Technical Contents

Engineering Guide: Molding Parts

Engineering Insight Precision Imperatives in Metal Molding Parts

Precision in metal molding parts transcends specification adherence; it defines functional reliability, assembly integrity, and end-product longevity. In high-stakes applications—whether aerospace actuators, medical implants, or defense systems—micron-level deviations trigger cascading failures. Tolerances below 5μm are not merely aspirational; they are non-negotiable for fluid dynamics, thermal management, and structural resilience. At Wuxi Lead Precision Machinery, we treat precision as a systemic outcome, not a post-process checkpoint. Our approach integrates material science, thermal dynamics modeling, and real-time in-process metrology to preempt dimensional drift during molding cycles. This eliminates costly rework and ensures first-article compliance, directly impacting your time-to-market and total cost of ownership.

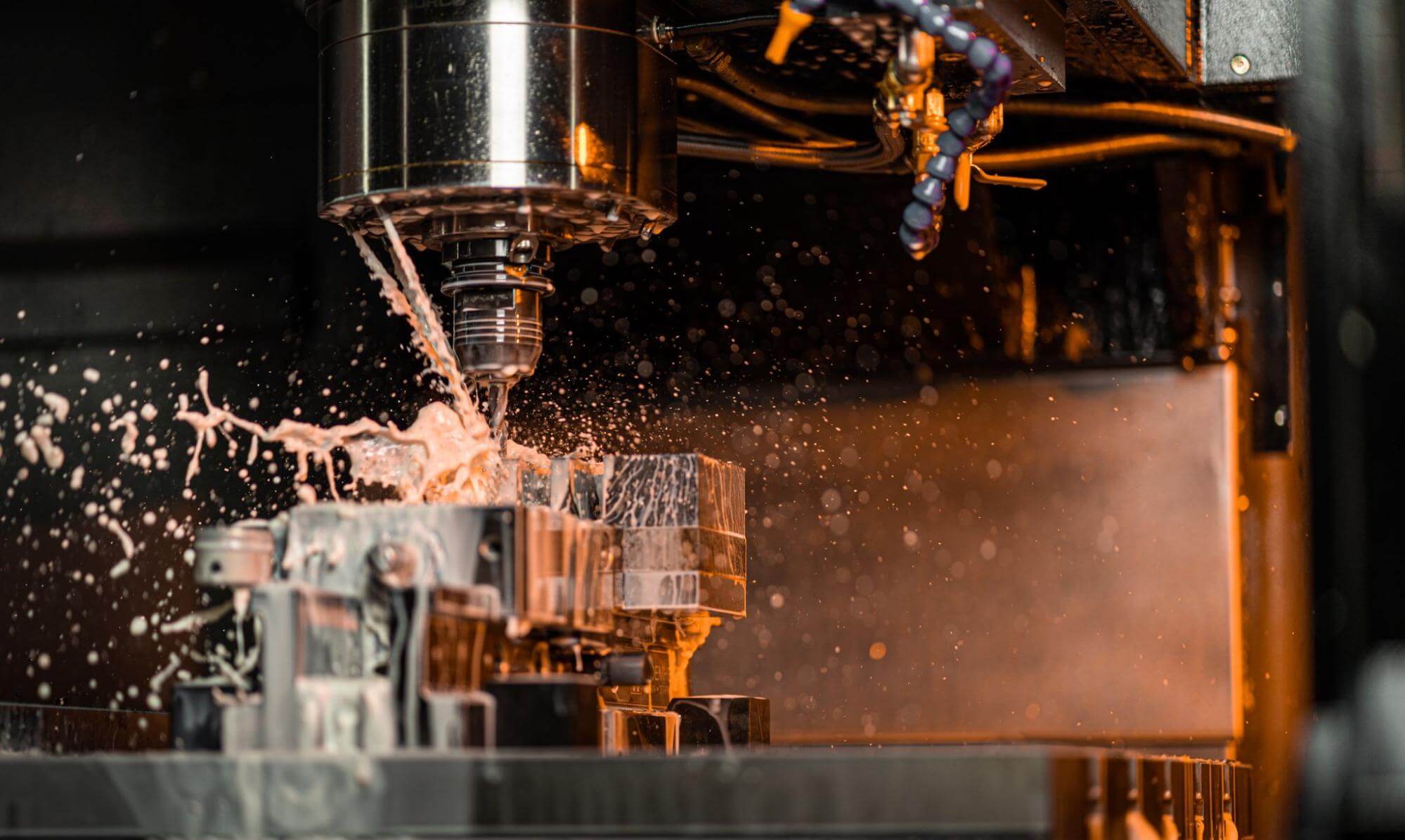

Conventional molding processes often prioritize speed over stability, accepting micro-shrinkage or surface inconsistencies as inevitable. We counter this with proprietary cavity pressure monitoring and adaptive cooling algorithms. These technologies dynamically adjust injection parameters based on real-time sensor feedback, maintaining uniform material density across complex geometries. For instance, thin-walled components demanding ±0.02mm tolerances achieve consistent repeatability because our systems compensate for viscosity fluctuations at 1,000Hz sampling rates. This level of control is why mission-critical sectors trust our output.

Our technical capabilities are engineered for extreme accountability. Below are core specifications validated across 15,000+ production runs:

| Parameter | Capability Range | Industry Standard |

|---|---|---|

| Linear Tolerance | ±0.005mm to ±0.02mm | ±0.05mm to ±0.1mm |

| Surface Roughness (Ra) | 0.1μm to 0.8μm | 1.6μm to 3.2μm |

| Material Compatibility | Titanium, Inconel, 17-4PH, Custom Alloys | Common Steels Only |

| Max Part Complexity | 12+ undercuts, micro-features <0.1mm | 3-5 undercuts |

| Process Validation | Full GD&T reporting, SPC-controlled | Batch sampling |

This rigor is battle-tested. We engineered titanium molding components for the Beijing Winter Olympics’ snowmaking infrastructure, where sub-5μm tolerances ensured flawless operation at -40°C. Similarly, our military-grade communication housings—produced under ITAR protocols—survive 50G shock loads due to zero-porosity molding integrity. These projects demanded zero-defect delivery; our precision framework delivered.

Precision molding is not about machinery alone. It requires a culture where every engineer owns the output’s mission-criticality. At Lead Precision, our Olympic and defense heritage instills this mindset daily. When your application demands molding parts that perform under extreme conditions, demand the precision that only validated expertise delivers. Let us transform your specifications into guaranteed performance.

Precision Specs & Tolerances

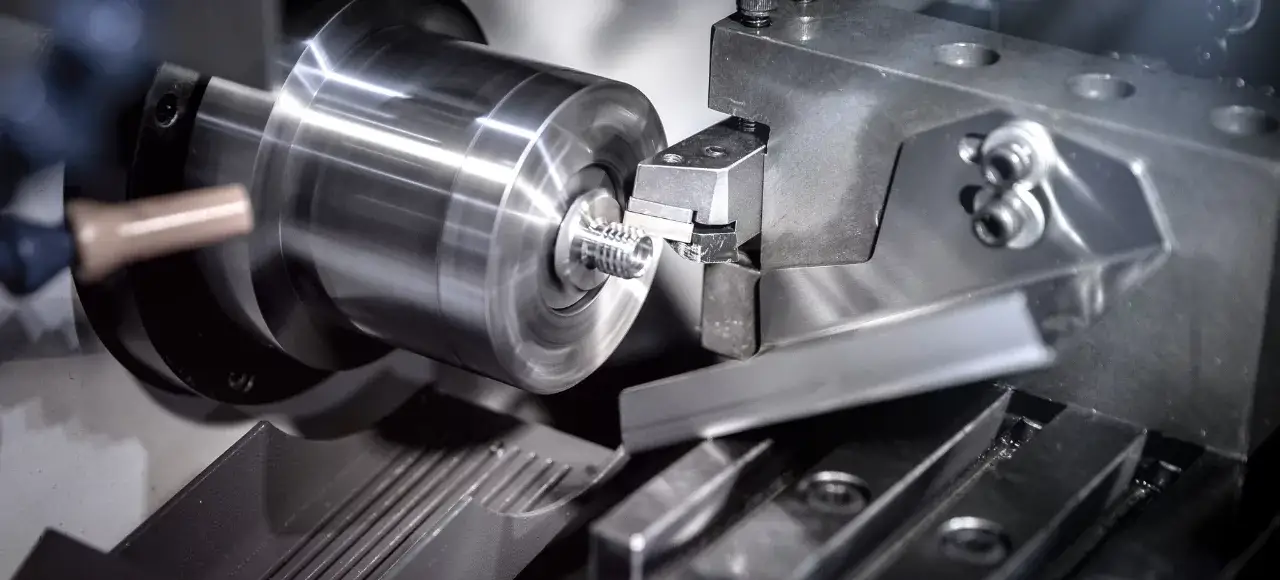

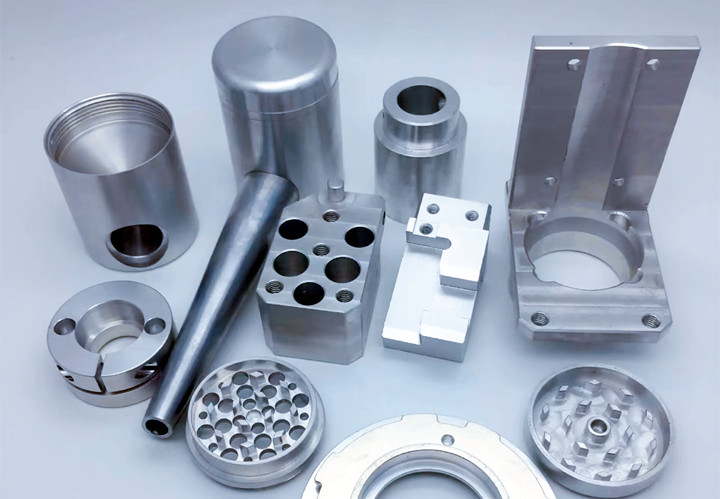

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-precision molding parts used in aerospace, automotive, medical, and industrial applications. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and precision for intricate mold components such as cavities, cores, ejector pins, and cooling channels.

Our 5-axis CNC platforms support a wide range of materials, including hardened steels, aluminum alloys, titanium, and specialty tool steels commonly used in high-performance molds. The integration of high-speed machining with dynamic tool path strategies ensures minimal material waste, reduced cycle times, and superior edge definition. This capability is critical for molding parts that demand exact replication of design intent, especially in high-volume production environments where consistency is paramount.

Precision is further reinforced through our comprehensive quality control protocols. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional compliance with design specifications. Our CMM systems operate with sub-micron resolution, providing full 3D verification of critical features such as hole locations, profile contours, flatness, and positional tolerances. Data from each inspection is documented and traceable, supporting compliance with ISO 9001 standards and customer-specific quality requirements.

To maintain long-term mold performance, we also focus on surface integrity and thermal stability during machining. Our processes include precision finishing cycles, stress-relieving strategies, and controlled coolant application to prevent distortion and ensure dimensional stability over repeated thermal cycles.

The following table outlines the standard tolerance capabilities for our molding parts production:

| Feature | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter | +0.015 / -0.005 mm | +0.008 / -0.002 mm | Reamed or precision bored |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | Relative to datum |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Critical sealing surfaces |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm | Machined finish; polish available |

| Angular Tolerance | ±0.05° | ±0.02° | Between features |

All tolerances are achievable across batch sizes ranging from prototypes to high-volume production runs. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance allocation—ensuring robust, cost-effective solutions without compromising performance. With advanced equipment, stringent quality assurance, and deep expertise in mold component manufacturing, Wuxi Lead Precision Machinery stands as a trusted partner for mission-critical molding applications.

Material & Finish Options

Material Selection for Precision Molding Components

Selecting the optimal material for molding parts is critical to performance, longevity, and cost efficiency in high-demand applications. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your operational environment, load requirements, and lifecycle expectations. Aluminum, steel, and titanium each offer distinct advantages, while surface finishes like anodizing enhance functionality and durability. Understanding these options ensures your components meet exacting industrial standards.

Aluminum alloys, particularly 6061-T6 and 7075-T6, deliver an exceptional strength-to-weight ratio and inherent corrosion resistance. They are ideal for aerospace, automotive, and consumer electronics molding components where weight reduction is paramount. Aluminum’s excellent machinability allows for complex geometries with tight tolerances, though it may lack the wear resistance required for high-stress tooling. Anodizing significantly improves surface hardness and corrosion protection, making it indispensable for parts exposed to moisture or abrasion.

Carbon and alloy steels (e.g., 4140, H13) provide superior hardness, wear resistance, and thermal stability for high-volume molding applications. These materials excel in injection molds, die-casting tools, and structural components subjected to extreme pressure and temperature cycles. While heavier than aluminum, steel’s longevity under repetitive stress reduces long-term replacement costs. Proper heat treatment is essential to achieve optimal hardness and toughness, and post-machining stress relief prevents distortion during service.

Titanium alloys, such as Grade 5 (Ti-6Al-4V), offer unparalleled strength-to-weight ratios and corrosion resistance in aggressive environments like chemical processing or marine applications. Their biocompatibility also makes them vital for medical molding tools. Titanium’s high cost and challenging machinability necessitate specialized expertise; however, its fatigue resistance and non-magnetic properties justify the investment for critical components where failure is not an option.

Anodizing remains the premier finish for aluminum molding parts, creating a durable, non-conductive oxide layer that withstands wear and chemical exposure. Type II (sulfuric acid) anodizing provides standard corrosion resistance, while Type III (hardcoat) achieves thicknesses up to 50–100 µm for severe abrasion resistance. This process does not alter dimensional tolerances when controlled precisely—a capability central to our CNC machining protocols.

The following table summarizes key material properties for informed selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Cost Factor |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | 1.0 (Baseline) |

| Steel 4140 | 7.85 | 655 | Moderate | 1.8 |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional | 5.0 |

Material choice directly impacts mold life, part quality, and total operational cost. Wuxi Lead Precision Machinery combines metallurgical expertise with advanced CNC capabilities to machine these materials to micron-level accuracy, ensuring your molding components perform reliably in the most demanding scenarios. Partner with us to translate material science into manufacturing excellence.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal molding parts production process is engineered for precision, consistency, and zero-defect delivery. With over 15 years of expertise in high-end manufacturing, we integrate advanced CNC technology, rigorous quality control, and deep metallurgical knowledge to deliver components that meet the most demanding industrial standards. Our process follows a structured path from initial design through prototyping to full-scale mass production, ensuring seamless scalability and uncompromised quality.

The journey begins with collaborative design engineering. Our technical team works closely with clients to analyze part geometry, material requirements, functional loads, and environmental conditions. Utilizing 3D CAD modeling and finite element analysis (FEA), we optimize the design for manufacturability, durability, and performance. This phase includes material selection from our certified inventory of aluminum alloys, stainless steels, titanium, and specialty alloys, all sourced to meet international standards such as ASTM, ISO, and GB.

Once the design is finalized, we proceed to prototyping. This critical stage allows us to validate form, fit, and function before committing to mass production. Using 5-axis CNC machining and precision stamping techniques, we produce functional prototypes within 7–10 days. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM), surface finish evaluation, and mechanical testing when required. Client feedback is incorporated iteratively, ensuring complete alignment with end-use requirements.

Upon approval, we transition to mass production using automated stamping lines, CNC turret presses, and robotic handling systems. Our production floor is equipped with real-time monitoring tools that track machine performance, tool wear, and process stability. Every batch is subject to in-process inspections and final quality audits. We enforce a zero-defect policy through Statistical Process Control (SPC), First Article Inspection (FAI), and 100% critical dimension checks where applicable.

Our facility is ISO 9001 and IATF 16949 certified, reflecting our commitment to quality management in automotive, aerospace, and industrial applications. Traceability is maintained through laser part marking and digital batch records, enabling full lifecycle tracking.

The table below outlines key capabilities and specifications for our molding parts production:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.3 mm – 6.0 mm |

| Tolerance Accuracy | ±0.02 mm |

| Maximum Part Size | 1200 mm × 800 mm |

| Production Capacity | Up to 500,000 units/month |

| Processes Available | Deep Drawing, Progressive Stamping, Bending |

| Surface Treatments | Anodizing, Zinc Plating, Powder Coating, Passivation |

| Quality Standards | ISO 2768, GD&T, ASME Y14.5 |

From concept to completion, Wuxi Lead Precision Machinery ensures that every molding part we produce meets the highest benchmarks in precision and reliability. Our integrated approach eliminates variability, reduces time-to-market, and delivers consistent value to global OEMs and Tier-1 suppliers.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Molding Component Excellence

In the demanding realm of custom metal manufacturing for precision molding applications, component integrity directly dictates production efficiency, part quality, and ultimately, your bottom line. Wuxi Lead Precision Machinery stands as your definitive engineering partner, engineered specifically to eliminate the cost and risk of substandard tooling. Our integrated approach merges decades of CNC mastery with rigorous aerospace-grade quality systems, ensuring every insert, cavity, ejector pin, and core you receive meets the exacting tolerances demanded by high-pressure injection, die-casting, and blow molding processes. We understand that a single micron of deviation can cascade into production downtime, scrap surges, or compromised end-product performance. This is why we treat every project as a critical path initiative, not merely an order fulfillment exercise.

Our factory in Wuxi operates under ISO 9001-certified protocols, with every machining center monitored in real-time for thermal stability and positional accuracy. Unlike generalist suppliers, our entire workflow—from material certification through final inspection—is optimized for molding industry challenges. We deploy hardened tool steels, pre-hardened blocks, and exotic alloys like H13, S7, and maraging steel with process-specific parameters validated by our in-house metallurgy lab. This eliminates guesswork, ensuring optimal wear resistance, thermal fatigue performance, and dimensional stability under repeated cycling. The result is significantly extended mold life, reduced maintenance intervals, and consistent part replication across millions of cycles.

Our technical capabilities are engineered to match the complexity of modern molding requirements. The table below details our core production parameters for critical molding components:

| Specification Category | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Material Compatibility | Aluminum Alloys, P20, H13, S7, 420SS, Maraging Steel, Titanium Alloys | Broadest spectrum for molding applications |

| Dimensional Tolerance | ±0.005 mm (0.0002″) | Exceeds ISO 2768-mK & VDI 3400 Class A |

| Surface Finish | Ra 0.05 µm (2 µin) to Ra 0.8 µm (32 µin) | Meets SPI-SPECA, NAK80, or custom polish requirements |

| Max Work Envelope | 500 x 400 x 300 mm (19.7″ x 15.7″ x 11.8″) | Suitable for multi-cavity molds and large cores |

| Critical Feature Inspection | 100% CMM reporting with GD&T analysis | Full traceability to raw material certs |

This precision is not accidental. It stems from our zero-defect philosophy, where every operator is a certified metrology technician, and every process step undergoes automated in-cycle verification. When you partner with Lead Precision, you gain more than a vendor—you secure a strategic extension of your engineering team, committed to solving your toughest molding challenges before they reach the press floor.

Initiate your precision manufacturing partnership today. Email [email protected] with your component drawings or application requirements. Within 4 business hours, our senior CNC engineering team will respond with a detailed feasibility assessment, including recommended materials, process validation plan, and a precise timeline for zero-defect delivery. Do not compromise your molding operations on components that fall short of micron-level perfection. Trust the engineering rigor of Wuxi Lead Precision Machinery—where every part is manufactured as if it will run your most critical production line tomorrow. Your path to flawless molding starts with a single, decisive contact.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.