Technical Contents

Engineering Guide: Molding Die Parts

Engineering Insight Precision Imperatives in Molding Die Manufacturing

Achieving flawless part replication in high-volume production hinges entirely on the foundational precision of the molding die itself. Minute deviations in cavity geometry, core alignment, or cooling channel placement propagate exponentially through thousands of cycles, resulting in dimensional drift, surface defects, increased scrap rates, and costly production downtime. The thermal and mechanical stresses inherent in molding processes demand dies engineered not just to initial specifications, but to maintain dimensional stability and micro-geometric integrity throughout their operational lifespan. This requires moving beyond basic dimensional accuracy to encompass comprehensive control of material homogeneity, residual stress management, and exacting surface finishes that minimize friction and wear. In industries where component failure is not an option – aerospace, medical devices, or critical automotive systems – the die is the silent guardian of product integrity. Its precision directly dictates the repeatability, quality, and ultimately, the safety of the final manufactured part.

Wuxi Lead Precision Machinery operates at this critical intersection of extreme tolerance and functional reliability. Our engineering discipline is forged through direct experience delivering mission-critical die components for applications where compromise is unacceptable. We engineered precision molding die elements for structural components within Beijing Winter Olympics venue construction, demanding absolute consistency under severe environmental loads. Similarly, our work on specialized tooling for aerospace fastener systems serving military programs required adherence to stringent AS9100 and MIL-SPEC standards, where tolerances reside deep within the micron range and material certifications are non-negotiable. This experience instills a zero-defect manufacturing culture, utilizing advanced multi-axis CNC machining centers, coordinate measuring machines (CMM) with sub-micron resolution, and rigorous in-process metrology protocols. We understand that precision is not merely a number on a drawing; it is the cumulative result of material science expertise, thermal compensation strategies, and unwavering process control from raw billet to final assembly.

The tangible difference manifests in critical die performance metrics. Below illustrates the standard expectations versus the precision threshold Wuxi Lead consistently achieves for high-demand molding applications:

| Parameter | Standard Die Tolerance | Precision Die Requirement | Wuxi Lead Precision Standard |

|---|---|---|---|

| Linear Tolerance | ±0.010 mm | ±0.005 mm | ±0.002 mm |

| Surface Roughness | Ra 0.8 µm | Ra 0.4 µm | Ra 0.2 µm |

| Material Hardness | HRC 48-52 | HRC 52-54 | HRC 54-56 (Uniform) |

| Critical Runout | 0.015 mm | 0.008 mm | 0.003 mm |

This level of precision engineering translates directly to client value: extended die life exceeding 500,000+ cycles, reduced secondary operations, minimized material waste, and production lines running at optimal efficiency. When your molding process demands absolute fidelity cycle after cycle, the die’s precision is the non-negotiable starting point. Wuxi Lead Precision Machinery provides the engineering rigor and proven manufacturing excellence to make that precision a tangible reality for your most demanding applications.

Precision Specs & Tolerances

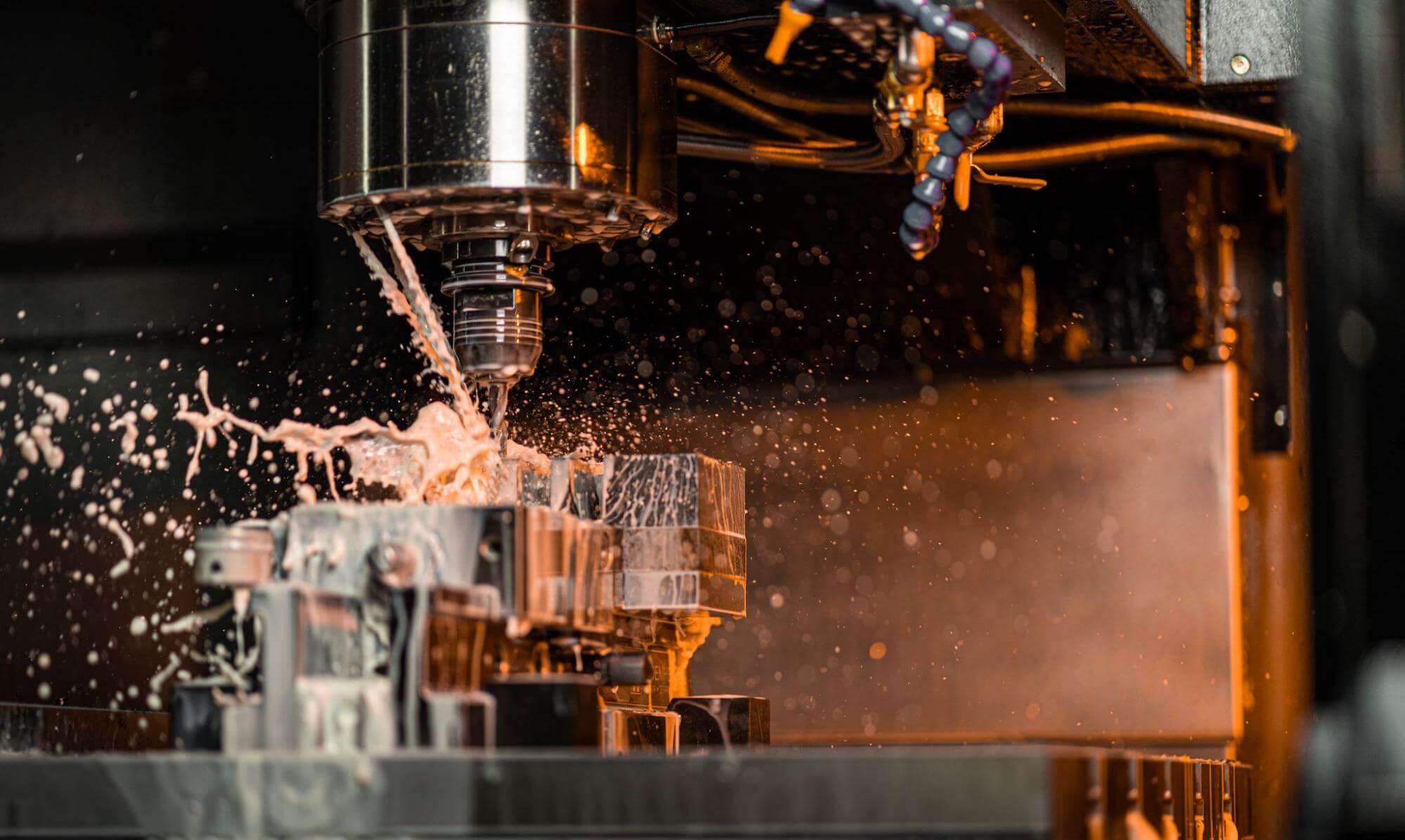

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of high-precision molding die parts, engineered to meet the rigorous demands of global manufacturing industries. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring, deep cavity machining, and undercuts—features often critical in mold die applications for automotive, aerospace, and consumer electronics sectors.

Our 5-axis CNC platforms are operated by certified machinists with extensive experience in toolpath optimization, high-speed machining, and material-specific strategies. This expertise ensures minimal setup changes, reduced cycle times, and superior part consistency. We work with a wide range of tool steels, stainless alloys, aluminum, and hardened materials up to 60 HRC, supporting both prototype development and high-volume production runs. Advanced CAM software integrates seamlessly with our machines, ensuring precise tool engagement, collision avoidance, and efficient material removal rates.

Quality control is embedded into every stage of our manufacturing process. All molding die parts undergo comprehensive inspection using a Zeiss DuraMax and O-Inspect 863 coordinate measuring machine (CMM), providing metrology-grade verification of dimensional accuracy and geometric conformity. Our CMM system supports both contact and optical probing, enabling non-destructive measurement of fine details and tight tolerance features. Each component is validated against the original CAD model, with full inspection reports available upon request. This metrology-backed approach ensures compliance with ISO 10360 standards and customer-specific quality requirements.

We maintain strict environmental controls in our inspection lab to minimize thermal drift, ensuring measurement repeatability within microns. In addition to CMM validation, we employ surface roughness testers, hardness testers, and optical comparators to verify critical surface and material properties. All quality data is documented and traceable, supporting full production lot traceability for audit and certification purposes.

The following table outlines the standard tolerance capabilities we achieve on molding die parts using our 5-axis CNC and inspection systems:

| Feature | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Tolerances (mm) | ±0.010 | ±0.005 |

| Positional Tolerance (mm) | ±0.012 | ±0.008 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Geometric Tolerances (Flatness, Parallelism) | 0.015 mm/m | 0.008 mm/m |

| Hole Diameter Tolerance | H7 | H6 |

| Edge Radius Control | ±0.02 mm | ±0.01 mm |

These capabilities, combined with our engineering-first approach, position Wuxi Lead Precision Machinery as a trusted partner for technically demanding molding die components. We consistently deliver parts that meet stringent performance, durability, and interchangeability requirements.

Material & Finish Options

Material Selection for High-Performance Molding Die Components

Selecting the optimal material for molding die components is fundamental to achieving precision, longevity, and cost-efficiency in demanding production environments. At Wuxi Lead Precision Machinery, our decades of experience machining critical tooling underscore that material choice directly impacts cycle times, part quality, and overall tooling investment. This section provides essential guidance for selecting aluminum, steel, or titanium alloys based on specific application requirements, alongside the critical role of surface finishing like anodizing.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are preferred for prototype dies, low-volume production, and applications requiring rapid heat dissipation. Their high thermal conductivity accelerates cooling cycles, while lower density reduces machine load and handling costs. However, aluminum’s lower hardness and wear resistance compared to steel limit its use in high-volume or abrasive material molding. Precision machining of aluminum demands expertise to maintain tight tolerances without deformation.

Tool steels remain the dominant choice for high-volume, production-critical molding dies. Grades like H13 (hot work), S7 (shock resisting), and D2 (high-carbon, high-chromium) offer exceptional hardness, wear resistance, and thermal stability under repeated heating and cooling cycles. H13 excels in die casting and injection molding of thermoplastics due to its superior hot hardness and toughness. Selecting the precise steel grade requires careful analysis of molding material abrasiveness, operating temperature, required part complexity, and expected production volume. Our advanced heat treatment and precision grinding capabilities ensure these steels achieve their full performance potential.

Titanium alloys (e.g., Ti-6Al-4V) are specialized solutions for extreme conditions, such as molding highly corrosive materials or where exceptional strength-to-weight ratio is paramount. While offering outstanding corrosion resistance and strength at elevated temperatures, titanium presents significant machining challenges and higher material costs. Its use is typically justified only for niche applications where steel or aluminum fail prematurely, demanding a thorough cost-benefit analysis.

Surface treatment, particularly anodizing for aluminum components, is not merely cosmetic. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness, lubricity, and corrosion resistance. This extends die life in abrasive molding processes and reduces part sticking, directly improving yield. Proper anodizing parameters must be meticulously controlled to avoid dimensional changes or brittleness.

Material selection must be a calculated decision based on the specific demands of the molding process. The following comparative table highlights key properties influencing die performance:

| Material | Typical Hardness (HRC) | Thermal Conductivity (W/mK) | Primary Applications |

|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130 | Prototypes, Low-volume production, Core pins |

| H13 Tool Steel | 48-52 (after HT) | 28-36 | High-volume injection/die casting dies |

| D2 Tool Steel | 58-62 (after HT) | 24-26 | High-wear inserts, Ejector pins, Trim dies |

| Titanium Ti-6Al-4V | 36-41 | 6.7 | Corrosive material molding, Weight-sensitive |

Wuxi Lead Precision Machinery leverages deep metallurgical knowledge and state-of-the-art CNC machining to transform these materials into die components that meet the most stringent global manufacturing standards. Partner with us to ensure your material selection delivers optimal performance and return on investment.

Manufacturing Process & QC

The production of high-precision molding die parts at Wuxi Lead Precision Machinery follows a rigorously controlled workflow designed to ensure zero defects, dimensional accuracy, and long-term performance under demanding industrial conditions. Our process integrates advanced engineering, precision machining, and real-time quality verification across three core phases: Design, Prototyping, and Mass Production.

Design begins with a collaborative review of customer specifications, including 3D CAD models, material requirements, and functional performance criteria. Our engineering team applies Design for Manufacturability (DFM) principles to optimize part geometry, minimize stress concentrations, and enhance cooling efficiency within the die structure. Finite Element Analysis (FEA) is used to simulate thermal and mechanical loads, ensuring structural integrity during injection or compression molding cycles. Material selection is critical—common choices include H13, P20, and S136 steels, selected based on hardness, corrosion resistance, and thermal stability. All design data is validated and locked into our digital manufacturing ecosystem to eliminate translation errors.

Prototyping is conducted using CNC machining centers with sub-micron positioning accuracy. This phase produces a fully functional die insert or cavity block that mirrors the final production component. The prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to nominal dimensions. Functional testing includes trial molding runs to assess part ejection, surface finish transfer, and cycle time consistency. Any deviations are traced to root causes and corrected before release to mass production. This stage not only validates design integrity but also confirms process stability.

Mass Production leverages automated CNC milling, wire EDM, and high-speed grinding operations under strict environmental controls. Each machine is calibrated daily, and tool wear is monitored in real time using in-process probes and acoustic emission sensors. All critical dimensions are inspected at defined intervals using statistical process control (SPC), ensuring process capability indices (Cp/Cpk) exceed 1.67. Surface finishes are maintained within tight Ra tolerances, and heat treatment parameters are logged for full traceability. Every batch is accompanied by a material certificate, inspection report, and process audit log.

Our zero-defect commitment is enforced through a closed-loop quality system that integrates corrective actions directly into production workflows. Non-conformances are escalated immediately, and containment measures are applied before any part leaves the facility.

Key production specifications are maintained as follows:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Tolerance | ±0.002 mm | ISO 2768-m |

| Surface Roughness (Ra) | 0.05 – 0.4 µm | ISO 4287 |

| Material Hardness | Up to 52 HRC (post-heat treatment) | ASTM E18 |

| Dimensional Accuracy | ±0.001 mm (CMM verified) | ISO 10360-2 |

| Production Lead Time | 15–25 days (based on complexity) | Internal SLA |

This disciplined approach ensures that every molding die part delivered by Wuxi Lead Precision Machinery meets the highest standards of precision, reliability, and performance in global manufacturing applications.

Why Choose Wuxi Lead Precision

Elevate Your Molding Performance Through Strategic Partnership

In the demanding realm of precision molding, the integrity and performance of your die components directly dictate production efficiency, part quality, and ultimately, your competitive edge. Generic solutions or inconsistent suppliers introduce unacceptable risk – dimensional drift, premature wear, and unplanned downtime erode profitability. Wuxi Lead Precision Machinery transcends the role of a standard manufacturer; we are your dedicated engineering partner, committed to delivering molding die parts engineered for exceptional longevity and flawless function within your specific production environment. Our foundation is built upon rigorous German-inspired quality protocols integrated within our advanced Chinese manufacturing facility, ensuring every component meets the exacting demands of high-volume, high-precision molding applications.

Our commitment begins with deep technical collaboration. We do not merely interpret drawings; our experienced CNC engineers engage proactively to understand your molding process parameters, material challenges, and lifecycle expectations. This consultative approach allows us to optimize material selection, heat treatment specifications, and critical feature geometry before machining commences, mitigating potential failure points inherent in less integrated supplier relationships. The result is die steel components exhibiting superior thermal stability, wear resistance, and micron-level dimensional accuracy, directly translating to reduced scrap rates, extended mold life, and minimized production interruptions for your operation.

The technical capabilities underpinning this partnership are demonstrable and consistently delivered. We specialize in the complex geometries and stringent tolerances essential for core pins, cavities, lifters, and sliders used in injection, blow, and compression molding:

| Critical Specification | Wuxi Lead Precision Capability | Industry Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Ensures perfect part fit, eliminates flash, maintains critical sealing surfaces |

| Surface Finish (Ra) | As low as 0.05 µm (2 µin) | Critical for part ejection, aesthetic surfaces, and reducing friction wear |

| Material Expertise | H13, S7, 420SS, PM Steels, Custom Alloys | Matched precisely to your resin type, production volume, and thermal demands |

| Hardness Range | 48-54 HRC (post-heat treat) | Optimized balance of wear resistance and toughness for specific die functions |

| Lead Time (Complex Components) | 15-25 Working Days | Accelerates your mold build schedules without compromising quality |

Partnering with Lead Precision means gaining access to more than just machining capacity. You secure a responsive engineering resource invested in your success. Our dedicated project managers and manufacturing engineers provide transparent communication, detailed first-article inspection reports (FAIRs) including CMM data, and rapid technical support throughout the component lifecycle. We implement stringent in-process controls and final validation against your specifications, backed by robust confidentiality protocols protecting your intellectual property.

When substandard die components threaten your production uptime and part quality, the cost of compromise becomes immediate and significant. Do not navigate these critical challenges with suppliers lacking the engineering depth and process discipline required. Contact our technical sales team today at [email protected]. Initiate a conversation where your specific molding challenges are met with actionable engineering solutions. Provide your project specifications, and we will respond within 24 hours with a detailed capability assessment and a clear path to achieving your precision die component goals. Partner with certainty; partner with Wuxi Lead Precision Machinery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.