Technical Contents

Engineering Guide: Mould Tools

Engineering Insight: The Critical Role of Precision in Mould Tools

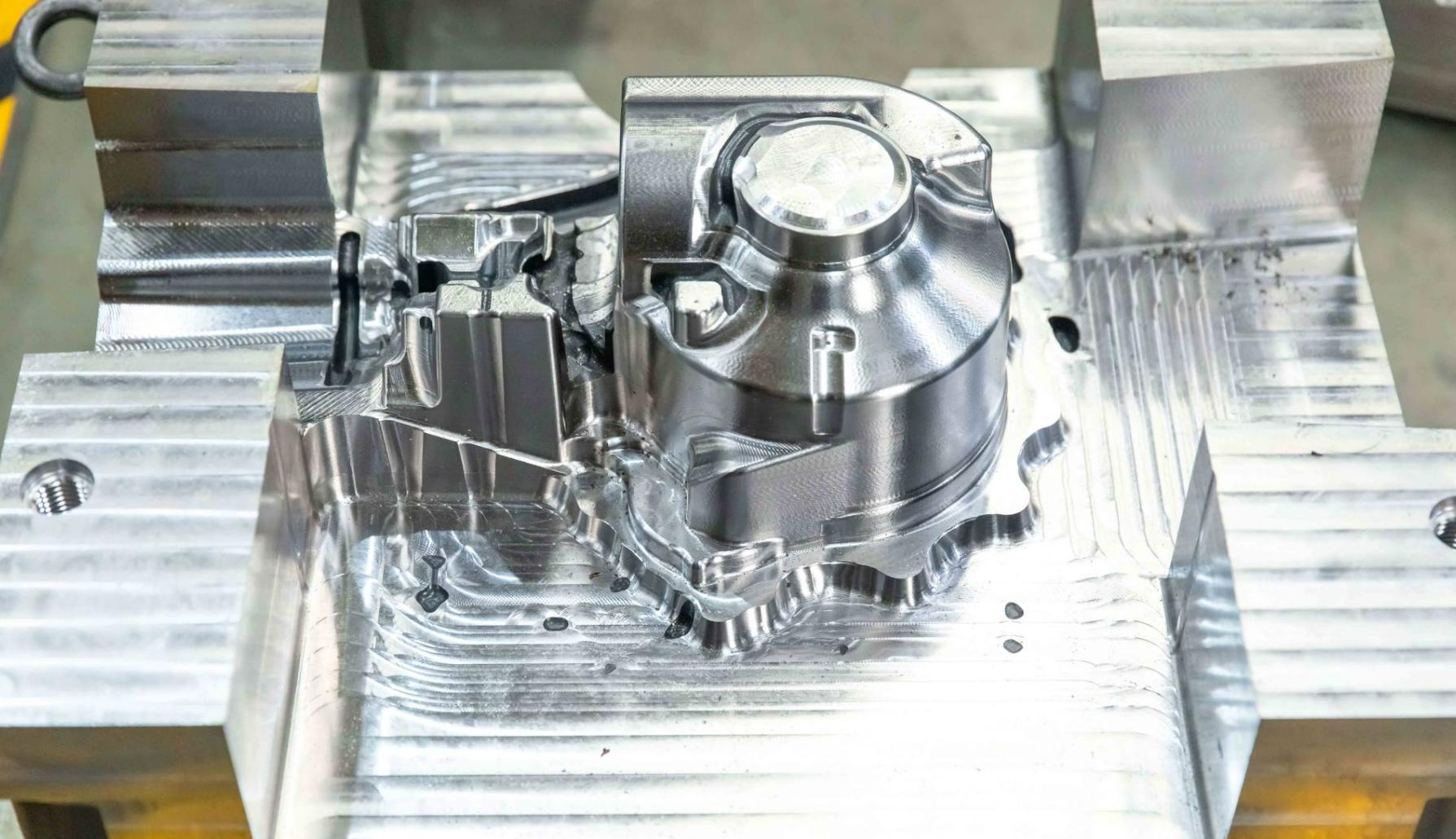

In the realm of custom metal manufacturing, mould tools serve as the foundational element in producing high-integrity components across aerospace, defense, medical, and high-performance industrial sectors. These tools, which shape molten or semi-solid materials into precise geometries, must meet exacting dimensional tolerances and surface finish requirements to ensure the repeatability and reliability of end products. At Wuxi Lead Precision Machinery, we recognize that precision in mould tool engineering is not merely a technical benchmark—it is a commitment to performance, safety, and long-term value.

The performance of a mould tool directly influences the quality, consistency, and lifecycle of the parts it produces. Even micron-level deviations can result in part failure, assembly misalignment, or accelerated tool wear—issues that compound rapidly in high-volume or mission-critical applications. This is why our engineering approach integrates advanced CNC machining, finite element analysis (FEA), and rigorous metrology protocols throughout the design and manufacturing cycle. Every cavity, core, ejector pin, and cooling channel is optimized for thermal stability, wear resistance, and dimensional accuracy.

Our experience in delivering mould tools for Olympic-grade equipment and military-grade hardware underscores this commitment. These projects demand absolute reliability under extreme conditions, where failure is not an option. For instance, components used in precision-guided systems or high-stress sporting equipment require materials and geometries that can withstand dynamic loads and environmental fluctuations. Our team leverages high-grade tool steels such as H13, S136, and PM-3V, combined with selective surface treatments like nitriding and PVD coating, to ensure durability and performance over thousands of cycles.

At Lead Precision, we also prioritize design-for-manufacturability (DFM) consultations at the outset of every project. This proactive collaboration allows us to identify potential challenges in part ejection, venting, or cooling efficiency before tool fabrication begins—reducing lead times and minimizing costly iterations. Our in-house capabilities span from 3D modelling and simulation to five-axis machining and automated quality inspection, ensuring seamless execution from concept to final validation.

The following table outlines key specifications and capabilities that define our mould tool offerings:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm (mirror polish available) |

| Maximum Tool Weight | 10,000 kg |

| Materials Supported | H13, S136, 420SS, P20, PM-3V, Maraging Steel |

| Machining Axes | Up to 5-axis simultaneous |

| Cooling Channel Design | Conformal cooling via DED (Direct Energy Deposition) |

| Quality Assurance | CMM, 3D scanning, cavity pressure monitoring |

| Industry Standards Complied | ISO 9001, AS9100, MIL-STD-810 |

Precision in mould tools is not an incremental advantage—it is the cornerstone of manufacturing excellence. With a proven track record in some of the most demanding applications, Wuxi Lead Precision Machinery continues to set the standard for reliability, innovation, and technical mastery in custom metal manufacturing.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Mould Tool Manufacturing

At Wuxi Lead Precision Machinery, our core strength in custom metal manufacturing for high-integrity mould tools stems from integrated precision engineering and rigorous quality validation. We specialize in transforming complex designs into dimensionally stable, production-ready components where micron-level accuracy directly impacts mould longevity and part consistency. This capability is non-negotiable for clients in automotive, medical, and consumer electronics sectors demanding zero-defect tooling.

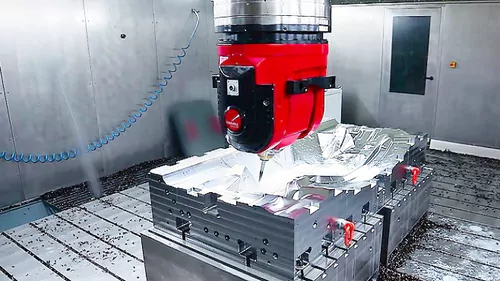

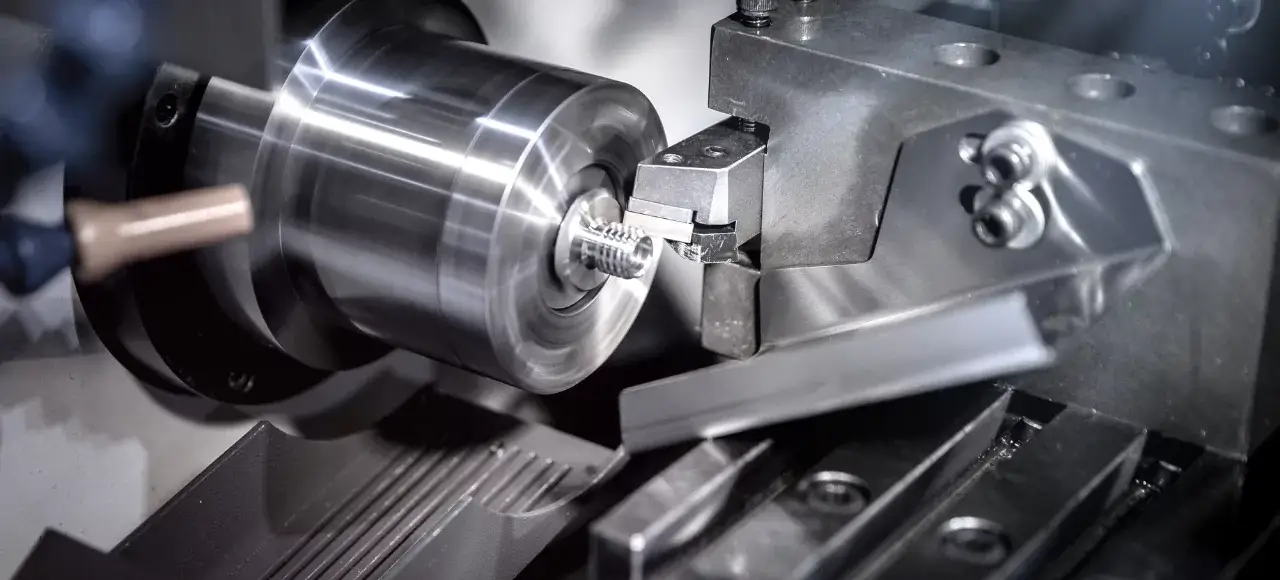

Our technical foundation is built upon a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems enable simultaneous multi-directional toolpath interpolation, critical for machining intricate core/cavity geometries, undercuts, and conformal cooling channels in a single setup. This eliminates cumulative error from multiple fixturing stages, significantly enhancing geometric accuracy while reducing lead times. We utilize machines equipped with high-resolution linear glass scales, thermal compensation systems, and rigid spindles capable of maintaining sub-micron positional stability during extended production runs. Material versatility spans hardened tool steels (P20, H13, S7), stainless grades, aluminum alloys, and specialized composites, all machined to exacting surface integrity standards required for optimal release and wear resistance.

Quality assurance is not a final checkpoint but an embedded process. Every critical dimension undergoes validation via our coordinate measuring machine (CMM) network, featuring high-precision tactile and optical probes. Our Zeiss and Hexagon CMMs operate within a climate-controlled metrology lab (20°C ±0.5°C), ensuring environmental stability for repeatable measurements. Full first-article inspection reports (FAIR) and production lot verification are standard, with data traceable to NIST standards. Statistical process control (SPC) methodologies are applied to monitor capability indices (Cp/Cpk), providing clients with quantifiable confidence in dimensional repeatability.

The following table details our standard achievable tolerance specifications for mould tool components, validated through our CMM processes and representative of our production capability under controlled conditions:

| Specification Category | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions (up to 500mm) | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | CMM |

| Geometric Tolerances (Flatness, Straightness) | 0.015 mm/m (0.0006″/ft) | 0.005 mm/m (0.0002″/ft) | CMM / Laser Tracker |

| Positional Accuracy (Holes, Features) | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) | CMM |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.4 μm (16 μin) | Profilometer |

| Angular Tolerances | ±0.005° | ±0.002° | CMM / Optical Comparator |

These capabilities are systematically applied across the entire mould tool lifecycle, from prototype validation to high-volume production tooling. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry for precision machining, ensuring the final tool meets stringent functional requirements while maximizing cost efficiency. This commitment to measurable precision and transparent quality data underpins Wuxi Lead’s reputation for delivering mould tools that consistently exceed industry performance benchmarks and accelerate time-to-market for your end products.

Material & Finish Options

Material selection is a critical factor in the performance, longevity, and cost-efficiency of mould tools used in high-precision manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions tailored to meet the demanding requirements of industries such as automotive, aerospace, and consumer electronics. The choice between aluminum, steel, and titanium depends on application-specific factors including strength, thermal conductivity, wear resistance, and production volume.

Aluminum is widely used for prototype and low-to-medium volume production moulds due to its excellent machinability and high thermal conductivity. It allows for faster cooling cycles, reducing overall production time. Aluminum alloys such as 7075 and 6061 offer a favorable strength-to-weight ratio, making them ideal for applications where weight reduction is essential. However, aluminum’s lower hardness compared to steel makes it less suitable for high-volume runs or abrasive materials.

Steel remains the standard for high-volume production moulds, particularly when durability and surface finish are paramount. Tool steels like P20, H13, and S136 provide superior hardness, wear resistance, and thermal stability. These properties ensure long service life even under repeated thermal cycling and high-pressure conditions. While steel is slower to machine and heavier than aluminum, its longevity and ability to maintain tight tolerances over thousands of cycles justify its use in mass production environments.

Titanium, though less common in mould tooling, offers exceptional strength-to-density ratio and corrosion resistance. It is typically reserved for specialized applications in aerospace or medical manufacturing where extreme environmental conditions exist. Its high cost and challenging machinability limit widespread adoption, but for niche high-performance tools, titanium delivers unmatched reliability.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional properties of mould tools—especially those made from aluminum. Anodizing increases surface hardness, improves wear resistance, and provides electrical insulation. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, more durable coatings suitable for high-stress environments. Anodized layers also allow for color coding, aiding in tool identification and quality control on the production floor.

Below is a comparative overview of key material properties relevant to mould tool applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum 7075 | 500–570 | 15–20 | 130 | Prototypes, low-volume tools | Excellent |

| P20 Steel | 900–1100 | 28–32 | 30 | High-volume moulds | Not applicable |

| H13 Steel | 1300–1600 | 45–50 | 25 | Die casting, hot forming | Not applicable |

| Titanium Grade 5 | 900–1000 | 35–40 | 7 | Aerospace, medical tools | Good (Type II) |

Selecting the optimal material and finish requires a balance between performance requirements and economic feasibility. Wuxi Lead Precision Machinery supports clients in making informed decisions through engineering consultation and precision manufacturing capabilities.

Manufacturing Process & QC

Precision Mould Tool Production: The Zero Defect Pathway

At Wuxi Lead Precision Machinery, we recognize that exceptional mould tools are the foundation of flawless end-part production. Our rigorously controlled production process, spanning Design through Mass Production, is engineered for Zero Defects from inception. This systematic approach eliminates costly iterations and ensures your tool delivers consistent, high-integrity parts meeting the most demanding specifications.

The journey begins with Advanced Design & Simulation. Our engineering team collaborates closely with your design data, conducting comprehensive Design for Manufacturability (DFM) analysis. Critical factors including material flow, cooling efficiency, ejection dynamics, and structural integrity are validated using industry-leading 3D simulation software. This phase identifies potential weaknesses – sink marks, warpage, or fill issues – before metal is cut. Thermal compensation algorithms are applied to the digital model, accounting for expected tool expansion during operation, ensuring geometric accuracy at running temperature. Precise material selection based on part volume, resin type, and surface finish requirements is finalized here, forming the bedrock of tool longevity.

Rigorous Prototyping & Validation follows the design freeze. We manufacture a fully functional prototype tool using the same hardened tool steels and precision processes intended for the production tool. This is not merely a form check; it is a comprehensive functional test under simulated production conditions. The prototype undergoes extensive trial runs on our dedicated press lines, validating cycle times, part ejection, cooling performance, and critical dimensions against your CAD data. Every parameter is meticulously measured and recorded. Any deviation triggers immediate root cause analysis and targeted design or process refinement. Only when the prototype consistently produces parts within specification, demonstrating process stability, does the design progress. This phase is non-negotiable for achieving Zero Defects in volume.

Controlled Mass Production leverages the validated prototype data. Our state-of-the-art CNC machining centers, including 5-axis milling and precision grinding, execute the manufacturing with micron-level accuracy. Real-time in-process inspection using calibrated CMMs and optical comparators monitors critical features at defined checkpoints. Statistical Process Control (SPC) is embedded throughout, tracking key parameters like cavity dimensions, core alignment, and surface finish. Final assembly occurs in a climate-controlled environment, with meticulous attention to fit, function, and lubrication. Full tool validation includes pressure mapping, thermal imaging, and a comprehensive production trial run, certifying the tool meets all performance and quality criteria before shipment. Continuous monitoring during your initial production runs ensures seamless transition and sustained Zero Defect output.

Mould Tool Production Phase Specifications

| Phase | Key Activities | Validation Metrics & Tolerances |

|---|---|---|

| Design & Simulation | DFM Analysis, 3D Flow/Cooling Simulation, Thermal Compensation, Material Specification | Simulation accuracy ±2%, Dimensional tolerance adherence to CAD ±0.005mm |

| Prototyping & Validation | Prototype Tool Build, Press Trials, Parameter Optimization, Root Cause Analysis | Part dimensional accuracy ±0.01mm, Process capability CpK ≥1.33, Zero functional defects |

| Mass Production | Precision CNC Machining, In-Process SPC, Climate-Controlled Assembly, Full Tool Validation | Critical feature tolerance ±0.002mm, Surface finish Ra ≤0.2µm, Final part CpK ≥1.67 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Mould Tool Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance manufacturing. As a trusted leader in custom metal manufacturing based in Wuxi, China, we specialize in the design and production of advanced mould tools engineered to meet the exacting standards of global industries including automotive, aerospace, medical devices, and consumer electronics. When you partner with us, you gain more than a supplier — you align with a team of engineers and technicians committed to delivering excellence at every stage of production.

Our advanced CNC machining centers, combined with rigorous quality control protocols, enable us to produce mould tools with micron-level accuracy and superior surface finishes. We work with a wide range of materials, including hardened steels, aluminum alloys, and specialty tool steels, ensuring optimal performance under demanding operational conditions. Whether you require single-cavity prototypes or multi-cavity production tools, our engineering team collaborates closely with your design specifications to deliver solutions that enhance efficiency, reduce cycle times, and extend tool life.

We pride ourselves on transparency, responsiveness, and technical agility. From initial concept review to final inspection and global logistics, our project management framework ensures seamless communication and on-time delivery. Our ISO 9001-certified processes and in-house metrology lab provide full traceability and compliance with international standards. This disciplined approach has made us a preferred partner for OEMs and Tier-1 suppliers across North America, Europe, and Asia.

Below are key technical specifications that define our mould tool capabilities:

| Specification | Detail |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 1000 mm |

| Tolerance Range | ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm (polished & textured) |

| Materials Supported | P20, 718H, S136, H13, NAK80, Aluminum 7075/6061, Stainless Steel |

| Electrode Machining | Graphite & Copper (high-speed EDM compatibility) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports |

| Lead Time (Typical) | 15–25 days, depending on complexity |

Our commitment to innovation extends beyond machining. We integrate mold flow analysis, thermal simulation, and DFM (Design for Manufacturability) reviews to optimize performance before tool fabrication begins. This proactive engineering approach minimizes risk, reduces iterations, and accelerates time to market.

For manufacturers seeking a strategic partner in precision mould tool development, Wuxi Lead Precision Machinery delivers the technical depth, operational scale, and global service required to succeed in today’s competitive landscape. Contact us today to discuss your next project.

Email us at [email protected] and let our engineering team provide a customized solution tailored to your production goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.