Technical Contents

Engineering Guide: Molding Hands Kit

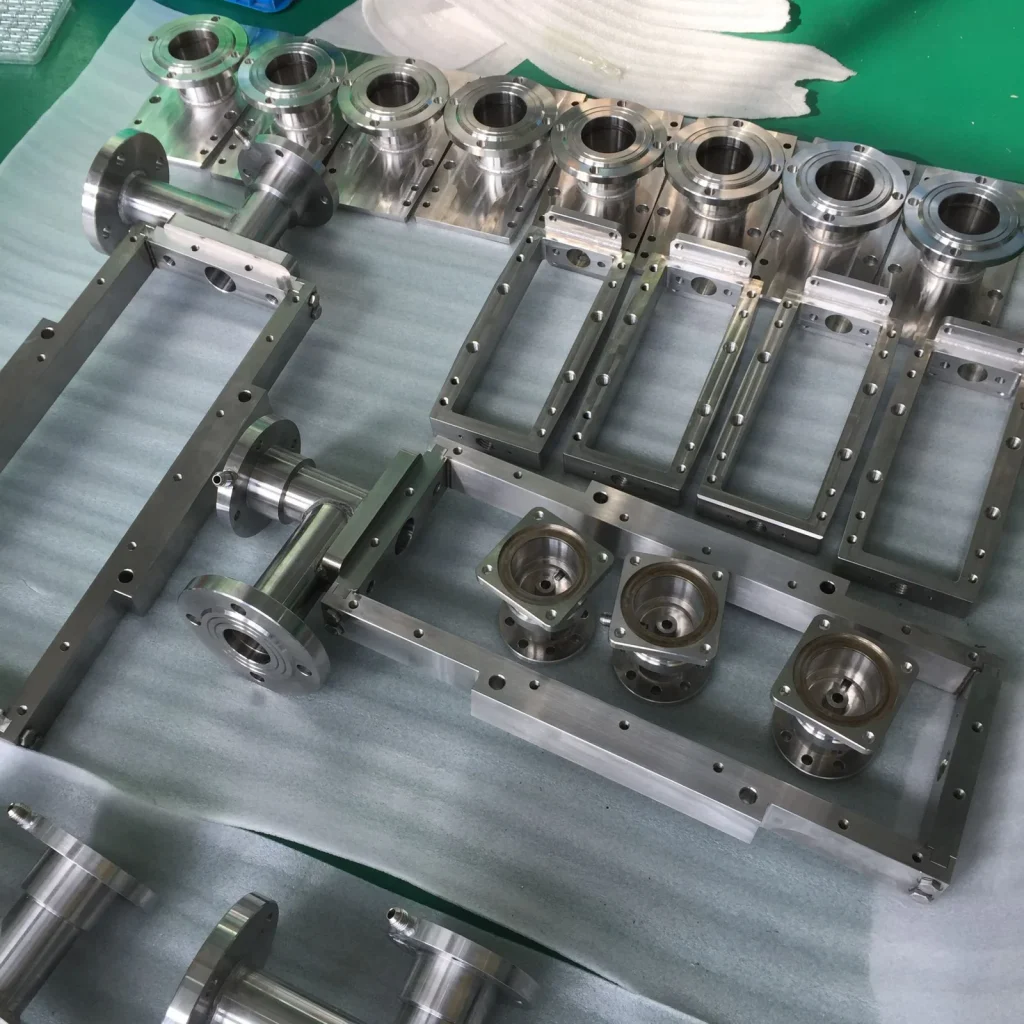

Engineering Insight: The Critical Role of Precision in Molding Hands Kit Manufacturing

In the realm of custom metal manufacturing, the performance and reliability of automated systems hinge on the precision of individual components. Among these, the molding hands kit stands as a pivotal element in high-speed, high-precision industrial automation—particularly within injection molding, die casting, and advanced material handling applications. These kits, responsible for gripping, transferring, and positioning components with exacting accuracy, must operate flawlessly across thousands of cycles. Any deviation in dimensional tolerance or surface integrity can lead to product defects, machine downtime, or cascading system failures.

At Wuxi Lead Precision Machinery, we recognize that the foundation of a high-performance molding hands kit lies in micron-level precision engineering. Our manufacturing processes integrate advanced CNC machining, multi-axis milling, and strict quality control protocols to ensure every component meets the most rigorous performance standards. With over 15 years of experience serving aerospace, defense, and high-end industrial sectors—including precision components for Olympic-standard equipment and military-grade systems—we bring unparalleled expertise to every custom solution.

Precision in molding hands kits is not solely about tight tolerances. It encompasses material selection, thermal stability, wear resistance, and dynamic balance under operational stress. For instance, a slight imbalance in a rotating gripper arm can amplify vibration at high cycle rates, compromising both part quality and equipment lifespan. Similarly, improper surface finish can accelerate wear on sealing surfaces or lead to inconsistent grip force, especially in environments involving elevated temperatures or corrosive materials.

Our engineering team employs finite element analysis (FEA) and real-world simulation to validate design integrity before production. This proactive approach ensures optimal load distribution, fatigue resistance, and long-term dimensional stability. Furthermore, all components undergo rigorous metrological inspection using coordinate measuring machines (CMM) and laser scanning technologies, guaranteeing compliance with ISO 2768-mK and customer-specific standards.

Below are key specifications that define the performance of our custom molding hands kits:

| Specification | Detail |

|---|---|

| Material Options | 7075-T6 Aluminum, 42CrMo4 Steel, 17-4 PH Stainless Steel, Titanium Grade 5 |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on geometry and size) |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm (custom finishes available) |

| Hardness | Up to HRC 58 (after heat treatment) |

| Coating Options | Hard Anodizing, DLC (Diamond-Like Carbon), PVD TiN |

| Testing Standards | Load cycling, thermal cycling, dimensional stability under stress |

| Compliance | ISO 9001:2015, RoHS, REACH |

Wuxi Lead Precision Machinery’s commitment to excellence is demonstrated not only in our technical capabilities but in our proven track record delivering mission-critical components where failure is not an option. When your production line demands reliability at scale, the precision of your molding hands kit becomes a strategic advantage—one that we are engineered to deliver.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Molding Hands Kits

Wuxi Lead Precision Machinery delivers mission-critical components for advanced molding systems, specializing in high-precision “molding hands kits” – complex ejector mechanisms, core pins, and guide systems essential for injection, blow, and die-casting molds. Our engineering rigor ensures these components withstand extreme cyclic loads, thermal stress, and stringent surface finish requirements inherent in modern high-volume production environments.

Our core competency lies in multi-axis CNC machining, leveraging state-of-the-art 5-axis vertical and horizontal machining centers. These systems perform simultaneous 5-axis interpolation, enabling the production of intricate geometries—such as undercuts, helical contours, and compound angles—in a single setup. This eliminates cumulative errors from multiple fixtures, critical for maintaining concentricity and positional accuracy in molding hands kits. We routinely machine hardened tool steels (HRC 50-60), stainless alloys, and wear-resistant materials with minimal thermal distortion, utilizing high-speed spindles (up to 24,000 RPM) and rigid toolholding systems to achieve superior surface integrity (Ra ≤ 0.4 µm).

Quality assurance is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ASME Y14.5 and ISO 1101 GD&T standards. Our metrology lab validates dimensional conformance, form accuracy, and surface texture against client CAD models, generating full inspection reports with traceable calibration data. This process ensures zero-defect delivery for components where micrometer-level deviations directly impact mold performance and part quality.

The table below defines our standard and precision tolerance capabilities for molding hands kits, reflecting our capacity to meet demanding automotive, medical, and aerospace specifications. All tolerances are achievable in production volumes without secondary operations.

| Feature Type | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 | CMM / High-Precision Micrometer |

| Geometric Tolerances | ±0.015 (Position) | ±0.003 (True Position) | CMM (GD&T Analysis) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| Concentricity (mm) | 0.015 | 0.005 | CMM / V-Block Indicator |

| Angle Tolerance (°) | ±0.05 | ±0.01 | CMM / Optical Comparator |

Our integrated workflow—from material certification through CNC machining to CMM validation—ensures molding hands kits exhibit exceptional wear resistance, dimensional stability, and functional reliability. We exceed ISO 2768-mK standards as baseline practice, providing clients with components that maximize mold uptime and part consistency. For mission-critical applications, our engineering team collaborates directly to refine tolerances, material selection, and inspection protocols, ensuring your molding system operates at peak efficiency with minimal maintenance. Wuxi Lead Precision Machinery transforms complex design challenges into precision-engineered reality.

Material & Finish Options

Material Selection for High-Performance Molding Hands Kits

Selecting the appropriate material for a molding hands kit is critical to ensuring reliability, longevity, and precision in high-cycle industrial automation environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exact mechanical and environmental demands of our clients. For molding hands kits—used in precision handling, insertion, and part transfer applications—three primary materials stand out: aluminum, steel, and titanium. Each offers distinct advantages depending on load requirements, weight sensitivity, corrosion exposure, and operational lifespan.

Aluminum is often the preferred choice for applications requiring lightweight construction without sacrificing structural integrity. Its high strength-to-weight ratio reduces inertia in fast-moving robotic arms, improving cycle times and energy efficiency. 6061-T6 and 7075-T6 aluminum alloys are commonly used due to their excellent machinability, weldability, and resistance to fatigue. However, aluminum is less wear-resistant than steel and may require surface enhancement for prolonged service in abrasive conditions.

Steel, particularly tool steel and stainless steel variants, delivers superior hardness, wear resistance, and load-bearing capacity. It is ideal for high-force gripping applications or environments with elevated temperatures and mechanical stress. While heavier than aluminum, steel ensures dimensional stability and durability over millions of cycles. For corrosive environments, 316 stainless steel provides excellent resistance to oxidation and chemical exposure, making it suitable for medical, food processing, and marine-related molding operations.

Titanium offers a unique combination of high tensile strength, exceptional corrosion resistance, and low density. Though more costly and challenging to machine, titanium is optimal for extreme environments—such as high-temperature molding or aerospace applications—where performance outweighs cost considerations. Its biocompatibility and non-magnetic properties also make it suitable for specialized sectors like medical device manufacturing.

Surface finishing plays a pivotal role in enhancing performance and longevity. Anodizing is a widely used electrochemical process, especially for aluminum components. It creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer increasing levels of wear resistance, with hardcoat anodizing suitable for high-friction contact points in molding hands.

Below is a comparative overview of key material properties for molding hands kits.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 95 | Moderate | Lightweight grippers, fast cycle arms |

| Steel (4140) | 7.85 | 655 | 200 | Low (unless coated) | High-load, high-wear tooling |

| Stainless Steel 316 | 8.0 | 580 | 160 | High | Sanitary, marine, chemical environments |

| Titanium Grade 5 | 4.5 | 900 | 360 | Very High | Aerospace, medical, extreme conditions |

Material selection must be guided by application-specific parameters. Wuxi Lead Precision Machinery supports clients in evaluating these factors to deliver optimized, high-precision molding hands kits with engineered finishes for maximum operational efficiency.

Manufacturing Process & QC

Precision Manufacturing Process: Molding Hands Kit

At Wuxi Lead Precision Machinery, our molding hands kit production follows a rigorously controlled sequence ensuring zero defects for high-stakes industrial applications. This process begins with collaborative engineering design, transitions through validated prototyping, and culminates in fully traceable mass production. Every phase integrates metrology-grade verification to eliminate tolerance drift and material inconsistencies.

Design Phase

Our engineering team initiates with comprehensive Design for Manufacturing (DFM) analysis, leveraging CAD/CAM simulations to optimize geometry, material flow, and thermal stability. Critical dimensions—such as finger curvature radii and pivot pin alignment—are stress-tested against real-world molding pressures (up to 150 bar) and temperature cycles (–40°C to 200°C). Material selection prioritizes 420 stainless steel or 17-4PH for corrosion resistance and wear longevity, validated through finite element analysis (FEA) to prevent deformation under cyclic loads. Design sign-off requires cross-functional approval from CNC programming, quality assurance, and client technical teams.

Prototyping Phase

A single prototype is machined using our DMG MORI CTX beta 1250 5-axis centers, applying final production toolpaths and coolant strategies. This unit undergoes 100% dimensional inspection via Zeiss CONTURA CMM (accuracy ±1.5 µm) and functional testing in client-simulated molding environments. Surface finish, positional tolerances, and thermal stability are validated against baseline specs. Only after achieving < 0.005 mm deviation across all critical features does the design advance. Prototype data directly informs fixture adjustments and in-process gauging protocols for mass production.

Mass Production Phase

Serial production deploys automated gantry loaders and real-time SPC (Statistical Process Control) monitoring. Each kit component is traced via laser-etched serial numbers, with critical dimensions measured at 30-minute intervals using in-line optical comparators. Our zero-defect mandate is enforced through:

Closed-loop tool wear compensation adjusting for micro-variation after 500 cycles

100% post-machining CMM validation of pivot bore concentricity (±0.002 mm)

Batch-level material certification (ASTM F899 for medical-grade alloys)

Final assembly in ISO Class 8 cleanrooms with torque-controlled fastening

Key Production Specifications

| Parameter | Specification | Verification Method | Acceptance Criteria |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Zeiss CMM | 100% within limits |

| Surface Roughness | Ra 0.8 µm max | Mitutoyo SJ-410 Profilometer | CpK ≥ 1.67 |

| Material Hardness | 48–52 HRC | Wilson Hardness Tester | ASTM E18 compliant |

| Corrosion Resistance | 96h salt spray (ASTM B117) | Q-Lab Q-FOG CCT600 | Zero pitting |

| Functional Cycle Life | 500,000+ cycles | Custom hydraulic test rig | < 0.01 mm wear |

This end-to-end discipline—rooted in predictive engineering and closed-loop quality control—ensures molding hands kits deliver uninterrupted performance in injection molding cells. Wuxi Lead’s integration of aerospace-grade metrology with lean manufacturing protocols guarantees zero client downtime risk. All production data is archived for full-lifecycle traceability, meeting ISO 13485 and IATF 16949 standards. Partner with us to transform precision requirements into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for your next high-performance molding hands kit project and experience unmatched precision, reliability, and engineering excellence. As a leading provider in custom metal manufacturing, we specialize in delivering mission-critical components tailored to the exacting demands of advanced automation, robotics, and industrial molding systems. Our molding hands kits are engineered for durability, repeatability, and seamless integration into high-speed production environments—ensuring maximum uptime and operational efficiency.

At Wuxi Lead Precision Machinery, we understand that every application presents unique challenges. Whether you require complex multi-axis gripper systems, custom end-of-arm tooling, or fully integrated handling solutions, our team of senior CNC engineers and design specialists works closely with you from concept to completion. We combine advanced 5-axis CNC machining, precision sheet metal fabrication, and rigorous quality control protocols to produce components that meet the highest international standards. Our facility in Wuxi, China, is equipped with state-of-the-art technology and operates under ISO 9001-certified processes, guaranteeing consistency and traceability across every production run.

Our molding hands kits are designed for superior performance in harsh industrial environments. Constructed from high-grade aluminum alloys, stainless steel, or customized materials based on operational requirements, these kits offer exceptional strength-to-weight ratios, wear resistance, and thermal stability. Each unit undergoes comprehensive dimensional inspection, load testing, and surface finish validation to ensure compliance with your exact specifications.

Below are the key technical specifications available for our standard and custom molding hands kits:

| Specification | Details |

|---|---|

| Material Options | 6061-T6, 7075-T6 Aluminum, Stainless Steel 304/316, Custom Alloys |

| Tolerance | ±0.005 mm to ±0.02 mm (depending on geometry and size) |

| Surface Finish | As-machined, Anodizing (Type II/III), Passivation, Powder Coating |

| Load Capacity | Up to 50 kg per finger (configurable) |

| Actuation Type | Pneumatic, Electric, Servo-Driven (customizable) |

| Interface Compatibility | ISO, DIN, and custom mounting patterns |

| Lead Time | 15–30 days (based on complexity and order volume) |

| Certifications | ISO 9001:2015, RoHS Compliant, Inspection Reports Available |

We serve global OEMs, automation integrators, and Tier-1 suppliers across the automotive, electronics, medical device, and consumer goods industries. Our commitment to technical innovation and customer collaboration has made Wuxi Lead Precision Machinery a trusted manufacturing partner in over 30 countries.

To discuss your specific requirements or request a detailed quotation, contact us today at [email protected]. Our engineering team is ready to support your project with technical consultation, 3D modeling, and rapid prototyping services. Let us help you achieve superior performance and reliability in your automated molding processes—partner with precision, partner with Wuxi Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.