Technical Contents

Engineering Guide: Moulding Finish

Engineering Insight Precision Surface Finish in Metal Moulding

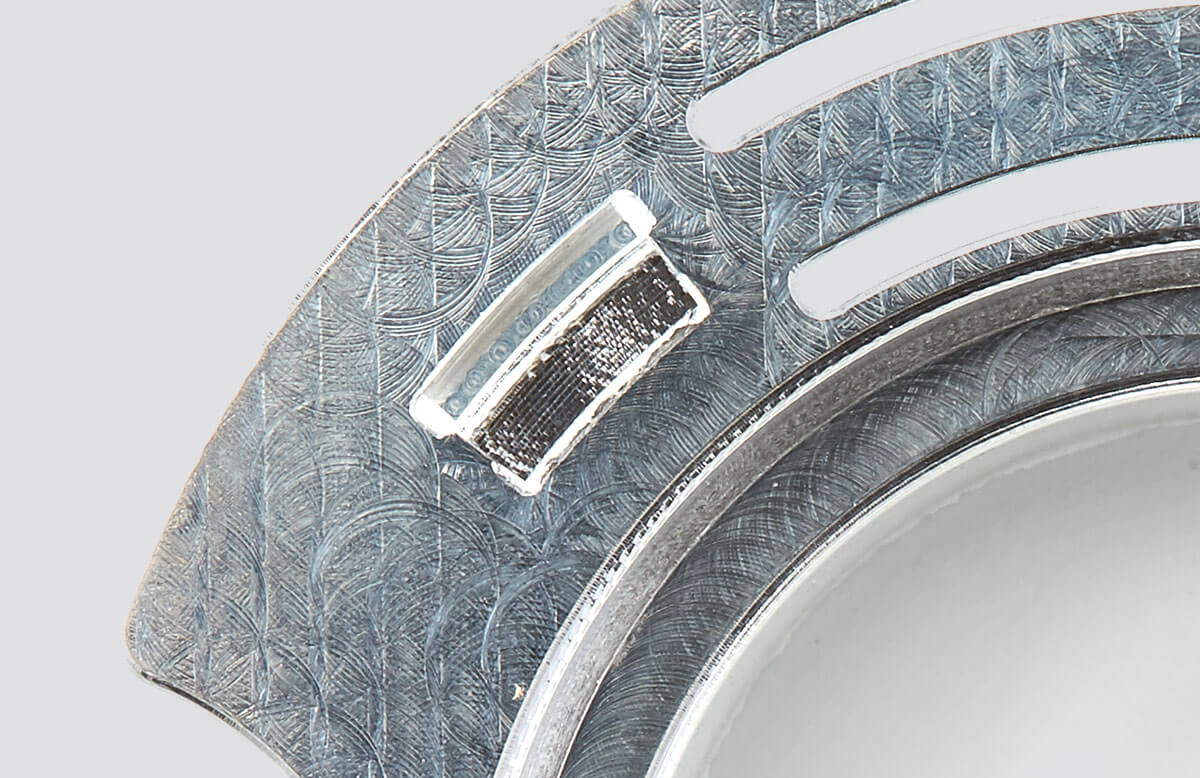

Surface finish in precision metal moulding transcends mere aesthetics; it is a critical engineering parameter directly impacting functional performance, longevity, and reliability. In high-stakes applications like aerospace components, medical implants, or hydraulic systems, microscopic surface texture dictates fatigue resistance, wear behavior, corrosion susceptibility, and even sealing integrity. Imperfections at the micron level can initiate cracks under cyclic stress or create pathways for fluid leakage, leading to catastrophic failure. Achieving the specified finish is not an optional final step but an integrated outcome of the entire manufacturing process, demanding absolute control from material selection through CNC programming, toolpath optimization, and rigorous in-process metrology. At Wuxi Lead Precision Machinery, we understand that surface finish is a non-negotiable dimension of part specification, as vital as geometric tolerances.

Our approach integrates advanced multi-axis CNC machining centers with real-time process monitoring and closed-loop feedback systems. Material science expertise informs optimal cutting parameters and tooling selection to minimize thermal distortion and burr formation. Crucially, surface integrity is continuously verified using calibrated profilometers and optical comparators at defined process checkpoints, not merely as a final inspection. This proactive methodology ensures consistency batch after batch, eliminating costly rework and guaranteeing parts perform as engineered under operational loads. We treat surface finish specifications with the same rigor as dimensional tolerances, embedding the requirements into the core of our manufacturing strategy.

The table below outlines typical surface finish capabilities achievable through our precision moulding and machining processes, reflecting the stringent standards demanded by our most critical sectors.

| Parameter | Standard Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Surface Roughness (Ra) | 0.8 – 1.6 µm | 0.2 – 0.4 µm | ISO 4287 / ASME B46.1 |

| Dimensional Accuracy | ±0.01 mm | ±0.002 mm | ISO 2768-mK |

| Geometric Tolerance | IT7 | IT5 | ISO 286-1 |

| Process Validation | Cpk ≥ 1.33 | Cpk ≥ 1.67 | ISO 22514-2 |

This level of precision is not theoretical. Wuxi Lead Precision Machinery has consistently delivered components meeting the exacting surface and dimensional requirements for projects where failure is not an option. Our processes have been validated through the production of critical components for Olympic-standard sporting equipment, where material consistency and surface integrity directly influence athlete performance and safety. Furthermore, we maintain stringent protocols compliant with military-grade specifications, where parts must withstand extreme environments and exhibit zero deviation over extended service life. These experiences underscore our fundamental principle: true precision manufacturing treats surface finish as an inseparable element of the part’s core functionality, not a superficial attribute. For mission-critical metal components, the finish is the performance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with a specialized focus on precision moulding finish for high-performance industrial applications. Our expertise lies in transforming complex design specifications into flawlessly finished components, ensuring consistency, durability, and exacting surface quality. Central to our precision finishing process is the integration of 5-axis CNC machining technology, which enables multi-directional cutting with unparalleled accuracy. This advanced machining approach allows us to produce intricate geometries and tight-tolerance features that are essential for moulding tools and master patterns used in downstream production.

The 5-axis CNC systems at Wuxi Lead operate with continuous motion across all five axes, minimizing setup changes and eliminating cumulative error. This capability is critical when achieving superior surface finishes on contoured or asymmetric parts, particularly in aerospace, medical, and high-end automotive tooling. Our machines utilize high-speed spindles and adaptive toolpath strategies to reduce tool marks and deliver a consistent, fine surface texture—often eliminating the need for extensive manual polishing. Materials such as hardened steels, aluminum alloys, titanium, and specialty alloys are routinely processed with controlled depth-of-cut and optimized feed rates to preserve material integrity while achieving the desired aesthetic and functional finish.

Quality assurance is embedded throughout every phase of production. Each component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D verification of dimensional accuracy and surface conformity against CAD models, ensuring that every feature aligns with design intent. This metrology-backed validation is essential for maintaining repeatability across production runs and for certifying components destined for regulated industries. All inspection reports are documented and archived, providing full traceability for our clients.

We maintain strict environmental and operational controls within our facility to ensure thermal stability and vibration isolation—factors that directly influence machining precision and surface quality. Our skilled engineers and machinists work in close collaboration with clients during the prototyping and production phases, offering technical feedback to optimize designs for manufacturability and finish performance.

The following table outlines the standard technical specifications and tolerances we achieve under normal production conditions:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensional Tolerance | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm (polished finish) |

| Geometric Tolerance (GD&T) | ±0.012 mm (profile) | ±0.006 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Feature Repeatability | ±0.01 mm (Cpk ≥ 1.33) | ±0.005 mm (Cpk ≥ 1.67) |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for clients demanding the highest standards in moulding finish and precision metalwork.

Material & Finish Options

Material Selection Fundamentals for Precision Moulding Finishes

Selecting the optimal material and complementary finish is critical for achieving dimensional stability, surface integrity, and extended tool life in high-volume moulding applications. At Wuxi Lead Precision Machinery, we prioritize material-finish synergy to ensure your moulds withstand thermal cycling, mechanical stress, and corrosive environments while maintaining part quality. Aluminum, steel, and titanium each offer distinct advantages, but their performance is significantly enhanced through targeted finishing processes, particularly anodizing for non-ferrous alloys.

Aluminum alloys, such as 7075-T6 and 6061-T6, are preferred for rapid prototyping and low-to-medium production runs due to their excellent machinability, thermal conductivity, and lightweight properties. Anodizing is essential for aluminium moulds, transforming the surface into a hard, wear-resistant ceramic layer. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and dye acceptance for cosmetic parts, while Type III (hard coat) anodizing achieves 500+ HV hardness, critical for abrasive polymer processing. Unanodized aluminum succumbs rapidly to galling and erosion in moulding cavities.

Tool steels like H13 and S7 dominate high-pressure, high-cycle moulding due to superior toughness and thermal fatigue resistance. Steel cannot be anodized; instead, we apply hard chrome plating or electroless nickel for corrosion and wear protection. These finishes reduce friction during ejection and resist chemical degradation from PVC or flame-retardant additives. For ultra-precision optical moulds, we recommend PVD coatings like TiN to maintain nanometer-level surface accuracy over millions of cycles.

Titanium alloys (e.g., Ti-6Al-4V) excel in corrosive or high-temperature environments but are cost-prohibitive for most standard moulds. Their natural oxide layer offers inherent corrosion resistance, yet plasma electrolytic oxidation (PEO) can further enhance surface hardness for specialized applications like medical implant moulding. Titanium’s low thermal expansion minimizes part warpage but requires stringent process control during finishing to avoid hydrogen embrittlement.

Critical Material & Finish Specifications for Moulding Applications

| Material | Recommended Finish | Hardness (HV) | Corrosion Resistance | Key Moulding Applications |

|---|---|---|---|---|

| Aluminum 7075 | Type III Anodizing | 500-700 | High | Prototype moulds, low-volume consumer goods |

| H13 Tool Steel | Hard Chrome Plating | 800-1000 | Moderate | High-volume injection moulds, die casting |

| Titanium Ti-64 | Plasma Electrolytic Oxidation | 600-800 | Exceptional | Medical device moulds, aerospace components |

Choosing the right combination requires balancing production volume, polymer chemistry, and part tolerances. Wuxi Lead engineers conduct material-finish compatibility testing during the quoting phase to eliminate field failures. For instance, abrasive glass-filled polymers demand Type III anodized aluminum or chrome-plated steel to prevent premature cavity wear. Contact our technical team to validate your material-finish strategy against specific operational parameters—ensuring maximum ROI through extended mould service life and reduced downtime.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the journey to a flawless moulding finish begins with meticulous design engineering. Our team of senior CNC engineers collaborates closely with clients to interpret technical drawings, CAD models, and surface finish requirements. Using advanced simulation software such as Siemens NX and Autodesk Moldflow, we analyze thermal distribution, material flow, and potential stress points to optimize the mould geometry. This phase ensures dimensional accuracy, minimizes warpage, and establishes the foundation for a consistent surface finish. Every design is validated through finite element analysis (FEA) to predict performance under production conditions, eliminating guesswork and reducing downstream risk.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to low-volume prototyping using high-precision CNC machining and EDM (Electrical Discharge Machining) to fabricate a functional mould. This prototype stage allows us to produce initial metal components under real process parameters—pressure, temperature, cycle time—for physical validation. Surface texture, part conformity, and ejection integrity are rigorously inspected using coordinate measuring machines (CMM) and 3D laser scanning. Any deviations from the target moulding finish are traced back to design or process variables and corrected iteratively. This closed-loop refinement ensures that the final tooling meets exacting aesthetic and functional standards before mass production begins.

Mass Production: Zero Defects Through Process Control

With design and prototype fully validated, we transition to full-scale manufacturing with a commitment to zero defects. Our production cells are equipped with state-of-the-art CNC machines, real-time monitoring systems, and automated in-process inspection. Each mould is maintained under strict preventive maintenance schedules to preserve surface integrity over extended cycles. We employ closed-loop cooling channels and pressure sensors to stabilize the forming environment, directly influencing surface replication and finish consistency. Every batch undergoes statistical process control (SPC), with surface roughness measured using profilometers to ensure compliance with Ra values down to 0.05 µm. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence.

Technical Specifications for Moulding Finish Capabilities

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Surface Roughness (Ra) | 0.05 µm – 1.6 µm | ISO 4287 |

| Dimensional Tolerance | ±0.005 mm | ISO 2768 |

| Mould Material | H13, S136, 718H, 2344 | AISI / DIN Standards |

| Process Types | Die Casting, Forging, Stamping | In-house Tooling & Control |

| Production Volume Capacity | 1,000 – 500,000+ units/year | Scalable Automation |

| Lead Time (Prototype) | 4 – 6 weeks | Based on Complexity |

This systematic approach—grounded in precision design, empirical prototyping, and disciplined mass production—enables Wuxi Lead Precision Machinery to deliver custom metal components with repeatable, high-end moulding finishes that meet global quality benchmarks.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Moulding Finish Excellence

Achieving flawless moulding finishes on precision metal components demands more than advanced machinery—it requires deep process mastery and unwavering commitment to dimensional integrity. At Wuxi Lead Precision Machinery, we engineer surface perfection for mission-critical applications in aerospace, medical device manufacturing, and high-performance automotive systems. Our integrated approach eliminates the trade-offs between micron-level tolerances and aesthetic or functional surface requirements, ensuring your components perform reliably under extreme operational demands.

We recognize that inconsistent surface finishes lead to premature wear, assembly failures, and costly field recalls. Our solution begins with proprietary CNC grinding and polishing protocols, validated through in-process metrology using Zeiss CONTURA CMM systems and Taylor Hobson surface profilers. Every stage—from material selection to final inspection—is governed by ISO 9001:2015 and IATF 16949 frameworks, with real-time SPC data tracking to preempt deviations. This rigor guarantees repeatable results across production runs, whether you require mirror finishes for optical housings or controlled texture for bonding adhesion.

Our technical capabilities are engineered to exceed industry benchmarks for complex geometries. The table below outlines core specifications achievable for moulding finish applications:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Surface Roughness (Ra) | 0.05 μm to 1.6 μm | ISO 4287 |

| Dimensional Tolerance | ±0.001 mm | ISO 2768-mK |

| Flatness | ≤ 0.0005 mm per 25 mm | ASME Y14.5 |

| Material Compatibility | Stainless Steel (316L, 17-4PH), Titanium (Gr5), Inconel 718, Aluminum 7075 | AMS, ASTM, EN |

| Max Component Size | Ø 650 mm x 1200 mm | Custom fixturing |

Beyond technical execution, we partner with your engineering team during DFM analysis to optimize part geometry for finish consistency, reducing post-processing iterations by up to 40%. Our facility in Wuxi operates 24/7 with dedicated cells for high-mix production, ensuring on-time delivery without sacrificing quality—even for urgent rework scenarios. Clients consistently achieve first-pass yield rates exceeding 98.5% through our closed-loop quality system, directly impacting your time-to-market and total cost of ownership.

The true measure of a manufacturing partner lies in their ability to solve problems you haven’t yet encountered. When surface integrity becomes a bottleneck in your supply chain, Lead Precision delivers engineered certainty. Initiate your precision journey with a technical consultation tailored to your component’s functional requirements. Contact our engineering team at [email protected] to submit specifications or request a finish capability assessment. Let us demonstrate how our process discipline transforms surface finish from a risk factor into your competitive advantage. Your critical components deserve nothing less than absolute precision—engineered, validated, delivered.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.