Technical Contents

Engineering Guide: Mould Decoration

Engineering Insight Precision Imperatives in Mould Decoration

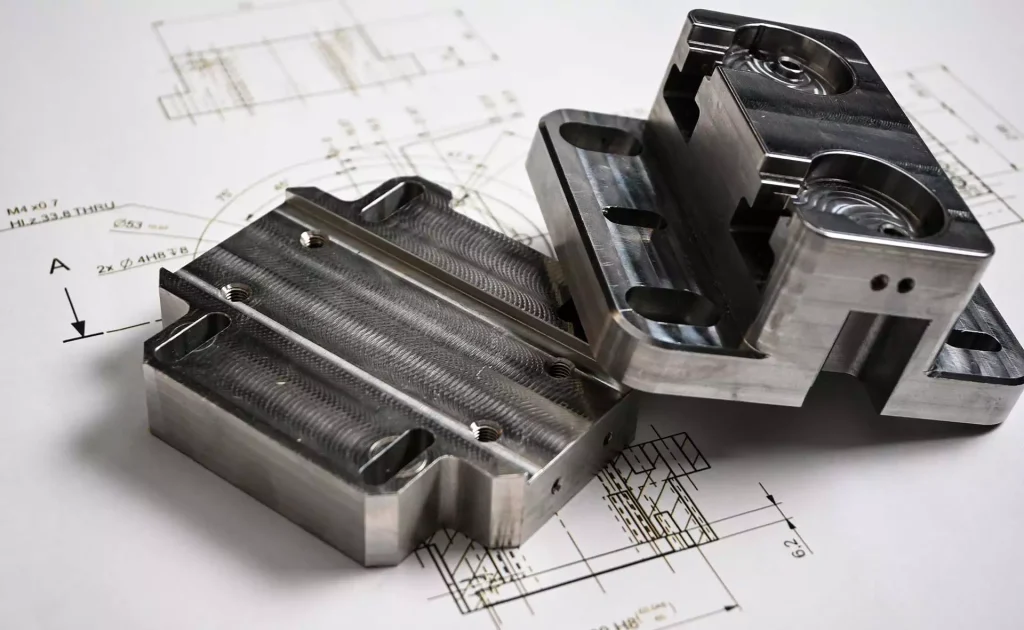

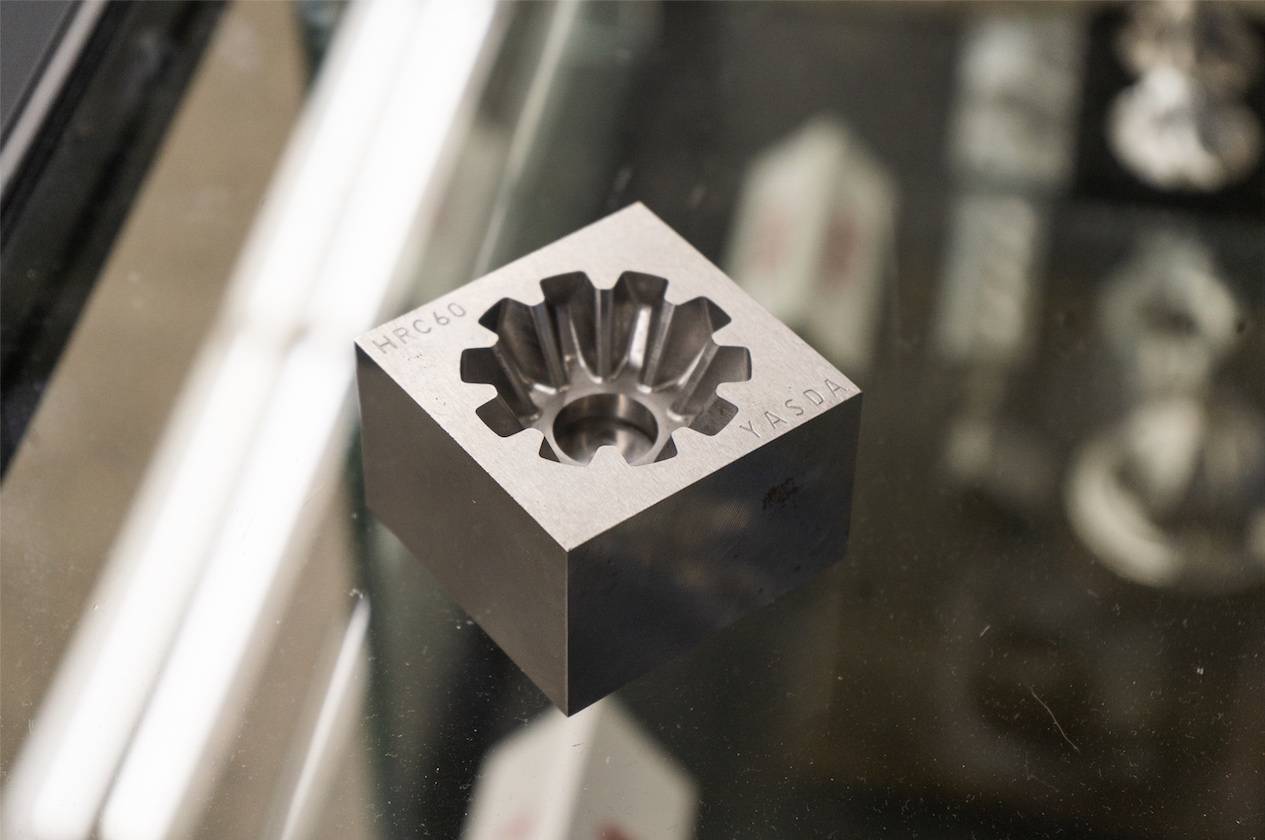

Mould decoration transcends mere aesthetic enhancement; it is a critical precision engineering process defining the functional integrity and market value of high-end metal components. Within custom metal manufacturing, the fidelity of the decoration pattern directly impacts part performance, assembly compatibility, and end-user perception. Achieving flawless results demands micron-level control over every machining parameter. Surface finish consistency, dimensional accuracy of engraved features, and absolute repeatability across production runs are non-negotiable. Variations exceeding tolerances as tight as ±0.005mm introduce defects like inconsistent texture depth, pattern misalignment, or compromised sealing surfaces, leading to part rejection, costly rework, and supply chain disruption. The complexity intensifies with intricate geometries, deep cavities, or demanding materials like hardened tool steels and exotic alloys common in aerospace and defense applications.

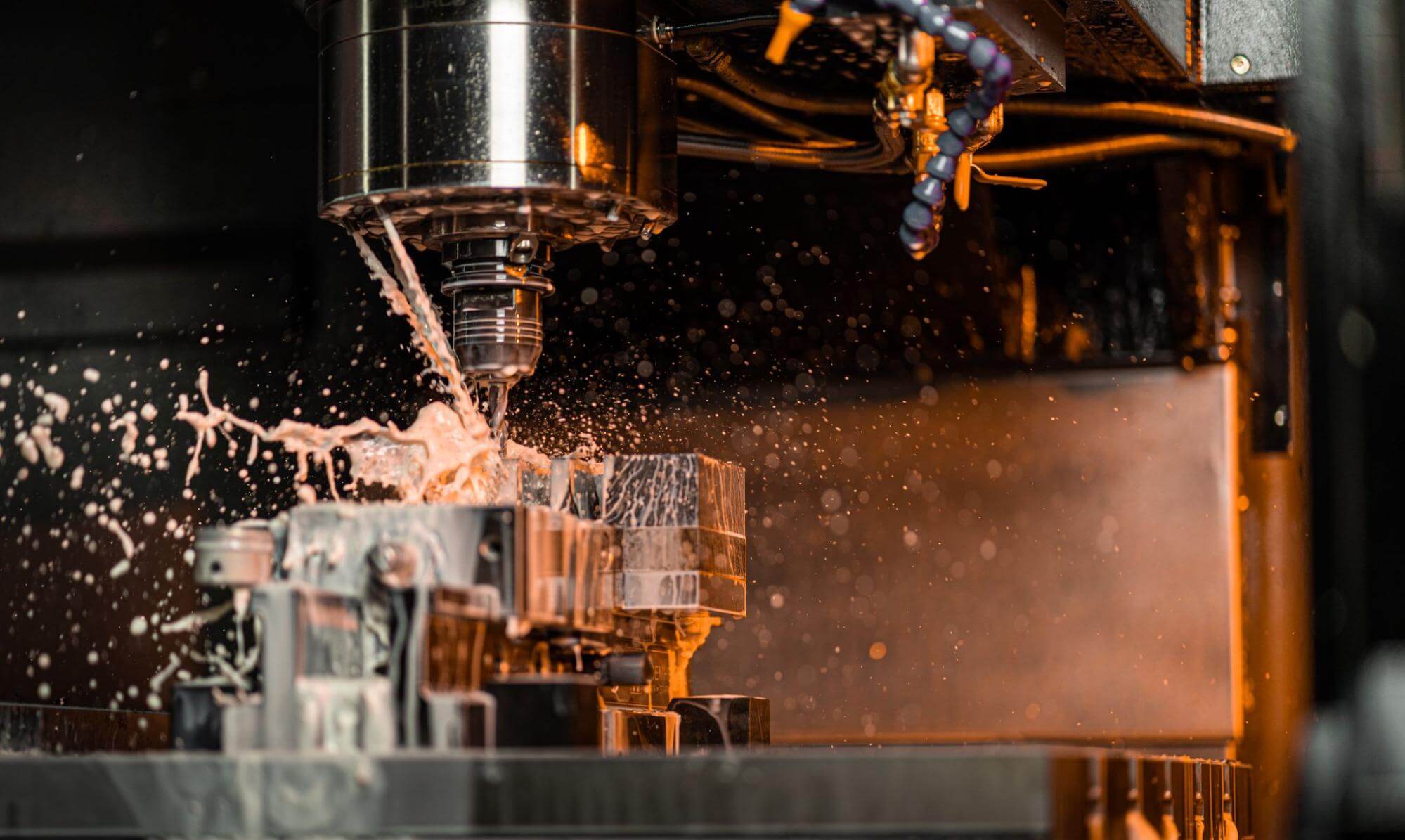

At Wuxi Lead Precision Machinery, we treat mould decoration as a core precision engineering discipline, not a superficial finishing step. Our approach integrates advanced 5-axis CNC milling, high-frequency micro-machining centers, and proprietary toolpath optimization software. This technological foundation, combined with rigorous metrology using coordinate measuring machines (CMMs) and optical comparators, ensures every decorative element meets exacting specifications. Our engineering protocols mandate in-process verification at critical stages, preventing deviations before they propagate through the production cycle. This systematic focus on precision minimizes scrap rates, guarantees batch-to-batch uniformity, and delivers the surface integrity required for subsequent processes like plating or coating adhesion.

Our commitment to precision is validated through demanding real-world applications. We have successfully engineered and manufactured decorated mould components for official Olympic equipment, where surface consistency directly influenced athletic performance metrics and global brand representation. Similarly, our precision decoration capabilities meet stringent military specifications (MIL-STD), producing components where pattern accuracy is integral to thermal management, electromagnetic shielding, or ergonomic functionality under extreme operational conditions. This experience underscores our ability to deliver when failure is not an option.

The technical specifications achievable through our dedicated mould decoration process are foundational to this reliability:

| Key Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Feature Tolerance | ±0.010 mm | ±0.003 mm | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| Pattern Depth Control | ±0.015 mm | ±0.005 mm | CMM / Depth Gauge |

| Repeatability (CpK) | ≥1.33 | ≥1.67 | Statistical Process Ctrl |

| Material Hardness Max | HRC 52 | HRC 60 | Rockwell Hardness Tester |

Precision in mould decoration is the cornerstone of premium metal component manufacturing. It transforms aesthetic requirements into engineered specifications, ensuring functional reliability and brand excellence. Wuxi Lead Precision Machinery leverages decades of advanced CNC engineering expertise and proven success in the most rigorous sectors to deliver decorated moulds where every micron matters. Partner with us to convert your decorative vision into a precision-engineered reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with a specialized focus on precision components for mould decoration applications. Our expertise lies in producing intricate, high-tolerance parts essential for the moulding industry, where surface finish, dimensional accuracy, and repeatability are critical. Utilizing state-of-the-art 5-axis CNC machining centers, we achieve complex geometries and tight tolerances that standard 3-axis systems cannot match. This multi-axis capability allows for continuous machining from multiple angles in a single setup, reducing lead times, minimizing human error, and ensuring superior part consistency.

Our 5-axis CNC systems are equipped with high-speed spindles and advanced control software, enabling precise tool path execution for sculpted surfaces, undercuts, and deep cavities commonly found in mould decoration tooling. Materials such as hardened steels, aluminum alloys, copper alloys, and specialty tool steels are routinely machined to meet the demanding requirements of injection moulds, compression moulds, and decorative surface inserts. The ability to maintain tight tolerances across complex contours ensures optimal fit and function during assembly and production use.

Quality control is fully integrated into our manufacturing workflow. Every critical component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring that all dimensions conform to engineering specifications. Our CMM systems provide full 3D metrology reports, traceable to international standards, allowing for complete quality documentation and process validation. This level of inspection is particularly vital in mould decoration, where minor deviations can impact the aesthetic quality of the final product or lead to premature tool wear.

In addition to machining and inspection, we employ stringent environmental controls and calibration protocols to maintain machine accuracy over time. Our technicians are trained in advanced CNC programming and GD&T (Geometric Dimensioning and Tolerancing), ensuring that design intent is fully realized in the final component. With a focus on continuous improvement and process optimization, Wuxi Lead Precision Machinery maintains a high first-pass yield rate, reducing rework and accelerating time-to-market for our clients.

The following table outlines typical machining tolerances achievable under standard production conditions:

| Feature | Standard Tolerance | High-Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.008 mm |

| Positional Tolerance | ±0.015 mm | ±0.01 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for high-end mould decoration projects requiring precision, reliability, and repeatable quality.

Material & Finish Options

Material Selection for Precision Mould Decoration Components

Selecting the optimal material for mould decoration components is critical to achieving dimensional stability, surface finish quality, and extended tool life under demanding production cycles. The thermal properties, hardness, and machinability of the base material directly impact decoration adhesion, cycle time efficiency, and resistance to wear or deformation. At Wuxi Lead Precision Machinery, our production data consistently shows material choice as the primary factor influencing defect rates in high-volume decoration processes. Understanding the specific demands of your application—prototype validation, medium-run production, or extreme high-volume tooling—is essential for informed selection.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer exceptional thermal conductivity and ease of machining. This makes them ideal for rapid prototyping and lower-volume production runs where quick heat dissipation accelerates cycle times and reduces energy costs. However, their lower hardness compared to steel limits longevity in high-abrasion decoration processes involving hard inks or frequent part ejection. Surface treatments like hard anodizing become crucial to enhance wear resistance for aluminum mould bases. Steel, specifically pre-hardened grades like P20 or H13 tool steel, provides superior hardness and wear resistance essential for high-volume, long-life tooling. Its lower thermal conductivity requires careful thermal management design but ensures dimensional stability over millions of cycles, especially critical for intricate decoration patterns demanding micron-level precision. Titanium alloys, while offering outstanding strength-to-weight ratio and corrosion resistance, present significant machining challenges and higher costs. Their use is typically reserved for highly specialized aerospace or medical applications where weight savings or extreme chemical resistance outweigh production complexity; standard mould decoration rarely justifies titanium due to cost and processing difficulties.

Anodizing is the dominant surface finish for aluminum mould components in decoration applications. This electrochemical process creates a durable, porous oxide layer that significantly enhances surface hardness, wear resistance, and corrosion protection. Crucially, the controlled porosity allows for effective dyeing, enabling precise color matching for mould identification or specific aesthetic requirements in the decoration process itself. Type II (sulfuric acid) anodizing is standard for decorative and moderate wear applications, while Type III (hard coat) anodizing provides maximum abrasion resistance for critical contact surfaces. Proper sealing after dyeing is non-negotiable to ensure colorfastness and corrosion resistance during production. Note that anodizing is specific to aluminum; steel components require alternative finishes like nitriding or specialized coatings.

Key material properties guide optimal selection for mould decoration tooling:

| Material | Thermal Conductivity (W/mK) | Hardness (HRC) | Cost Factor | Best For |

|---|---|---|---|---|

| Aluminum 7075 | 130 | 15-20 | Low | Prototypes, low-medium volume, fast cycles |

| P20 Tool Steel | 30 | 28-32 | Medium | Medium-high volume, general decoration |

| H13 Tool Steel | 25 | 45-50 | High | High-volume, high-wear decoration tooling |

Selecting the right material-finishing combination prevents premature tool failure and ensures consistent decoration quality. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to match material properties precisely to your decoration throughput and quality targets, minimizing total cost of ownership. Consult our engineering team for application-specific validation.

Manufacturing Process & QC

The journey of mould decoration in custom metal manufacturing begins with a precise and collaborative design phase. At Wuxi Lead Precision Machinery, we initiate this process by engaging directly with the client to understand functional requirements, aesthetic goals, and environmental conditions the final component will face. Using advanced CAD/CAM software, our engineering team develops 3D models that integrate both form and function, ensuring compatibility with downstream manufacturing stages. Finite element analysis (FEA) and mould flow simulation are applied to predict material behavior, minimize stress points, and optimize gate locations for uniform filling. This digital validation ensures that design integrity is maintained before any physical prototype is produced.

Once the digital model is approved, we transition to prototyping—a critical checkpoint in our zero-defect strategy. Utilizing high-precision CNC machining and EDM (Electrical Discharge Machining), we fabricate prototype moulds from tool steel or aluminum, depending on expected cycle life and surface finish requirements. These prototypes are used to produce initial sample parts, typically within 10 to 15 days from design approval. Each sample undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, part consistency, and surface texture are verified against the original specifications. Any deviations trigger an immediate design or process adjustment, ensuring full compliance before mass production begins.

Mass production is executed on fully automated, closed-loop monitored injection moulding lines, where real-time data collection ensures process stability. Our mould decoration process integrates in-mould labelling (IML) or in-mould decoration (IMD), allowing for high-resolution graphics, textures, and functional coatings to be applied during the injection cycle. This eliminates secondary operations, reduces handling damage, and ensures perfect alignment and adhesion. Each production run is governed by Statistical Process Control (SPC), with continuous monitoring of pressure, temperature, and cycle time. Every 50th part is inspected automatically via vision systems, and batch traceability is maintained through serialized data logging.

Our zero-defect commitment is enforced through a multi-stage quality gate system. From raw material certification to final packaging, every step is documented and auditable. Non-conforming parts are isolated instantly, and root cause analysis is performed using 8D methodology. This disciplined approach ensures that only components meeting the highest standards leave our facility.

The following table outlines key specifications and capabilities in our mould decoration production process:

| Parameter | Specification |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Brass, Titanium |

| Tolerance Range | ±0.005 mm |

| Surface Finish Options | Mirror polish, EDM texture, PVD coating, IML |

| Mould Life | 500,000+ cycles (hardened steel) |

| Production Capacity | Up to 500,000 units/month per line |

| Lead Time (Prototype) | 10–15 days |

| Quality Standards | ISO 9001:2015, IATF 16949, Six Sigma Level 4 |

| In-line Inspection | CMM, Vision Systems, SPC Monitoring |

Through seamless integration of design intelligence, precision prototyping, and error-proofed mass production, Wuxi Lead Precision Machinery delivers mould-decorated metal components with uncompromising quality and repeatability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Mould Decoration Excellence

In high-stakes mould decoration applications, surface integrity and dimensional precision are non-negotiable. Sub-micron deviations in electrode geometry or cavity finishing directly impact part aesthetics, functionality, and production yield. At Wuxi Lead Precision Machinery, we engineer custom metal components specifically for demanding decoration processes—where laser etching, in-mold labeling, or hot foil stamping demand absolute geometric fidelity. Our CNC platforms are calibrated to sustain ±0.0001″ tolerances across complex 3D contours, ensuring seamless integration with your decoration tooling and eliminating costly rework cycles.

Our facility operates under ISO 9001:2015 and IATF 16949 standards, with dedicated cells for electrode fabrication, cavity texturing, and precision grinding. Every mould component undergoes rigorous CMM validation against your CAD specifications before shipment. We prioritize thermal stability in material selection—utilizing hardened H13, S136, or bespoke alloys—to prevent distortion during high-cycle decoration operations. This disciplined approach guarantees consistent part release, optimal ink adhesion, and extended tool life, directly reducing your cost-per-part.

Technical Capabilities for Mould Decoration Systems

| Parameter | Specification | Relevance to Decoration Process |

|---|---|---|

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) | Ensures perfect alignment of textured zones |

| Surface Finish | Ra 0.025 µm (mirror grade) | Critical for uniform ink transfer |

| Spindle Runout | < 0.00004″ (0.001 mm) | Eliminates vibration marks on fine details |

| Thermal Compensation | Real-time laser calibration | Maintains tolerances during extended runs |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates large multi-cavity moulds |

Choosing a manufacturing partner is a strategic decision that affects your entire production ecosystem. Wuxi Lead Precision delivers more than components—we provide process certainty. Our engineering team collaborates from concept validation through to production ramp-up, conducting DFM analysis to preempt decoration-specific challenges like undercuts, venting requirements, or material flow constraints. We integrate seamlessly with your EDM, laser, and automation systems, ensuring zero surprises during tool tryouts. With in-house metallurgy labs and 24/7 technical support, we resolve issues before they reach your shop floor.

The cost of mould inaccuracies extends far beyond scrap rates—it erodes brand reputation and delays time-to-market. Partner with an organization that treats your decoration integrity as our core mission. Contact our engineering team today to discuss your project specifications, material requirements, and throughput targets. Let us demonstrate how our precision manufacturing ecosystem elevates your decoration outcomes.

Initiate your precision partnership: Contact [email protected]

Include your project timeline, CAD files, and critical tolerance zones for immediate technical assessment. Our engineers respond within 4 business hours with actionable solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.