Technical Contents

Engineering Guide: Moulding Defects In Plastics

Engineering Insight: Addressing Moulding Defects in Plastics Through Precision Engineering

In high-performance industries such as aerospace, defense, and advanced medical systems, the integrity of plastic components is non-negotiable. Even minor moulding defects can compromise functionality, safety, and compliance. At Wuxi Lead Precision Machinery, we recognize that eliminating these defects begins not with post-production inspection, but with the precision of the metal tooling that shapes every part. Our expertise in custom metal manufacturing directly influences the quality and consistency of plastic injection moulding outcomes.

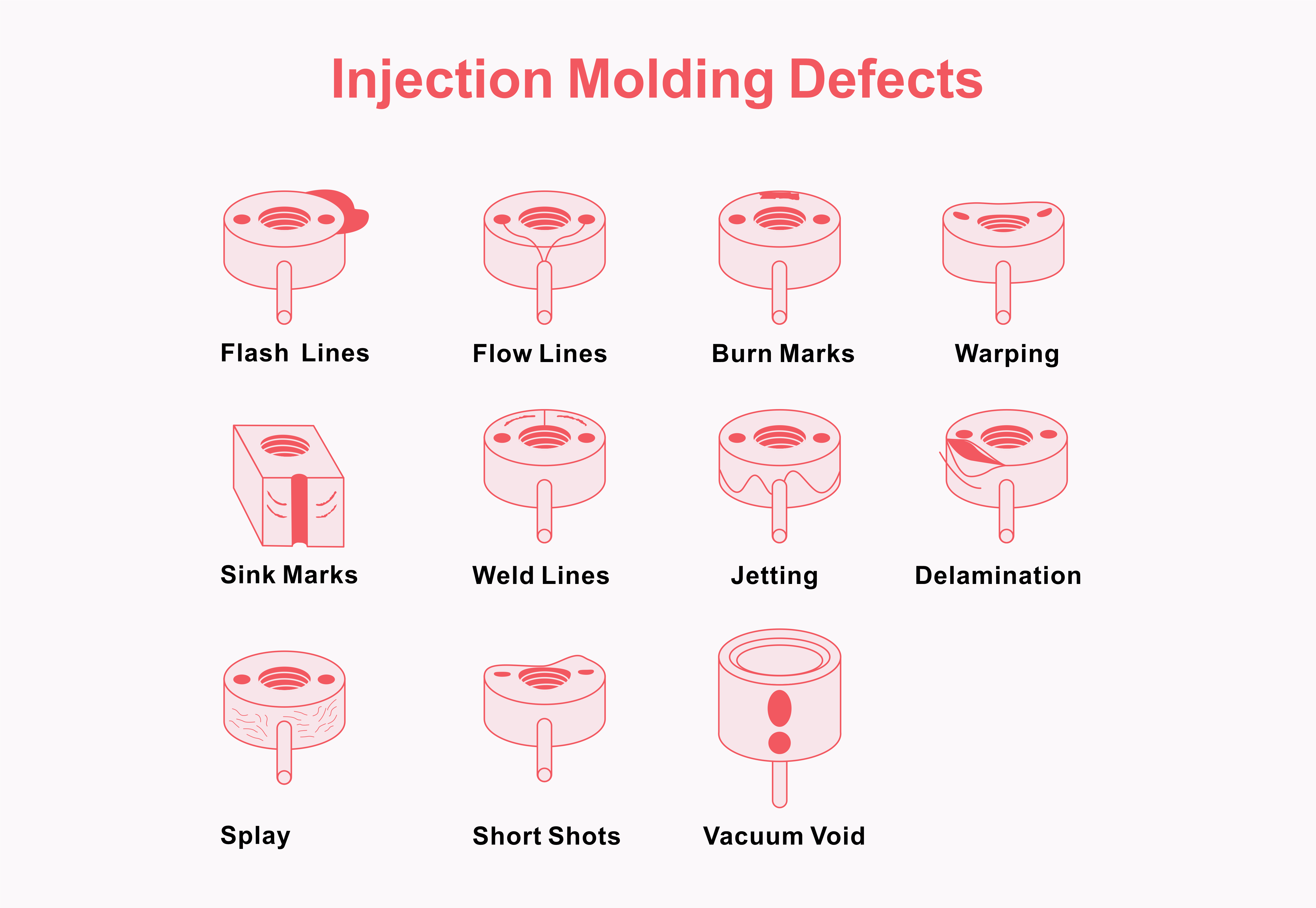

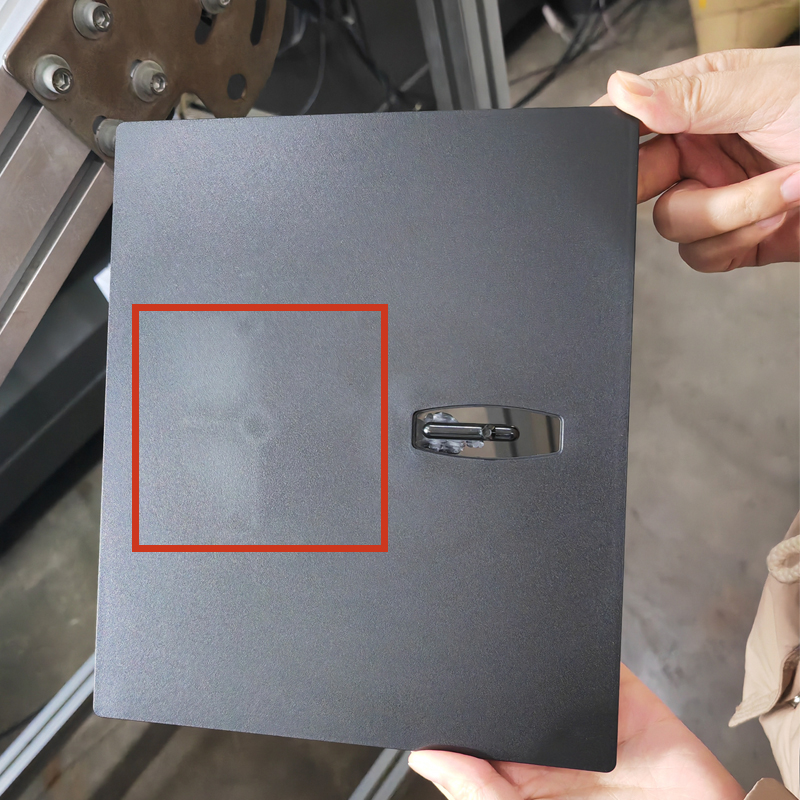

Moulding defects such as warping, sink marks, short shots, and flow lines are often symptomatic of underlying inconsistencies in mould design, thermal management, or material flow—issues rooted in the accuracy and durability of the mould itself. For instance, uneven cooling caused by poorly machined cooling channels leads to warpage, while inadequate venting due to imprecise cavity alignment can result in short shots or burn marks. These flaws are not merely cosmetic; in mission-critical applications, they can lead to component failure under stress or thermal load.

The root cause of many such defects lies in the tolerances and surface finishes of the mould tooling. At Lead Precision, we maintain machining tolerances down to ±0.002 mm and surface finishes reaching Ra 0.05 µm, ensuring uniform cavity replication and optimal release properties. Our CNC machining centers, operated by engineers with over 15 years of experience in high-stakes manufacturing, produce moulds that deliver consistent part geometry across production runs exceeding 500,000 cycles.

Our track record includes supplying precision tooling for components used in Olympic-grade sports equipment and military-grade communication housings—applications where failure is not an option. In these projects, the integration of advanced simulation software with ultra-precise metal fabrication allowed us to anticipate and eliminate potential defects before the first shot was moulded. This proactive engineering approach, grounded in material science and thermal dynamics, sets the standard for defect-free production.

Precision in mould manufacturing is not an incremental advantage—it is the foundation of reliability. By controlling variables at the metal stage, we enable our clients to achieve zero-defect output, reduce scrap rates, and meet stringent international quality benchmarks such as ISO 13485 and MIL-STD-810.

Below are the key specifications that define our mould production capabilities:

| Specification | Performance Value |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish (Cavity) | Ra 0.05 – 0.4 µm |

| Tool Life | Up to 1,000,000 cycles |

| Materials Used | P20, H13, S136, 718H, Stainless Steel, Aluminum |

| Cooling Channel Accuracy | ±0.01 mm |

| Lead Time (Standard Mould) | 25–35 days |

At Wuxi Lead Precision Machinery, we engineer not just components, but confidence—ensuring that every mould we deliver is a guarantee of performance, precision, and perfection in plastic manufacturing.

Precision Specs & Tolerances

Precision Metal Components for Defect-Free Plastic Moulding

Wuxi Lead Precision Machinery delivers critical metal solutions that directly eliminate root causes of plastic moulding defects. Our expertise in custom mould and die manufacturing ensures dimensional stability, thermal consistency, and surface integrity—addressing common failure points like sink marks, warpage, and flash at the source. By prioritizing micron-level accuracy in metal tooling, we prevent costly plastic part rejections and production downtime for global manufacturers.

Our 5-axis CNC machining centers form the backbone of this capability. Equipped with Siemens 840D controls and Heidenhain linear encoders, these systems achieve 0.001mm positional repeatability across complex geometries. This precision is non-negotiable for mould cavities, cores, and sliders where thermal expansion mismatches or micro-roughness directly translate to plastic part defects. We machine hardened P20, H13, and beryllium-copper alloys to mirror finishes (Ra 0.05µm) while maintaining tight tolerances on cooling channels—ensuring uniform heat dissipation critical for eliminating sink marks and internal stresses in plastic components.

Quality verification is integrated at every stage through Zeiss CONTURA CMM systems with 0.5µm volumetric accuracy. Unlike post-production spot checks, our in-process CMM inspections validate critical features during machining, including parting line alignment, ejector pin bores, and vent depths. This proactive approach identifies deviations before they propagate into moulding defects, such as flashing from mismatched shut-off surfaces or ejection marks from misaligned pins. All inspection data is traceable to ISO 17025 standards, providing full accountability for defect prevention.

The following table outlines our standard and enhanced tolerance capabilities for plastic injection mould components. These specifications directly correlate to defect mitigation—tighter control on critical zones minimizes common plastic part failures.

| Feature Category | Standard Tolerance | Enhanced Tolerance (Critical Zones) | Impact on Plastic Moulding Defects |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.025 mm | ±0.005 mm | Prevents warpage, shrinkage inconsistencies |

| Parting Line Match | ±0.015 mm | ±0.003 mm | Eliminates flash, reduces trimming costs |

| Cooling Channel Position | ±0.05 mm | ±0.01 mm | Ensures uniform cooling, avoids sink marks |

| Surface Roughness (Ra) | 0.2 µm | 0.05 µm | Reduces surface defects, improves part release |

| Ejector Pin Alignment | ±0.02 mm | ±0.005 mm | Prevents ejection marks, part deformation |

By engineering metal components to these exacting standards, Wuxi Lead transforms defect prevention from reactive troubleshooting to proactive design. Our integrated CNC and metrology workflow guarantees that every mould leaves our facility with the geometric and thermal stability required for high-yield plastic production. Partner with us to convert tooling precision into plastic part perfection—reducing scrap rates by up to 40% while accelerating time-to-market for demanding applications in automotive, medical, and consumer electronics.

Material & Finish Options

Material Selection for High-Precision Plastic Injection Moulds

The performance and longevity of plastic injection moulds are directly influenced by the choice of base material and surface treatment. At Wuxi Lead Precision Machinery, we prioritize material integrity and functional durability to minimize moulding defects such as warping, sink marks, and surface blemishes. The three primary metals used in custom mould fabrication—aluminum, steel, and titanium—each offer distinct mechanical and thermal properties suited to specific production demands.

Aluminum alloys, particularly 7075 and 6061 grades, are widely used for prototyping and low-to-medium volume production. Their high thermal conductivity ensures rapid and uniform cooling, reducing cycle times and minimizing thermal stress in the moulded part. Aluminum is also easier to machine, allowing for faster lead times and complex geometries. However, its lower hardness makes it more susceptible to wear in high-volume applications, potentially leading to flash or dimensional inaccuracies over time.

Tool steels such as P20, H13, and S136 are the standard for high-volume plastic injection moulds. These materials offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. Steel moulds maintain tight tolerances over millions of cycles, making them ideal for parts requiring high surface finish and consistency. While steel has lower thermal conductivity than aluminum, proper cooling channel design mitigates this limitation. Steel is also more resistant to corrosion when treated with appropriate coatings, reducing the risk of surface defects caused by moisture or chemical exposure.

Titanium alloys, though less common due to cost and machining complexity, are gaining attention for specialized applications requiring extreme corrosion resistance and lightweight strength. Titanium’s biocompatibility and inertness make it suitable for medical-grade plastic components where contamination must be avoided. However, its use is typically limited to niche, high-value production due to elevated material and processing costs.

Surface finishing, particularly anodizing, plays a critical role in enhancing mould performance. Anodizing aluminum increases surface hardness and wear resistance while improving release properties, reducing the need for mould release agents that can cause surface defects. Hard anodizing, in particular, forms a thick, durable oxide layer that resists abrasion and chemical attack. For steel and titanium, alternative treatments such as chrome plating, nitriding, or PVD coatings are often preferred due to material compatibility.

The following table summarizes key mechanical and thermal properties of common mould materials:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | 570 | Prototypes, low-volume runs |

| P20 Steel | 28–32 | 30 | 980 | Medium-to-high volume moulds |

| H13 Steel | 48–52 | 36 | 1,600 | High-stress, high-temp moulds |

| Titanium Ti-6Al-4V | 36–40 | 7 | 900 | Corrosion-resistant applications |

Material selection must balance production volume, part complexity, and environmental conditions. At Wuxi Lead Precision Machinery, we conduct comprehensive material analysis to ensure optimal mould performance and defect reduction across all plastic manufacturing processes.

Manufacturing Process & QC

Precision-Engineered Pathway to Zero Defects in Plastic Molding

Achieving zero defects in plastic injection molding demands a rigorously controlled production process, starting long before the first pellet enters the hopper. At Wuxi Lead Precision Machinery, we integrate advanced metal manufacturing expertise with deep polymer science understanding to eliminate common defects like sink marks, warpage, flash, and short shots at their source. Our methodology transforms the standard Design → Prototyping → Mass Production sequence into a closed-loop defect prevention system, ensuring dimensional stability and surface perfection for mission-critical components.

The foundation is laid during the Design phase, where 80% of potential defects originate. We conduct exhaustive Design for Manufacturability (DFM) analysis, scrutinizing part geometry, wall thickness transitions, and gate locations using Moldex3D simulation. This identifies stress concentrations and cooling imbalances that cause warpage or sink. Our engineers collaborate closely with clients to optimize rib design, eliminate sharp corners, and specify precise draft angles, ensuring the metal mold cavity and core—crafted from hardened H13 or S136 steel—will replicate the intended geometry without distortion. Material selection is validated against thermal properties and flow characteristics to prevent degradation or inconsistent filling.

Prototyping is not merely a validation step but a critical process calibration exercise. Using the actual production-grade mold manufactured in our facility, we run iterative trials under controlled parameters. Each prototype undergoes full metrology via CMM and optical scanning against CAD nominal data, measuring critical dimensions to ±0.02mm. We analyze weld lines, air traps, and packing pressure effects in real-time, adjusting cooling channel layouts or venting in the metal tool before mass production begins. This phase confirms that the mold’s thermal management system—precision-machined with conformal cooling channels—delivers uniform solidification, directly preventing internal stresses.

Mass Production execution relies on systemic process control, not operator intuition. Our automated cells implement Statistical Process Control (SPC) with real-time cavity pressure monitoring, ensuring shot-to-shot consistency. Each cycle is validated against the golden sample established during prototyping. In-process inspection stations use AI-powered vision systems to detect surface blemishes or dimensional drift within milliseconds, triggering automatic process correction. Preventive maintenance schedules for the mold, based on actual cycle counts and wear analysis, maintain tight tolerances indefinitely. This integrated approach guarantees that every part meets stringent automotive or medical standards, with scrap rates consistently below 0.1%.

Critical Defect Prevention Metrics in Production

| Defect Type | Root Cause in Metal Tooling | Wuxi Lead Prevention Method | Tolerance Standard |

|---|---|---|---|

| Warpage | Non-uniform cooling, ejector imbalance | Conformal cooling channels, balanced ejection force | ±0.05mm flatness |

| Sink Marks | Inadequate packing, thick sections | Optimized gate size/position, pressure profiling | Surface deviation < 0.1mm |

| Flash | Poor cavity/core alignment, wear | HRC 52+ hardened steel, hydraulic clamp monitoring | Parting line gap < 0.01mm |

| Short Shot | Insufficient venting, flow restriction | Precision vent depth (0.015-0.025mm), optimized runner system | Fill consistency 99.8% |

This seamless transition from virtual design to flawless volume production—underpinned by our precision metal tooling and process discipline—ensures clients achieve true zero-defect output. Wuxi Lead transforms molding defect prevention from an aspiration into a measurable, sustainable manufacturing reality.

Why Choose Wuxi Lead Precision

When it comes to precision manufacturing in the plastic moulding industry, even the smallest defect can compromise the integrity, performance, and appearance of a final product. At Wuxi Lead Precision Machinery, we understand that achieving flawless plastic components requires more than advanced equipment—it demands engineering expertise, rigorous process control, and a deep understanding of material behaviour. As a leading provider of custom metal manufacturing solutions based in China, we specialize in designing and producing high-precision moulds that eliminate common plastic moulding defects such as warping, sink marks, flow lines, short shots, and flash.

Our engineering team leverages decades of experience in die-casting and precision machining to deliver mould solutions that ensure consistent part quality, reduced cycle times, and minimal waste. By integrating advanced simulation software with real-world testing, we identify potential defects during the design phase and optimize mould geometry, gating systems, cooling channels, and ejection mechanisms accordingly. This proactive approach not only enhances product reliability but also significantly reduces costly trial-and-error iterations during production.

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem. From raw material selection to final inspection, every stage is monitored under strict ISO-certified quality protocols. Our facility is equipped with state-of-the-art CNC machining centres, wire EDM, surface grinders, and 3D metrology systems, enabling us to produce moulds with tolerances as tight as ±0.002 mm. Whether you are developing automotive components, medical devices, or consumer electronics, our custom solutions are engineered to meet the most demanding specifications.

We serve global clients across Europe, North America, and Southeast Asia, providing not just components but long-term manufacturing partnerships. Our commitment to innovation, quality, and on-time delivery has made us a trusted supplier to tier-one manufacturers who require zero-defect performance.

Below are key technical capabilities that define our precision mould manufacturing process:

| Specification | Detail |

|---|---|

| Maximum CNC Milling Size | 1200 × 800 × 650 mm |

| Positioning Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 μm |

| Materials Processed | P20, 718, H13, S136, 420 Stainless Steel, Aluminum Alloys |

| Mould Life Expectancy | Up to 1,000,000 cycles (depending on design and material) |

| Lead Time (Average) | 25–35 days from design approval |

| Quality Standards | ISO 9001:2015 certified, Full inspection reports provided |

If you are facing persistent challenges with plastic moulding defects and require a reliable, high-precision moulding partner, we invite you to contact us today. Our engineering team is ready to review your project requirements, provide technical consultation, and deliver a custom solution that ensures defect-free production at scale.

For expert support and precision manufacturing excellence, contact us at [email protected]. Let Wuxi Lead Precision Machinery be your strategic partner in achieving superior moulding performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.