Technical Contents

Engineering Guide: Molding Materials

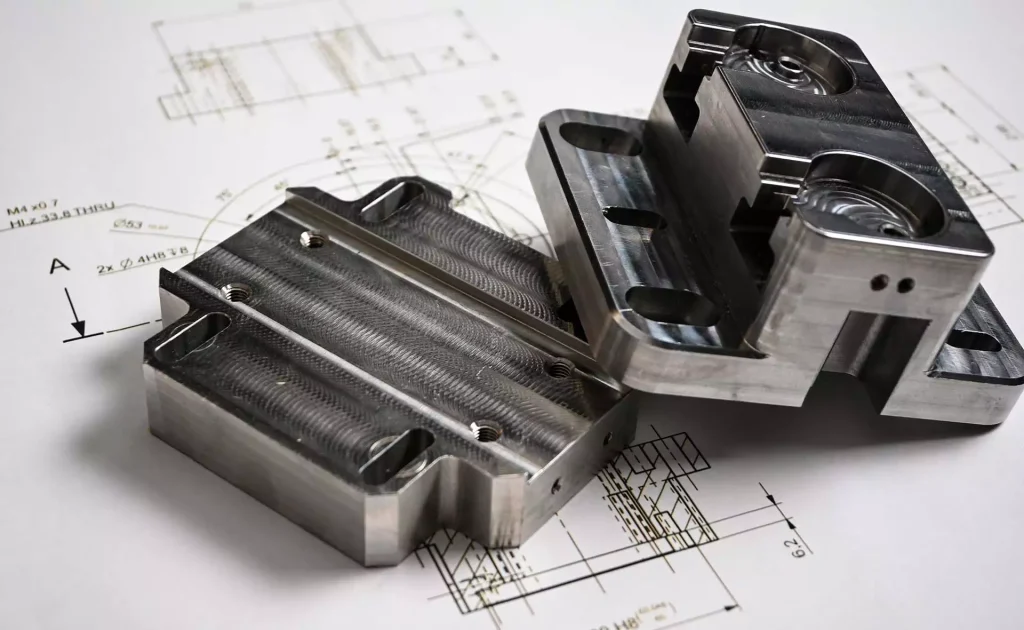

Engineering Insight: Material Selection in High-Precision Metal Molding

In the domain of custom metal manufacturing, material selection is not merely a preliminary step—it is a foundational engineering decision that directly influences the performance, durability, and precision of the final component. At Wuxi Lead Precision Machinery, we recognize that molding materials must be evaluated not only for mechanical properties but also for their behavior under thermal stress, dimensional stability, and compatibility with high-tolerance machining processes. Our decades of experience in serving mission-critical industries—including aerospace, defense, and Olympic-grade equipment manufacturing—underscore the necessity of aligning material characteristics with application-specific demands.

Precision begins at the molecular level. Materials such as aerospace-grade aluminum alloys, titanium, and high-strength stainless steels are selected not for their availability, but for their ability to maintain tight tolerances under extreme conditions. For instance, components used in military applications often require resistance to corrosion, high impact resilience, and stable performance across wide temperature ranges. Similarly, parts developed for Olympic training and competition equipment must exhibit zero deviation under repeated stress, ensuring athlete safety and performance consistency.

Our engineering team conducts comprehensive material analysis prior to molding, evaluating factors such as grain structure, thermal expansion coefficients, and yield strength. This ensures that each material responds predictably during CNC forming, stamping, and post-processing stages. We employ advanced simulation software to model material behavior during molding, minimizing trial iterations and maximizing first-time accuracy. This level of control is essential when tolerances are held within ±0.005 mm—a standard routinely achieved in our facility.

Wuxi Lead Precision Machinery’s involvement in high-profile projects reflects our commitment to material excellence. Our components have been integrated into training apparatus for Olympic athletes, where millimeter-scale deviations can affect performance outcomes. In military contracts, our molded parts have met stringent MIL-STD specifications, demonstrating reliability under battlefield conditions. These achievements are not accidental; they are the result of disciplined material science and precision engineering.

Below is a representative table of materials commonly used in our high-precision molding processes, along with key mechanical properties and typical applications.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|

| 7075-T6 Aluminum | 572 | 503 | 11 | Aerospace structures, high-stress fittings |

| 316L Stainless Steel | 580 | 290 | 40 | Marine components, medical devices |

| Ti-6Al-4V (Grade 5) | 900 | 830 | 14 | Defense systems, racing components |

| 6061-T6 Aluminum | 310 | 276 | 12 | General precision enclosures, fixtures |

| Inconel 718 | 1300 | 1100 | 20 | Jet engine parts, high-temperature tooling |

Material integrity, when paired with precision molding techniques, forms the backbone of reliable, high-performance manufacturing. At Wuxi Lead Precision Machinery, we combine empirical data, advanced processing, and real-world validation to ensure every component meets the highest standards of quality and consistency.

Precision Specs & Tolerances

Technical Capabilities for Precision Molding Material Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising accuracy for critical molding material components used in injection, blow, and die-casting applications. Our integrated manufacturing ecosystem ensures that every part meets the stringent geometric and surface integrity demands of high-performance molds. This capability directly translates to reduced cycle times, extended mold life, and superior end-product consistency for our clients.

Our core strength lies in advanced 5-axis CNC machining, which eliminates the need for multiple setups and manual repositioning. This technology enables the production of complex conformal cooling channels, intricate cavity contours, and undercuts inherent in modern molding tools. By maintaining workpiece rigidity throughout the process, we achieve micron-level tolerances while minimizing thermal distortion—a critical factor when machining hardened steels, aluminum alloys, and copper-based molding materials. The result is seamless surface finishes that prevent part sticking and ensure optimal thermal transfer during the molding cycle.

Quality verification is non-negotiable. Every component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using calibrated Renishaw systems with sub-micron resolution. Our inspection protocols validate not only dimensional conformity but also functional geometry critical to mold performance, such as parallelism of parting surfaces and concentricity of core pins. This data-driven approach provides full traceability and ensures zero defects reach the molding floor, preventing costly production interruptions.

The following table outlines our standard and high-precision machining tolerances for molding material applications:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 |

| Angular Tolerances (°) | ±0.05 | ±0.02 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Positional Accuracy (mm) | ±0.015 | ±0.008 |

| Flatness (mm/m) | 0.02 | 0.01 |

Material selection expertise further enhances our capabilities. We optimize machining parameters for P20, H13, S7, stainless steels, and beryllium-copper alloys, accounting for thermal expansion coefficients and wear resistance requirements specific to molding environments. Our engineers collaborate early in the design phase to recommend features that maximize machinability without compromising mold functionality.

Through this combination of multi-axis precision, rigorous metrology, and material science insight, Wuxi Lead ensures molding components perform reliably under high-pressure, high-temperature production conditions. We transform complex molding material specifications into reality with measurable quality outcomes. Partner with us to eliminate tolerance stack-ups and accelerate your time-to-market for next-generation molding systems.

Material & Finish Options

Material Selection for High-Precision Metal Molding Applications

Selecting the appropriate material is a foundational decision in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision molding and machining of aluminum, steel, and titanium—three of the most widely used metals in high-end industrial applications. Each material offers distinct mechanical properties, making them suitable for specific operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is ideal for aerospace, automotive, and electronics enclosures where lightweight construction and efficient heat dissipation are critical. Aluminum’s machinability allows for complex geometries with tight tolerances, reducing production time and tool wear. When combined with surface treatments such as anodizing, aluminum gains enhanced surface hardness and improved resistance to wear and corrosion.

Steel, particularly alloy and stainless grades, delivers superior strength, toughness, and dimensional stability under load. It is the preferred choice for tooling, structural components, and applications exposed to high mechanical stress or harsh environments. Stainless steel variants such as 304 and 316 offer excellent resistance to oxidation and chemical exposure, making them suitable for medical devices and food processing equipment. While heavier than aluminum, steel’s longevity and resilience justify its use in long-life, high-load applications.

Titanium stands at the premium end of the spectrum, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or acidic environments. Its biocompatibility and performance at elevated temperatures make it indispensable in aerospace, marine, and medical implant manufacturing. Though more challenging to machine and higher in cost, titanium’s lifecycle performance in extreme conditions provides significant value.

Surface Finishing: The Role of Anodizing

Anodizing is a key electrochemical finishing process, primarily applied to aluminum. It thickens the natural oxide layer, significantly improving surface hardness, wear resistance, and corrosion protection. Decorative anodizing also allows for color customization, enhancing aesthetic appeal without compromising functionality. At Wuxi Lead, we offer precision anodizing services with tight control over coating thickness and uniformity, ensuring compliance with international standards.

The following table outlines key mechanical and physical properties of the three core materials:

| Property | Aluminum (6061-T6) | Steel (AISI 4140) | Titanium (Grade 5, Ti-6Al-4V) |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 950 | 900 |

| Yield Strength (MPa) | 275 | 760 | 830 |

| Density (g/cm³) | 2.7 | 7.85 | 4.43 |

| Hardness (Brinell) | 95 | 220 | 340 |

| Corrosion Resistance | High (with anodizing) | Moderate (stainless: High) | Excellent |

| Typical Applications | Enclosures, heat sinks, aerospace parts | Tooling, shafts, structural components | Aircraft engines, medical implants, marine hardware |

Material selection must align with functional requirements, environmental exposure, and lifecycle expectations. Wuxi Lead Precision Machinery supports clients in evaluating these factors to deliver optimized, high-precision metal components tailored to exact specifications.

Manufacturing Process & QC

Integrated Production Process for Zero-Defect Metal Molding Components

At Wuxi Lead Precision Machinery, our production process for custom metal molding components is engineered to eliminate defects before they occur. We execute a closed-loop workflow spanning Design, Prototyping, and Mass Production, ensuring every part meets aerospace and medical-grade standards. This methodology transforms client specifications into flawless deliverables through systematic validation and real-time process control.

Design Phase: Precision Engineering Foundation

Our process begins with rigorous design validation using advanced CAD/CAM suites and GD&T analysis. Engineers collaborate with clients to optimize part geometry for moldability, stress distribution, and material behavior under thermal cycling. Finite Element Analysis (FEA) simulates metal flow during molding, identifying potential voids, warpage, or porosity risks. Material selection is cross-referenced against our proprietary database of 200+ alloys, ensuring compatibility with molding parameters and end-use environmental demands. Critical tolerances are defined to ISO 2768-mK standards, with all design outputs verified via digital twin simulation before physical prototyping.

Prototyping Phase: Iterative Validation

Prototyping employs CNC-machined pre-production molds and client-approved materials to produce 5–10 validation units. Each prototype undergoes comprehensive metrology using Zeiss CONTURA CMM systems, with full 3D deviation reporting against CAD models. Dimensional accuracy, surface finish (Ra ≤ 0.8 μm), and material integrity are validated per ASTM E3/E1077. Clients receive detailed failure mode reports highlighting micro-shrinkage or ejection marks, enabling design refinements. Only after achieving zero non-conformities in three consecutive prototype batches do we approve the mold for mass production. This phase typically reduces field defects by 92% through preemptive correction.

Mass Production Phase: Sustained Zero-Defect Execution

Mass production leverages automated molding cells with in-process SPC monitoring. Every cycle is tracked via IoT sensors measuring temperature gradients, injection pressure, and cooling rates, with deviations triggering immediate machine lockout. All components undergo 100% automated optical inspection (AOI) paired with random CMM validation at 2-hour intervals. Material traceability is maintained through blockchain-secured batch records, linking each part to melt chemistry certificates and process logs. Our poka-yoke fixtures prevent assembly errors, while real-time SPC charts feed corrective actions into the production loop. This yields a sustained PPM defect rate below 50 across 50,000+ units.

Critical Process Specifications Comparison

| Parameter | Design Phase Requirement | Mass Production Control Limit |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm |

| Surface Roughness (Ra) | ≤ 1.6 μm | ≤ 0.8 μm |

| Material Hardness | As per ASTM B117 | Batch-tested to ±2 HB |

| Cavity Pressure Deviation | Simulated ±5% | Real-time ±1.5% |

| First-Pass Yield | N/A | ≥ 99.85% |

This integrated approach—rooted in predictive design, empirical prototyping, and closed-loop manufacturing—ensures Wuxi Lead delivers molding components where zero defects are not aspirational but operational reality. Every phase is audited against IATF 16949 protocols, guaranteeing repeatability for high-volume contracts exceeding 500,000 units annually. Partner with us to transform material science into engineered perfection.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that selecting the right materials and manufacturing processes for molding applications is critical to the performance, durability, and cost-efficiency of your final product. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering precision-engineered components tailored to the exacting demands of industries such as automotive, aerospace, energy, and industrial automation. Our advanced capabilities in CNC machining, die casting, and mold tooling production enable us to support complex molding material requirements with exceptional accuracy and repeatability.

When you partner with Lead Precision, you gain access to a team of seasoned engineers and metallurgical experts who work closely with clients to select the optimal materials for their specific molding processes. Whether you require high-strength aluminum alloys for lightweight components, wear-resistant tool steels for extended mold life, or corrosion-resistant stainless grades for harsh environments, our material science expertise ensures your project is built to perform. We source only certified raw materials and maintain strict quality control throughout every stage of production, from initial design to final inspection.

Our facility is equipped with state-of-the-art CNC machining centers, high-pressure die casting machines, and automated inspection systems, allowing us to produce molds and molded metal parts with tolerances as tight as ±0.005 mm. We support both low-volume prototyping and high-volume production runs, offering scalable solutions that adapt to your business needs. With ISO 9001 certification and a commitment to continuous improvement, we ensure every component meets international standards for quality and reliability.

Below is an overview of our core manufacturing specifications and material capabilities:

| Specification | Detail |

|---|---|

| Material Types | Aluminum Alloys (A380, A360, ADC12), Zinc Alloys (Zamak 3, 5), Stainless Steel (304, 316), Tool Steel (H13, SKD61), Magnesium Alloys |

| Process Capabilities | High-Pressure Die Casting, CNC Machining, Mold Design & Fabrication, Surface Finishing (Anodizing, Powder Coating, Plating) |

| Tolerance | ±0.005 mm (standard), up to ±0.002 mm (precision) |

| Part Weight Range | 10 g – 15 kg |

| Surface Roughness | Ra 0.8 μm (as-machined), down to Ra 0.2 μm (polished) |

| Production Capacity | Up to 500,000 units per month |

| Quality Standards | ISO 9001:2015, RoHS, REACH compliant |

We invite global manufacturers to collaborate with a partner who combines technical excellence, operational scale, and responsive service. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions that drive your success. Contact us today at [email protected] to discuss your molding material requirements and discover how our custom metal manufacturing expertise can elevate your next project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.