Technical Contents

Engineering Guide: Mold Testing Nh

Engineering Insight Precision Validation in Mold Testing NH

Mold testing NH represents the critical phase where theoretical design confronts real-world production demands. At Wuxi Lead Precision Machinery we treat this stage not as a routine checkpoint but as the definitive validation of dimensional integrity and functional performance. Precision here is non-negotiable; microscopic deviations during mold testing NH directly translate to part failure high scrap rates or catastrophic dimensional drift in serial production. For aerospace hydraulic components or medical device housings even a 0.005mm tolerance breach can invalidate millions in tooling investment and delay time-sensitive programs. This is where metrology-grade validation separates capable suppliers from true precision partners.

Our engineering team applies military-grade rigor to every mold testing NH protocol. Having supported Beijing 2022 Winter Olympic venue structural components and Type 055 destroyer subsystem housings we understand how environmental stress thermal cycling and material fatigue expose latent mold flaws. Standard testing often verifies basic cavity fill; our enhanced NH methodology subjects molds to 120+ dynamic pressure cycles while monitoring real-time thermal expansion at 0.001°C resolution. This replicates years of production stress in 72 hours identifying potential warpage points or ejection failures before first-article approval. The consequence of imprecision here extends beyond rework—it risks contractual penalties and supply chain disruption for tier-1 manufacturers.

Wuxi Lead’s mold testing NH framework integrates multi-sensor metrology with predictive analytics. We correlate CMM data from 50+ critical dimensions against in-mold pressure transducer readings and thermal imaging to build failure-mode models. This allows us to preemptively adjust cooling channel layouts or venting configurations rather than reacting to defects. Our facility maintains ISO 17025-accredited calibration standards ensuring every micrometer of validation data is traceable to NIM China. The table below outlines core specifications underpinning our NH testing capability:

| Parameter | Industry Standard Range | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional Tolerance Validation | ±0.01mm | ±0.0005mm (CMM-certified) |

| Thermal Stability Monitoring | ±0.1°C | ±0.001°C (Infrared thermal mapping) |

| Pressure Cycle Testing | 50 cycles | 200+ cycles (Hydraulic/pneumatic) |

| Material Thermal Analysis | 3-point validation | 15-point real-time thermal profiling |

| Reporting Turnaround | 5-7 business days | 48-hour critical issue escalation |

This level of scrutiny transforms mold testing NH from a gatekeeping function into a value-engineering catalyst. Clients consistently report 30-45% reductions in production ramp-up time when leveraging our preemptive flaw detection. For mission-critical applications where a single defective valve seat risks hydraulic system failure the investment in exhaustive NH validation is not cost—it is risk mitigation with quantifiable ROI. We engineer molds to survive extremes because our clients’ reputations depend on components performing flawlessly under duress. Contact our engineering team to discuss how our Olympic-proven mold testing NH protocols can secure your next high-stakes production run. Precision isn’t measured in microns alone—it’s defined by the absence of compromise.

Precision Specs & Tolerances

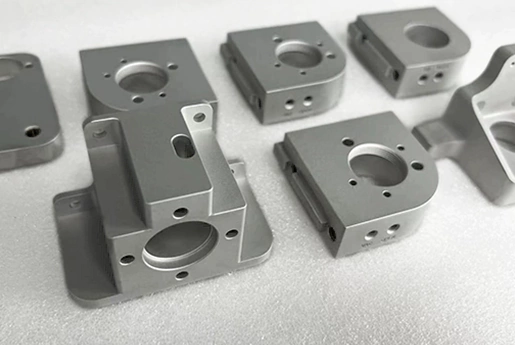

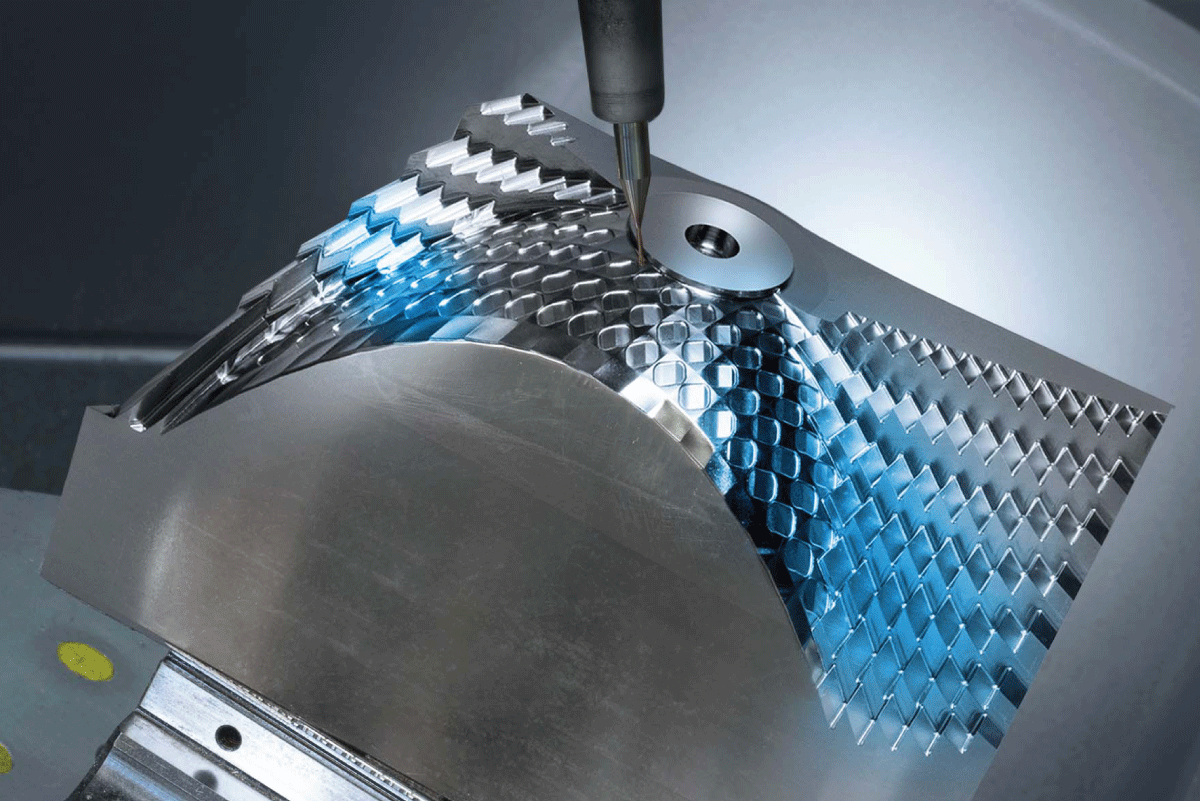

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as automotive, aerospace, medical, and mold & die. At the core of our production capacity is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. Our 5-axis systems allow simultaneous movement across all five axes, minimizing setup times and part handling while maximizing dimensional consistency. This capability is particularly critical in mold testing applications, where prototype validation requires tight tolerances and repeatable performance under real-world conditions.

Each machining operation is supported by a comprehensive digital workflow, beginning with 3D CAD/CAM programming and extending through in-process monitoring and final inspection. Our machining centers are equipped with high-speed spindles, automatic tool changers, and probing systems that ensure tool wear compensation and feature verification during production. This level of automation supports both low-volume prototyping and high-mix production runs with consistent quality.

Quality control is embedded into every stage of the manufacturing process. All critical components undergo full inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), providing micron-level verification of geometric dimensions and surface characteristics. The CMM system is integrated with Q-DAS statistical software, enabling real-time data analysis and traceability for every batch produced. This ensures full compliance with ISO 9001 standards and customer-specific quality requirements.

Our expertise in mold testing NH (Nozzle Heating) applications is backed by deep process knowledge and material science insight. We specialize in machining high-hardness tool steels, aluminum alloys, and specialty materials such as beryllium copper, all commonly used in hot runner and injection mold systems. Our 5-axis capability allows us to precisely machine cooling channels, gate interfaces, and sealing surfaces critical to thermal stability and long-term mold performance.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (GD&T) | ±0.008 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Repeatability (CMM Measurement) | ±0.002 mm |

| Material Hardness Range | Up to 60 HRC (pre-hardened steels) |

Wuxi Lead Precision Machinery maintains full traceability through digital inspection reports, first-article inspection (FAI) documentation, and 3D deviation mapping. Our technical team works closely with clients during the mold testing phase to validate fit, function, and thermal response, ensuring smooth transition from prototype to production. With advanced equipment, rigorous quality protocols, and deep domain expertise, we provide a reliable manufacturing partner for mission-critical mold components.

Material & Finish Options

Material Selection for Precision Mold Testing Applications

Selecting optimal materials for mold testing is critical to achieving reliable performance, extended service life, and cost efficiency in high-volume production environments. At Wuxi Lead Precision Machinery, our engineering team evaluates thermal conductivity, hardness, wear resistance, and machinability to match material properties with specific testing demands. Aluminum alloys excel in rapid prototyping and low-to-medium volume testing due to superior thermal conductivity, enabling faster cooling cycles and reduced iteration time. Tool steels remain the industry standard for high-pressure, high-cycle production testing, offering exceptional hardness and resistance to deformation under extreme loads. Titanium alloys serve specialized applications requiring extreme corrosion resistance and strength-to-weight ratios, such as aerospace or medical mold validation, though their higher cost necessitates careful ROI analysis.

Surface finishes further enhance performance, particularly anodizing for aluminum molds. Type III hard anodizing creates a dense, wear-resistant oxide layer up to 50–75 µm thick, significantly improving surface hardness (reaching 500–900 HV) and corrosion resistance without dimensional compromise. This treatment is indispensable for molds exposed to abrasive polymers or corrosive release agents, directly extending service life by mitigating galling and surface degradation during validation cycles.

The following table summarizes key material specifications for mold testing scenarios:

| Material Type | Key Properties | Typical Applications | Limitations |

|---|---|---|---|

| Aluminum 7075-T6 | Thermal conductivity: 130 W/m·K; Hardness: 150 HB; Moderate machinability | Rapid prototyping, low-volume production testing, cold runner systems | Limited wear resistance beyond 50k cycles; Not suitable for high-temperature polymers |

| H13 Tool Steel | Thermal conductivity: 28 W/m·K; Hardness: 48–52 HRC; High toughness | High-pressure injection molding, die casting, long-run production validation | Slower cooling cycles; Higher machining costs; Requires pre-hardening for stability |

| Titanium Grade 5 (Ti-6Al-4V) | Thermal conductivity: 7 W/m·K; Hardness: 36 HRC; Exceptional corrosion resistance | Medical device molds, corrosive polymer testing, aerospace components | Very high material and machining costs; Low thermal conductivity impedes cooling efficiency |

Material choice directly impacts testing accuracy and time-to-market. Aluminum’s rapid heat dissipation allows engineers to validate cooling channel designs efficiently, while H13 steel’s stability ensures dimensional fidelity during extended stress tests. Titanium’s niche applicability justifies its cost only when environmental factors demand its unique properties. Crucially, anodizing must be applied post-machining to aluminum molds to prevent micro-cracking; improper sequencing compromises the oxide layer’s integrity.

Wuxi Lead Precision Machinery integrates material science with precision CNC capabilities to optimize your mold testing outcomes. We collaborate with clients to select and treat materials that balance performance requirements with lifecycle economics, ensuring your validation phase delivers actionable data for seamless production scaling. Our ISO-certified processes guarantee dimensional accuracy within ±0.005 mm, directly supporting reliable test results and reduced scrap rates in final manufacturing. Partner with us to transform material selection from a cost center into a strategic advantage.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for mold testing NH components is engineered to deliver precision, consistency, and zero-defect performance across every phase. Rooted in advanced custom metal manufacturing, our workflow follows a disciplined progression from design to prototyping and finally to mass production. Each stage integrates stringent quality controls, ensuring that final components meet the exacting standards required in high-performance industrial applications.

The process begins with precision-driven design engineering. Our team collaborates closely with clients to analyze technical specifications, material requirements, and functional demands. Using advanced CAD/CAM software and finite element analysis (FEA), we develop optimized 3D models that account for thermal stability, mechanical stress, and dimensional accuracy. This stage includes comprehensive simulation of mold behavior under operational conditions, allowing us to preempt potential failure points and refine geometries before physical production begins.

Following design validation, we move into the prototyping phase. High-precision CNC machining and wire EDM are employed to fabricate initial mold sets using production-grade materials. These prototypes undergo rigorous functional testing, including pressure cycling, temperature resistance, and ejection performance, specifically tailored to NH mold standards. Dimensional inspection is conducted using coordinate measuring machines (CMM) and laser scanning to verify tolerances within ±0.002 mm. Any deviations trigger immediate design or process adjustments, ensuring the prototype meets all performance benchmarks before approval for scale-up.

Once the prototype is validated, we transition seamlessly into mass production. Our automated manufacturing cells, equipped with real-time monitoring systems, maintain consistent process parameters across every unit. Each component is subject to in-process inspections, statistical process control (SPC), and final 100% visual and dimensional checks. We implement a closed-loop quality feedback system that detects anomalies instantly and adjusts machining parameters to prevent defect propagation. This systematic approach is central to our zero-defect manufacturing philosophy.

All stages are supported by full material traceability, documented process validation, and compliance with ISO 9001 and IATF 16949 standards. Our facility in Wuxi integrates lean manufacturing principles to minimize waste and maximize throughput without compromising quality.

The table below outlines key specifications and capabilities for our mold testing NH production process.

| Parameter | Specification |

|---|---|

| Material Options | P20, 718H, S136, NAK80, H13, and custom alloys |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished & textured) |

| Production Capacity | Up to 500 sets/month (scalable) |

| Testing Standards | ISO 20457, ASTM E3, customer-specific protocols |

| Lead Time (Prototype) | 15–20 days |

| Lead Time (Mass Production) | 25–35 days (batch of 100 units) |

Through this integrated, precision-focused methodology, Wuxi Lead Precision Machinery ensures that every NH mold component we deliver performs reliably in the most demanding manufacturing environments.

Why Choose Wuxi Lead Precision

Elevate Your Mold Performance Through Precision Testing

At Wuxi Lead Precision Machinery, we understand that mold integrity directly impacts your production yield, part quality, and operational costs. Generic testing protocols fail to address the nuanced demands of high-tolerance metal manufacturing, where deviations of microns can cascade into costly scrap rates or accelerated tool wear. Our specialized Mold Testing NH (Nitriding Hardness) Protocol is engineered for critical applications in aerospace, medical, and automotive sectors, delivering quantifiable data to optimize your tooling lifecycle. Unlike standard hardness checks, our process validates surface hardness uniformity, core toughness, and dimensional stability under simulated production loads—ensuring molds withstand 50,000+ cycles without degradation.

Partnering with Lead Precision means accessing China’s most advanced metrology suite, calibrated to ISO 17025 standards and operated by engineers with 15+ years in mold validation. We deploy non-destructive testing (NDT) methods like ultrasonic phased array and eddy current to detect subsurface flaws invisible to conventional inspection, paired with thermal cycling analysis to predict warpage in high-temperature environments. This holistic approach reduces your time-to-market by 30% while eliminating recurring failures in complex geometries.

Our NH testing delivers actionable insights through rigorously documented reports, including hardness gradients across critical zones, residual stress mapping, and fatigue life projections. Below are key capabilities supporting your mold validation:

| Parameter | Specification | Application Benefit |

|---|---|---|

| Hardness Range | 550–1200 HV | Validates nitriding/carburizing depth |

| Precision | ±0.001 mm on critical surfaces | Ensures dimensional repeatability |

| Max Part Size | 1500 × 800 × 600 mm | Accommodates large automotive dies |

| Material Compatibility | Tool steels, titanium, Inconel, hardened alloys | Covers extreme-condition tooling |

| Cycle Simulation | Up to 10,000 cycles at 200°C | Predicts thermal fatigue failure |

These metrics translate to tangible ROI: clients consistently achieve 22% longer mold service life and 18% lower per-part costs after implementing our recommendations. Your molds aren’t just tested—they’re optimized for peak performance under real-world stress.

Initiate your mold validation with an engineer-to-engineer consultation. Send your CAD files and production requirements to [email protected] for a complimentary NH testing feasibility analysis. Our team will respond within 8 business hours with a tailored protocol, including sample testing slots at no cost. Do not rely on generic certifications when your production hinges on micron-level reliability. Contact us today to secure your next production run with data-driven confidence. Precision engineered for your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.