stress and temperature. Stainless steel is preferred in medical, food processing, and marine environments due to its outstanding corrosion resistance and hygienic surface properties. While heavier than aluminum, steel delivers unmatched reliability in load-bearing and safety-critical components. CNC machining of steel requires robust tooling and precise parameters to manage higher cutting forces and heat generation.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. With a strength-to-density ratio exceeding that of many steels and exceptional resistance to corrosion and high temperatures, titanium is widely used in aerospace, defense, and biomedical implants. However, its low thermal conductivity and high chemical reactivity demand specialized machining strategies, including controlled feed rates, rigid setups, and optimized coolant application. Despite higher material and processing costs, titanium’s longevity in aggressive environments justifies its use in mission-critical systems.

Surface Finishing: The Role of Anodizing in Aluminum Components

Anodizing is a key post-machining process for aluminum parts, particularly Type II (sulfuric acid) and Type III (hard anodizing). This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and aesthetic consistency. Type III anodizing can achieve coating thicknesses up to 50–75 µm with hardness comparable to sapphire, making it suitable for high-abrasion environments. Anodized layers are also electrically insulating and can be dyed in various colors for identification or branding. At Wuxi Lead, we integrate precision machining with controlled anodizing protocols to ensure dimensional stability and coating uniformity.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | Excellent (Machining Index: 90–100%) | 6061-T6, 7075-T6 | Aerospace, Electronics, Automotive |

| Stainless Steel | 7.9 | 505–760 | Moderate (Machining Index: 45–60%) | 304, 316, 17-4PH | Medical, Marine, Industrial |

| Titanium | 4.5 | 900–1000 | Poor (Machining Index: 20–30%) | Ti-6Al-4V, CP-Ti | Aerospace, Defense, Biomedical |

Material selection directly impacts component performance, production lead time, and lifecycle cost. Wuxi Lead Precision Machinery supports global clients with expert consultation, ensuring the right material and finish are matched to each application’s technical demands.

Manufacturing Process & QC

Precision CNC Aluminum Machining: From Concept to Zero-Defect Production

Wuxi Lead Precision Machinery executes a rigorously controlled production process for CNC aluminum components, ensuring absolute adherence to specifications from initial design through to high-volume manufacturing. Our methodology eliminates defects at every stage, delivering components that meet exacting aerospace, medical, and industrial standards. The journey begins with collaborative engineering. Our team works with client CAD models to conduct comprehensive design for manufacturability (DFM) analysis, optimizing geometry for aluminum’s properties. We identify potential stress points, verify tolerance stack-ups using GD&T principles, and recommend anodizing or coating strategies for corrosion resistance. Finite element analysis (FEA) simulates part performance under load, preventing costly revisions later. Critical parameters like thermal expansion coefficients and chip evacuation paths are modeled to ensure dimensional stability during machining.

Prototyping transforms validated designs into physical reality under full production conditions. We utilize 5-axis machining centers to produce functional prototypes from client-specified aluminum alloys, typically 6061-T6 or 7075-T6. Each prototype undergoes first-article inspection (FAI) per AS9102 standards. Coordinate measuring machines (CMM) verify critical dimensions to sub-5μm accuracy, while surface roughness testers confirm Ra values meet requirements. Material certification and metallurgical reports are provided. This phase validates tool paths, fixture setups, and coolant strategies, ensuring the process is mature before scaling. Client feedback on prototypes triggers immediate process adjustments, not design compromises.

Mass production leverages our zero-defect manufacturing system. Every component is machined on dedicated cells with automated tool presetter calibration and real-time tool wear monitoring. In-process inspections occur at defined intervals using optical comparators and air gauging, with statistical process control (SPC) charts tracking critical dimensions. Our closed-loop system automatically adjusts feeds and speeds to counteract thermal drift, while robotic part handling minimizes human error. Final inspection includes 100% dimensional verification for mission-critical features and batch sampling for material properties. Traceability is maintained via laser-etched part IDs linked to machine parameters and inspection data in our ERP system. This integrated approach ensures consistent output where rework is economically impossible.

Key aluminum alloys selected for optimal CNC performance include:

| Alloy Grade | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|

| 6061-T6 | 310 | Excellent (7/10) | Structural brackets, hydraulic manifolds, marine hardware |

| 7075-T6 | 572 | Good (5/10) | Aerospace fittings, high-stress automotive components |

| 2024-T3 | 470 | Fair (4/10) | Aircraft structural parts, military hardware |

Wuxi Lead’s process eliminates the traditional trade-off between precision and volume. By embedding quality into design validation, prototype refinement, and production controls, we achieve zero-defect delivery for aluminum CNC components. This methodology reduces total cost of ownership through eliminated scrap, accelerated time-to-market, and unwavering reliability in demanding applications. Your design integrity is preserved from digital model to finished part.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Excellence in CNC Aluminum Machining

When your manufacturing demands require precision, consistency, and technical mastery in aluminum components, partnering with Wuxi Lead Precision Machinery ensures your project is in expert hands. As a leading provider of high-end CNC machining services based in China, we specialize in the precise fabrication of aluminum parts for industries where performance and reliability are non-negotiable—ranging from aerospace and automotive to medical devices and industrial automation.

Aluminum presents unique advantages: it is lightweight, corrosion-resistant, thermally conductive, and highly machinable. However, achieving tight tolerances, superior surface finishes, and complex geometries in aluminum requires more than just advanced equipment—it demands deep material knowledge, refined processes, and engineering foresight. At Wuxi Lead, our team combines decades of CNC expertise with state-of-the-art 3-, 4-, and 5-axis milling and turning centers to deliver aluminum components that meet exacting international standards.

We understand that your success depends on more than just parts—it depends on partnership. From initial design consultation to prototyping, production, and quality assurance, we work collaboratively to optimize manufacturability, reduce lead times, and control costs without sacrificing precision. Our facility operates under strict ISO 9001-certified quality systems, with full traceability, in-process inspections, and final QA reporting to ensure every component meets your specifications.

Our investment in advanced tooling, high-speed machining, and automated workflows allows us to handle both low-volume prototypes and high-volume production runs with equal efficiency. Whether you require simple brackets or complex housings with intricate internal features, our engineers apply proven best practices in chip control, thermal management, and fixturing to maintain dimensional stability and surface integrity throughout the machining process.

Below are key technical capabilities we offer for CNC aluminum machining:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 × 800 × 650 mm (47 × 31.5 × 25.6 in) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Standard) | Ra 0.8 µm (achievable down to Ra 0.2 µm) |

| Tolerance Capability | As tight as ±0.01 mm |

| Common Aluminum Alloys | 6061, 7075, 2024, 5052, 6082, and custom alloys |

| Secondary Operations | Deburring, anodizing (Type II & III), sandblasting, laser marking, precision assembly |

Every project begins with a technical review to ensure design for manufacturability, followed by a detailed quotation and production plan tailored to your delivery schedule and quality requirements.

To elevate your aluminum CNC machining outcomes, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing—where engineering excellence meets flawless execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.