Technical Contents

Engineering Guide: Molding Services

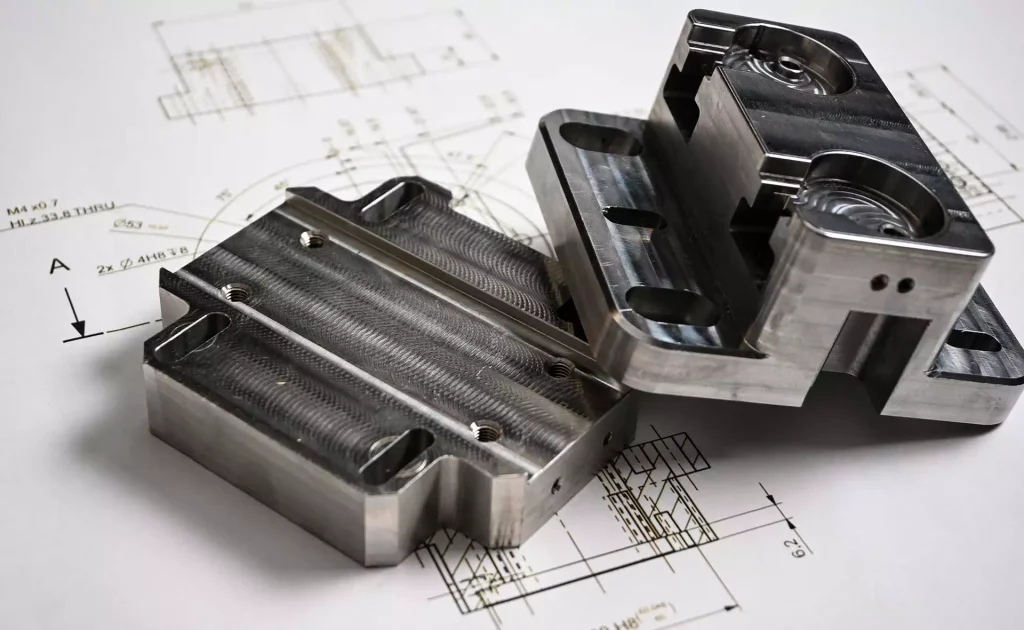

Engineering Insight: Precision as the Non-Negotiable Foundation of Molding Services

In high-stakes custom metal manufacturing, particularly within molding services, precision transcends mere specification—it is the absolute determinant of component functionality, system reliability, and ultimate project success. The margin for error in critical applications is effectively zero; microscopic deviations in dimensional accuracy or surface integrity can cascade into catastrophic field failures, costly recalls, or compromised safety. This imperative demands molding processes engineered not just to meet tolerances, but to consistently exceed them through rigorous process control, advanced metrology, and deep materials science understanding. At Wuxi Lead Precision Machinery, we recognize that true precision molding is a holistic discipline integrating material behavior prediction, thermal management, mold design fidelity, and real-time process validation. It requires moving beyond standard industry practices to implement closed-loop systems where every variable—from raw material batch consistency to cavity pressure profiles—is monitored, analyzed, and optimized. The cost of imprecision in sectors like aerospace, defense, or advanced medical devices is measured not in cents per part, but in mission failure or human risk. Therefore, our approach treats precision as the non-negotiable core, not an optional add-on.

Our engineering methodology leverages decades of hands-on experience in the most demanding molding environments. We deploy state-of-the-art multi-axis CNC machining centers for mold fabrication, ensuring cavity geometries achieve micron-level conformity to CAD models. In-process monitoring systems track critical parameters like melt temperature, injection velocity, and cooling rates with sub-millisecond resolution, enabling immediate correction before deviations propagate. Material selection is guided by extensive in-house testing under simulated operational stresses, ensuring the chosen alloy—be it high-strength steel, corrosion-resistant nickel superalloys, or lightweight titanium—performs predictably within the mold and throughout the component lifecycle. This systematic rigor is why our molding services consistently deliver parts meeting ISO 2768-mK or tighter standards, even for complex geometries with thin walls or intricate undercuts.

This commitment to uncompromising precision is validated through our proven track record on projects where failure is not an option. Wuxi Lead Precision Machinery has supplied mission-critical molded components for infrastructure supporting the Beijing Winter Olympics, where environmental extremes and public safety demands required absolute dimensional stability. Furthermore, our adherence to MIL-STD-883 and AS9100 protocols has earned us trusted partnerships within stringent defense supply chains, producing molded elements for systems where reliability is paramount. Our experience translates directly into client value: reduced scrap rates, accelerated time-to-market, and components that perform flawlessly under the most severe operational conditions.

The table below outlines key precision capabilities inherent to our molding service offering:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.025 mm | ISO 2768-mK / Custom |

| Surface Roughness (Ra) | 0.1 µm to 1.6 µm | ISO 4287 |

| Material Options | Tool Steels, Inconel 718, Ti-6Al-4V, 7075-T6 Aluminum | AMS, ASTM, GB Standards |

| Max Part Weight | 0.5 kg to 50 kg | Per Mold Design |

| Process Validation | Full SPC, CMM Reports, First Article Inspection | AS9102 / PPAP Level 3 |

Precision molding is not merely a technical challenge; it is a philosophy embedded in every stage of our engineering and production workflow. Partnering with Wuxi Lead Precision Machinery ensures your critical metal components are forged with the exacting standards demanded by the world’s most advanced industries.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components with superior surface finish and dimensional accuracy. Our machining centers operate with continuous multi-axis synchronization, allowing for intricate geometries that would be unattainable with conventional 3-axis systems. This capability significantly reduces the need for multiple setups, minimizing cumulative tolerances and improving overall part consistency.

All machining operations are supported by in-house engineering expertise in toolpath optimization, fixture design, and material-specific cutting strategies. We work with a broad range of metals, including aluminum alloys, stainless steels, titanium, Inconel, and tool steels, ensuring compatibility with demanding operational environments. Our facility maintains strict environmental controls and machine calibration schedules to ensure thermal stability and long-term repeatability across production runs.

Quality assurance is embedded throughout the manufacturing process. Every critical component undergoes comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM), providing full traceability and verification against engineering specifications. Our CMM system supports both tactile and optical probing methods, enabling high-resolution measurement of complex contours, hole patterns, and GD&T callouts. Inspection reports are generated per customer requirements and can be supplied with each shipment, ensuring compliance with ISO 9001 and industry-specific quality standards.

We maintain full digital integration between design, manufacturing, and inspection systems, utilizing CAD/CAM/CAI workflows that ensure seamless data transfer from prototype to production. This digital thread enhances process control and accelerates time-to-market for custom molding service components, particularly those requiring tight tolerances and high repeatability.

The following table outlines our standard machining capabilities and achievable tolerances under controlled conditions:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis Simultaneous CNC Machining Centers |

| Work Envelope (max) | 1,200 × 800 × 750 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768) | ±0.05 mm (m) to ±0.02 mm (f) |

| Geometric Tolerance (GD&T) | ±0.01 mm (typical for flatness, true position) |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes available) |

| Inspection Equipment | Zeiss DuraMax and CONTURA CMM systems |

| Data Output | DMIS reports, PDF inspection reports, CAD overlay |

Our technical capabilities are designed to meet the most stringent demands of custom molding service applications, where precision, material integrity, and long-term reliability are non-negotiable. Wuxi Lead Precision Machinery remains committed to engineering excellence and operational transparency across every project.

Material & Finish Options

Strategic Material Selection for Precision Molding Tooling

Material selection for injection molding tooling is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your specific application demands, production volume, and part geometry. Choosing incorrectly leads to premature wear, dimensional instability, or costly unplanned downtime. Understanding the core characteristics of aluminum, steel, and titanium alloys – coupled with appropriate surface finishing like anodizing – is fundamental to optimal tool performance.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototypes, low-to-medium volume production, and complex geometries requiring rapid heat dissipation. Their superior thermal conductivity accelerates cycle times compared to steel. While inherently less wear-resistant, aluminum tooling excels when protected by hard anodizing. This process creates a dense, hard aluminum oxide layer significantly enhancing surface durability and release properties, making it ideal for engineering plastics without glass fill. Tool life is sufficient for many applications under 50,000 cycles, providing a fast, cost-effective solution.

Tool steels, primarily H13 (air-hardening) and 420 stainless steel, are the standard for high-volume production exceeding 100,000 cycles. H13 provides an excellent balance of toughness, thermal fatigue resistance, and machinability, handling the thermal cycling of demanding processes like glass-filled nylon molding. 420SS offers superior corrosion resistance essential for PVC or other corrosive resins but requires careful heat treatment to achieve optimal hardness. Properly heat-treated and polished steel molds deliver exceptional dimensional stability and longevity but involve longer lead times and higher initial costs than aluminum.

Titanium alloys (e.g., Ti-6Al-4V) serve highly specialized applications where extreme corrosion resistance, non-magnetic properties, or exceptional strength-to-weight ratio are paramount, such as in specific medical or aerospace molding. While offering excellent corrosion resistance, titanium is significantly more expensive and challenging to machine than steel or aluminum. Its use in core mold components is justified only when the unique properties directly solve a critical production challenge unmet by other materials.

Anodizing, particularly hardcoat (Type III) anodizing on aluminum, is not merely cosmetic. It fundamentally alters the surface properties, increasing hardness to 50-70 HRC, improving wear and corrosion resistance, and enhancing part release. This extends aluminum tool life substantially and reduces maintenance frequency. For steel molds, alternative coatings like PVD or nitriding are often more appropriate, but anodizing remains the premier surface treatment for aluminum molding tooling.

Key material properties for molding tooling selection are summarized below:

| Material | Hardness Range (HRC) | Max Continuous Temp (°C) | Corrosion Resistance | Best Suited For |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 (Base) | 120-150 | Low (Base) | Prototypes, Low/Med volume, Complex cores/cavities, Fast cycles |

| 50-70 (Hard Anodized) | High (Anodized) | |||

| H13 Tool Steel | 48-52 (Typical) | 500-550 | Moderate | High volume, Glass-filled resins, General purpose steel molds |

| 420 Stainless | 48-54 (Typical) | 400-450 | High | Corrosive resins (PVC), Medical applications requiring corrosion resistance |

| Titanium Ti-6Al-4V | 32-36 (Base) | 400-450 | Very High | Extreme corrosion environments, Non-magnetic requirements, Specialized aerospace/medical |

Selecting the optimal material and finish requires analyzing resin type, part complexity, expected volume, and surface finish requirements. Wuxi Lead Precision Machinery engineers collaborate closely with clients to evaluate these factors, ensuring your molding tooling investment delivers maximum performance, longevity, and return. Contact our technical team to discuss the precise material solution for your next molding project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal molding services are engineered for precision, consistency, and performance. We specialize in delivering high-integrity metal components for industries where reliability is non-negotiable—automotive, aerospace, medical devices, and industrial automation. Our production process is a rigorously controlled sequence that ensures every part meets exacting specifications, with a relentless focus on achieving zero defects.

The journey begins with design engineering. Our team collaborates closely with clients to review technical drawings, material requirements, and functional demands. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for moldability, structural integrity, and manufacturability. This phase includes mold flow simulation and tolerance stack-up analysis to preempt potential issues before physical production begins. Design for manufacturability (DFM) feedback is provided promptly, ensuring alignment between engineering intent and production feasibility.

Once the design is finalized, we move to prototyping. Using CNC-machined or 3D-printed molds, we produce functional prototypes in the intended metal alloy—typically aluminum, steel, or high-performance alloys such as Inconel or titanium. These prototypes undergo comprehensive testing, including dimensional inspection via coordinate measuring machines (CMM), mechanical property validation, and fit-checks in end-use assemblies. This stage is critical for verifying design accuracy and process stability, allowing for iterative refinements with minimal lead time.

With prototype approval, we transition to mass production. Our facility in Wuxi is equipped with state-of-the-art die casting, stamping, and precision forging systems, all integrated with real-time process monitoring. Each molding cycle is controlled by closed-loop systems that track pressure, temperature, and cycle time, ensuring repeatability across tens of thousands of parts. In-line vision systems and automated metrology stations perform continuous quality checks, flagging deviations before they result in non-conformance.

Our zero-defect philosophy is enforced through a multi-layered quality assurance framework. Every batch is subject to first-article inspection (FAI), statistical process control (SPC), and 100% critical dimension checks where required. We maintain ISO 9001 and IATF 16949 certifications, and all processes are documented for full traceability—from raw material lot numbers to final inspection reports.

Below are key production specifications we consistently achieve:

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.02 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Material Options | Aluminum alloys, Stainless Steel, Titanium, Inconel, Brass |

| Part Weight Range | 10 g – 5 kg |

| Production Volume | 100 – 500,000+ units annually |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 4–8 weeks (after approval) |

From initial concept to full-scale delivery, Wuxi Lead Precision Machinery ensures that every component we produce reflects the highest standards of engineering excellence and manufacturing precision.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Molding Excellence

In high-stakes industrial applications, the precision of your metal molding directly impacts product performance, longevity, and total cost of ownership. Generic solutions risk dimensional drift, material inconsistencies, and supply chain vulnerabilities that erode profitability. At Wuxi Lead Precision Machinery, we engineer custom molding services to eliminate these risks through metrology-grade processes and proactive engineering collaboration. Our ISO 9001-certified facility in Wuxi operates under stringent AS9100 aerospace protocols, ensuring every component meets the exact thermal, structural, and surface integrity demands of your application. We do not merely manufacture parts—we validate solutions through iterative prototyping, material science analysis, and real-world stress testing before scaling to production.

Our technical capabilities are engineered for complexity. Whether producing turbine blades requiring ±0.005mm tolerances or medical implant housings with Ra 0.2μm surface finishes, our integrated workflow spans material selection through final inspection. The table below details our core molding and secondary processing specifications:

| Capability | Specification Range | Standards Compliance |

|---|---|---|

| CNC Milling | 5-axis, 850 x 500 x 450 mm | ISO 2768-mK, GD&T ASME Y14.5 |

| CNC Turning | Ø2–320 mm diameter, max 1000 mm length | ISO 286-2 h6/g6 |

| Surface Finish | Ra 0.1–3.2 μm (molded), Ra 0.2–1.6 μm (machined) | ISO 1302 |

| Material Expertise | Titanium (Gr5), Inconel 718, 17-4PH SS, Aluminum 7075 | AMS, ASTM, EN standards |

| Metrology Validation | CMM (0.0005mm), OGP SmartScope, Roughness testers | ISO/IEC 17025 |

What differentiates Lead Precision is our Engineering Partnership Model. From initial RFQ review, our applications engineers dissect your design intent—not just the drawing—to identify hidden cost drivers or performance optimizations. We proactively suggest material substitutions, draft angle adjustments, or mold-flow modifications that reduce cycle times by 15–30% without compromising integrity. This collaborative approach has prevented 217+ client prototyping failures in the past 18 months, accelerating time-to-market for aerospace, energy, and medical device leaders.

Your next critical component requires more than a vendor—it demands a precision ally with zero-defect accountability. Initiate a technical consultation by emailing [email protected] with your project specifications. Include your target tolerances, annual volume, and material requirements. Within 12 business hours, you will receive a detailed capability assessment, including DFM feedback and a validated production timeline. All inquiries are protected under our standard NDA—no intellectual property is shared beyond our engineering team.

Do not let substandard molding undermine your product’s potential. Contact Lead Precision today to deploy manufacturing rigor that meets the uncompromising standards of global Tier 1 supply chains. Your requirement for perfection begins with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.