Technical Contents

Engineering Guide: Mold Texture

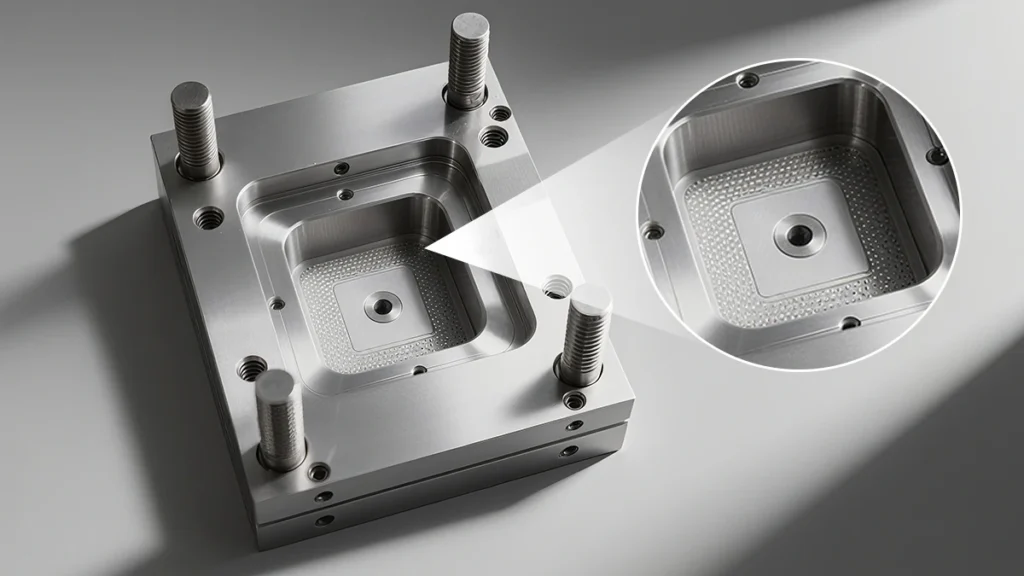

Engineering Insight: Mold Texture as a Functional Imperative

Surface finish on injection molds transcends mere aesthetics; it is a critical functional parameter directly influencing part performance, cycle time, and longevity. In high-stakes applications demanding zero-defect output—such as aerospace components, medical devices, or premium consumer electronics—the precision of the mold texture dictates product integrity. A poorly controlled texture can cause part ejection failures, inconsistent gloss levels, micro-fractures, or accelerated wear, leading to costly downtime and scrap. At Wuxi Lead Precision Machinery, we treat texture specification not as an afterthought but as an engineered variable integral to the mold’s core functionality. Our CNC-machined textures achieve sub-micron repeatability, ensuring every cavity performs identically across thousands of cycles. This level of control is non-negotiable when manufacturing parts for Olympic-grade sporting equipment or mission-critical military hardware, where microscopic surface deviations can compromise structural reliability or aerodynamic efficiency.

Achieving such precision requires marrying advanced metrology with deep process knowledge. We utilize multi-axis CNC milling, precision etching, and laser texturing, all governed by ISO 2768-Geometric Tolerances standards. Each texture profile is validated against Ra (arithmetic average roughness), Rz (maximum height), and Rsk (skewness) parameters using calibrated profilometers. Our proprietary algorithms compensate for material behavior during texturing, preventing thermal distortion or edge rounding that plagues less rigorous processes. This capability was rigorously proven in our work on titanium alloy molds for Paralympic prosthetic limb housings, where a 0.2 μm Ra variance would alter skin adhesion dynamics. Similarly, military-spec connectors demanded textures resistant to salt fog corrosion—achieved through controlled VDI 3400 Grade 22 micro-pitting that traps protective coatings without compromising electrical contact points.

The following table outlines common precision texture specifications we engineer and validate:

| Texture Type | Ra Range (μm) | Typical Depth (μm) | Primary Applications | Lead Precision Validation Method |

|---|---|---|---|---|

| Mirror Polish | 0.005 – 0.05 | < 0.1 | Optical lenses, medical implants | White light interferometry, ISO 10110 |

| Fine Satin | 0.1 – 0.4 | 0.5 – 2.0 | Automotive interior panels | Stylus profilometry, visual comparator |

| Controlled Grain | 0.4 – 1.6 | 2.0 – 10.0 | Consumer electronics housings | 3D confocal microscopy, gloss meter |

| Functional Micro-Texture | 1.6 – 6.3 | 10.0 – 50.0 | Sealing surfaces, wear plates | SEM imaging, tribological testing |

Wuxi Lead’s military and Olympic project heritage instills an uncompromising approach: texture must perform under extreme thermal cycling, chemical exposure, or mechanical stress. We document every texture parameter in our FAI (First Article Inspection) reports, providing traceability from CAD model to production part. This engineering discipline transforms mold texture from a cosmetic variable into a quantifiable driver of yield, quality, and product lifecycle value—proving that in precision manufacturing, the surface is never just skin deep.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Mold Texturing

At Wuxi Lead Precision Machinery, our technical capabilities in custom metal manufacturing are engineered to meet the rigorous demands of high-performance mold production, particularly in the specialized domain of mold texturing. Our integrated approach combines state-of-the-art 5-axis CNC machining with stringent quality control protocols to deliver surface finishes and textures that conform precisely to customer specifications. Mold texturing is not merely cosmetic—it plays a critical role in part release, surface consistency, and end-product functionality across industries such as automotive, consumer electronics, and medical devices.

Our 5-axis CNC machining centers provide unparalleled flexibility in creating complex 3D surface geometries required for advanced mold textures. Unlike conventional 3-axis systems, the additional rotational axes allow for continuous tool engagement from multiple angles, minimizing setup changes and ensuring superior surface continuity. This capability is essential when machining deep cavities, undercuts, or intricate patterns where tool access and surface fidelity are paramount. We utilize high-speed machining techniques with micro-diameter end mills to produce fine textures such as matte, grain, or custom logo embossing with micron-level accuracy.

All mold texturing operations are supported by advanced CAD/CAM software, enabling precise programming of texture depth, directionality, and pattern repetition. Our engineering team works closely with clients to translate design intent into executable toolpaths, ensuring consistency between prototype and production runs. Whether replicating industry-standard SPI finishes or developing proprietary textures, our process ensures repeatability and dimensional stability across molds.

Quality assurance is integral to our manufacturing workflow. Every textured mold undergoes comprehensive inspection using a coordinate measuring machine (CMM) to validate geometric accuracy and surface conformity. The CMM verifies critical dimensions, texture depth uniformity, and alignment relative to parting lines and core/cavity interfaces. Data from each inspection is documented and traceable, providing full transparency for audit and compliance purposes.

In addition to dimensional accuracy, we evaluate surface roughness using profilometry to ensure texture consistency across the entire mold surface. This dual verification—dimensional and surface—ensures that the final mold performs reliably in high-cycle injection molding environments, reducing wear and improving part ejection.

The following table outlines our standard technical specifications for mold texturing operations:

| Specification | Capability |

|---|---|

| Machine Platform | 5-Axis CNC (Simultaneous) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness Range (Ra) | 0.05 µm to 3.2 µm |

| Texture Depth Control | ±0.01 mm tolerance |

| Inspection Equipment | Zeiss CMM (Automated) |

| Standard Tolerances (Feature) | ±0.01 mm (critical), ±0.03 mm (general) |

| Lead Time (Typical) | 15–25 days (based on complexity) |

Wuxi Lead Precision Machinery is committed to delivering mold texturing solutions that combine aesthetic precision with functional performance. Our technical capabilities ensure that every mold meets the highest standards of quality, durability, and repeatability in industrial applications.

Material & Finish Options

Material Selection for Precision Mold Texturing

Selecting the optimal material for mold texturing directly impacts texture fidelity, production efficiency, and component lifespan. At Wuxi Lead Precision Machinery, we prioritize material properties that ensure consistent replication of fine surface details under high-pressure injection cycles. Aluminum, steel, and titanium each offer distinct advantages depending on application demands, volume requirements, and texture complexity.

Aluminum alloys, particularly 6061-T6 and 7075-T6, provide exceptional thermal conductivity and machinability for rapid texture prototyping and low-to-medium volume production. Their lower hardness allows precise engraving of intricate patterns like matte finishes or geometric micro-structures but necessitates protective surface treatments for extended use. Steel variants such as P20, H13, and S136 dominate high-volume applications due to superior hardness and wear resistance. Pre-hardened P20 balances machinability with durability for textures requiring moderate depth, while H13 excels in high-temperature environments demanding sharp, repeatable patterns like leather grains or optical textures. Titanium alloys, though less common, offer unmatched corrosion resistance for specialized medical or aerospace molds where texture integrity must persist in aggressive chemical environments.

Anodizing remains the premier finish for aluminum molds to enhance texture longevity. Hard anodizing (Type III) builds a dense, abrasion-resistant oxide layer up to 50–75 µm thick, preserving fine details during demolding. This process also improves release properties for complex textures, reducing silicone spray dependency. For steel molds, texturing is typically performed directly on the hardened substrate, though PVD coatings like TiAlN may supplement wear resistance for ultra-fine patterns. Titanium molds generally require no additional finishing beyond precision texturing due to their inherent surface stability.

Material performance metrics guide critical decisions. The table below summarizes key properties for texture-critical applications:

| Material | Hardness Range | Texture Fidelity | Thermal Conductivity (W/m·K) | Best Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 HB | High (with anodizing) | 167 | Prototypes, low-volume consumer goods |

| P20 Steel | 28–32 HRC | Very High | 28–36 | Medium-volume automotive, electronics |

| H13 Steel | 48–52 HRC | Exceptional | 24–29 | High-volume optical, medical devices |

| Titanium Grade 5 | 36 HRC | High | 7.2 | Corrosive environment aerospace parts |

Choosing the right material-texture combination minimizes production downtime and ensures aesthetic consistency across millions of cycles. Aluminum suits agile development phases where texture iteration is frequent, while hardened steels deliver ROI in mass production through unmatched dimensional stability. Titanium serves niche high-corrosion scenarios where texture failure risks component rejection. At Wuxi Lead, our CNC texturing centers leverage ISO 5 cleanroom environments and 5-axis micro-milling to achieve Ra values down to 0.05 µm, regardless of substrate. Partner with us to align material science with your texture specifications—maximizing both visual quality and mold service life.

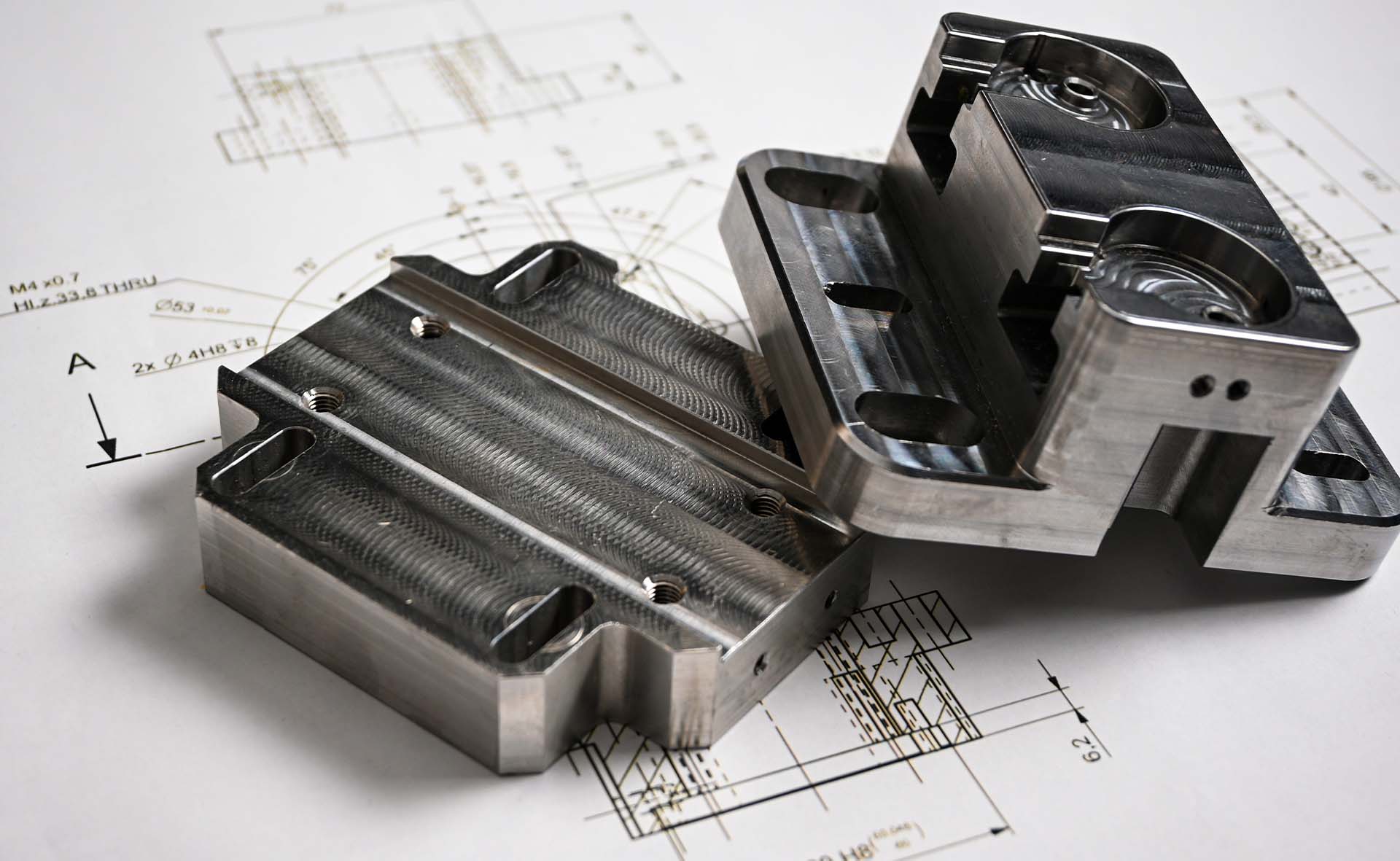

Manufacturing Process & QC

The production process for high-precision mold textures at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure zero defects, meeting the exacting standards required in industries such as automotive, medical, and consumer electronics.

Design begins with a comprehensive analysis of the customer’s technical specifications, including surface finish requirements, material compatibility, and functional performance under operational conditions. Our engineering team utilizes advanced CAD/CAM software to model the mold geometry and simulate texture patterns at micron-level accuracy. Finite element analysis (FEA) is applied to predict stress distribution and thermal behavior, ensuring long-term durability. Surface texture parameters—such as Ra, Rz, and Rmax—are defined in alignment with international standards (ISO 4287, ASME B46.1) to guarantee consistency. This digital-first approach allows for early detection of potential flaws and enables rapid iteration before physical production begins.

Prototyping follows the design phase, serving as a critical validation step. We fabricate a limited set of molds using the same materials and CNC processes intended for mass production—typically hardened tool steels such as H13, S136, or NAK80. High-speed precision milling, wire EDM, and micro-texturing techniques such as laser etching or chemical milling are employed to achieve the specified surface characteristics. The prototype molds undergo full metrological inspection using 3D coordinate measuring machines (CMM) and white-light interferometry to verify texture depth, uniformity, and dimensional accuracy. Functional testing, including mold release performance and replication fidelity on sample parts, is conducted under simulated production conditions. Any deviations are traced to root causes and corrected through closed-loop feedback to the design model.

Mass Production commences only after prototype approval, with full implementation of Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. Each mold is manufactured on dedicated CNC platforms with real-time tool wear monitoring and automated in-process gauging. Our production floor operates under ISO 9001-certified quality management, with 100% inspection of critical features. Traceability is maintained via laser-etched QR codes on every component, linking to digital quality records. Throughout the production run, random sampling and accelerated life testing ensure sustained compliance.

This integrated approach—grounded in precision engineering, digital validation, and continuous quality assurance—enables Wuxi Lead Precision Machinery to deliver mold textures with zero-defect reliability.

| Parameter | Specification |

|---|---|

| Surface Roughness Range | Ra 0.05 – 3.2 µm |

| Texture Depth Tolerance | ±2 µm |

| Material Options | H13, S136, NAK80, 718H, 2738 |

| Dimensional Accuracy | ±0.005 mm |

| Production Capacity | Up to 500 molds/month |

| Quality Standard | ISO 9001:2015, ISO 4287, ASME B46.1 |

| Inspection Tools | 3D CMM, Interferometer, SEM |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Definitive Mold Texture Execution

Achieving flawless mold texture is not merely an aesthetic consideration; it is a critical manufacturing variable directly impacting part release, surface quality, cycle time, and end-product performance. In high-stakes industries like automotive, aerospace, and medical device manufacturing, inconsistent or poorly executed textures lead to costly production delays, scrap, and compromised functionality. At Wuxi Lead Precision Machinery, we engineer texture solutions with the same rigor applied to core mold geometry. Our integrated approach combines advanced CNC texturing capabilities with deep metallurgical expertise, ensuring textures meet exact functional and visual specifications on the first iteration. We eliminate the guesswork inherent in traditional EDM or chemical etching methods through direct, programmable control over surface topography.

Our state-of-the-art multi-axis CNC texturing centers deliver unparalleled precision and repeatability across complex geometries. Unlike conventional processes constrained by electrode limitations or chemical variability, our machining-driven methodology achieves deterministic results on hardened tool steels, aluminum, and exotic alloys. The table below outlines our core technical capabilities for mold texture execution. This precision ensures your texture performs as engineered—whether optimizing grip for assembly, minimizing friction in moving parts, or achieving Class A automotive finishes.

| Parameter | Capability Range | Tolerance Control |

|---|---|---|

| Surface Roughness (Ra) | 0.05 µm to 25.0 µm | ±0.1 µm (sub-micron) |

| Maximum Texture Depth | Up to 0.5 mm | ±2 µm |

| Feature Resolution | 5 µm minimum detail | ±1 µm |

| Material Hardness | Up to 62 HRC | N/A |

| Geometric Complexity | Freeform 3D contours | ±5 µm positional |

Partnering with Lead Precision means engaging a team that treats texture as a core engineering discipline, not a secondary finish. Our process begins with collaborative analysis of your functional requirements—translating design intent into measurable texture parameters. Our CNC programmers and tooling engineers work in tandem to develop optimized toolpaths that maintain texture integrity across cavity cores, inserts, and undercuts. We provide comprehensive texture validation through 3D profilometry and cross-sectional analysis, delivering certified reports traceable to your quality standards. This eliminates subjective approval cycles and ensures seamless integration into your production workflow.

For mission-critical applications where texture reliability dictates production success, settle for nothing less than engineered precision. Contact our technical sales team to schedule a direct consultation with our CNC texture specialists. We will review your specific requirements, material constraints, and performance targets to develop a validated execution plan. Provide your CAD data and texture specifications for a rapid feasibility assessment and precision quotation.

Initiate your precision texture project today. Email technical inquiries and project details to [email protected]. Our engineering-led response will include actionable insights, capability alignment, and a clear path to texture excellence. Trust Wuxi Lead Precision Machinery to transform surface texture from a production variable into a competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.