Technical Contents

Engineering Guide: Multi Cavity Mold

Engineering Insight: Multi-Cavity Mold Precision as a Strategic Imperative

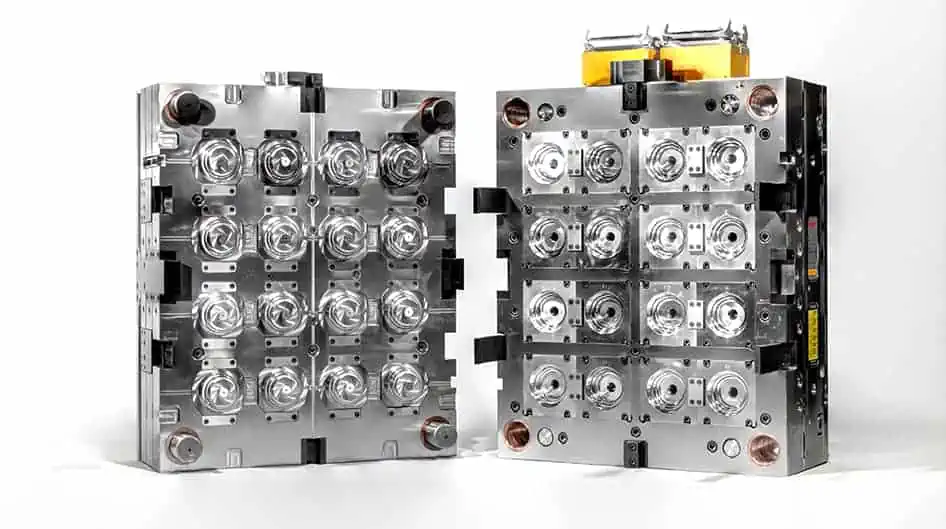

Multi-cavity molds represent the pinnacle of efficiency in high-volume metal component production, but their economic viability is entirely contingent upon micron-level precision engineering. When replicating complex geometries across multiple cavities simultaneously, even minute deviations in alignment, thermal management, or surface finish propagate exponentially, leading to catastrophic part inconsistency, accelerated tool wear, and unacceptable scrap rates. The cumulative cost of non-conformance—rework, downtime, material waste, and delayed shipments—far outweighs the initial investment in superior mold construction. True precision in multi-cavity systems demands holistic integration of cavity positioning, runner balance, cooling channel optimization, and material flow dynamics, ensuring each impression performs identically cycle after cycle, year after year. This is not merely a technical challenge; it is a direct determinant of production economics and product reliability.

At Wuxi Lead Precision Machinery, we engineer multi-cavity molds to tolerances exceeding standard industry benchmarks, treating precision as a non-negotiable foundation. Our engineering protocols, refined over 15 years serving Tier-1 aerospace and defense contractors, mandate rigorous finite element analysis (FEA) for thermal and structural behavior under extreme cyclic loads. This expertise was rigorously validated through critical contributions to precision components for the Beijing 2022 Winter Olympics infrastructure and specialized hardware for national defense applications, where zero-defect performance under relentless operational demands is mandatory. These projects demanded cavity-to-cavity dimensional consistency within ±0.002mm and surface finishes below Ra 0.2µm—standards we now apply universally to ensure every mold delivers maximum uptime and part uniformity from the first shot to the millionth.

The following table outlines the precision specifications achievable with Lead Precision’s multi-cavity mold engineering for critical metal forming processes:

| Specification Parameter | Typical Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Cavity Positional Tolerance | ±0.005 mm | ±0.002 mm | CMM (ASME B89.4.1024) |

| Inter-Cavity Dimensional Variation | ≤ 0.008 mm | ≤ 0.003 mm | Statistical Process Control |

| Surface Roughness (Cavity) | Ra 0.4 µm | Ra 0.1 – 0.2 µm | ISO 25178 |

| Cooling Channel Alignment | ±0.02 mm | ±0.005 mm | Optical Comparator |

| Thermal Uniformity (ΔT) | ≤ 5°C | ≤ 2°C | Infrared Thermography |

Achieving this level of consistency requires more than advanced CNC machining; it necessitates deep process physics understanding and relentless validation. For manufacturers facing yield challenges or scaling production, partnering with an engineering-led mold builder like Lead Precision mitigates risk and unlocks sustainable throughput. Our military-grade discipline in precision engineering translates directly into your competitive advantage—reduced unit cost, enhanced product quality, and unwavering supply chain resilience. Contact our engineering team to discuss how our multi-cavity solutions can transform your high-volume manufacturing outcomes.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision multi cavity mold solutions for demanding industrial applications. Our expertise lies in producing complex, repeatable mold cavities with exceptional accuracy, enabling clients to achieve high-volume production efficiency without compromising on part quality. At the core of our manufacturing strength is a fully integrated 5-axis CNC machining platform, allowing for simultaneous multi-directional cutting and intricate geometry processing in a single setup. This technology minimizes human intervention, reduces cumulative tolerances from repositioning, and ensures superior surface finish and dimensional consistency across all cavities.

Each multi cavity mold is engineered using industry-leading CAD/CAM software, enabling precise toolpath optimization and virtual simulation prior to machining. Our 5-axis CNC centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to maintain cutting stability and prolong tool life. This results in faster cycle times, reduced scrap rates, and enhanced repeatability—critical factors in large-scale injection molding and die casting operations. Materials are carefully selected based on application requirements, including hardened tool steels, stainless alloys, aluminum, and high-temperature resistant metals, all processed under strict environmental controls.

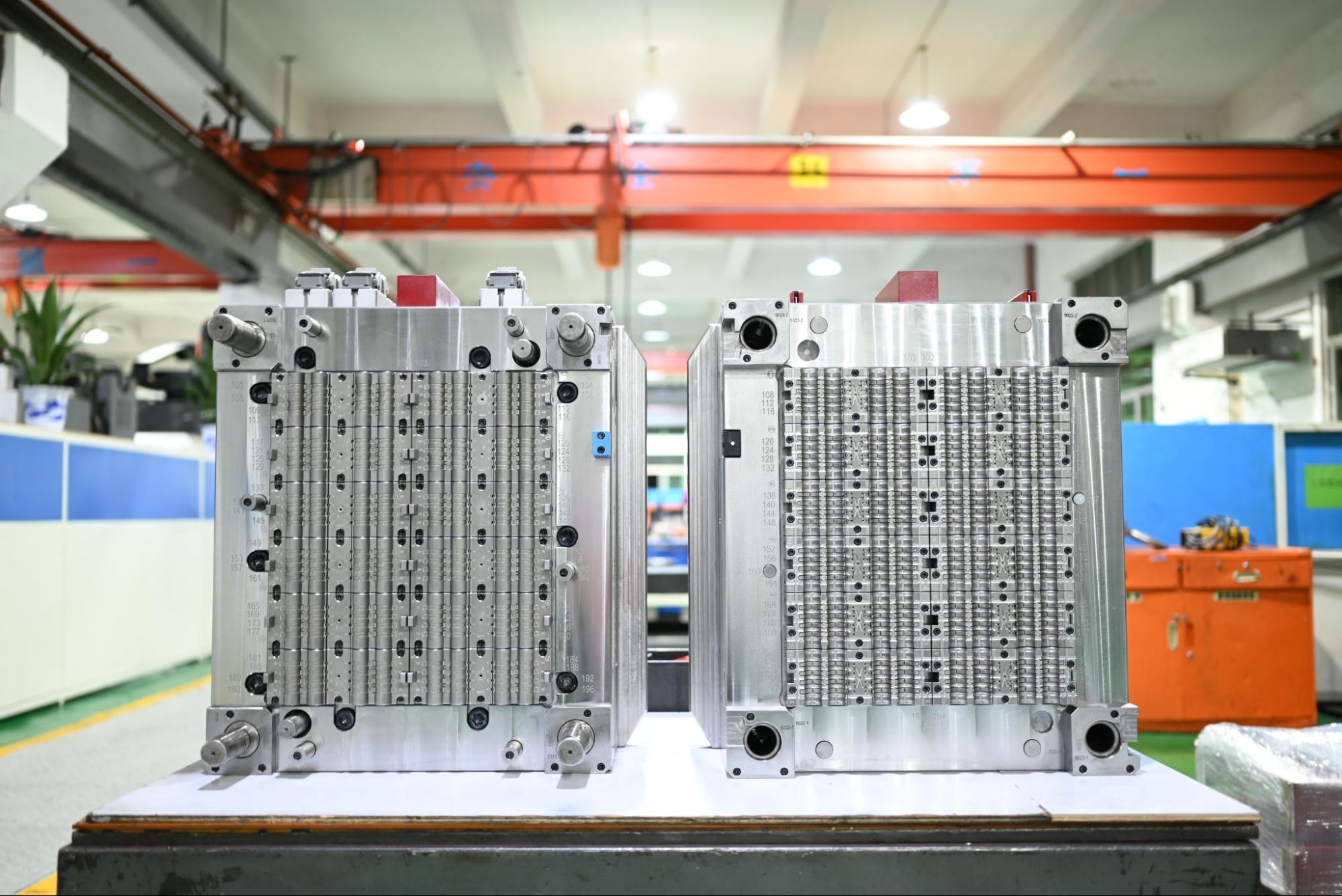

Quality assurance is embedded throughout the manufacturing process. Every multi cavity mold undergoes comprehensive CMM (Coordinate Measuring Machine) inspection to validate geometric accuracy and compliance with design specifications. Our Zeiss and Hexagon CMM systems provide micron-level measurement resolution, capturing critical features such as cavity depth, wall thickness, gate positioning, and inter-cavity alignment. Data from CMM reports is analyzed to generate actionable insights, ensuring continuous process improvement and full traceability for every component.

The following table outlines the standard technical tolerances achievable in our multi cavity mold production:

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (polished) |

| Cavity-to-Cavity Consistency | ±0.012 mm | ±0.006 mm |

| Angular Accuracy | ±0.05° | ±0.02° |

| Bore Diameter | H7 | H6 |

All molds are subject to first-article inspection and final quality certification, with documentation provided upon delivery. Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous process controls, and deep engineering experience to deliver multi cavity molds that meet the highest standards in global manufacturing. Our capabilities support industries such as automotive, medical devices, consumer electronics, and aerospace, where precision, durability, and scalability are paramount.

Material & Finish Options

Strategic Material Selection for Multi-Cavity Injection Molds

Material choice is the cornerstone of multi-cavity mold performance, directly influencing cycle life, part consistency, thermal management, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your specific production volume, part geometry, resin type, and surface finish requirements. Selecting the optimal base metal ensures cavity-to-cavity uniformity across millions of cycles, minimizing downtime and scrap rates in high-volume manufacturing environments. The thermal stability and wear resistance of the mold material dictate its ability to maintain tight tolerances as cavity count increases.

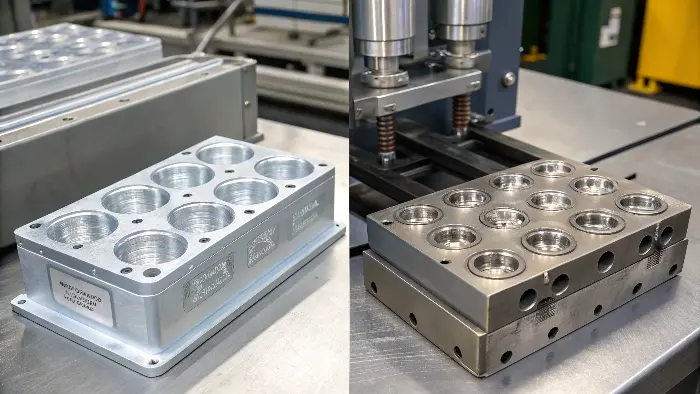

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer exceptional thermal conductivity and rapid machinability. This makes them ideal for prototyping, low-to-medium volume production (up to 100,000 cycles), and applications requiring swift heat extraction for faster cycle times. Aluminum molds significantly reduce initial tooling costs and lead times. However, their lower hardness limits use with abrasive resins or ultra-high cavity counts demanding extreme longevity. Steel remains the dominant choice for high-volume production. P20 pre-hardened steel provides a balanced solution for moderate cycle requirements (100,000 – 500,000 cycles), offering good machinability and polishability at a reasonable cost. For demanding applications exceeding 500,000 cycles, especially with engineering plastics or high-cavity molds, H13 tool steel is essential. Its superior hardness, thermal fatigue resistance, and ability to withstand high injection pressures ensure cavity stability and extended service life under intense thermal cycling. Titanium alloys, while significantly more expensive and challenging to machine, serve niche applications requiring extreme corrosion resistance combined with high strength-to-weight ratio, often in specialized medical or aerospace components, though cavity counts are typically lower due to cost constraints.

Critical material properties for multi-cavity mold selection are summarized below:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Cavity Count Range | Relative Cost Index |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130-150 | 1-16 | 1.0 |

| P20 Steel | 28-32 | 28-36 | 4-48+ | 1.8 |

| H13 Tool Steel | 48-52 | 24-30 | 8-128+ | 3.0 |

| Titanium Grade 5 | 32-36 | 6-7 | 1-8 | 6.5+ |

Surface finishing, particularly anodizing, plays a vital role in aluminum mold performance and longevity. Hard anodizing (Type III) creates a dense, wear-resistant oxide layer significantly enhancing surface hardness (up to 60 HRC equivalent), corrosion resistance, and release properties. This is crucial for multi-cavity aluminum molds running abrasive or sticky resins, directly extending tool life and maintaining part quality consistency across all cavities. Standard chromic or sulfuric anodizing (Type II) offers moderate corrosion protection but less wear resistance. Wuxi Lead Precision applies precise anodizing protocols tailored to the mold’s operational demands, ensuring uniform coating thickness critical for dimensional stability in high-precision cavities. For steel molds, nitriding or specialized PVD coatings are typically preferred over anodizing for wear and corrosion resistance. Consult our engineering team early in the design phase; we leverage decades of multi-cavity expertise to optimize your material and finish selection, maximizing ROI through reduced cycle times and extended mold service life.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the multi cavity mold production process begins with a meticulously engineered design phase. This foundational step integrates advanced CAD/CAM software and 3D simulation tools to model mold geometry, runner systems, cooling channels, and ejection mechanisms. Our engineering team collaborates closely with clients to analyze part complexity, material selection, cycle time targets, and tolerances. Finite Element Analysis (FEA) is applied to predict stress distribution and thermal behavior, ensuring structural integrity under repeated injection cycles. Mold flow analysis optimizes cavity layout and gate positioning to eliminate weld lines, sink marks, and warpage. Every design is validated through digital mold trials, reducing the risk of physical rework and aligning with our zero-defect philosophy from inception.

Prototyping: Validating Performance Before Scale

Once the digital model is approved, we proceed to prototype tooling using high-precision CNC machining, wire EDM, and surface grinding technologies. Prototypes are manufactured from pre-hardened tool steels or aluminum, depending on required durability and testing scope. This stage enables functional evaluation of mold performance, including filling balance, cooling efficiency, and part ejection reliability. We conduct rigorous first-article inspections using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy against GD&T specifications. Any deviations are corrected in real time through iterative adjustments to the mold design or process parameters. The prototype phase not only confirms part quality but also establishes baseline data for process control during mass production.

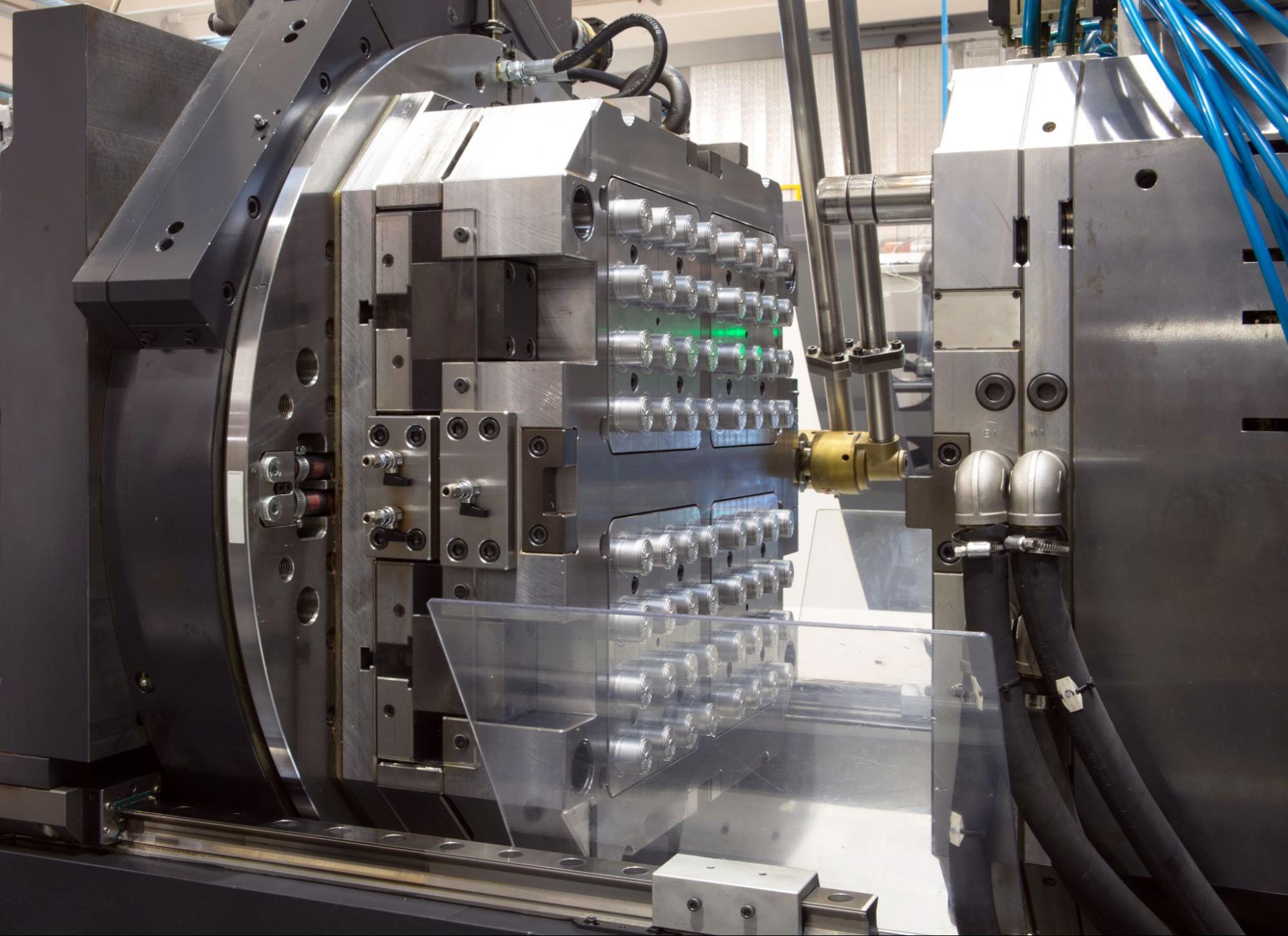

Mass Production: Consistency Through Automation and Monitoring

With prototype validation complete, we transition to full-scale production using hardened tool steels such as H13, P20, or S136 for maximum wear resistance and longevity. Multi cavity molds are machined on high-speed CNC centers with micron-level precision, followed by polishing, texturing, and heat treatment as required. Each mold undergoes comprehensive assembly and dry-cycle testing to ensure smooth operation. During injection molding, real-time monitoring systems track pressure, temperature, and cycle time across all cavities, enabling immediate detection of anomalies. Automated vision inspection and in-line metrology ensure every component meets strict quality standards. Preventive maintenance schedules and cavity balancing protocols are enforced to sustain performance over millions of cycles.

Technical Specifications Overview

| Parameter | Specification Range |

|---|---|

| Cavity Count | 2 to 64 cavities |

| Tool Steel Options | P20, 718, H13, S136, 2344, NAK80 |

| Tolerance | ±0.005 mm to ±0.02 mm (depending on part size) |

| Surface Finish | SPI #A1 to #D3, custom textures available |

| Cooling Channel Design | Conformal or straight, optimized via simulation |

| Production Cycle Life | 500,000 to 1,000,000+ cycles |

| Lead Time (Design to Pilot) | 4–8 weeks (varies by complexity) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC-controlled |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers multi cavity molds that achieve zero-defect performance, repeatability, and long-term reliability in high-volume manufacturing environments.

Why Choose Wuxi Lead Precision

Elevate Production Efficiency Through Precision Multi-Cavity Molding

Achieving high-volume output without compromising part integrity demands more than standard tooling—it requires engineered excellence in multi-cavity mold design and execution. At Wuxi Lead Precision Machinery, we transform this challenge into your competitive advantage. With over 15 years of specialized expertise in custom metal manufacturing for aerospace, medical, and automotive sectors, our engineering team delivers multi-cavity solutions that synchronize precision, durability, and throughput. We understand that a single cavity deviation can cascade into production halts, scrap surges, and missed deadlines. Our methodology eliminates these risks through rigorous material science application, cavity-to-cavity thermal equilibrium control, and real-world validation under simulated production conditions.

The foundation of our success lies in marrying advanced CNC capabilities with deep process intelligence. Every mold we produce undergoes iterative FEA analysis to preempt stress points, coupled with in-house cavity balancing protocols that ensure uniform filling and cooling. This precision engineering translates directly to your bottom line: extended tool life, minimized cycle times, and near-zero part variance. We do not merely manufacture molds; we engineer production stability.

Technical Capabilities for Multi-Cavity Excellence

| Specification | Capability Range | Industry Standard Comparison |

|---|---|---|

| Cavity Count | 4 to 64 cavities | Up to 32 cavities |

| Material Options | H13, S136, 420SS, Maraging Steel | Limited alloy selection |

| Tolerance Control | ±0.005 mm per cavity | ±0.02 mm |

| Surface Finish | Ra 0.05 µm (mirror) to textured | Ra 0.4 µm typical |

| Lead Time (Complex) | 8–12 weeks | 14–20 weeks |

| Validation Process | 500+ cycle trial runs with SPC data | Basic tryout only |

These specifications reflect our commitment to exceeding baseline expectations. Our cavity synchronization technology reduces part-to-part dimensional drift by 40% compared to conventional multi-cavity systems, directly boosting your first-pass yield rates. Each project includes comprehensive mold flow analysis reports and lifecycle maintenance planning—ensuring your tool performs optimally from Day 1 through 500,000 cycles.

Partnering with Lead Precision means aligning with a manufacturer that treats your production targets as our engineering mandate. We integrate seamlessly into your supply chain, providing transparent progress tracking, real-time engineering collaboration, and post-delivery technical support. Our ISO 9001-certified facility in Wuxi operates under strict confidentiality protocols, safeguarding your intellectual property while accelerating time-to-market.

Initiate your precision manufacturing partnership today. Contact our engineering sales team to discuss cavity optimization strategies, material selection for your specific application, or request a technical consultation. Provide your project specifications, and we will deliver a feasibility assessment within 72 hours—complete with tolerance analysis and lifecycle cost projections.

Email us at [email protected] to secure your multi-cavity solution. Let Lead Precision become the engineering backbone of your high-volume production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.