Technical Contents

Engineering Guide: Moldes De Inyección

Engineering Insight: Precision as the Non-Negotiable Foundation of Injection Molding

In injection molding, precision isn’t merely desirable; it is the absolute bedrock of part quality, production efficiency, and long-term mold viability. Minute deviations in cavity geometry, core alignment, or thermal management directly translate into costly defects: flash, sink marks, dimensional instability, or premature wear. For high-value applications in automotive, medical devices, and consumer electronics, where tolerances often reside in the single-digit micron range, the mold itself must be manufactured to exacting standards exceeding the final part specification. This level of precision demands more than advanced machinery; it requires deep metallurgical understanding, sophisticated thermal analysis, and rigorous process validation at every manufacturing stage. Compromising on mold precision inevitably leads to increased scrap rates, unplanned downtime, and significant secondary operations, eroding profitability and damaging brand reputation.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our engineering philosophy centers on achieving micron-level accuracy consistently, proven through the most demanding validation environments. We have successfully engineered and manufactured molds for components utilized in Olympic Winter Games infrastructure, where extreme environmental resilience and flawless aesthetics were paramount under global scrutiny. Furthermore, our adherence to stringent aerospace and defense protocols for military-grade components underscores our capability to meet the highest reliability and traceability standards. These projects demanded not only exceptional dimensional accuracy but also unparalleled material integrity and process repeatability – capabilities forged through decades of specialized experience in China’s advanced manufacturing sector. This heritage directly benefits commercial clients, transforming precision from a theoretical requirement into a measurable, guaranteed outcome.

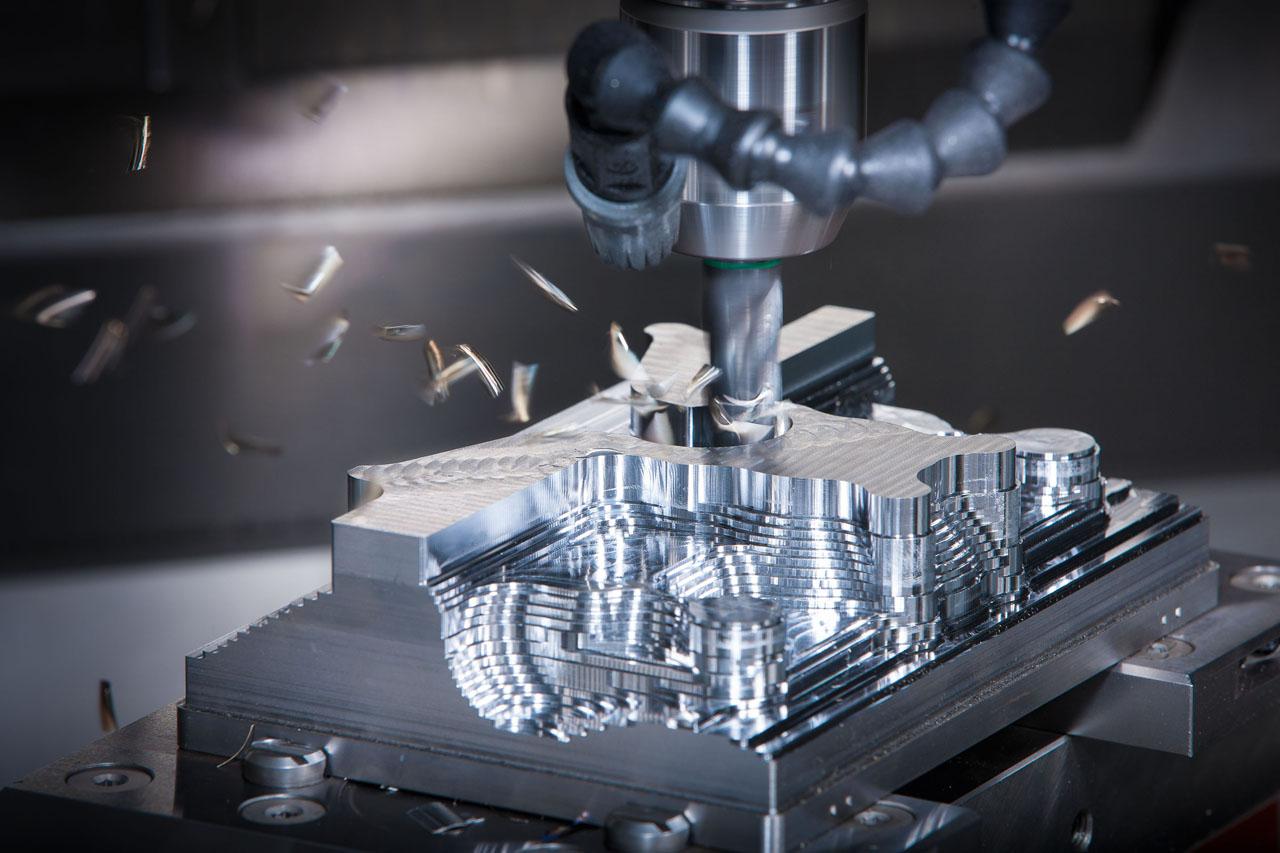

The tangible manifestation of this precision engineering is evident in our core manufacturing capabilities. We leverage state-of-the-art multi-axis CNC machining centers, wire EDM, and precision grinding, all operating within tightly controlled environmental conditions and supported by comprehensive metrology. The table below outlines key specifications achievable for critical mold components:

| Parameter | Specification | Application Impact |

|---|---|---|

| Cavity/Core Tolerance | ±0.002 mm | Ensures perfect part fit, eliminates flash |

| Surface Roughness (Ra) | 0.025 µm (Mirror) | Critical for optical clarity, medical biocompatibility |

| Thermal Uniformity | ΔT ≤ 1.5°C across cavity | Prevents warpage, ensures consistent material flow |

| Runout (Ejection) | ≤ 0.003 mm | Guarantees smooth part release, prevents damage |

| Material Hardness | HRC 52-58 (Verified) | Maximizes wear resistance, extends mold life |

This commitment to measurable precision translates directly to client success. Reduced cycle times, minimal scrap, extended mold service life, and consistent part quality are not aspirational goals but standard deliverables. When your application demands zero-defect performance under high-volume production, the foundational investment in a truly precise mold from Wuxi Lead Precision Machinery mitigates risk and delivers superior total cost of ownership. Contact our engineering team to discuss how our Olympic and military-proven precision standards can be applied to your next critical molding project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision moldes de inyección for global industrial clients. Our engineering expertise is built on a foundation of cutting-edge equipment, rigorous quality control, and a deep understanding of the demanding requirements associated with injection mold production. We focus on delivering components that meet exacting performance standards, ensuring longevity, repeatability, and flawless integration into high-volume manufacturing environments.

At the core of our production capability is our fleet of 5-axis CNC machining centers. These advanced systems enable us to execute complex geometries and tight-tolerance features that are often unattainable with conventional 3-axis technology. The simultaneous movement across five axes allows for single-setup machining of intricate mold cores, cavities, and inserts, minimizing human intervention and reducing cumulative error. This results in superior surface finishes, improved part accuracy, and faster turnaround times. Our machinists are trained to leverage multi-axis programming and high-speed machining strategies, ensuring optimal tool paths and material removal rates while maintaining dimensional integrity across diverse alloys, including tool steels, stainless steels, and aluminum.

Quality assurance is integral to every stage of production. All critical components undergo comprehensive inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), which provides micron-level measurement accuracy in a temperature-controlled environment. Our inspection protocols include full first-article inspection (FAI) reports, geometric dimensioning and tolerancing (GD&T) validation, and in-process checks to ensure conformance throughout the manufacturing cycle. This metrology-backed approach guarantees that every mold component meets or exceeds customer specifications and international quality standards.

The following table outlines our standard machining tolerances, which are consistently achieved under controlled production conditions. These values reflect our commitment to precision and serve as a benchmark for clients requiring reliable, repeatable results in their injection mold applications.

| Feature Type | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 500 mm |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed/precision bored |

| Positional Tolerance | ±0.015 mm | ±0.01 mm | Includes hole patterns and features |

| Flatness | 0.01 mm | 0.005 mm | Over 100 mm surface |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined finish; polish available |

| Angular Features | ±0.05° | ±0.02° | Verified via CMM and optical probes |

Our technical capabilities are designed to support the full lifecycle of injection mold development, from prototype to mass production. By combining 5-axis CNC precision with certified quality control, Wuxi Lead ensures that every mold component performs reliably under high-pressure, high-cycle conditions. We partner with clients to optimize designs for manufacturability, reduce lead times, and deliver solutions that enhance overall production efficiency.

Material & Finish Options

Material Selection for High-Performance Injection Molds: Precision Engineered for Your Application

Selecting the optimal material for injection molds is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we leverage advanced CNC machining capabilities to transform premium raw materials into molds that meet the most demanding specifications. Understanding the distinct properties of Aluminum, Steel, and Titanium, alongside strategic surface finishing like Anodizing, is essential for maximizing mold performance and longevity.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping, low-to-medium volume production, and applications requiring rapid heat dissipation. Their superior thermal conductivity accelerates cycle times, while lower density reduces weight and machining costs. Aluminum molds are ideal for validating part designs and initial production runs where ultimate wear resistance is secondary. However, their lower hardness necessitates protective surface treatments like hard anodizing for extended use with abrasive materials.

Tool steels, especially H13 (1.2344) and S136 (1.2085), remain the industry standard for high-volume production. These materials provide exceptional hardness, wear resistance, and thermal fatigue resistance, ensuring dimensional stability over millions of cycles. H13 excels in demanding thermal cycling environments, while corrosion-resistant grades like S136 are mandatory for medical or optical applications using PVC or other corrosive resins. Proper heat treatment and precision CNC machining are non-negotiable to achieve the required core hardness and surface integrity.

Titanium alloys (primarily Ti-6Al-4V) represent the pinnacle for extreme applications, offering unparalleled strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. While significantly more expensive and challenging to machine, titanium molds are indispensable for highly corrosive environments, ultra-clean medical device production, or aerospace components where contamination or weight is critical. Their use requires specialized CNC expertise to manage material work-hardening and achieve precise tolerances.

Anodizing is a vital surface enhancement for aluminum molds, transforming the outer layer into a hard, wear-resistant aluminum oxide ceramic. Type III (Hard Anodizing) to thicknesses of 50-75µm significantly extends mold life in production scenarios, improves release properties, and enhances corrosion resistance. While primarily applied to aluminum, specialized anodizing processes can also benefit specific titanium applications requiring electrical isolation or enhanced surface lubricity.

The following table summarizes key comparative properties to guide initial material assessment:

| Material | Typical Hardness | Thermal Conductivity (W/m·K) | Relative Cost | Typical Mold Life (Cycles) | Primary Application Focus |

|---|---|---|---|---|---|

| Aluminum 7075 | 150 HB | 130 | Low | 10,000 – 100,000 | Prototyping, Low/Med Volume |

| H13 Steel | 48-52 HRC | 35 | Medium | 500,000 – 1,000,000+ | High-Volume Production (General) |

| S136 Steel | 48-52 HRC | 25 | High | 1,000,000+ | Corrosive Resins, Medical, Optics |

| Ti-6Al-4V | 36 HRC | 7 | Very High | 1,000,000+ (Corrosive Env) | Extreme Corrosion, Medical, Aerospace |

Material choice is never one-size-fits-all. It requires a detailed analysis of your resin, part geometry, production volume, surface finish requirements, and budget. Wuxi Lead Precision Machinery combines deep metallurgical knowledge with state-of-the-art 5-axis CNC machining and finishing capabilities. Our engineering team collaborates closely with clients to select and process the optimal material solution, ensuring your mold delivers precision, durability, and maximum return on investment from the first shot. Consult our specialists to define the precise material and finish strategy for your next critical mold project.

Manufacturing Process & QC

The production process for high-precision injection molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects and full compliance with international quality standards. Our approach integrates advanced engineering, precision manufacturing, and systematic validation across three core phases: Design, Prototyping, and Mass Production.

The process begins with Design, where our engineering team collaborates closely with the client to translate product requirements into technical specifications. Utilizing 3D CAD software such as Siemens NX and SolidWorks, we develop detailed mold layouts that account for material flow, cooling efficiency, ejection mechanics, and part tolerance. Finite Element Analysis (FEA) is applied to simulate stress distribution and thermal behavior, ensuring structural integrity under repeated injection cycles. Design for Manufacturability (DFM) reviews are conducted to optimize tool life and minimize cycle time, reducing long-term production costs.

Following design approval, we proceed to Prototyping. A single-cavity prototype mold is fabricated using CNC machining, wire EDM, and surface grinding to achieve tolerances as tight as ±0.002 mm. This phase allows us to produce initial sample parts for functional and dimensional validation. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and 3D scanning to verify conformity to the original CAD model. Any deviations are addressed through iterative adjustments, ensuring the final mold design is perfected before scaling to full production.

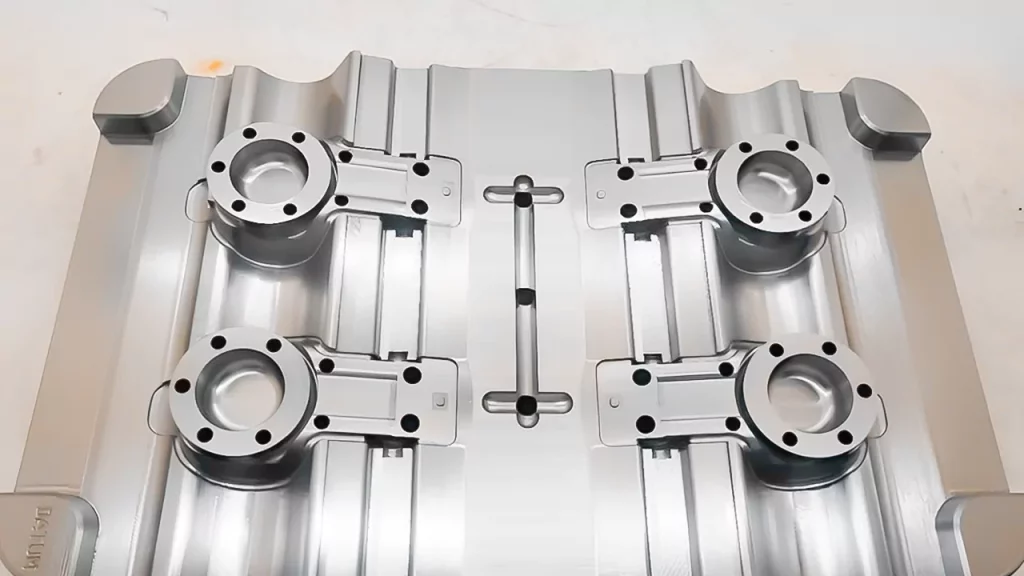

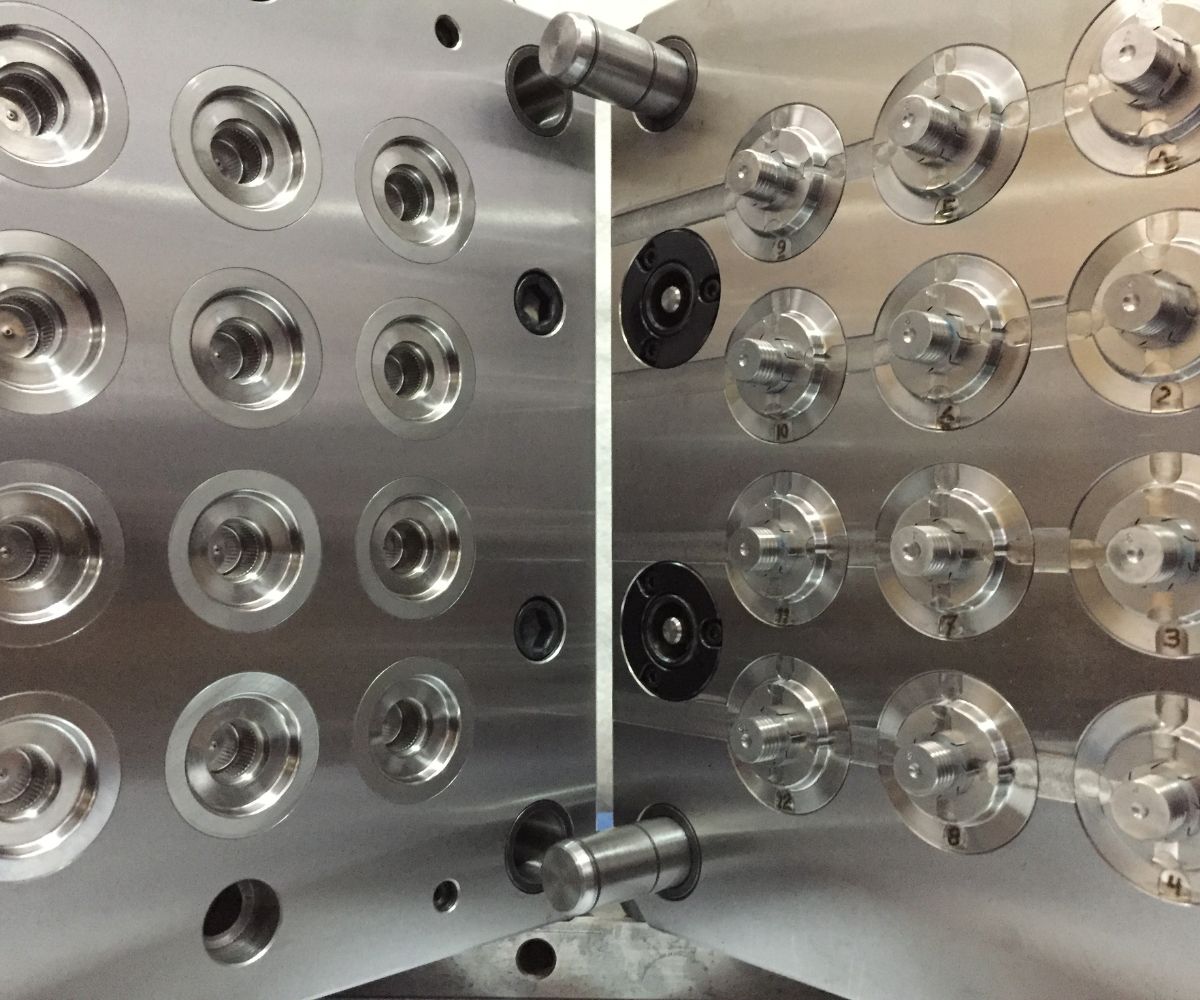

Once the prototype is validated, the project transitions to Mass Production. Multi-cavity molds are manufactured using hardened tool steels such as P20, 718H, or H13, selected based on production volume and material aggressiveness. Our automated CNC cells, equipped with high-speed spindles and in-process probing, ensure repeatability and precision across all cavities. Each mold is subjected to a comprehensive quality assurance protocol, including mold flow analysis, pressure testing, and 100% dimensional inspection of critical features. Final molds are coated with TiN or DLC (Diamond-Like Carbon) where necessary to enhance wear resistance and release properties.

Throughout the entire process, Wuxi Lead maintains full traceability through our ERP system, documenting material certifications, process parameters, and inspection reports. This disciplined methodology ensures every injection mold meets the highest standards of reliability, performance, and longevity.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Standard Tool Steels | P20, 718H, H13, S136 |

| Surface Finish | Ra 0.05 µm (mirror) to Ra 3.2 µm (textured) |

| Mold Life | 500,000 to 1,000,000+ cycles |

| Cooling Time Reduction | Up to 30% via conformal cooling channels |

| Quality Standards | ISO 9001:2015, IATF 16949 |

| Inspection Equipment | CMM, 3D Scanner, Vision System, Hardness Tester |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Mold Excellence

In the high-stakes realm of injection molding, your mold’s precision directly dictates part quality, production efficiency, and ultimately your market competitiveness. Generic solutions compromise yield; engineered excellence ensures profitability. At Wuxi Lead Precision Machinery, we transcend standard manufacturing by integrating deep metallurgical expertise with advanced CNC capabilities. Our dedicated engineering teams collaborate from initial concept through validation, transforming complex geometries into robust, high-cavitation molds that deliver consistent repeatability under demanding production cycles. This partnership minimizes trial-and-error costs while maximizing your uptime and part integrity across automotive, medical, and aerospace applications.

Our technical foundation rests on proprietary processes validated through rigorous in-house testing. Below are core specifications defining our mold performance standards:

| Parameter | Capability Range | Industry Standard Comparison |

|---|---|---|

| Material Grades | H13, S136, NAK80, 1.2344, Custom Alloys | Standard: P20, 718 |

| Tolerance Control | ±0.002 mm (critical features) | Typical: ±0.01–0.02 mm |

| Cavity Configuration | 1–96 cavities (multi-gate optimized) | Standard: 1–16 cavities |

| Surface Finish | VDI 3400 ≤ Ra 0.05 µm (mirror polish) | Typical: Ra 0.2–0.8 µm |

| Lead Time (Complex) | 12–20 weeks (including validation) | Industry Avg: 18–30 weeks |

These metrics are not theoretical—they are proven in daily production for global Tier-1 suppliers. We mitigate your risk through finite element analysis (FEA) for thermal stress prediction, hardened core/cavity inserts with 50+ HRC surface durability, and dynamic cooling channel design that reduces cycle times by 15–25%. When dimensional stability under thermal cycling is non-negotiable, our molds consistently achieve <0.005 mm warpage deviation across 500,000+ shots. This reliability eliminates scrap surges and unplanned downtime, directly protecting your production schedule and brand reputation.

The true cost of mold failure extends far beyond replacement expenses—it erodes customer trust and stalls innovation. Partnering with Lead Precision means aligning with engineers who speak your technical language and prioritize your operational outcomes. We do not sell molds; we deliver production assurance through metallurgical oversight, real-time progress tracking via our client portal, and post-delivery support that includes mold performance audits. Our facility in Wuxi operates under IATF 16949 and ISO 13485 frameworks, ensuring every process—from electrode EDM to final polishing—meets the exacting demands of regulated industries.

Initiate your next mold project with engineering certainty. Contact our technical sales team to schedule a confidential consultation where we will analyze your part geometry, material requirements, and volume targets to propose a precision solution. Provide your project specifications to [email protected] with the subject line Injection Mold Partnership. Our engineers will respond within 12 business hours with actionable insights—not generic brochures. Elevate your manufacturing capability where precision is the foundation, not the exception.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.