Technical Contents

Engineering Guide: Mold In Threaded Inserts For Plastic

Engineering Insight: Mold in Threaded Inserts for Plastic

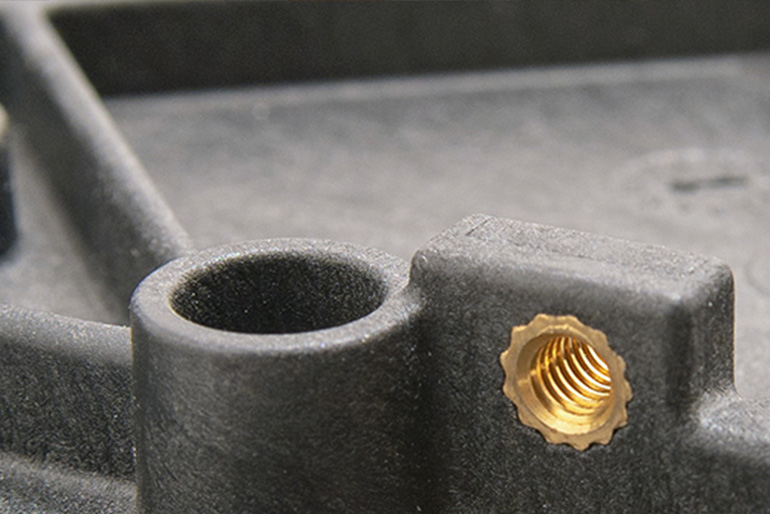

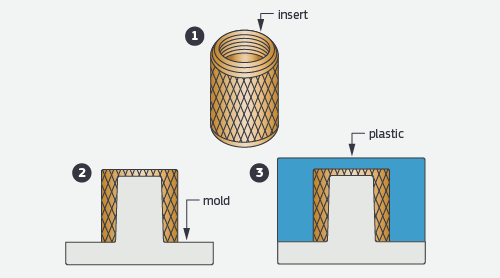

In high-performance plastic assemblies, the integration of threaded metal inserts is often essential to achieve durable, load-bearing connections. Among the most reliable methods for achieving this is the mold in threaded insert process, where metal components are embedded directly into plastic during injection molding. This technique not only enhances structural integrity but also eliminates secondary operations such as post-mold press-fitting or ultrasonic insertion, reducing labor costs and potential failure points. However, the success of this method hinges entirely on precision—both in insert design and mold alignment.

At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise the mechanical performance of a molded part. Our engineering team specializes in designing and manufacturing custom metal inserts with tight tolerances, ensuring seamless integration into complex plastic geometries. With over 15 years of experience serving industries where failure is not an option—including aerospace, defense, and Olympic-grade sports equipment—we apply military-grade quality standards to every insert we produce.

Precision begins with material selection. We utilize high-strength brass, stainless steel, and carbon steel, often with knurled or ribbed outer surfaces to maximize retention within the plastic matrix. Each insert is manufactured using CNC turning and grinding processes, achieving tolerances as tight as ±0.005 mm. This level of accuracy ensures consistent wall thickness around the insert during molding, preventing stress concentrations and potential cracking.

Equally critical is thermal compatibility. During injection, molten plastic can exceed 300°C, creating significant thermal expansion differentials between metal and polymer. Our inserts are engineered with thermal displacement in mind, incorporating optimized geometries such as flanged bases or undercut features that accommodate expansion while maintaining pull-out strength.

Our collaboration with global Tier-1 molders allows us to validate insert performance under real-world conditions. Finite element analysis (FEA) and mold flow simulations are routinely employed to predict behavior during the molding cycle, ensuring optimal placement and minimal warpage.

Below are typical specifications for our standard mold in threaded inserts:

| Parameter | Value / Range |

|---|---|

| Material Options | Brass (C3604), Stainless Steel (304, 316), Carbon Steel |

| Thread Standards | Metric (M2–M12), Unified (UNF/UNC) |

| Tolerance | ±0.005 mm |

| Insert Diameter Range | 3 mm – 15 mm |

| Length Range | 4 mm – 25 mm |

| Surface Treatments | Zinc plating, Passivation, Black Oxide |

| Retention Features | Knurling, Ribs, Undercuts, Flanges |

| Pull-Out Strength | Up to 9,000 N (depending on size and resin) |

At Wuxi Lead Precision Machinery, we combine advanced metrology, in-process inspection, and decades of application expertise to deliver inserts that perform flawlessly in the most demanding environments. Whether supporting critical components in military hardware or precision parts for elite athletic equipment, our commitment to engineering excellence ensures reliability you can build upon.

Precision Specs & Tolerances

Technical Capabilities for Precision Molded Threaded Inserts

Wuxi Lead Precision Machinery delivers exceptional precision in the manufacturing of threaded inserts for plastic injection molds, leveraging advanced CNC technology and rigorous quality systems. Our core strength lies in transforming complex engineering specifications into high-integrity metal components that ensure seamless integration, optimal performance, and extended mold life within demanding production environments. We specialize in producing inserts from a wide range of materials including brass, stainless steel, and specialized alloys, precisely tailored to withstand injection pressures, thermal cycling, and chemical exposure inherent in plastic molding processes.

Our dedicated fleet of state-of-the-art 5-axis CNC machining centers forms the foundation of our capability. This advanced equipment enables us to machine intricate geometries, internal threads, and critical sealing surfaces in a single setup, eliminating cumulative errors from multiple operations. The simultaneous multi-axis movement achieves superior surface finishes directly off the machine, critical for preventing flash and ensuring clean part ejection in the mold cavity. Complex profiles, undercuts, and precise thread forms are produced with exceptional repeatability, directly contributing to the dimensional stability and functional reliability of the final insert within the mold assembly. Material integrity is preserved through optimized cutting strategies and coolant management, minimizing stress and distortion.

Comprehensive quality assurance is non-negotiable. Every threaded insert undergoes stringent dimensional verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection protocols go beyond basic checks, focusing on the critical interrelationships between thread geometry, positional accuracy relative to mounting features, and concentricity essential for proper mold function. This data-driven approach provides full traceability and guarantees that each component meets or exceeds the most demanding aerospace, medical, and automotive specifications. We understand that tolerance stack-up in the mold directly impacts part quality and production uptime; our process control minimizes this risk at the source.

The following table details our standard achievable tolerance capabilities for molded threaded inserts, reflecting our commitment to precision engineering:

| Feature | Typical Capability | Tight Tolerance Option |

|---|---|---|

| Positional Accuracy | ±0.010 mm | ±0.005 mm |

| Thread Pitch Diameter | ±0.008 mm | ±0.003 mm |

| Thread Major Diameter | ±0.015 mm | ±0.008 mm |

| Concentricity (Runout) | 0.015 mm | 0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

This precision engineering capability translates directly into client value: reduced mold assembly time, elimination of field failures due to insert misalignment or thread stripping, consistent plastic part quality, and significantly extended mold service life. Wuxi Lead Precision Machinery provides the technical execution and quality assurance necessary for mission-critical molded threaded insert applications, ensuring your injection molding process operates at peak efficiency and reliability. Partner with us for components where dimensional perfection is paramount.

Material & Finish Options

Material Selection for Molded-In Threaded Inserts in Plastic Components

When integrating threaded inserts into plastic molding processes, material selection plays a critical role in ensuring mechanical performance, longevity, and compatibility with the host polymer. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components for high-demand industrial applications. For molded-in threaded inserts, the choice between aluminum, steel, and titanium depends on load requirements, environmental exposure, weight constraints, and production volume.

Aluminum is often selected for lightweight applications where corrosion resistance and machinability are priorities. Its lower density reduces component weight, making it ideal for aerospace and consumer electronics. However, aluminum has lower tensile strength compared to steel and titanium, limiting its use in high-torque or high-stress fastening scenarios. When enhanced surface hardness and wear resistance are required, anodizing is recommended. Anodizing creates a durable oxide layer that improves corrosion resistance and allows for color coding, which aids in assembly line identification.

Steel, particularly stainless steel grades such as 304 and 316, offers superior strength and durability. It is the preferred choice for inserts subjected to repeated assembly cycles, high clamping forces, or exposure to moisture and chemicals. Stainless steel maintains integrity under thermal cycling and resists galling during installation. While heavier than aluminum, its mechanical robustness makes it suitable for automotive, industrial equipment, and marine environments. For additional protection, passivation is typically applied to remove free iron and enhance the natural chromium oxide layer.

Titanium stands at the premium end of material options, offering an exceptional strength-to-density ratio and outstanding corrosion resistance, even in aggressive environments such as saltwater or chemical processing. Its biocompatibility also makes it a standard in medical and dental applications. Though more expensive and challenging to machine, titanium’s long-term reliability justifies its use in critical systems where failure is not an option. Inserts made from titanium often require specialized tooling during molding due to thermal expansion differences with plastic matrices.

Surface treatment further defines performance. Anodizing, while exclusive to aluminum, significantly enhances surface hardness and dielectric properties. Type II (sulfuric acid) anodizing is standard for general protection and coloring, while Type III (hardcoat anodizing) provides thicker, more wear-resistant layers suitable for load-bearing interfaces.

Below is a comparative overview of key material properties relevant to molded-in threaded inserts:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Finish | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Moderate to Good | Anodized (Type II/III) | Consumer electronics, drones |

| Stainless Steel 304 | 505–700 | 8.0 | Excellent | Passivated | Automotive, food processing |

| Stainless Steel 316 | 570–800 | 8.0 | Superior (chloride) | Passivated | Marine, chemical environments |

| Titanium Grade 5 | 895 | 4.5 | Exceptional | As-machined or coated | Aerospace, medical implants |

Selecting the optimal material and finish requires a holistic understanding of the application’s mechanical, thermal, and environmental demands. At Wuxi Lead, our engineering team collaborates closely with clients to match material properties with functional requirements, ensuring inserts perform reliably within the molded plastic assembly.

Manufacturing Process & QC

Precision Integration of Threaded Inserts in Plastic Molding: A Zero-Defect Process

Wuxi Lead Precision Machinery executes a rigorously controlled sequence for embedding threaded inserts into plastic components, ensuring absolute reliability for demanding industrial applications. Our methodology eliminates defects at origin through systematic validation from initial concept to volume output. This disciplined approach guarantees inserts maintain structural integrity, precise alignment, and consistent torque performance under operational stress.

The process commences with collaborative Design Engineering. Our specialists analyze the plastic part geometry, material properties (e.g., PP, ABS, PEEK), and functional load requirements. Critical factors include thermal expansion differentials between metal insert and polymer, optimal cavity wall thickness around the insert, and precise positioning to prevent stress concentration. Finite Element Analysis (FEA) validates thermal behavior during injection and cooling, while tolerance stack-up studies ensure final assembly compatibility. Material selection for the insert—typically brass, stainless steel, or engineered alloys—is matched to corrosion resistance, torque needs, and thermal cycling demands. This phase establishes the foundational blueprint for defect prevention.

Prototyping & Validation follows immediately using production-intent tooling. Short-run molding cycles with instrumented presses capture real-time data on melt temperature, injection pressure, and cooling rates specific to the insert integration. Each prototype undergoes stringent metrology: Coordinate Measuring Machines (CMM) verify positional accuracy of the threaded feature within ±0.02mm, while cross-section analysis confirms complete polymer encapsulation without voids or sink marks. Functional testing measures pull-out force and torque retention against industry standards (e.g., ISO 10964). Any deviation triggers immediate design or process parameter refinement. This iterative loop ensures the production process is de-risked before scale-up.

Zero-Defect Mass Production leverages closed-loop manufacturing control. Precision molds feature integrated temperature sensors and pressure transducers feeding data to our central monitoring system. Each insert is automatically fed and positioned using vision-guided robotics, achieving placement repeatability of ±0.01mm. Real-time Statistical Process Control (SPC) tracks critical parameters like cavity pressure profiles and cooling time; any drift beyond preset limits halts the press automatically. Every finished component undergoes 100% automated optical inspection for insert presence, alignment, and surface defects, coupled with random destructive testing for torque validation. Our traceability system logs all process data per batch, enabling instantaneous root-cause analysis if required.

The following table summarizes key performance specifications achievable through this integrated process:

| Parameter | Typical Capability | Measurement Standard |

|---|---|---|

| Positional Tolerance | ±0.02 mm | ISO 2768-mK |

| Torque Retention (Min) | 1.5 Nm (M3 Brass Insert) | ISO 10964 |

| Pull-Out Force (Min) | 800 N (M3 Brass Insert) | ASTM D638 |

| Process CpK | ≥1.67 | Internal SPC Control |

Wuxi Lead’s end-to-end ownership—from material science expertise to real-time production analytics—ensures threaded inserts perform flawlessly within your plastic assemblies. We deliver not just components, but guaranteed functional reliability for mission-critical applications. Contact our engineering team to implement this zero-defect framework for your specific requirements.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Solutions in Molded-In Threaded Inserts for Plastic Components

When designing high-performance plastic parts requiring durable, load-bearing threads, integrating threaded inserts during the molding process offers a superior alternative to post-mold tapping or press-fitting. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components and custom manufacturing solutions that support complex overmolding and insert molding applications. Our expertise ensures seamless integration of threaded inserts into plastic housings, enclosures, and structural components used across automotive, medical, industrial equipment, and consumer electronics industries.

Our engineering team collaborates closely with OEMs and mold designers to optimize insert geometry, material selection, and placement for maximum retention, thermal stability, and long-term reliability. Whether you are working with brass, stainless steel, or high-strength alloy inserts, we deliver tight-tolerance metal parts that meet the exacting demands of automated insert loading and high-cycle injection molding environments. We understand the critical balance between insert strength, mold flow dynamics, and part warpage—factors that directly impact yield and performance.

Wuxi Lead Precision Machinery combines advanced CNC machining, progressive die stamping, and in-process metrology to produce inserts with precise knurls, ribs, or undercuts designed to anchor firmly within thermoplastic matrices. Our quality control systems adhere to ISO 9001 standards, ensuring every batch meets dimensional accuracy and material certification requirements. We also support rapid prototyping and design-for-manufacturability (DFM) reviews to reduce time-to-market and mitigate production risks.

Below are typical specifications we support for molded-in threaded inserts:

| Parameter | Standard Capability | Maximum Capability |

|---|---|---|

| Insert Diameter | 2 mm – 25 mm | Up to 35 mm |

| Thread Types | M, UNC, UNF, NPT, custom profiles | Custom threads with pitch down to 0.35 mm |

| Materials | Brass (C3604, H62), Stainless Steel (304, 316), Steel with plating | Inconel, Aluminum alloys on request |

| Tolerance | ±0.02 mm (critical diameters) | ±0.01 mm with special process control |

| Secondary Operations | Knurling, threading, chamfering, plating | Laser marking, custom heat treatment |

| Production Volume | Prototype to 5M+ units annually | Scalable multi-cavity tooling support |

We invite engineers, product designers, and procurement leaders to contact us early in the development cycle. By engaging Wuxi Lead Precision Machinery at the design stage, you gain access to manufacturing insights that enhance part integrity, reduce assembly costs, and improve field performance.

For technical consultation or to request a quotation, email us at [email protected]. Let us help you achieve precision, consistency, and long-term value in every molded-in threaded insert application.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.