Technical Contents

Engineering Guide: Nylon Injection Molding

Engineering Insight Precision Imperatives in Nylon Injection Molding

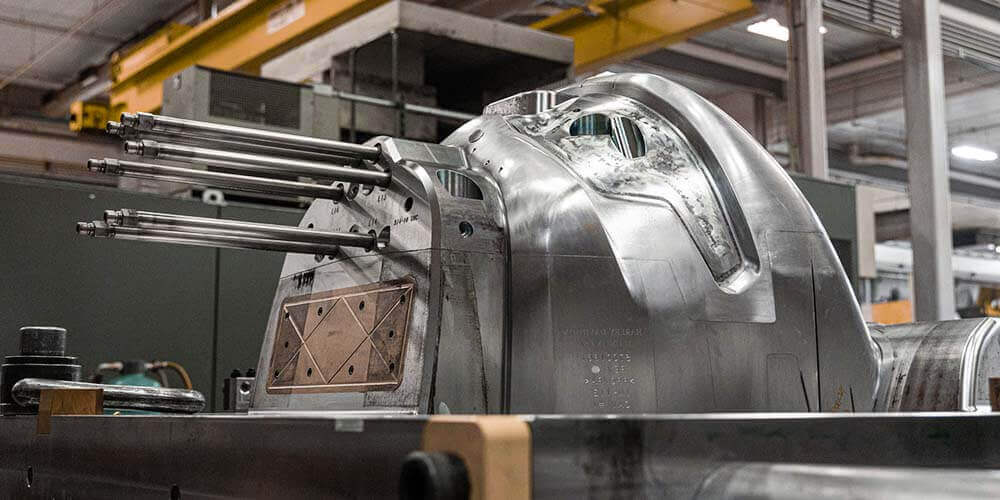

Nylon injection molding demands exceptional precision engineering far beyond standard thermoplastic processes. As a semi-crystalline, hygroscopic polymer, nylon exhibits significant moisture absorption and variable shrinkage rates directly tied to processing parameters and part geometry. Inconsistent temperature control, inadequate clamp force, or suboptimal cooling channel design within the mold tooling inevitably manifest as dimensional instability, warpage, or internal stresses. These defects are catastrophic in high-performance applications where nylon’s strength, wear resistance, and chemical stability are mission-critical. Achieving true net-shape molding requires tolerances held within ±0.025 mm – a standard dictated not by convenience, but by functional necessity in aerospace actuators, medical fluidics, or defense mechanisms. The metal tooling foundation is non-negotiable; only hardened, stress-relieved steel molds with precision-machined conformal cooling channels can consistently manage nylon’s thermal profile and crystallization kinetics.

At Wuxi Lead Precision Machinery, our expertise originates in ultra-precision CNC machining for mission-critical sectors. We apply the same rigorous metrology standards used in Olympic timing system components and military-specification hardware to nylon mold fabrication. This means mold bases held to ±0.005 mm flatness, cavity/core geometries verified via CMM against first-article inspection reports, and cooling circuits optimized through thermal simulation software. We understand that a 0.1°C fluctuation in melt temperature or a 0.5-second deviation in packing time alters nylon’s final crystalline structure – impacting fatigue life by up to 30%. Our process control protocols, inherited from aerospace subcontracting, ensure repeatability across production runs exceeding 500,000 cycles. This is precision engineering translated into polymer processing.

The following table outlines critical nylon 6/6 processing parameters where precision directly determines part integrity. Deviations beyond these ranges compromise mechanical properties even if visual inspection passes.

| Parameter | Standard Range | Precision Requirement at Lead | Consequence of Variation |

|---|---|---|---|

| Melt Temperature | 260°C – 290°C | ±3°C control | Degradation or incomplete melt |

| Mold Temperature | 70°C – 120°C | ±2°C uniformity across cavities | Warpage, sink marks |

| Injection Pressure | 80 – 150 MPa | Ramp control within 5% tolerance | Flash, short shots |

| Cooling Time | 15 – 45 sec | Optimized per geometry ±1 sec | Residual stress, dimensional drift |

| Moisture Content | < 0.2% pre-processing | Verified via LECO analysis | Splay, hydrolysis, voids |

Our facility’s ISO 9001 and IATF 16949 certifications formalize this discipline, but the true validation lies in deployment. Components molded using Lead Precision tooling operate within systems where failure equates to national security risk or elite athletic performance loss. When your application demands nylon parts performing under extreme thermal cycling, constant load, or sterile conditions, the mold tool’s precision isn’t merely a specification – it is the sole determinant of functional success. Partner with engineering rigor, not just manufacturing capacity.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-performance applications involving nylon injection molding components. Our expertise lies in producing precision-machined metal parts that serve as critical elements in mold tooling, inserts, and support structures used in the injection molding of engineering-grade nylon materials. With a focus on dimensional accuracy, thermal stability, and long-term durability, our manufacturing solutions are designed to meet the rigorous demands of automotive, medical, and industrial sectors.

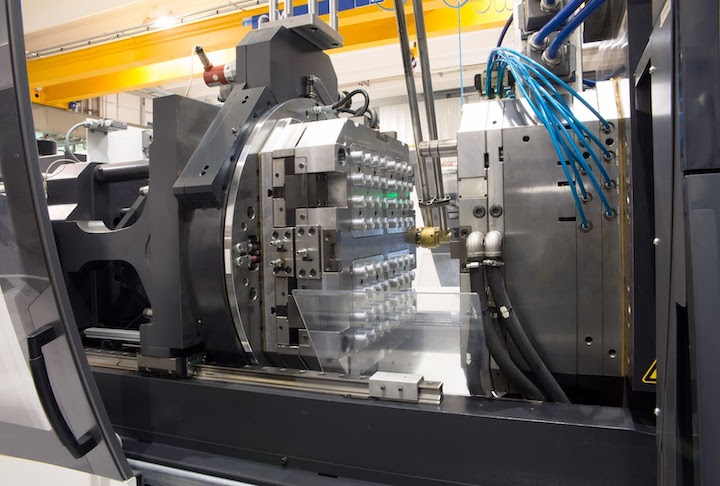

At the core of our production capability is a state-of-the-art 5-axis CNC machining center. This technology enables us to execute complex geometries with superior surface finish and tight tolerances, essential for mold components that interface directly with molten nylon. The simultaneous multi-axis movement allows for single-setup machining of intricate features, minimizing human error and ensuring consistency across production runs. Our machining processes are optimized for a range of tooling alloys, including hardened steels and aluminum alloys, commonly used in high-cycle nylon molding applications.

Quality assurance is integral to our workflow. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with the most stringent dimensional specifications. Our CMM system provides full 3D measurement validation, capturing critical data points across complex contours and internal features. This metrology-backed verification process ensures that all parts meet print requirements and perform reliably in the final molding environment.

In nylon injection molding, even minor deviations in mold geometry can lead to part warpage, flow imbalances, or premature wear. To address this, we maintain strict control over key tolerances across various features. The table below outlines our standard achievable tolerances for machined components used in this application:

| Feature Type | Dimensional Tolerance | Geometric Tolerance (GD&T) | Surface Roughness (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.01 mm (Position) | 0.4–1.6 µm |

| Bore Diameters | +0.010 / -0.005 mm | 0.01 mm (Cylindricity) | 0.8 µm |

| Flat Surfaces | ±0.003 mm | 0.005 mm (Flatness) | 0.4 µm |

| Angular Features | ±0.05° | 0.02 mm (Angularity) | 1.6 µm |

| Complex Contours | ±0.01 mm (Profile) | 0.01 mm (Profile of Surface) | 1.6–3.2 µm |

All tolerances are verified under controlled environmental conditions to eliminate thermal drift effects. Our engineering team collaborates closely with clients during the design phase to optimize manufacturability, suggest material pairings, and ensure compatibility with nylon processing parameters such as mold temperature, pressure, and cycle time. This proactive approach reduces time-to-production and enhances tool longevity.

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous CMM-based quality control to deliver metal components that meet the exacting standards of nylon injection molding. Our technical capabilities ensure reliability, repeatability, and performance in the most demanding manufacturing environments.

Material & Finish Options

Material Selection for Nylon Injection Molding Tooling

Selecting the optimal mold material is critical for successful nylon injection molding, directly impacting part quality, production efficiency, and tool longevity. While nylon itself is a polymer, the metal alloys comprising the mold cavity and core dictate thermal management, dimensional stability, and resistance to wear during high-volume cycles. At Wuxi Lead Precision Machinery, we prioritize materials that withstand nylon’s processing demands—typically 250–320°C melt temperatures and moderate to high injection pressures—while ensuring precise replication of intricate geometries.

Aluminum alloys (e.g., 7075-T6) offer superior thermal conductivity, enabling rapid cooling cycles ideal for prototyping or low-volume production. However, their lower hardness (150 HB) limits durability against abrasive glass-filled nylons. Tool steel variants like H13 or S136 provide balanced toughness and wear resistance for medium to high-volume runs, maintaining dimensional accuracy under thermal cycling. For extreme longevity with reinforced nylons, precipitation-hardening stainless steels (e.g., 17-4 PH) or maraging steels deliver exceptional hardness (>40 HRC) and corrosion resistance, though at higher initial cost. Titanium alloys remain niche due to poor thermal conductivity and high cost, rarely justifying use in standard nylon tooling.

Surface finishing, particularly anodizing, is non-negotiable for nylon molds. Anodized layers (5–25μm thickness) create a hard, non-stick barrier that prevents nylon adhesion, reduces ejection force, and mitigates wear from glass or mineral fillers. Type III (hard) anodizing on aluminum molds extends service life by 30–50% in abrasive applications, while electroless nickel plating on steel offers similar benefits. Avoid untreated surfaces—nylon’s polarity promotes sticking, causing part defects and accelerated mold erosion.

Critical Mold Material Properties for Nylon Applications

| Material | Thermal Conductivity (W/m·K) | Hardness (HRC) | Cost Index (1–5) | Nylon Suitability |

|---|---|---|---|---|

| Aluminum 7075-T6 | 130–150 | 36–40 HB | 2 | Prototyping, unfilled nylon |

| H13 Tool Steel | 28–36 | 48–52 | 3 | Medium-volume, 30% GF nylon |

| S136 Stainless | 20–25 | 50–54 | 4 | High-volume, chemical-resistant |

| 17-4 PH Stainless | 16–18 | 42–44 | 5 | Extreme wear, filled nylons |

Material choice must align with nylon grade, part complexity, and production volume. Unfilled nylons tolerate softer molds, but glass-filled variants demand hardened steel with anodized or plated surfaces to prevent galling. Wuxi Lead Precision Machinery engineers rigorously validate material selections against your nylon formulation and cycle requirements, ensuring molds deliver consistent part tolerances (<±0.05mm) and 500,000+ cycles where specified. Partner with us to transform material science into optimized production outcomes.

Manufacturing Process & QC

Nylon injection molding is a high-precision manufacturing process that transforms engineered thermoplastic resins into durable, dimensionally stable components for industrial and commercial applications. At Wuxi Lead Precision Machinery, we integrate advanced design engineering, rigorous prototyping, and fully controlled mass production to deliver zero-defect nylon molded parts tailored to exact client specifications.

The process begins with precision design, where our engineering team collaborates with clients to analyze functional requirements, load conditions, and environmental exposure. Utilizing CAD/CAM and finite element analysis (FEA), we optimize part geometry for moldability, structural integrity, and thermal performance. Special attention is given to wall thickness uniformity, gate placement, and shrinkage compensation—critical factors in nylon molding due to its hygroscopic nature and variable expansion characteristics. Design for manufacturability (DFM) reviews ensure tool longevity and part consistency before any physical prototype is produced.

Prototyping follows design validation, employing rapid tooling or pre-series steel molds to produce functional samples. These prototypes undergo comprehensive testing, including dimensional inspection via coordinate measuring machines (CMM), mechanical stress evaluation, and moisture absorption trials. This phase verifies material behavior under real-world conditions and confirms fit, function, and assembly compatibility. Any deviations are corrected through iterative design refinement, ensuring the final mold design achieves full compliance before transitioning to full-scale production.

Mass production leverages high-tonnage electric and hybrid injection molding machines with closed-loop process control. Our facility uses premium-grade nylon resins—such as PA6, PA66, and glass-reinforced variants—processed under strictly controlled drying, temperature, and pressure parameters. Each molding cycle is monitored in real time using integrated sensors and statistical process control (SPC) systems to detect variances before they affect part quality. Automated robotic handling ensures consistent cycle times and minimizes human error, while 100% inline visual inspection and periodic metrology sampling enforce zero-defect standards.

Throughout all stages, traceability is maintained via our digital manufacturing execution system (MES), logging material batches, machine settings, and inspection data for every production lot. This end-to-end control guarantees repeatability and compliance with ISO 9001 and IATF 16949 quality standards.

The following table outlines key process specifications for nylon injection molding at Wuxi Lead Precision Machinery:

| Parameter | Specification Range |

|---|---|

| Material Types | PA6, PA66, PA6+GF30, PA66+GF25, PA12 |

| Molding Machine Capacity | 80–1,200 tons clamping force |

| Shot Weight Range | 5 g – 1,200 g |

| Dimensional Tolerance | ±0.05 mm (standard), ±0.02 mm (tight) |

| Surface Finish | SPI-A1, SPI-B2, textured, or custom |

| Moisture Content (pre-mold) | < 0.2% for standard nylon |

| Production Cycle Time | 15–90 seconds (part-dependent) |

| Quality Standards | ISO 9001, IATF 16949, 100% traceability |

By integrating precision engineering with disciplined process control, Wuxi Lead Precision Machinery ensures that every nylon injection molded component meets the highest standards of performance, reliability, and consistency.

Why Choose Wuxi Lead Precision

Elevate Your Nylon Injection Molding Capabilities Through Precision Engineering

Nylon injection molding demands exceptional thermal stability, precise dimensional control, and robust tooling to overcome inherent challenges like moisture sensitivity, variable crystallinity, and post-molding shrinkage. At Wuxi Lead Precision Machinery, we bridge the gap between high-performance polymer requirements and uncompromising metal engineering. Our expertise in custom metal manufacturing directly translates to superior molding outcomes—delivering molds and auxiliary systems that ensure repeatability, extended service life, and minimized scrap rates for demanding nylon applications. We engineer solutions where material science meets micron-level precision, transforming complex nylon part specifications into production reality.

Our dedicated molding platforms integrate advanced thermal management and pressure control systems, specifically calibrated for nylon’s unique behavior. Below are critical performance specifications achievable with our machinery and tooling:

| Parameter | Specification Range | Industrial Relevance for Nylon Molding |

|---|---|---|

| Temperature Control | ±0.5°C stability | Prevents thermal degradation and ensures uniform crystallinity |

| Injection Pressure | 2,500 bar max | Compensates for nylon’s high viscosity during filling |

| Clamp Force Accuracy | ±1.0% repeatability | Eliminates flash in thin-walled or high-tolerance parts |

| Shot Size Precision | ±0.05% variation | Critical for consistent part mass in multi-cavity tools |

| Cycle Time Optimization | Up to 18% reduction | Achieved through rapid thermal cycling and ejection dynamics |

Beyond hardware, our partnership includes collaborative engineering support from concept to validation. We analyze your nylon grade (PA6, PA66, or filled variants), part geometry, and application environment to optimize gate design, cooling channel layout, and ejection sequences. This proactive approach mitigates warpage, sink marks, and internal stress—common failure points in nylon molding. Our in-house metrology lab validates tool performance against ISO 2768-mK tolerances before shipment, ensuring immediate production readiness. Clients consistently achieve >95% first-pass yield rates on complex nylon components, from automotive connectors to medical fluid handling systems.

Wuxi Lead Precision Machinery operates at the intersection of metallurgical excellence and polymer processing intelligence. We understand that nylon’s performance hinges on the stability of the metal systems surrounding it. By choosing us, you gain a partner committed to reducing your total cost of ownership through longer mold life, lower energy consumption, and accelerated time-to-market. Our facility in Wuxi adheres to ISO 9001:2015 standards, with dedicated project managers providing transparent communication from RFQ to volume production.

Initiate a technical dialogue to transform your nylon molding challenges into competitive advantages. Contact our engineering team directly at [email protected] to request a capability assessment or schedule a virtual factory audit. Include your part specifications and volume requirements for a tailored process proposal within 48 hours. Partner with precision—where every micron matters.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.