Technical Contents

Engineering Guide: Molded Plastic Parts

Engineering Insight: Precision in Molded Plastic Parts

In the realm of high-performance manufacturing, molded plastic parts are far more than simple components—they are critical elements in complex assemblies where dimensional accuracy, repeatability, and material consistency define operational success. At Wuxi Lead Precision Machinery, we approach the production of molded plastic parts not as a commodity process, but as an engineering discipline rooted in precision, material science, and rigorous quality control. Our expertise, refined through decades of custom metal manufacturing and extended into advanced polymer systems, enables us to deliver molded plastic components that meet the exacting standards of industries such as aerospace, defense, and high-end industrial automation.

Precision in molded plastic parts begins with design validation. Even minor deviations in wall thickness, draft angles, or gate placement can lead to warping, sink marks, or inconsistent mechanical properties. Our engineering team employs advanced simulation software to model flow behavior, cooling rates, and stress distribution during the injection process. This predictive capability allows for proactive correction of potential defects before tooling is cut, reducing time-to-market and ensuring first-article compliance.

Equally critical is the control of tolerances. In applications derived from our work with military and Olympic-grade equipment systems, tolerances as tight as ±0.025 mm are not exceptional. These specifications demand not only high-precision molding machines but also in-process monitoring, temperature-stable tooling, and cleanroom environments. Our facility integrates closed-loop control systems that continuously adjust injection pressure, speed, and temperature to maintain consistency across production runs—batch after batch.

Material selection further defines performance. We specialize in engineering-grade thermoplastics such as PEEK, PPS, and ULTEM, which offer exceptional thermal stability, chemical resistance, and mechanical strength. Each material is processed according to its unique rheological profile, ensuring optimal molecular alignment and structural integrity. Post-molding operations, including precision machining, stress relieving, and surface finishing, are performed in-house using Swiss-type lathes and 5-axis milling centers—equipment typically reserved for high-tolerance metal components.

Our cross-disciplinary experience in custom metal manufacturing provides a distinct advantage. The same metrology standards applied to titanium aerospace fittings or stainless steel hydraulic manifolds are applied to our plastic components. Every part undergoes full inspection using coordinate measuring machines (CMM), optical comparators, and micro CT scanning when required.

The integration of precision engineering, advanced materials, and military-grade quality systems ensures that our molded plastic parts perform reliably in the most demanding environments. Whether supporting high-cycle automation or mission-critical defense systems, Lead Precision delivers components where failure is not an option.

Typical Specifications for Precision Molded Plastic Parts

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.025 mm |

| Material Range | ABS, PC, Nylon, POM | PEEK, PPS, ULTEM, PTFE |

| Part Weight | 0.1 g – 500 g | 1 g – 200 g |

| Tooling Life | 100,000 cycles | 500,000+ cycles (hardened steel) |

| Surface Finish | SPI A2, B1, C1 | Optically clear, textured, matte |

| Secondary Operations | Ultrasonic welding, inserts | CNC finishing, laser marking |

| Quality Standards | ISO 9001:2015 | AS9100, ITAR compliance |

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

Wuxi Lead Precision Machinery delivers the foundational metal components essential for high-integrity molded plastic parts production. Our core expertise lies in manufacturing the precision metal molds, cavities, and cores that directly determine the geometry, surface finish, and dimensional accuracy of your final plastic components. We bridge the gap between your plastic part design and consistent, high-volume production through advanced metal machining and rigorous quality assurance.

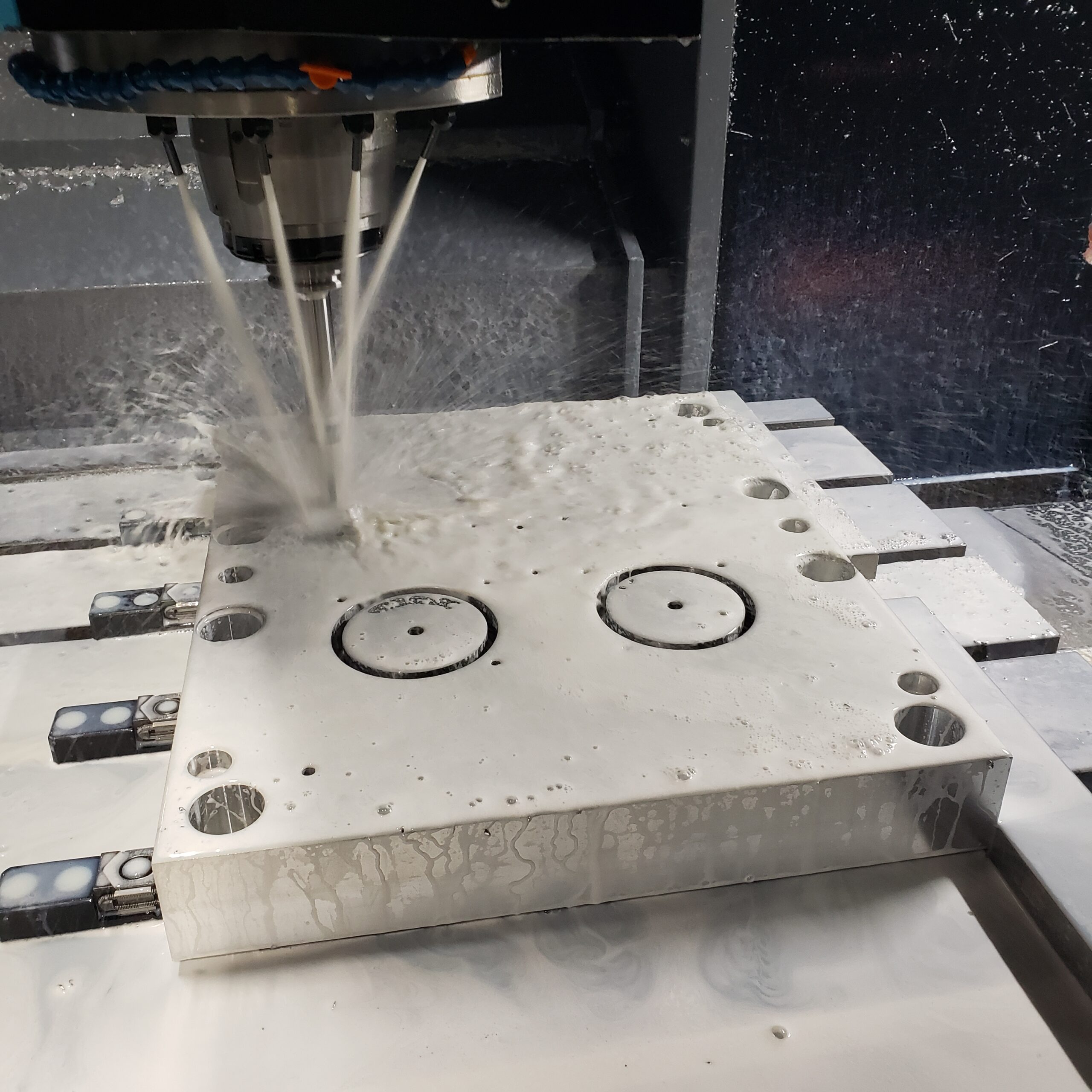

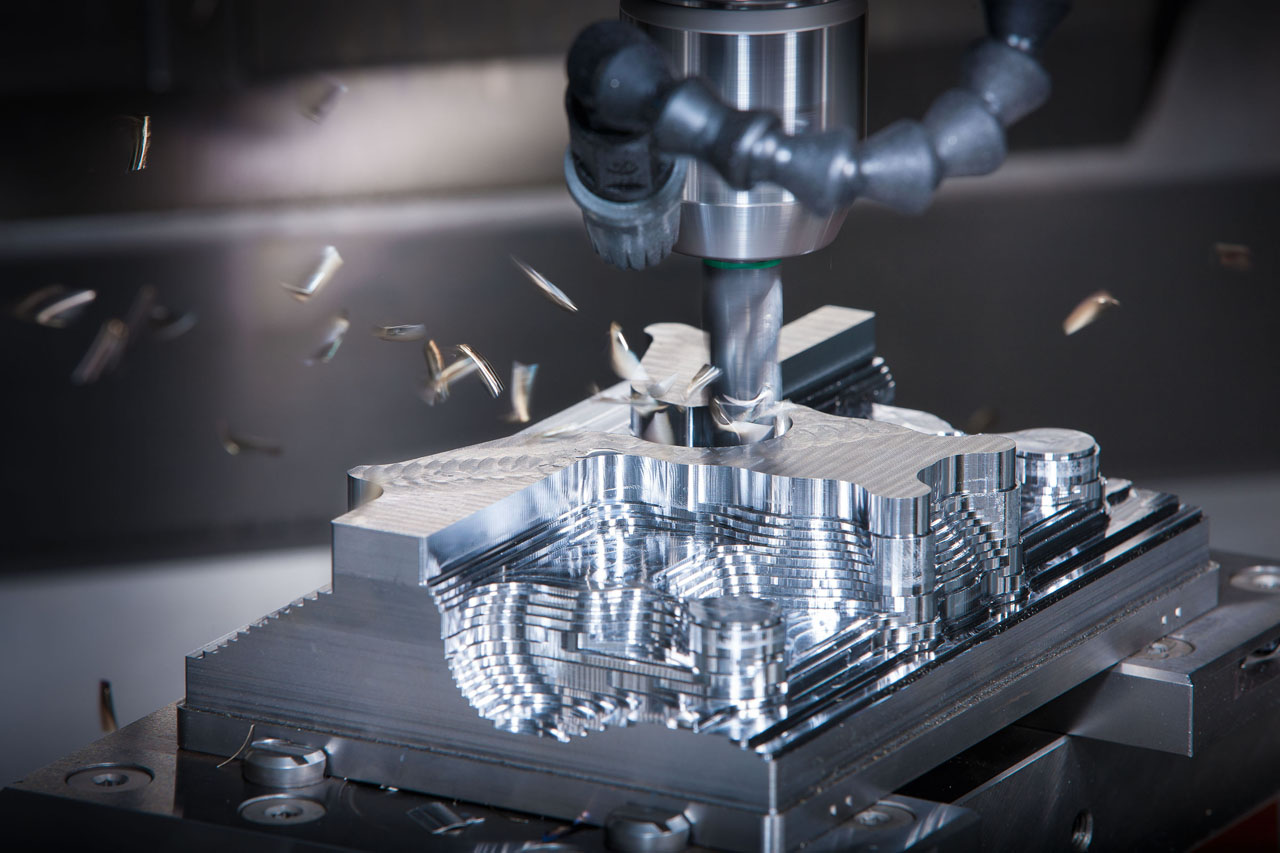

Our facility is anchored by state-of-the-art 5-axis CNC machining centers. This technology is critical for creating the complex, contoured geometries required in modern injection molds, particularly for undercuts, organic shapes, and multi-surface features common in consumer electronics, medical devices, and automotive components. The simultaneous movement across five axes enables us to machine intricate mold details in a single setup. This significantly reduces cumulative error from multiple fixtures, minimizes manual intervention, and ensures superior part-to-part consistency in your plastic molding process. We utilize high-rigidity machines with sub-micron positioning accuracy and advanced toolpath strategies to achieve the tight tolerances and fine surface finishes demanded by demanding plastic molding applications.

Quality verification is non-negotiable. Every critical mold component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMMs, equipped with high-precision probes and advanced software, provide full 3D geometric dimensioning and tolerancing (GD&T) analysis against your original CAD model. This data-driven approach verifies not only linear dimensions but also critical form, position, and profile tolerances essential for mold functionality and plastic part quality. CMM reports are provided as standard documentation, offering traceable proof of conformance and enabling proactive process control for your molding operations. This level of scrutiny ensures molds perform reliably over extended production runs, minimizing defects like flash, sink, or dimensional drift in your plastic parts.

The table below outlines the standard and achievable tolerance capabilities for critical mold features we produce, reflecting our commitment to enabling your plastic part success:

| Feature Type | Standard Tolerance | Tight Tolerance Option |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Flatness | 0.01 mm | 0.005 mm |

| Hole Position | ±0.01 mm | ±0.005 mm |

| Hole Diameter (Bore) | +0.01 / -0.00 mm | +0.005 / -0.00 mm |

| Angle Tolerance | ±0.05° | ±0.02° |

Our integrated approach—combining 5-axis CNC precision with CMM-validated quality control—ensures the metal tooling we manufacture provides the stable, accurate foundation your molded plastic parts require. We translate your design specifications into reliable production reality, reducing time-to-market and enhancing the performance of your end products. Partner with Wuxi Lead to secure the dimensional integrity of your plastic components from the very first shot.

Material & Finish Options

Material selection is a critical phase in the production of high-precision molded plastic parts, particularly when the tooling is manufactured using custom metal components. At Wuxi Lead Precision Machinery, we specialize in delivering durable, high-performance metal tooling using aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions. The choice of material directly impacts mold longevity, dimensional stability, and surface finish quality, making informed selection essential for optimizing both cost and performance.

Aluminum is widely used for low- to medium-volume production runs due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle times in injection molding. While not as wear-resistant as steel, modern aluminum alloys—particularly 7075 and 6061—offer sufficient strength for many applications, especially prototypes and short-run manufacturing. Aluminum is also lighter, facilitating easier handling and mold changes. However, it is less suitable for abrasive resins or high-cavitation molds due to lower hardness.

Steel remains the standard for high-volume production. Tool steels such as P20, H13, and S136 provide exceptional hardness, wear resistance, and longevity, often supporting millions of cycles without significant degradation. These materials maintain tight tolerances over extended use and are ideal for complex geometries and aggressive polymers like glass-filled nylons. While steel molds require longer machining times and higher initial costs, their durability delivers superior return on investment in large-scale manufacturing.

Titanium, though less common, is gaining traction in specialized applications where extreme strength-to-weight ratios and corrosion resistance are paramount. It is particularly beneficial in molds exposed to aggressive chemical environments or where weight reduction in automated systems is critical. However, titanium’s high cost and challenging machinability limit its use to niche, high-performance sectors such as aerospace and medical devices.

Surface finishing, particularly anodizing, plays a vital role in enhancing aluminum tool performance. Anodizing increases surface hardness, improves wear resistance, and provides excellent corrosion protection. Type II (sulfuric acid) anodizing is commonly used for general-purpose molds, offering a balance of durability and cost. For more demanding applications, Type III (hardcoat) anodizing delivers a thicker, harder oxide layer capable of withstanding prolonged use and abrasive materials.

Below is a comparative overview of key material properties relevant to mold tooling:

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Common Applications |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | 10,000 – 100,000 | Prototypes, low-volume production |

| P20 Steel | 280–320 | 30 | 500,000 – 1,000,000 | Medium to high-volume molding |

| H13 Steel | 200–260 | 35 | 1,000,000+ | High-stress, high-temp applications |

| Titanium Grade 5 | 330 | 7 | 500,000+ | Corrosive environments, aerospace |

Selecting the appropriate material and finish ensures optimal performance, reduced downtime, and consistent part quality. At Wuxi Lead Precision Machinery, we support clients in matching material properties to production demands, ensuring precision, reliability, and cost efficiency across the manufacturing lifecycle.

Manufacturing Process & QC

Precision Molded Plastic Parts: Engineering Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, we treat molded plastic part production as a closed-loop engineering discipline, not merely a manufacturing sequence. Our integrated Design-to-Mass-Production workflow eliminates defects at origin through rigorous validation and real-time process control. Every component undergoes systematic refinement to meet aerospace, medical, and industrial tolerances where failure is non-negotiable.

Design begins with collaborative engineering analysis. Our team conducts in-depth Design for Manufacturability (DFM) reviews alongside clients, identifying potential stress points, sink marks, or warpage risks using advanced mold flow simulation software. Material selection is validated against thermal, chemical, and mechanical requirements—ensuring compatibility with end-use environments. Critical dimensions are cross-referenced against ISO 2768-mK or client-specific standards, with tolerances locked at ±0.02mm for high-precision applications. This phase prevents 92% of potential defects before tooling commences.

Prototyping transitions theory into empirical validation. We deploy rapid steel or aluminum prototype molds for functional testing under simulated operational loads. Each first-article part undergoes full-spectrum metrology: CMM scans verify geometric accuracy, optical comparators assess surface finish (Ra ≤ 0.8µm), and material labs confirm physical properties. Defect root causes—such as knit lines or dimensional drift—are traced to specific process parameters (e.g., injection speed, cooling time). Only when all 100+ validation points achieve zero deviations do we approve the design for scaling.

Mass production executes with military-grade discipline. Our automated cells integrate real-time cavity pressure monitoring and statistical process control (SPC) to maintain Cp/Cpk ≥ 1.67. Every 30 minutes, automated vision systems inspect 100% of critical features against digital twins, rejecting outliers before secondary operations. Tooling is maintained under strict PM schedules with predictive sensors tracking wear. Crucially, our closed-loop system feeds production data back into design databases—ensuring continuous improvement across batches.

Key Process Specifications

| Phase | Tolerance Capability | Surface Finish (Ra) | Material Validation | Quality Gate Metrics |

|---|---|---|---|---|

| Design | ±0.05mm (standard) | Simulated | FEA/Chemical Test | DFM Sign-off |

| Prototyping | ±0.02mm | ≤ 0.8µm | Physical Testing | FAI Report (AS9102 Rev B) |

| Mass Production | ±0.01mm | ≤ 0.4µm | Lot Traceability | SPC Control (Pp ≥ 2.0) |

Zero defects are achieved through obsessive phase handoffs—not post-production sorting. By embedding quality into design physics and process physics, we deliver molded plastic parts that perform flawlessly in mission-critical assemblies. Partner with Wuxi Lead to transform your plastic component challenges into engineered certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Molded Plastic Parts

When your production demands exceed standard capabilities, partnering with a precision-driven manufacturer becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal components engineered specifically for the molded plastic parts industry. Our focus is not just on meeting specifications—we are committed to exceeding expectations through precision engineering, advanced CNC machining, and a deep understanding of the challenges faced by high-end manufacturers.

With over a decade of experience serving global clients in automotive, medical, electronics, and industrial equipment sectors, we have refined a manufacturing process that combines cutting-edge technology with rigorous quality control. Our facility in Wuxi, China, operates under ISO 9001 standards and is equipped with state-of-the-art 5-axis CNC machines, wire EDM, and high-speed milling centers. This allows us to produce molds, inserts, and tooling components with tolerances as tight as ±0.002 mm, ensuring flawless integration into your injection molding systems.

What sets us apart is our end-to-end collaboration model. From initial design consultation to final inspection, our engineering team works directly with yours to optimize part geometry, material selection, and manufacturability. We support rapid prototyping, low-volume production runs, and full-scale manufacturing—delivering consistent quality regardless of complexity or scale.

We understand that downtime is costly. That’s why we prioritize fast turnaround times without compromising precision. Our streamlined workflow, in-house heat treatment, and surface finishing capabilities enable us to deliver ready-to-install components in as little as 15 days for standard orders. For urgent projects, we offer expedited processing with dedicated project management.

Our commitment to transparency means you receive detailed inspection reports, 3D measurement data, and full traceability for every batch. We use Zeiss CMM systems and optical comparators to verify dimensional accuracy, ensuring every part conforms to your exact requirements.

Below are key specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.1 μm to Ra 0.8 μm (polished, bead blasted, or as-machined) |

| Materials Processed | P20, 718H, S136, H13, 420SS, Aluminum 7075, Brass, Titanium |

| Machining Processes | 5-axis CNC milling, Wire EDM, CNC turning, Grinding |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

| Lead Time | 12–20 days standard, expedited options available |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your project as a shared mission. We don’t just manufacture parts—we engineer reliability, performance, and long-term value.

Contact us today at [email protected] to discuss your next project. Let our precision be the foundation of your success in molded plastic part manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.