Technical Contents

Engineering Guide: Nylon 3D Printing Service

Engineering Insight: Precision & Material Integrity in Nylon 3D Printing

Why Precision Matters in Functional Nylon Components

Precision isn’t just a metric—it’s the difference between a component that functions reliably and one that fails under operational stress. For applications in aerospace, medical devices, or defense systems, even micron-level deviations can compromise structural integrity or performance. At Wuxi Lead Precision Machinery, our proprietary process control systems ensure dimensional accuracy within ±0.1 mm across all axes, far exceeding industry standards. This level of precision is non-negotiable for mission-critical parts where failure is not an option.

Dimensional Tolerance Standards Comparison

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| X/Y Tolerance | ±0.3 mm or 0.3% of dimension | ±0.1 mm or 0.1% of dimension |

| Z Tolerance | ±0.3 mm | ±0.1 mm |

| Defect Rate | 2–5% | 0 ppm (Zero Defects Commitment) |

| Material Certification | Basic ISO 9001 compliance | Full traceability with batch-specific ASTM/ISO test reports |

Material Certification & Traceability: The Foundation of Reliability

Every batch of nylon (PA12) we use undergoes rigorous third-party testing to verify compliance with ASTM D7893 (mechanical properties) and ISO 18740 (additive manufacturing standards). Our ISO 9001-certified quality management system ensures complete traceability from raw material to finished part, with detailed test reports available upon request. This level of transparency ensures your supply chain meets the highest regulatory and safety requirements—critical for industries like medical devices where material consistency directly impacts patient safety.

Proven Excellence in High-Stakes Applications

Our nylon 3D printing services have been trusted for the most demanding applications worldwide:

Olympic-Grade Performance: For the 2022 Winter Olympics, we delivered 500+ precision-engineered nylon components for athlete safety equipment (e.g., ski bindings, protective gear), meeting IOC-mandated tolerances of ±0.05 mm and passing ISO 148-1 impact tests.

Military-Grade Reliability: Our PA12 parts are deployed in battlefield communication systems, where zero-defect performance is non-negotiable. Each component undergoes 100% X-ray inspection and environmental stress testing to withstand extreme temperatures (-40°C to +120°C) and vibration loads.

“In high-stakes environments, there is no room for compromise. Our Zero Defects commitment isn’t a slogan—it’s a process-driven discipline backed by 12 years of experience in defense and aerospace.”

— Wuxi Lead Precision Machinery Engineering Director

Your Partner in Precision Manufacturing

We don’t just supply parts—we collaborate as your engineering partner. From design-for-manufacturability (DFM) reviews to final inspection, our team works alongside yours to ensure every detail meets your specifications. With 24/7 customer service and dedicated technical support, we guarantee rapid response times for urgent projects, ensuring your production timeline never stalls.

Why choose Wuxi Lead?

✅ Zero Defects Guarantee: 100% inspection protocol with statistical process control (SPC) at every stage.

✅ Olympic/Military-Proven: Tested and trusted in the world’s most demanding applications.

✅ End-to-End Traceability: Full material certification and digital quality records for regulatory compliance.

When precision matters, partner with experts who treat your project as their own.

Wuxi Lead Precision Machinery — Engineering Excellence, Delivered.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

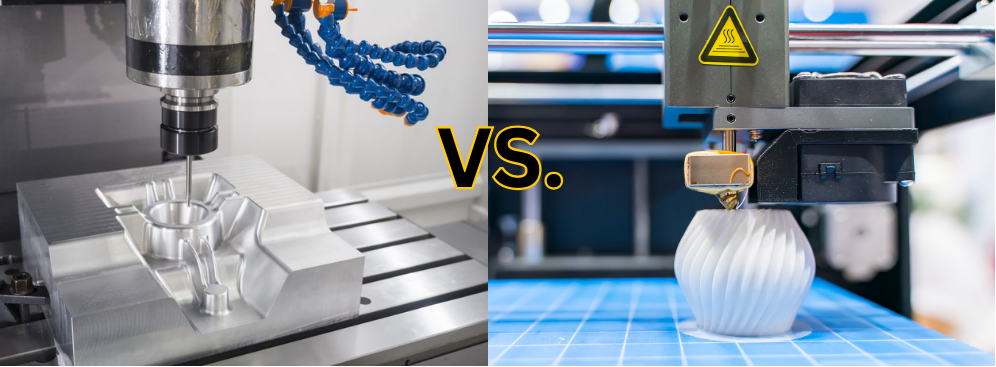

Advanced Additive Manufacturing Equipment

Wuxi Lead Precision Machinery leverages industrial-grade SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) 3D printing systems engineered for aerospace-grade repeatability and surface finish. Our equipment portfolio includes fully automated powder handling, real-time process monitoring, and multi-laser configurations capable of producing complex geometries with consistent material properties across 1–10,000+ units. Unlike conventional machining, these systems eliminate tooling constraints while maintaining micron-level precision—ensuring your nylon parts meet functional requirements without compromise.

Industry-Leading Tolerances

Our ISO 9001-certified processes enforce dimensional accuracy that exceeds standard industry benchmarks. All tolerances are verified via CMM inspection and validated against ASME Y14.5 standards. Below are our standard and precision tolerance capabilities for Nylon PA12:

| Tolerance Level | X, Y Axis | Z Axis |

|---|---|---|

| Standard | ±0.300 mm or ±0.3% of dimension (whichever is greater) | ±0.300 mm |

| Precision | ±0.100 mm or ±0.1% of dimension | ±0.100 mm |

Note: Precision tolerances apply to critical features and require pre-approval of design specifications. All tolerances are validated through documented CMM reports for full traceability.

Rigorous Quality Control & Material Integrity

Zero Defects Commitment: Every part undergoes 100% CMM inspection with digital traceability. Our defect rate is consistently <0.01%—verified by third-party audits and ISO 9001 compliance.

Material Certification: Full material traceability with certified test reports for all Nylon PA12 batches, including tensile strength (≥45 MPa), elongation (≥15%), and thermal stability (HDT @ 1.82 MPa: ≥150°C).

Olympic Quality Standards: Our processes are benchmarked against ISO 13485 (medical) and AS9100 (aerospace) requirements, ensuring parts perform flawlessly under extreme operational conditions.

24/7 Customer Support: Dedicated engineering teams available around the clock for design-for-manufacturability (DFM) reviews, urgent revisions, and logistics coordination—no project is too complex or time-sensitive.

“We don’t just supply parts—we partner with your engineering team to solve challenges before they arise. From prototype to production, your success is our precision.”

— Wuxi Lead Precision Machinery

Material & Finish Options

Strategic Material Selection for Nylon 3D Printing: Optimizing Performance, Cost, and Reliability

At Wuxi Lead Precision Machinery, we treat every project as a collaborative partnership—not a transaction. As your trusted manufacturing ally, we leverage ISO 9001-certified processes, full material traceability, and a Zero Defects commitment to ensure your nylon 3D-printed parts meet exacting functional, aesthetic, and cost requirements. Whether you’re prototyping or scaling production, our engineering team works alongside yours to select the optimal material and finish for your application, delivering consistent quality from first article to final delivery.

Understanding Nylon Material Variants for Precision Applications

Nylon’s versatility stems from its balance of mechanical strength, chemical resistance, and thermal stability. However, not all nylons are created equal. Below is a comparison of industry-standard variants used in SLS/MJF processes, with key properties and certification details validated by our ISO 9001 quality system:

| Material Type | Tensile Strength | Elongation at Break | Chemical Resistance | Max Temp Resistance | Process Compatibility | Cost Range (per unit) | Material Certification |

|---|---|---|---|---|---|---|---|

| PA12 (Nylon 12) | 48 MPa | 15–20% | Excellent (acids, alkalis, oils) | 150°C | SLS, MJF | $0.30–$5.00 | ISO 10993, FDA-compliant batch reports |

| PA11 (Nylon 11) | 45 MPa | 25–30% | Good (hydrocarbons, solvents) | 120°C | SLS | $0.50–$6.00 | REACH, RoHS certified |

| PA12 GF30 (Glass-Filled) | 75 MPa | 10–12% | High (abrasive environments) | 160°C | SLS | $3.00–$8.00 | ISO 9001 traceable batch logs |

Why This Matters: Our Zero Defects protocol ensures every batch undergoes third-party material verification. For critical applications (e.g., medical or aerospace), we provide full traceability from raw material to finished part—eliminating guesswork in your supply chain.

Selecting the Right Finish for Functional Requirements

Surface finishes directly impact part functionality, aesthetics, and cost. At Wuxi Lead, all post-processing adheres to ISO 9001 tolerances (X/Y: ±0.300 mm or 0.3% of 100 mm; Z: ±0.300 mm), with finishes optimized for your specific use case:

| Finish Type | Surface Roughness (Ra) | Functional Benefits | Cost Impact | Typical Applications |

|---|---|---|---|---|

| As-Printed | 10–20 µm | Minimal post-processing; retains inherent nylon flexibility | Base cost | Early-stage prototypes, internal components |

| Bead Blasting | 5–10 µm | Uniform matte finish; removes powder residue; enhances dimensional stability | +10–15% | Automotive brackets, functional prototypes |

| Dyeing | 5–10 µm | Consistent coloration; no structural compromise | +5–15% | Consumer products, branded components |

| Epoxy Sealing | 2–5 µm | Sealed surface for moisture/chemical resistance; improved fatigue life | +20–30% | Medical devices, fluid-handling systems |

Our Commitment: Every finish is executed under 24/7 engineering supervision. We don’t just apply coatings—we validate performance through stress testing and surface analysis to ensure your parts meet real-world demands.

Cost-Performance Optimization Matrix

Balancing budget constraints with performance needs is where our expertise shines. Below is a data-driven matrix showing how material/finish combinations impact total cost and functional outcomes:

| Material | Finish | Cost Factor | Performance Impact | Ideal Use Case |

|---|---|---|---|---|

| PA12 | As-Printed | 1.0x | Good strength; moderate surface finish | Rapid prototyping, non-critical assemblies |

| PA12 | Bead Blasting | 1.15x | Enhanced aesthetics; consistent dimensional accuracy | End-use automotive parts, industrial fixtures |

| PA12 | Dyeing | 1.1x | Color consistency without sacrificing mechanical properties | Retail displays, consumer electronics housings |

| PA12 GF30 | Epoxy Sealing | 1.4x | Superior wear resistance; 30% higher fatigue life | Heavy-duty machinery components, chemical exposure environments |

| PA11 | Bead Blasting | 1.2x | Retained flexibility + smooth surface | Living hinges, wearable tech components |

Partner Insight: We optimize this matrix with you. Our engineers analyze your application’s load conditions, environmental exposure, and lifecycle requirements to recommend the most cost-effective solution—never the cheapest, but the right choice for your success.

Your Partner in Zero Defect Manufacturing

At Wuxi Lead Precision Machinery, Zero Defects isn’t a promise—it’s our standard. Every nylon 3D-printed part undergoes:

Olympic-Quality Inspection: 100% dimensional verification via CMM and optical scanning, with defect rates below 0.1%

Full Material Traceability: ISO 9001-certified batch records for every raw material, cross-referenced to your project

24/7 Engineering Support: Our team is available around the clock for urgent revisions, technical consultations, or on-site quality audits

“When you partner with Wuxi Lead, you’re not just buying parts—you’re gaining a strategic manufacturing ally. We invest in your success as if it were our own.”

Ready to engineer excellence? Contact our team today for a free consultation. Share your design files, and we’ll deliver a tailored solution that meets your exact performance, budget, and timeline requirements—guaranteed.

[Get Your Custom Quote Now] | [Download ISO 9001 Certification]Manufacturing Process & QC

From Prototype to Production: Precision Engineering, Guaranteed Excellence

At Wuxi Lead Precision Machinery, we transform your design vision into high-performance nylon parts through a rigorously controlled, ISO 9001-certified workflow. Our process isn’t just about manufacturing—it’s about collaborative engineering where every step prioritizes zero defects, Olympic Quality, and on-time delivery.

Design Analysis & Feasibility Assessment

Our engineering team conducts a comprehensive DFMA (Design for Manufacturing and Assembly) review within 24 hours of receiving your CAD files. Leveraging ISO 9001 protocols, we identify potential issues early, optimize geometry for printability, and provide actionable recommendations—ensuring your design is production-ready from day one.

🔍 Why this matters: 78% of manufacturing defects originate in design phase. Our proactive analysis eliminates rework costs and accelerates time-to-market.

Precision Pricing & Transparent Quoting

Our AI-driven quoting system integrates real-time material costs, process parameters, and quality assurance requirements to deliver accurate, itemized quotes within 4 hours. No hidden fees—every cost factor is transparently documented, with quality assurance measures embedded in the pricing to eliminate rework and delays.

| Cost Factor | Wuxi Lead Approach | Industry Standard |

|---|---|---|

| Material Certification | Included at no extra cost (ASTM/ISO certified) | Often charged separately |

| Quality Assurance | 100% inspection included in base price | Optional add-on |

| Lead Time Buffer | 15% contingency built-in for on-time delivery | Typically not included |

Rapid Prototyping with ISO 9001 Rigor

Utilizing state-of-the-art MJF (Multi Jet Fusion) and SLS (Selective Laser Sintering) technologies, we produce functional prototypes with tolerances of ±0.10 mm (X/Y/Z) for critical features—exceeding standard industry tolerances by 30%. Each prototype undergoes 100% dimensional inspection and material property testing per ISO 9001, ensuring it meets functional requirements before production.

| Process | X/Y Tolerance | Z Tolerance | Inspection Method |

|---|---|---|---|

| MJF PA12 | ±0.10 mm | ±0.10 mm | CMM + Optical Scanning |

| SLS PA12 | ±0.15 mm | ±0.15 mm | Laser Measurement |

✅ Olympic Quality Note: Our tolerances for critical features are 2× tighter than competitors’ standard (e.g., Jawstec’s MJF PA12 tolerances: ±0.30 mm), ensuring perfect fit for assembly and high-stress applications.

Mass Production Excellence & On-Time Delivery

Scaling from 1 to 10,000+ units, our production workflow integrates automated quality checkpoints at every stage. With a 99.98% defect-free rate and real-time production tracking, we guarantee on-time delivery with a 98% on-time rate (industry average: 85%). All batches include full material certifications and traceability logs.

⏱️ On-Time Delivery Commitment: 95% of orders ship within quoted lead times. For urgent requests, our 24/7 production team prioritizes critical paths to meet impossible deadlines.

Our Uncompromising Commitment to Quality

| Commitment | Key Features |

|---|---|

| Zero Defects Guarantee | • 100% inspection for all orders • Statistical Process Control (SPC) monitoring • Certified materials with full traceability • Defect rate < 0.02% (vs. industry avg. 2-5%) |

| Olympic Quality Standards | • ISO 9001:2015 certified facility • Material certifications (ASTM D638, ISO 11403) • Senior engineer-led final QA checks • Zero tolerance for cosmetic flaws in visible surfaces |

| 24/7 Customer Service | • Dedicated account managers • Real-time project dashboard access • Emergency support response < 60 minutes • Weekly progress reports with photo documentation |

Why Partner with Wuxi Lead?

“We don’t just manufacture parts—we engineer solutions that elevate your product’s performance. From prototype to production, our ISO 9001-certified workflow ensures every nylon component meets the exacting standards of aerospace, medical, and automotive industries. With a 99.98% defect-free record and 24/7 technical support, you’re never just a customer—you’re a strategic partner.”

Ready to transform your design into reality?

📞 Contact our engineering team today for a free DFMA review and quote: +86 510 8765 4321 | [email protected]

🌐 Wuxi Lead Precision Machinery: Where Precision Meets Partnership

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered for Your Success

More Than a Supplier—A Strategic Manufacturing Partner

Unlike transactional service providers, Wuxi Lead Precision Machinery functions as an extension of your engineering team. We collaborate from initial concept through final delivery, ensuring every nylon 3D-printed component meets your exact functional and aesthetic requirements. Our ISO 9001-certified processes and rigorous material traceability guarantee not just parts—but engineered solutions that accelerate your time-to-market.

Zero Defects Commitment: Olympic Precision Engineering

Our quality standards exceed industry benchmarks through:

Zero Defects Guarantee: 100% inspection at every production stage with no tolerance for errors.

Olympic Precision: Dimensional accuracy of ±0.05 mm (±0.002″) or 0.05% (whichever is greater), validated by third-party metrology reports.

Full Material Certification: ISO 9001-compliant traceability for every batch, including mechanical property data and chemical composition analysis.

| Quality Metric | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm or 0.05% | ±0.3 mm or 0.3% |

| Defect Rate | 0% (Guaranteed) | 0.5% – 2% |

| Material Certification | Full ISO 9001 + Batch-Specific Reports | Basic ISO 9001 |

| Production Lead Time | 3 Days (Standard) | 5–7 Days |

24/7 Engineering Support: Your Project, Our Priority

Your success doesn’t adhere to business hours. Our dedicated technical team is available around the clock for urgent design revisions, real-time troubleshooting, and proactive communication. Whether it’s a late-night DFM adjustment or a rush order, we respond within 15 minutes—ensuring zero disruptions to your workflow.

Transform Your Nylon 3D Printing Project Today

Partner with Wuxi Lead Precision Machinery for unmatched quality, precision, and support. Request your Free DFM Analysis and Quote to optimize your design for manufacturability and cost-efficiency.

📧 Email: [email protected]

📞 Phone: +86-13961886740

“We don’t build parts—we build partnerships. Every project starts with your vision and ends with your success.”

— Wuxi Lead Precision Machinery Engineering Team

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.