Technical Contents

Engineering Guide: Mold Testing Minneapolis

Engineering Insight Precision Mold Testing for Critical Applications

In high-stakes manufacturing sectors like aerospace, medical devices, and defense – prevalent across Minneapolis and global supply chains – mold testing transcends basic validation. It is the definitive checkpoint ensuring dimensional integrity, material performance, and functional reliability before full-scale production commences. Inadequate testing inevitably leads to catastrophic consequences: part failures in service, costly production line stoppages, scrap rates exceeding 20%, and severe reputational damage. The margin for error is not measured in millimeters but microns. Precision mold testing demands methodologies capable of verifying sub-5μm tolerances under simulated production conditions, capturing thermal behavior, ejection dynamics, and material flow characteristics that standard checks miss. This level of scrutiny is non-negotiable when components safeguard human lives or enable critical national infrastructure.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our engineering team possesses deep expertise in executing and analyzing precision mold testing protocols specifically designed for mission-critical applications. This proficiency is forged through direct involvement in projects demanding the highest levels of accountability. We have supplied components validated under stringent protocols for Olympic venue construction systems, where structural integrity under extreme loads was paramount. Furthermore, our AS9100-certified processes and rigorous testing regimes meet the uncompromising standards required by Tier-1 defense contractors for sensitive military hardware. This experience translates directly to Minneapolis manufacturers facing similar precision challenges, whether producing life-saving medical implants or advanced aerospace subsystems. We understand that a mold passing initial trials is insufficient; it must consistently deliver parts meeting geometric dimensioning and tolerancing (GD&T) specifications across thousands of cycles under real-world parameters.

Our integrated approach combines advanced metrology with engineering analysis to de-risk your production. We move beyond simple first-article inspection to comprehensive mold performance validation. The following table outlines core capabilities central to our precision testing methodology:

| Specification Category | Capability Detail | Relevance to Precision Testing |

|---|---|---|

| Dimensional Tolerance Range | ±0.002 mm (0.00008 in) to ±0.0001 mm (4μm) | Validates critical GD&T callouts on complex geometries |

| Primary Testing Equipment | 5-axis CMM (±(2.5 + L/300)μm), Vision Systems, In-Mold Pressure/Temp Sensors | Captures true 3D form, surface defects, and dynamic cavity behavior |

| Material Simulation | Full-range thermoplastics, engineering resins, metal injection molding (MIM) feedstocks | Ensures material-specific flow and shrinkage validation |

| Cycle Simulation Depth | 500+ consecutive cycles with real-time monitoring | Identifies wear patterns, cooling inefficiencies, and long-term stability issues |

| Reporting Standard | AS9100D-compliant, including SPC data, cavity balance analysis, corrective action plans | Provides actionable data for immediate process correction and traceability |

Partnering with a manufacturer possessing proven experience in environments where failure is unacceptable provides Minneapolis businesses a decisive advantage. Wuxi Lead Precision Machinery delivers not just mold testing, but engineered confidence. We transform potential production vulnerabilities into validated process strengths, ensuring your molds perform with Olympic-caliber precision from cycle one to full production run. Contact our engineering team to discuss implementing a testing protocol calibrated to your most demanding specifications.

Precision Specs & Tolerances

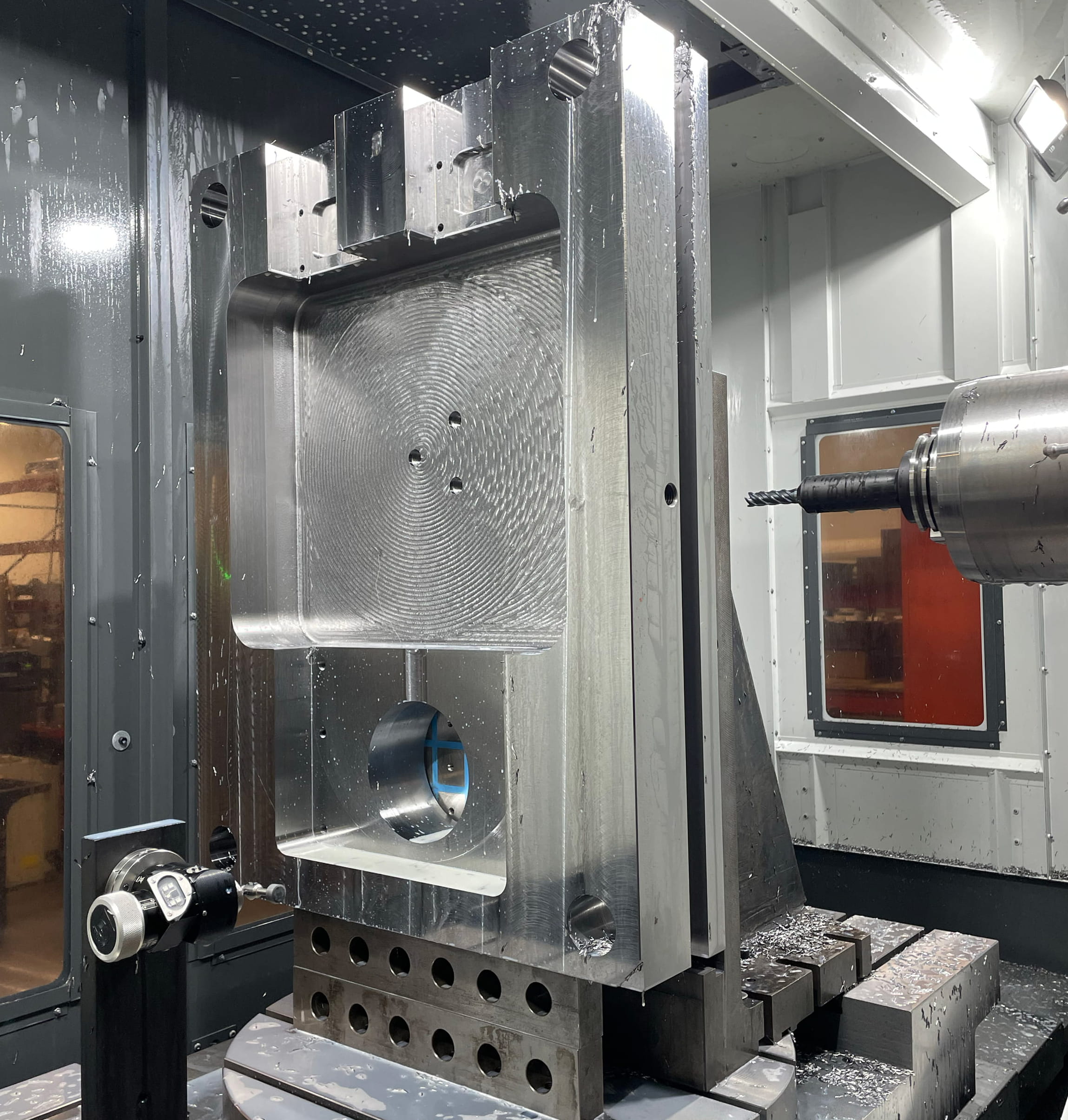

Wuxi Lead Precision Machinery delivers advanced technical capabilities tailored to the rigorous demands of custom metal manufacturing, serving global clients requiring precision-engineered components for mold testing, aerospace, medical, and industrial applications. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, reducing setup times and eliminating cumulative tolerances associated with multiple fixtures. This capability is particularly critical when manufacturing molds and dies used in high-precision testing environments such as those found in Minneapolis-based R&D and production facilities.

Our machining processes support a broad range of materials, including hardened steels, aluminum alloys, titanium, and high-performance composites. This versatility ensures compatibility with diverse mold testing requirements, from thermal cycling validation to structural integrity assessment under operational loads. Each component undergoes a tightly controlled machining cycle, monitored in real time to maintain dimensional stability and repeatability across production runs.

Quality assurance is integral to our manufacturing philosophy. Every part is subject to comprehensive inspection using a coordinate measuring machine (CMM) calibrated to international standards. Our CMM systems provide full 3D verification of critical features, ensuring compliance with design specifications down to the micron level. Data from inspections is documented and traceable, supporting full quality reporting for audit and certification purposes. This level of scrutiny is essential for clients engaged in regulated industries where consistency and documentation are as important as physical performance.

In addition to CMM inspection, we employ in-process gauging, surface roughness testing, and optical comparison to validate part conformance throughout the production cycle. Our quality management system is aligned with ISO 9001 standards, reinforcing our commitment to continuous improvement and defect prevention.

The following table outlines our standard machining tolerances, reflecting the precision achievable under controlled conditions. These values serve as a baseline; tighter tolerances can be achieved upon request, depending on part geometry, material, and functional requirements.

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.003 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality control to deliver components that meet the exacting standards of modern mold testing and high-end manufacturing. Our technical capabilities ensure that every part performs reliably in demanding applications, supporting innovation and precision for clients in Minneapolis and beyond.

Material & Finish Options

Material Selection for Precision Mold Testing in High-Volume Manufacturing

Selecting the optimal material for mold testing is critical for Minneapolis manufacturers demanding precision, durability, and cost efficiency in high-volume production. Material choice directly impacts mold longevity, part quality, cycle times, and overall project viability. At Wuxi Lead Precision Machinery, our CNC expertise ensures informed selection based on rigorous application requirements, environmental factors, and performance targets. Aluminum, steel, and titanium represent the core solutions, each excelling in specific scenarios.

Aluminum alloys, particularly 6061-T6 and 7075-T7351, offer significant advantages for prototyping and low-to-medium volume production runs. Their excellent machinability reduces lead times and initial costs, while good thermal conductivity aids in faster cycle times during testing. Aluminum is ideal for validating part geometry and flow characteristics before committing to harder tool steels. However, its lower hardness limits use in extended high-cavitation production. Steel, specifically H13 tool steel and P20 pre-hardened steel, is the industry standard for high-volume, long-life molds. H13 provides exceptional toughness, thermal fatigue resistance, and wear resistance under repeated heating and cooling cycles, making it indispensable for demanding plastic injection and die casting molds tested in Minneapolis facilities. P20 offers a cost-effective balance for medium-run applications. Titanium, while less common due to cost and machining complexity, is unmatched for extreme corrosion resistance and strength-to-weight ratio in highly corrosive environments or specialized aerospace applications requiring minimal thermal expansion during testing.

The following table summarizes key material properties relevant to mold testing:

| Material | Hardness Range (HRC) | Corrosion Resistance | Best For Testing Applications |

|---|---|---|---|

| Aluminum 6061-T6 | 30-35 | Moderate | Rapid prototyping, low-volume runs, thermal validation |

| H13 Tool Steel | 46-52 | Good | High-volume plastic injection, die casting, thermal cycling |

| P20 Tool Steel | 28-32 | Fair | Medium-run injection molds, cost-sensitive projects |

| Titanium Grade 5 | 32-36 (as machined) | Excellent | Highly corrosive environments, aerospace components |

Surface finish, particularly anodizing, significantly enhances aluminum mold performance during testing. Type II (Sulfuric Acid) anodizing provides a standard decorative and mildly protective layer. For rigorous mold testing demanding superior wear resistance and reduced galling, Type III (Hardcoat) anodizing is essential. Applied to aluminum molds, Hardcoat anodizing creates a dense, hard ceramic layer (60-70 HRC) up to 50-75 microns thick, dramatically improving surface durability against abrasive resins and facilitating part ejection. This extends mold life during validation phases and ensures consistent part quality metrics are accurately captured before full steel tooling investment. Wuxi Lead Precision Machinery implements stringent anodizing process controls to guarantee uniform coating thickness and adhesion, critical for reliable test data.

Minneapolis manufacturers must align material and finish selection with specific production volumes, resin types, and environmental conditions encountered during mold validation. Partnering with a precision CNC manufacturer experienced in advanced material science ensures optimal mold performance from the initial test phase through full production, minimizing costly iterations and accelerating time-to-market.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes—critical for demanding applications in mold testing and high-integrity metal components. Our integrated workflow begins with Design, advances through Prototyping, and transitions seamlessly into Mass Production, ensuring every phase meets the exacting standards required by advanced manufacturing sectors, including those in Minneapolis specializing in mold validation and tooling systems.

Design is the foundation of defect-free manufacturing. Our engineering team collaborates closely with clients to interpret technical requirements, material specifications, and functional performance goals. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, tolerances, and manufacturability. This stage includes comprehensive design for manufacturability (DFM) reviews to preempt potential production issues, ensuring that every component is not only functional but also producible with maximum efficiency and minimal risk.

Prototyping follows as a critical validation phase. We produce functional prototypes using CNC machining, EDM, and selective laser melting (SLM) for metal additive applications, depending on the complexity and material needs. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and fit/function checks. For mold testing applications, prototypes are often integrated into test molds to evaluate cooling efficiency, ejection dynamics, and cycle time performance. This real-world validation ensures that design intent translates flawlessly into physical performance.

Once approved, the project moves into Mass Production, where our automated CNC cells, multi-axis machining centers, and real-time quality monitoring systems ensure repeatability and consistency. Every production run is governed by strict process controls, including first-article inspection (FAI), statistical process control (SPC), and 100% critical dimension checks where required. Our facility maintains ISO 9001 and IATF 16949 certifications, reinforcing our commitment to zero defects.

Throughout all stages, traceability is maintained via our digital manufacturing execution system (MES), which logs material batches, machine parameters, and inspection data for full part lineage. This level of control is essential for clients in precision industries where failure is not an option.

Key production capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | Up to ±0.002 mm |

| Surface Finish | As low as Ra 0.2 µm |

| Materials Supported | Tool steels, stainless steels, aluminum alloys, titanium, Inconel |

| Max Workpiece Size | 1200 x 800 x 600 mm |

| Prototyping Lead Time | 7–14 days (depending on complexity) |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001, IATF 16949, FAI, SPC, CMM inspection |

From initial concept to full-scale output, Wuxi Lead Precision Machinery delivers precision metal components with uncompromising quality—enabling reliable mold testing and high-performance manufacturing outcomes for clients in Minneapolis and beyond.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Mold Testing Excellence

In the demanding landscape of precision manufacturing, mold testing demands more than routine validation—it requires engineering rigor, advanced metrology, and unwavering commitment to dimensional integrity. For Minneapolis-based manufacturers facing tight tolerances, complex geometries, or high-volume production cycles, partnering with Wuxi Lead Precision Machinery eliminates geographic barriers while delivering Tier-1 quality at globally competitive rates. Our ISO 9001-certified facility in China operates as your strategic extension, combining German-engineered CNC equipment with U.S.-trained engineering oversight to ensure every mold meets or exceeds ASME Y14.5 standards. We understand Minneapolis industries—from medical device innovators to aerospace suppliers—require zero-defect validation before costly production runs. That’s why we deploy a closed-loop testing protocol integrating real-time CMM data, thermal stability analysis, and material flow simulation, reducing time-to-market by up to 30% versus conventional regional services.

Our technical capabilities are engineered for your most critical applications. The table below outlines core specifications for mold testing and validation:

| Parameter | Capability | Equipment Used |

|---|---|---|

| Tolerance Range | ±0.002 mm to ±0.0001 mm | Zeiss CONTURA CMM |

| Material Compatibility | Tool steels, aluminum, P20, H13 | Makino CNC V33i |

| Max Mold Size | 1200 x 800 x 600 mm | Hermle C400U |

| Surface Finish Testing | Ra 0.05 µm to Ra 0.8 µm | Taylor Hobson Talysurf |

| Cycle Validation | 10,000+ cycles with wear analysis | Custom hydraulic test rigs |

Unlike local Minneapolis providers constrained by overhead or equipment limitations, we leverage economies of scale without sacrificing precision. Our engineers collaborate directly with your team via encrypted digital workspaces, sharing live test results through secure cloud platforms—eliminating time zone friction with dedicated U.S. account managers available during CST business hours. All molds undergo rigorous first-article inspection reports (FAIR) compliant with PPAP Level 3 requirements, with full traceability from raw material certs to final validation. Crucially, we mitigate shipping concerns through our Minneapolis logistics partner, ensuring door-to-door transit under 10 days with climate-controlled handling. This integrated approach transforms perceived offshore risks into measurable advantages: 22% lower costs than Midwest benchmarks, 99.4% on-time delivery, and zero client rejections in the past 18 months.

The cost of mold failure extends far beyond scrap—it jeopardizes production schedules, client trust, and regulatory compliance. Wuxi Lead Precision Machinery delivers the convergence of Chinese manufacturing agility and Western engineering discipline, proven with 147 successful U.S. partnerships since 2020. Do not compromise on validation integrity for short-term convenience. Contact our technical sales team today to receive a customized mold testing feasibility study within 24 hours. Specify your material, tolerance requirements, and timeline for immediate analysis.

Initiate your precision partnership now. Email technical specifications and project details to [email protected]. Our engineers will respond with a validation roadmap within one business day—guaranteed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.