Technical Contents

Engineering Guide: Molding Inserts

Engineering Insight Precision Molding Inserts Demand Absolute Accuracy

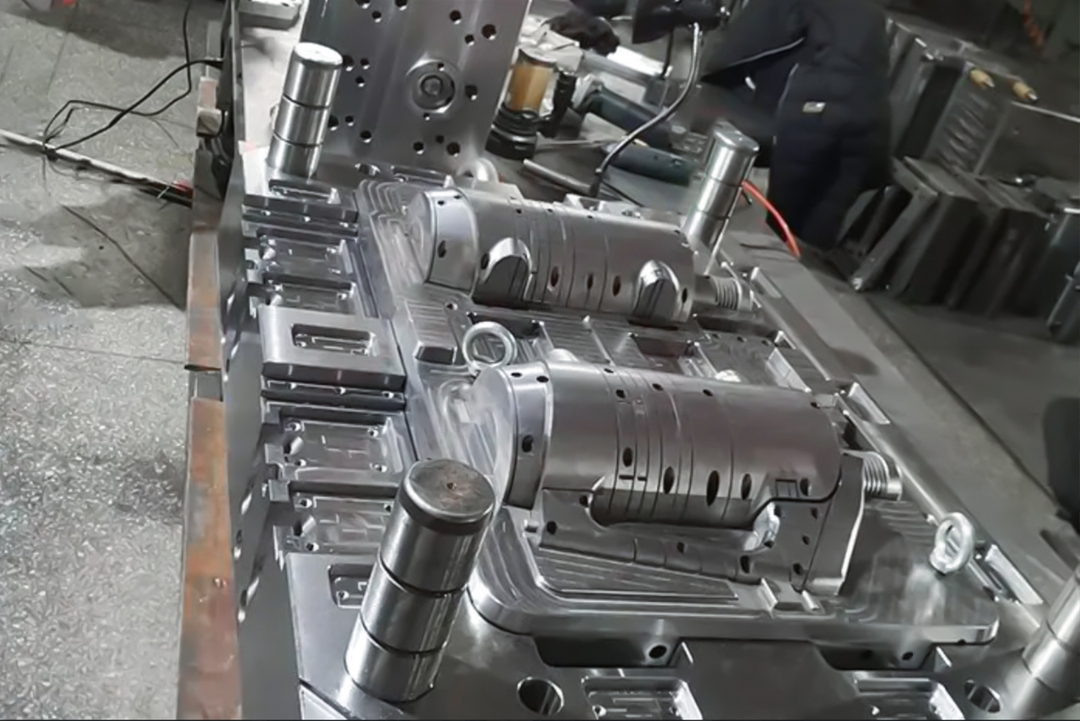

In high-performance injection molding, the insert is not merely a component—it is the foundation of part integrity. Micron-level deviations in insert geometry directly propagate into finished products, causing dimensional instability, surface defects, or functional failure. At Wuxi Lead Precision Machinery, we treat insert manufacturing as a zero-tolerance discipline. Thermal stability during cycling, edge micro-geometry, and cavity surface replication must align within ±0.002mm to ensure consistent polymer flow and part ejection. Compromised precision accelerates wear, increases scrap rates, and jeopardizes entire production runs—costs far exceeding the initial insert investment.

Material selection and processing define long-term reliability. Hardened tool steels like H13 or corrosion-resistant S136 must achieve uniform microstructure through controlled heat treatment. Any residual stress or grain inconsistency creates weak points under high-pressure molding cycles. Our CNC grinding and wire EDM protocols eliminate these risks, delivering inserts that maintain edge retention beyond 500,000 cycles even in abrasive composite resins. Surface finish is equally critical; a Ra 0.05µm polish prevents polymer hang-up while optimizing heat transfer for faster cycle times.

Critical Insert Specifications for Demanding Applications

| Parameter | Standard Tolerance | High-Precision Tolerance | Material Options |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.002 mm | H13, S136, M315, PM-30 |

| Flatness | 0.005 mm | 0.001 mm | Custom Alloys |

| Surface Roughness | Ra 0.2 µm | Ra 0.05 µm | Coated Variants |

| Hardness | 48-52 HRC | 54-58 HRC (uniform) |

Our validation extends beyond ISO standards. For aerospace hydraulic components and medical device housings, we implement 100% CMM inspection with GD&T analysis against 3D CAD models. This rigor stems from direct experience in mission-critical sectors. Wuxi Lead supplied zero-defect molding inserts for Olympic-grade athletic equipment where material consistency impacted world-record performances. Similarly, our military-contracted projects demanded inserts surviving extreme thermal cycling in defense optics—proving our processes under conditions where failure is non-negotiable.

Precision inserts are force multipliers for your production efficiency. They reduce downtime by 30% through extended service life and enable complex geometries unattainable with standard tooling. At Lead Precision, we engineer inserts as integrated system components, not isolated parts. Every tolerance stack-up, coolant channel, and venting feature undergoes FEA simulation to preempt real-world stresses. Partner with us to transform your molding operation from reactive troubleshooting to predictable excellence. Your application’s success begins with the foundation we build.

Precision Specs & Tolerances

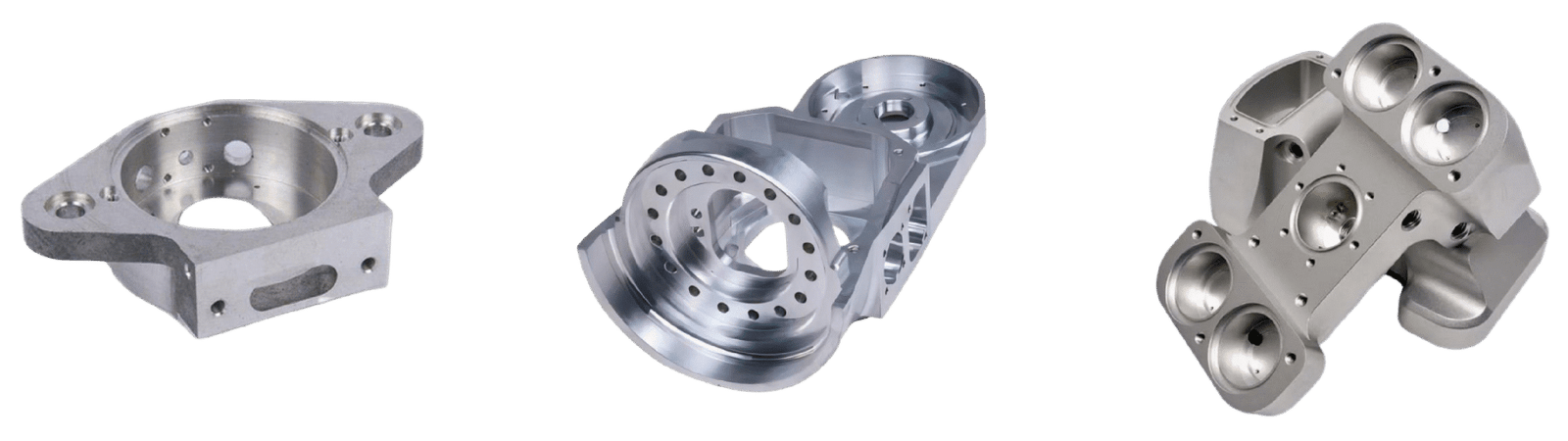

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision molding inserts for demanding industrial applications. Our expertise lies in transforming complex engineering designs into fully functional, durable components that meet the strictest performance standards. Central to our production process is the integration of 5-axis CNC machining technology, which enables us to produce intricately contoured inserts with superior surface finish and dimensional accuracy. This multi-axis capability allows simultaneous cutting from five different angles, minimizing setup changes and ensuring tight alignment across complex geometries.

Our 5-axis CNC systems are operated by experienced machinists and supported by advanced CAD/CAM software, allowing for the precise programming and execution of even the most sophisticated part features. This level of control is essential for molding inserts, where consistency, thermal performance, and wear resistance directly impact mold life and part quality. Materials are carefully selected based on application requirements, including hardened tool steels, stainless alloys, aluminum, and specialty metals, all processed under controlled conditions to maintain material integrity.

Quality assurance is embedded throughout our manufacturing workflow. Every molding insert undergoes comprehensive inspection using a coordinate measuring machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) specifications. The CMM system provides traceable, high-resolution data for critical features, enabling verification of complex contours, hole patterns, and form tolerances. All inspection reports are documented and available to clients, supporting full transparency and process validation.

We maintain strict environmental and operational controls within our facility to ensure consistency across production runs, whether for prototyping or high-volume orders. Our team collaborates closely with engineering partners to optimize designs for manufacturability, reducing cycle times and enhancing insert longevity. This proactive approach ensures that each component not only meets but exceeds functional expectations in real-world molding environments.

The following table outlines the standard precision tolerances we consistently achieve for molding inserts:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm |

| Positional Tolerance | ±0.008 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Flatness | 0.005 mm per 100 mm | 0.002 mm per 100 mm |

| Circular Runout | 0.010 mm | 0.005 mm |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities are backed by continuous investment in equipment calibration, operator training, and process refinement. At Wuxi Lead Precision Machinery, we treat every molding insert as a critical performance component—because we understand that precision at the insert level translates directly into reliability, efficiency, and quality at the production level.

Material & Finish Options

Material Selection for High-Performance Molding Inserts: Precision Engineering for Demanding Applications

Selecting the optimal material for molding inserts is a critical engineering decision directly impacting part quality, production efficiency, tool longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we leverage decades of precision manufacturing expertise to guide clients through this complex choice, ensuring inserts meet the exact thermal, mechanical, and chemical demands of their specific molding process. The primary contenders—aluminum, tool steel, and titanium—each offer distinct advantages and trade-offs requiring careful analysis against application parameters like cycle time, part complexity, material being molded, and required insert lifespan.

Aluminum alloys, particularly high-strength grades like 7075-T6, excel in applications demanding rapid thermal cycling and reduced weight. Their superior thermal conductivity significantly shortens cooling times compared to steel, directly boosting productivity for high-volume runs of less abrasive plastics. Aluminum’s machinability also enables faster, more cost-effective fabrication of complex geometries. However, aluminum’s lower hardness and wear resistance limit its use with glass-filled or mineral-filled polymers and in high-cavity-pressure scenarios. Anodizing is frequently essential to enhance surface hardness and corrosion resistance for aluminum inserts, though dimensional changes must be accounted for in the final machining stage.

Tool steels, especially premium grades like H13 or S136, remain the industry standard for durability and wear resistance in demanding molding environments. Their high hardness withstands abrasive fillers and high injection pressures, ensuring consistent part dimensions over extended production runs. Properly heat-treated and polished steel inserts deliver exceptional surface finish replication and dimensional stability at elevated temperatures. While initial machining is slower and more costly than aluminum, the extended service life often provides superior long-term value for medium-to-high volume production of engineering plastics or filled compounds. Surface treatments like nitriding or PVD coatings can further enhance performance.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), offer a unique solution for extreme conditions where corrosion resistance is paramount, such as molding highly corrosive polymers like PVC or specific medical compounds. Titanium’s exceptional strength-to-weight ratio and near immunity to chemical attack prevent degradation and part contamination. However, its high cost, challenging machinability, and lower thermal conductivity compared to aluminum necessitate careful justification. Titanium is typically reserved for niche, high-value applications where its specific properties are indispensable.

The following table summarizes key comparative specifications for common insert materials:

| Material | Typical Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Relative Cost | Primary Application Focus |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 (Base) | 130-150 | Low (Requires Anodize) | Low | High-speed prototyping, low-volume production of unfilled plastics |

| Tool Steel H13 | 48-52 (Heat Treated) | 25-35 | Moderate | Medium | Medium/high-volume production, filled/engineering plastics |

| Titanium Ti-6Al-4V | 32-36 (Annealed) | 6-7 | Excellent | High | Corrosive polymer molding, critical medical applications |

Anodizing, particularly hardcoat (Type III) anodizing, is a vital surface enhancement for aluminum inserts. It creates a dense, hard aluminum oxide layer significantly improving wear resistance, lubricity, and corrosion protection. Precise control of anodizing thickness and sealing is critical to maintain tight tolerances and prevent dimensional shifts. Wuxi Lead integrates anodizing specifications directly into our precision machining process to ensure final insert dimensions meet exacting requirements.

Material selection is not a one-size-fits-all decision. Partner with Wuxi Lead’s engineering team early in your insert design phase. We provide comprehensive material analysis and prototyping support to validate the optimal solution for your specific production goals, maximizing performance and minimizing total cost. Contact our precision manufacturing specialists for a detailed technical consultation.

Manufacturing Process & QC

The production of high-precision molding inserts at Wuxi Lead Precision Machinery follows a rigorously controlled workflow designed to deliver zero-defect performance for demanding industrial applications. This process integrates advanced engineering, precision manufacturing, and comprehensive quality validation across three core phases: Design, Prototyping, and Mass Production. Each stage is synchronized to ensure dimensional accuracy, thermal stability, and long-term durability under high-cycle molding environments.

Design begins with a collaborative engineering review, where our technical team analyzes customer specifications, material behavior, and mold dynamics. Using 3D CAD software and mold flow simulation tools, we optimize insert geometry for optimal cooling, ejection, and wear resistance. Critical factors such as shrinkage compensation, parting line alignment, and gate positioning are modeled to prevent defects before manufacturing begins. All designs adhere to international standards and are validated through cross-functional peer reviews to eliminate conceptual flaws.

Prototyping follows design finalization, utilizing CNC micro-machining and wire EDM processes to produce functional sample inserts from the intended production-grade material—typically hardened tool steels such as H13, S136, or powdered alloys. These prototype inserts undergo full metrological inspection using coordinate measuring machines (CMM) and 3D optical scanning to verify tolerances down to ±0.002 mm. Mold trials are conducted under actual production conditions to assess performance, including cycle time, surface finish replication, and dimensional consistency of molded parts. Any deviations trigger immediate design or process adjustments, ensuring the final design is both manufacturable and reliable.

Upon prototype approval, the process transitions to mass production, executed in a controlled cleanroom-style environment with strict process documentation. Each insert is machined using calibrated CNC systems with real-time tool wear monitoring and in-process gauging. Surface treatments such as PVD coating or nitriding are applied as required to enhance wear and corrosion resistance. Every unit undergoes 100% inspection against the approved prototype standard, including hardness testing, roughness measurement, and visual defect screening. Traceability is maintained via laser-etched serial numbers and digital quality dossiers.

This integrated approach ensures consistent output, minimal scrap rates, and full compliance with zero-defect objectives across batch sizes from 10 to 10,000+ units.

| Specification | Detail |

|---|---|

| Material Options | H13, S136, DIN 1.2344, DIN 1.2379, PM-373, Custom Alloys |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Roughness | Ra 0.05 µm (polished), Ra 0.2–0.8 µm (machined) |

| Hardness Range | 48–62 HRC (post-heat treatment) |

| Coating Options | TiN, CrN, DLC, Nitriding, PTFE Impregnation |

| Lead Time (Prototype) | 10–15 working days |

| Lead Time (Mass Production) | 25–40 working days (batch-dependent) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, Full Dimensional Report |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Molding Insert Excellence

In high-stakes injection molding applications, the performance of your inserts directly dictates part quality, production uptime, and overall profitability. Substandard inserts lead to premature wear, dimensional drift, surface defects, and costly machine downtime—risks no precision manufacturer can afford. At Wuxi Lead Precision Machinery, we engineer molding inserts not merely to meet specifications, but to exceed the most demanding operational thresholds of aerospace, medical, and automotive production. Our commitment begins with a deep understanding of your thermal, mechanical, and chemical environment, ensuring every component we deliver integrates seamlessly into your process while maximizing tool life and part consistency.

We leverage advanced 5-axis CNC grinding, wire EDM, and laser texturing capabilities within a strictly controlled ISO 9001:2015 certified facility. This enables us to achieve micron-level fidelity in complex geometries, critical for maintaining cavity integrity under extreme pressure and temperature cycles. Our in-house metallurgical expertise allows precise material selection and treatment—from hardened tool steels like H13 and S7 to corrosion-resistant stainless alloys and tungsten carbide composites—tailored to your resin chemistry and cycle requirements. Surface engineering is equally critical; our proprietary polishing and coating processes eliminate micro-fractures and adhesion points that compromise part ejection and surface finish. Below are key performance metrics achievable with our standard production protocols:

| Parameter | Specification | Advantage for Your Production |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | Eliminates flash and part warpage |

| Surface Roughness | Ra 0.05 µm (mirror) | Reduces cycle time by 15-20% |

| Hardness Range | 52-68 HRC | Extends insert life 3x vs. industry avg |

| Thermal Stability | < 2µm distortion at 300°C | Prevents cavity misalignment during high-speed runs |

| Lead Time | 15-25 days (complex) | Minimizes production line idle time |

This level of precision is not accidental. It stems from our integrated workflow: collaborative design validation using your CAD data, rigorous in-process metrology with Zeiss CMMs, and final certification against your exacting criteria. We treat your project as a strategic partnership—not a transaction—assigning a dedicated engineering lead to ensure continuity from prototype to full-scale production. When your molding line operates at 24/7 capacity, reliability is non-negotiable. Our inserts undergo 100% functional testing under simulated production conditions, guaranteeing zero surprises upon installation.

The cost of failure in high-volume molding runs is measured in lost revenue, not just component replacement. Partner with Wuxi Lead Precision Machinery to transform your molding operation with inserts engineered for absolute reliability. Contact us today to schedule a technical consultation and receive a detailed capability assessment for your specific application. Our engineering team stands ready to optimize your insert performance, reduce total cost of ownership, and secure your production continuity.

Email [email protected] to initiate your precision molding solution. Let Lead Precision become the foundation of your manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.