Technical Contents

Engineering Guide: Mouldings Plus

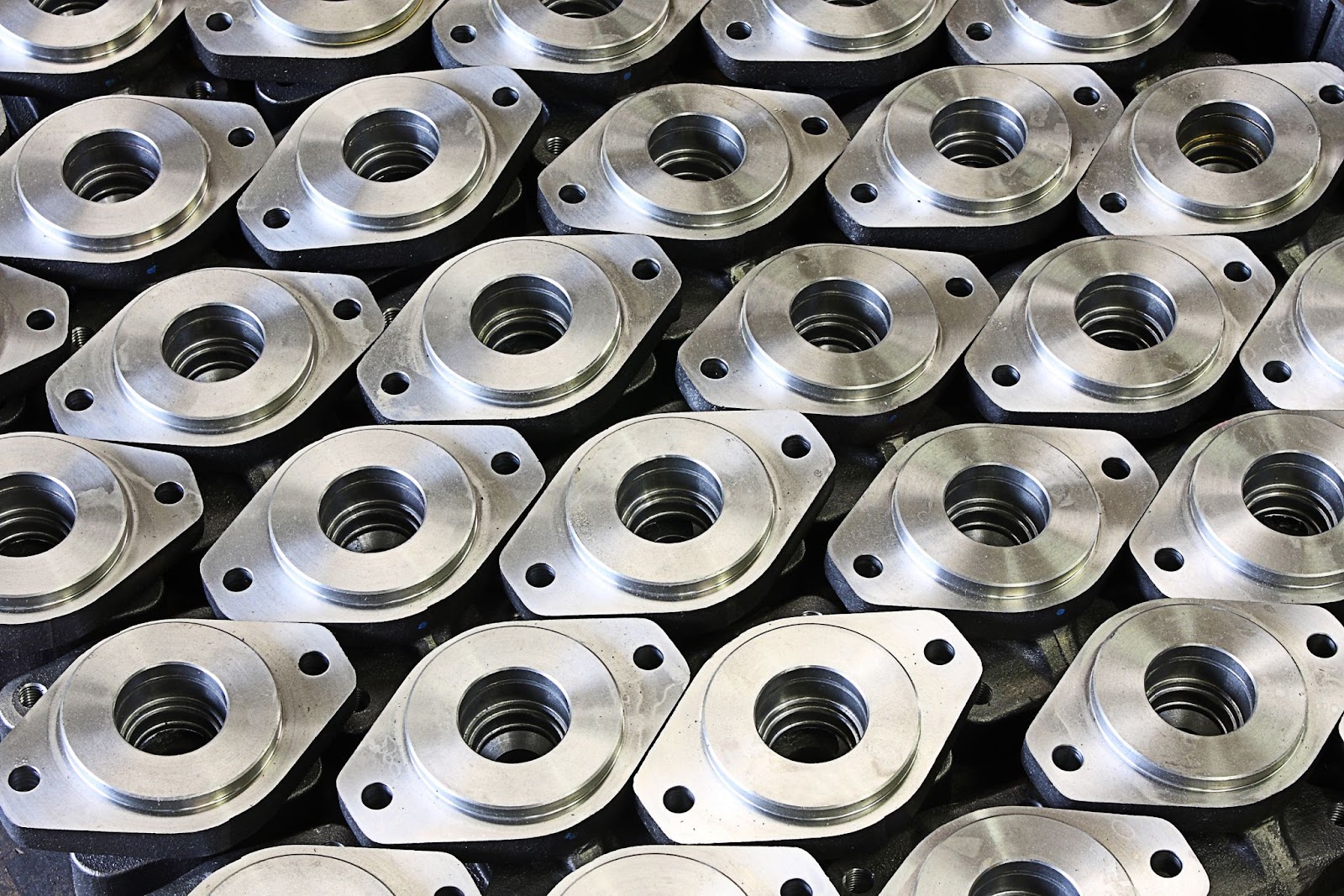

Engineering Insight: The Critical Role of Precision in Advanced Metal Mouldings Plus Applications

In the realm of high-performance industrial manufacturing, the term mouldings plus extends beyond conventional forming processes. It represents the integration of precision engineering, advanced material science, and repeatable accuracy to produce components that meet exacting functional and structural demands. At Wuxi Lead Precision Machinery, we define mouldings plus as the synthesis of custom metal forming with secondary precision operations—such as CNC machining, laser cutting, and post-forming inspection—ensuring each component not only conforms to geometric intent but performs reliably under real-world conditions.

Precision is not an incremental advantage; it is a foundational requirement. In sectors such as aerospace, defense, and high-end sports infrastructure—including projects tied to Olympic facilities—dimensional tolerances measured in microns directly impact system integrity, longevity, and safety. A deviation of even 0.05 mm in a load-bearing bracket or enclosure can compromise fatigue resistance or assembly alignment, leading to cascading failures in complex systems. Our engineering philosophy centers on eliminating variability through closed-loop manufacturing processes, where every stage—from raw material selection to final inspection—is monitored and controlled using calibrated metrology systems.

With over 15 years of specialized experience in custom metal manufacturing, Wuxi Lead Precision Machinery has delivered mission-critical components for military-grade enclosures and large-scale public infrastructure. Our work on Olympic-standard facility components, including seismic-resistant mounting systems and modular structural housings, underscores our capability to merge aesthetic design with engineering rigor. These projects demanded not only compliance with international standards (such as ISO 2768-mK and GB/T 1804–c) but also zero-defect delivery under compressed timelines.

Our facility leverages state-of-the-art press brakes with real-time crowning compensation, fiber laser cutting systems with ±0.03 mm positioning accuracy, and automated bending cells capable of producing complex geometries with consistent angular repeatability. Each component undergoes first-article inspection and batch traceability protocols, ensuring full documentation for audit and compliance purposes.

The following table outlines key precision capabilities relevant to mouldings plus applications:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12.0 mm (steel) |

| Bending Tolerance | ±0.2° angular, ±0.1 mm linear |

| Laser Cutting Accuracy | ±0.03 mm per 100 mm |

| Minimum Feature Resolution | 1.0 mm (piercing), 2.0 mm (slot) |

| Positional Repeatability (CNC) | ±0.01 mm |

| Surface Flatness (post-form) | ≤ 0.1 mm over 1,000 mm length |

| Process Control Standard | ISO 9001, IATF 16949 (automotive) |

These capabilities are not theoretical—they are proven through sustained delivery for clients who operate in zero-margin-for-error environments. At Wuxi Lead Precision Machinery, mouldings plus is not a product category; it is a commitment to engineering excellence where precision defines performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy for complex metal components through integrated advanced manufacturing and metrology systems. Our core strength lies in 5-axis CNC machining, enabling single-setup production of intricate geometries that traditional 3-axis systems cannot achieve. This capability eliminates cumulative errors from multiple fixturing stages, ensuring superior part integrity for aerospace structural elements, medical implant subassemblies, and energy sector turbine components. We deploy DMG MORI CTX beta 1250 and Hermle C30U 5-axis platforms with 0.001mm positioning accuracy and sub-micron thermal compensation, handling materials from titanium alloys and Inconel to hardened tool steels up to 1,200mm in diameter. Simultaneous 5-axis interpolation allows continuous toolpath optimization, reducing cycle times by 35% while maintaining surface finishes down to Ra 0.4µm.

Rigorous quality control is non-negotiable in high-stakes manufacturing. Every critical dimension undergoes verification via Zeiss CONTURA G3 Coordinate Measuring Machines (CMM), certified to ISO 10360-2 standards with 1.9 + L/300 µm volumetric accuracy. Our inspection protocol exceeds standard first-article requirements: 100% of geometric dimensioning and tolerancing (GD&T) callouts are validated against CAD models, with full traceability through our Q-DAS statistical process control (SPC) system. Real-time SPC feedback directly informs CNC program adjustments, ensuring process stability across production runs. All inspection reports include comprehensive deviation mapping and measurement uncertainty analysis, meeting AS9100 and ISO 13485 documentation mandates for aerospace and medical clients.

Tolerance execution is the definitive measure of precision manufacturing capability. The following table reflects our validated performance across material classes and feature types under controlled environmental conditions (20±0.5°C):

| Feature Type | Standard Capability (mm) | Precision Capability (mm) | Conditions |

|---|---|---|---|

| Linear Dimensions | ±0.010 | ±0.003 | Up to 300mm length |

| Bore Diameter | +0.012 / -0.005 | +0.005 / -0.002 | H7 tolerance class achievable |

| Flatness | 0.020 | 0.005 | Per 100mm² area |

| True Position | ±0.025 | ±0.008 | Relative to primary datums |

| Surface Roughness (Ra) | 1.6 | 0.4 | Machined surfaces |

These specifications are consistently achieved within defined part complexity and material constraints, validated through annual NIST-traceable calibration. Our engineering team collaborates pre-production to optimize designs for manufacturability, ensuring tolerances align with functional requirements without unnecessary cost escalation. For mission-critical applications requiring micron-level repeatability, we implement in-process probing and adaptive machining strategies to counter thermal drift and tool wear. Wuxi Lead’s technical infrastructure transforms dimensional ambition into certified reality—where every micron of tolerance represents a commitment to your operational success. Partner with us to convert engineering intent into flawlessly executed metal solutions.

Material & Finish Options

Material Selection for High-Precision Metal Components

Selecting the appropriate material is critical in custom metal manufacturing, particularly when producing high-performance components for industries such as aerospace, automotive, medical, and industrial automation. At Wuxi Lead Precision Machinery, we specialize in precision machining of aluminum, steel, and titanium—each offering distinct mechanical, thermal, and corrosion-resistant properties tailored to specific application demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, electrical conductivity, and machinability. It is ideal for components requiring lightweight durability and resistance to atmospheric corrosion. Commonly used in transportation and electronics, aluminum alloys such as 6061 and 7075 deliver reliable performance under moderate stress and are easily finished through anodizing for enhanced surface hardness and aesthetics.

Steel, particularly stainless steel grades like 304 and 316, provides superior strength, wear resistance, and structural integrity at elevated temperatures. Its high tensile strength and resistance to corrosion in harsh environments make it suitable for medical devices, food processing equipment, and marine applications. While heavier than aluminum, steel offers unmatched durability and long-term reliability in demanding operational conditions.

Titanium stands at the premium end of material selection due to its exceptional strength-to-density ratio, outstanding corrosion resistance, and ability to perform under extreme temperatures. Frequently used in aerospace and biomedical implants, titanium maintains structural integrity in aggressive environments, including saltwater and high-heat settings. Though more challenging and costly to machine, its performance benefits justify its use in mission-critical applications.

Surface Finishing: The Role of Anodizing

Anodizing is a key finishing process, primarily applied to aluminum components. This electrochemical treatment thickens the natural oxide layer on the metal surface, significantly improving wear resistance, corrosion protection, and adhesion for paint primers. Type II (sulfuric acid) anodizing is commonly used for general-purpose applications, offering a range of color options for branding or identification. Type III, or hard anodizing, delivers a thicker, denser coating suitable for high-wear environments, enhancing surface hardness up to 60 HRC.

Anodized finishes do not chip or peel like paint, maintaining integrity over extended service life. They are also non-conductive, making them appropriate for electrical enclosures and housings where insulation is required.

Below is a comparative overview of key material properties and finishing options.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High (with oxide layer) | Aerospace, automotive | Anodizing, powder coating |

| Stainless Steel 304 | 8.0 | 505–860 | Very High | Medical, food processing | Passivation, polishing |

| Titanium Grade 5 | 4.5 | 900–1,000 | Exceptional | Aerospace, biomedical | Anodizing, laser marking |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on functional requirements, environmental exposure, and lifecycle expectations. Our engineering team supports optimal decision-making to ensure performance, cost-efficiency, and compliance with international standards.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Production Process for High-Performance Metal Mouldings Plus

Achieving flawless metal mouldings plus components demands a rigorously controlled, phase-gated production methodology. At Wuxi Lead Precision Machinery, we integrate advanced engineering with closed-loop quality systems across three critical stages: Collaborative Design, Validated Prototyping, and Scalable Mass Production. This structured approach ensures every component meets exacting dimensional, material, and functional specifications before volume manufacturing commences.

The process initiates with deep Collaborative Design engagement. Our engineering team partners directly with your designers to conduct comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis. Utilizing advanced CAD/CAM simulation software, we identify potential thin-wall deformation risks, optimize toolpaths for complex geometries inherent in mouldings plus, and validate thermal management strategies. This phase establishes precise material selection criteria and critical tolerance zones, forming the foundational blueprint for zero-defect execution. Early virtual validation prevents costly downstream errors and accelerates time-to-market.

Prototyping transitions the validated design into physical reality under full production-intent conditions. We employ multi-axis CNC milling and precision turning centers, mirroring the exact equipment and tooling strategies planned for mass production. Each prototype undergoes meticulous First-Article Inspection (FAI) per AS9102 standards, with full CMM reporting, surface roughness verification, and material certification. This stage is not merely sample creation; it is a critical process capability study. Dimensional data feeds directly into Statistical Process Control (SPC) models, confirming the process can consistently achieve target tolerances before scaling. Iterations are rapid, data-driven, and focused solely on process refinement.

Mass Production leverages the validated process parameters within our ISO 9001 and IATF 16949 certified facility. Every machining cell operates under real-time SPC monitoring, with automated in-process gauging triggering immediate corrective action for any parameter drift. Our closed-loop system integrates CNC machine feedback, CMM results from randomized in-line checks, and final 100% visual inspection for surface integrity. Material traceability is maintained from raw bar stock to finished component. This relentless focus on process stability, combined with operator expertise and automated documentation, guarantees sustained zero-defect output at scale. The result is consistent delivery of complex metal mouldings plus components that perform reliably in the most demanding applications.

Key process specifications maintained throughout production are detailed below:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm (Production) / ±0.01 mm (Prototype) |

| Surface Roughness (Ra) | 0.4 µm – 1.6 µm (as specified) |

| Material Certification | Full Mill Test Reports, 100% Traceable |

| In-Process Inspection | SPC Monitored, Automated Gauging |

| Final Inspection | 100% Visual, CMM Sampling per AQL 0.65 |

| Defect Rate Target | 0 PPM (Zero Defects Commitment) |

This disciplined progression from collaborative design through rigorously validated prototyping to stabilized mass production, underpinned by our integrated quality management system, is the cornerstone of Wuxi Lead’s zero-defect guarantee for premium metal mouldings plus components.

Why Choose Wuxi Lead Precision

When it comes to custom metal manufacturing in the realm of precision engineering, the partnership you choose defines the quality, reliability, and scalability of your production outcomes. At Wuxi Lead Precision Machinery, we don’t just deliver components—we deliver engineered solutions built on decades of technical mastery, advanced CNC capabilities, and an unwavering commitment to excellence. As a trusted name in high-end manufacturing based in Wuxi, China, we specialize in producing mission-critical metal moldings and precision-machined parts for industries where performance under extreme conditions is non-negotiable.

Our clients span aerospace, automotive, medical device manufacturing, and industrial automation—sectors that demand micron-level accuracy, repeatable consistency, and full traceability. What sets us apart is not only our state-of-the-art facility equipped with 5-axis CNC machining centers, Swiss-type lathes, and automated inspection systems but also our engineering-first approach. From initial concept and material selection to prototyping, DFM analysis, and full-scale production, our team collaborates closely with your engineers to ensure every component meets or exceeds your exact specifications.

We understand that in high-performance applications, tolerances matter. Surface finish matters. Material integrity matters. That’s why we invest in cutting-edge metrology equipment, including CMMs and optical comparators, to validate every dimension. Our ISO 9001:2015 certification is not just a credential—it’s a reflection of our culture of continuous improvement and process discipline.

Partnering with Lead Precision means gaining access to a vertically integrated manufacturing ecosystem. We control every step in-house: CNC turning, milling, grinding, EDM, heat treatment coordination, surface finishing, and assembly. This integration reduces lead times, enhances quality control, and allows for rapid iteration—critical advantages in today’s fast-moving industrial markets.

Below are key technical capabilities that define our production capacity:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (XYZ) |

| Materials Processed | Aluminum alloys, Stainless Steel (303, 304, 316), Titanium, Inconel, Brass, Tool Steels |

| Equipment Types | 5-Axis CNC Machining Centers, CNC Lathes with Live Tooling, Swiss Screw Machines, EDM (Wire & Sinker) |

| Secondary Operations | Deburring, Anodizing, Passivation, Plating, Laser Marking |

| Quality Assurance | ISO 9001:2015 Certified, Full First Article Inspection (FAI), PPAP Documentation, Batch Traceability |

Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing model adapts to your project’s scale and complexity. We pride ourselves on transparency, responsiveness, and technical collaboration—qualities that have made us a preferred partner for global OEMs and engineering firms.

For your next precision metal molding project, choose a manufacturer that combines technical depth with operational agility. Contact us today at [email protected] to discuss your requirements with our engineering team. Let Wuxi Lead Precision Machinery become an extension of your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.